oil BMW 540i 2000 E39 Workshop Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 2000, Model line: 540i, Model: BMW 540i 2000 E39Pages: 1002

Page 735 of 1002

Downloaded from www.Manualslib.com manuals search engine

330-39

I Rear suspension1

- Remainder of installation is reverse of removal, noting the fol-

lowing.

Models with coil springs: Fit spring correctly in lower spring

seat.

* Models with air suspension: Fit eccentric lug at bottom of

air spring in recess of wheel carrier spring seat.

Always use new self-locking nuts.

- Make sure all threaded bolts, nuts and mating surfaces are

clean.

a Tighten fasteners to final torque only after vehicle has

been lowered and suspension has settled.

Stake axle collar nut afler tightening.

Tightening torques

ABS pulse sensor to wheel bearing 8 Nm (6

ft-lb)

carrier

Air spring to wheel bearing carrier 20 Nm (15 ft-lb)

Brake rotor to hub 16 Nm (12

it-lb)

Rear axle shaft to hub (M27) 300 Nm (221 ft-lb)

Rear brake pad carrier (caliper) to wheel 65 Nm (48 ft-lb)

bearing carrier

Road wheel to hub

120ilONm

(89 k7 ft-lb)

Swing arm to wheel bearing carrier 256 Nm (189 it-lb)

Upperfrontcontrol arm (traction strut) to 65 Nm (48 ft-lb)

wheel carrier

Upper rear control arm to wheel carrier 142 Nm (105 ft-lb)

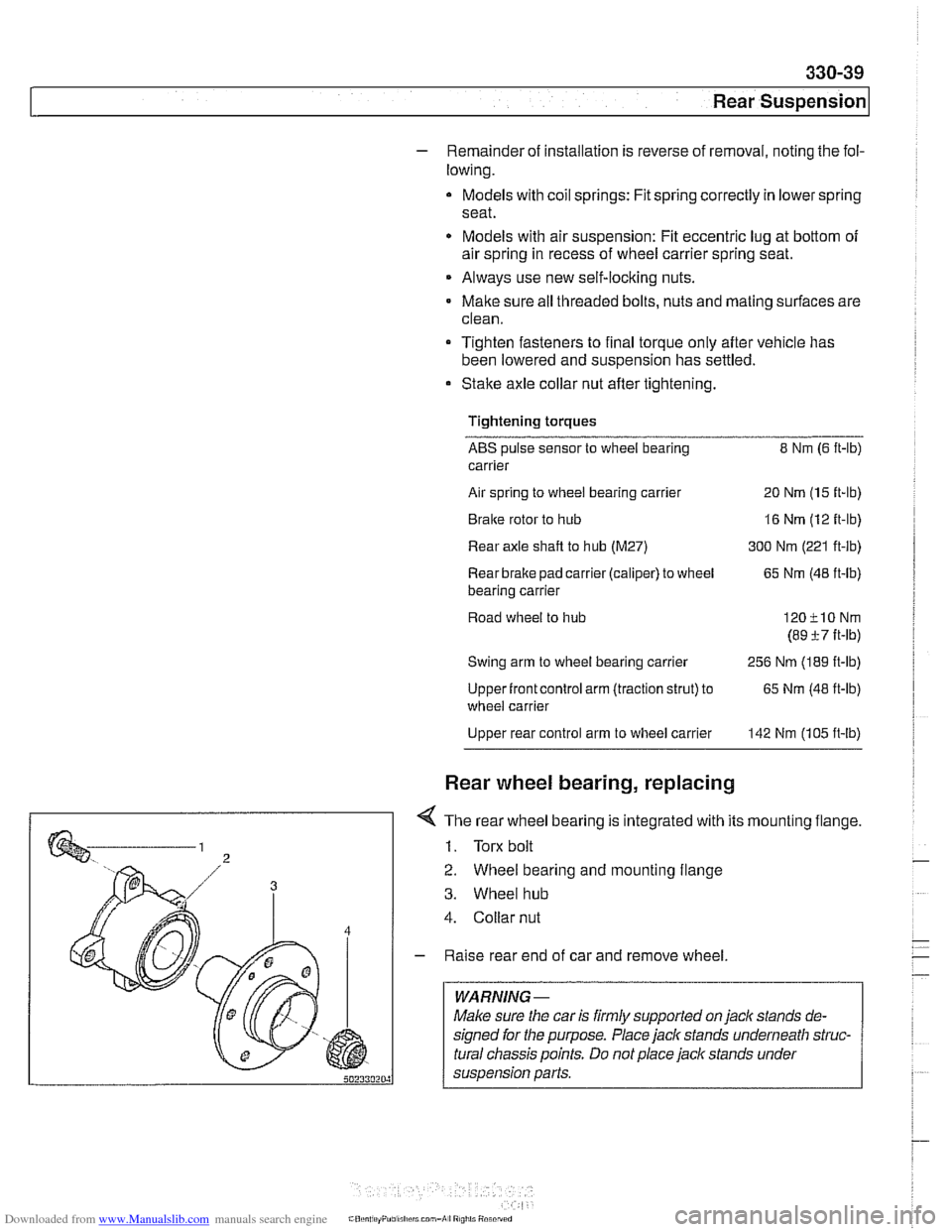

Rear wheel bearing, replacing

< The rear wheel bearing is integrated with its mounting flange.

1. Torx bolt

2. Wheel bearing and mounting flange

3. Wheel hub

4. Collar nut

- Raise rear end of car and remove wheel.

WARNING -

Make sure the car is firmly supported on jaclc stands de-

signed for the purpose. Place jack stands underneath struc-

tural chassis points. Do not place jack stands under

suspension parts.

Page 737 of 1002

Downloaded from www.Manualslib.com manuals search engine

--. ..

Rear Suspension

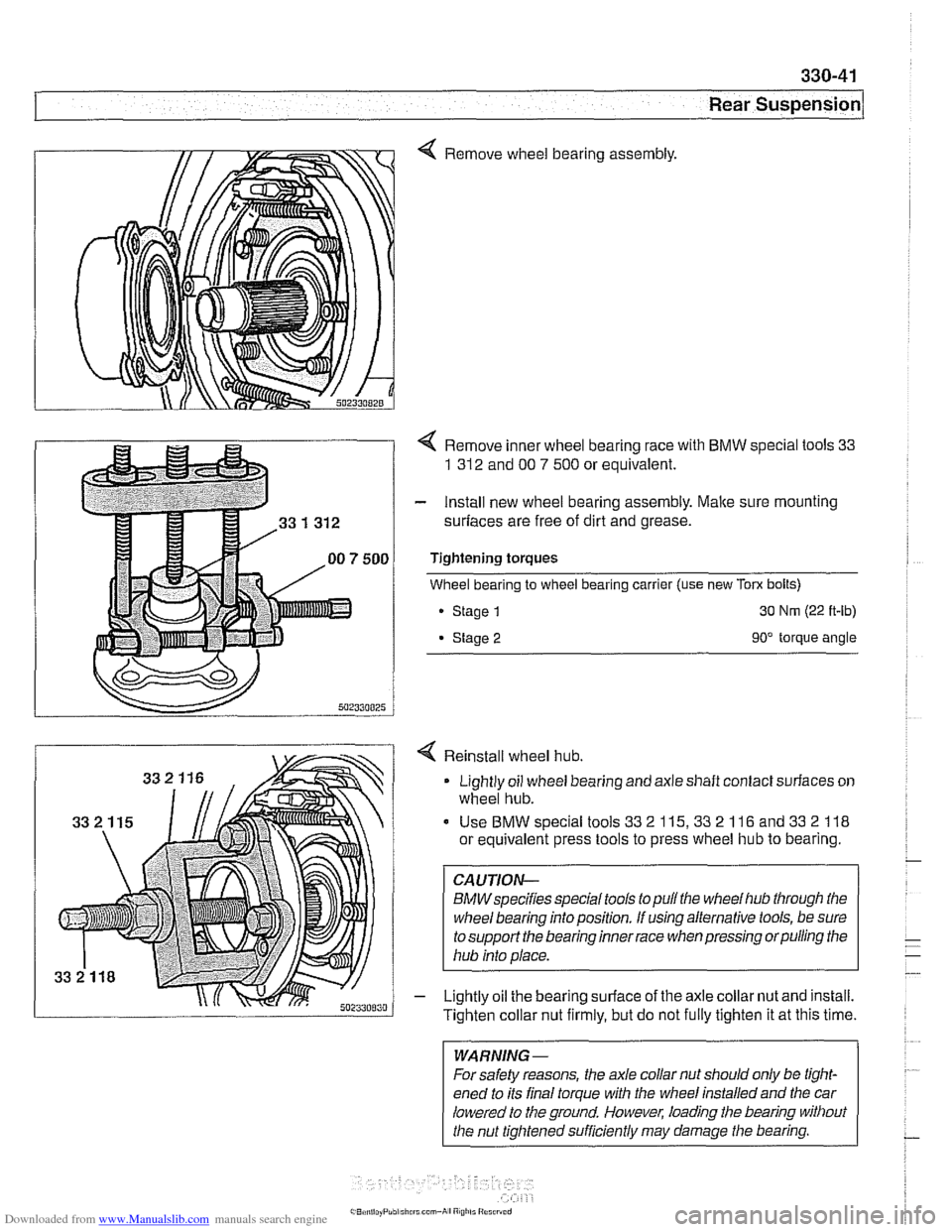

4 Remove wheel bearing assembly.

4 Remove inner wheel bearing race with BMW special tools 33

1 312

and 00 7 500 or equivalent.

- Install new wheel bearing assembly. Malte sure mounting

surfaces are free of dirt and grease.

Tightening torques

Wheel bearing to wheel bearing carrier (use new

Tom bolts)

Stage

1 30 Nm (22 ft-lb)

Stage 2 90" torque angle

4 Reinstall wheel hub.

Lightly oil wheel bearing and axle shaft contact surfaces on

wheel hub.

Use BMW special tools

33 2 115,33 2 116 and 33 2 118

or equivalent press tools to press wheel hub to bearing.

CAUTION-

BMWspecifies speclaltools to pull the wheel hub through the

wheel bearing into position. If using alternative tools, be sure

to support the bearing inner race when pressing orpulling the

hub into place.

- Lightly oil the bearing surface of the axle collar nut and install.

Tighten collar nut firmly, but do not fully tighten it at this time.

WARNING-

For safety reasons, the axle collar nut should only be tight-

ened to its final torque with the wheel installed and the car

lowered to the ground. However, loading the bearing without

the nut tightened sufficiently may damage

the bearing.

Page 745 of 1002

Downloaded from www.Manualslib.com manuals search engine

33UFinal Drive

General ........................... ,331 -2 Drive Axles ....................... 331 -1 4

Special tools

........................ ,331 -2 Drive axle assembly ................. 331-14

Aluminum suspension components

...... ,331-4 Drive axle, removing and

installing (sedan)

.................... 331-14 ........................ Final Drive ,331 -5

Drive axle, removing

........... ...... Final drive, removing and installing ,331-5 and (Sport Wagon) 331-15

...................... Differential oil level, checking ........... ,331-6 CV joint boots 331-17 Final drive in~ut shaft seal, replacing ..... ,331-7 .

Final drive oitput shaft seals, replacing . . ,331-10

Final drive cover, removing and installing ,331-12

Final drive mounts, replacing .......... ,331-12

Page 749 of 1002

Downloaded from www.Manualslib.com manuals search engine

Final Drive

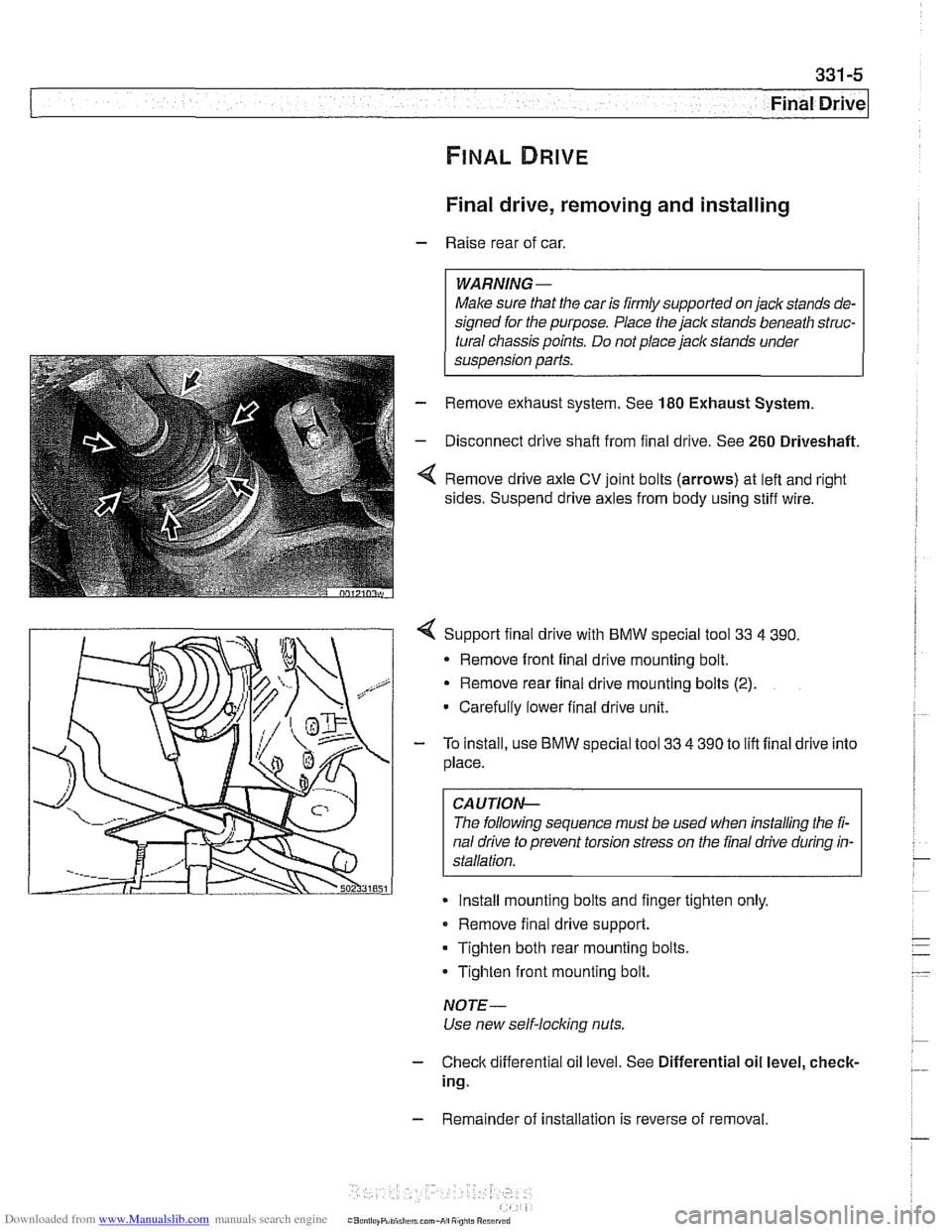

Final drive, removing and installing

- Raise rear of car.

WARNING-

Make sure that the car is firmly supported on jack stands de-

signed for the purpose. Place the jaclc stands beneath struc-

tural chassis

~oints. Do not i lace iaclc stands under

( suspension barfs.

Remove exhaust system. See 180 Exhaust System.

Disconnect drive shaft from final drive. See

260 Driveshaft.

Remove drive axle CV joint bolts (arrows) at left and right

sides. Suspend drive axles from body using stiff wire.

4 Support final drive with BMW special tool 33 4 390.

* Remove front final drive mounting bolt.

Remove rear final drive mounting bolts

(2).

Carefully lower final drive unit.

- To install, use BMW special tool 33 4 390 to lift final drive into

place.

CA UTIOP&

The following sequence must be used when installing the fi-

nal drive to prevent torsion stress on the final drive during in-

Install mounting bolts and finger tighten only.

Remove final drive support.

Tighten both rear mounting bolts.

Tighten front mounting bolt.

NOTE-

Use new self-locking nuts.

- Check differential oil level. See Differential oil level, check-

ing.

- Remainder of installation is reverse of removal.

Page 750 of 1002

Downloaded from www.Manualslib.com manuals search engine

Final Drive

Tightening torques

F~nal drive to rear axle carrier 105 Nm (77 it-lb)

Driveshaft CV joint to final drive flange

- MlO (Torx bolt) 70

Nm (51 ft-lb)

- M8 (compression nut) 32 Nm (24

ft-lb)

Drive axle to final drive

ilange

Torx bolts (M10) 83 Nm (61 ft-lb)

Torx bolt with

rlbbed teeth (M10) 64 Nm (47 ft-lb)

Torx bolt

wlth ribbed teeth (MI0 sliver) 80 Nm (59 ft-lb)

Torx

bolt with ribbed teeth (M10 black) 100 Nm (74 ft-lb)

* Torx bolt with ribbed teeth (M12) 135 Nm (100 ft-lb)

Differential oil level, checking

The E39 differential is filled with lifetime oil that ordinarily

does not need to be changed. BMW recommends using only

a specially formulated synthetic gear oil

(SAF-XO) that is

available through an authorized BMW dealer parts depart-

ment. For additional information on this lubricant and any oth-

er lubricants that may be compatible, contact an authorized

BMW dealer service department.

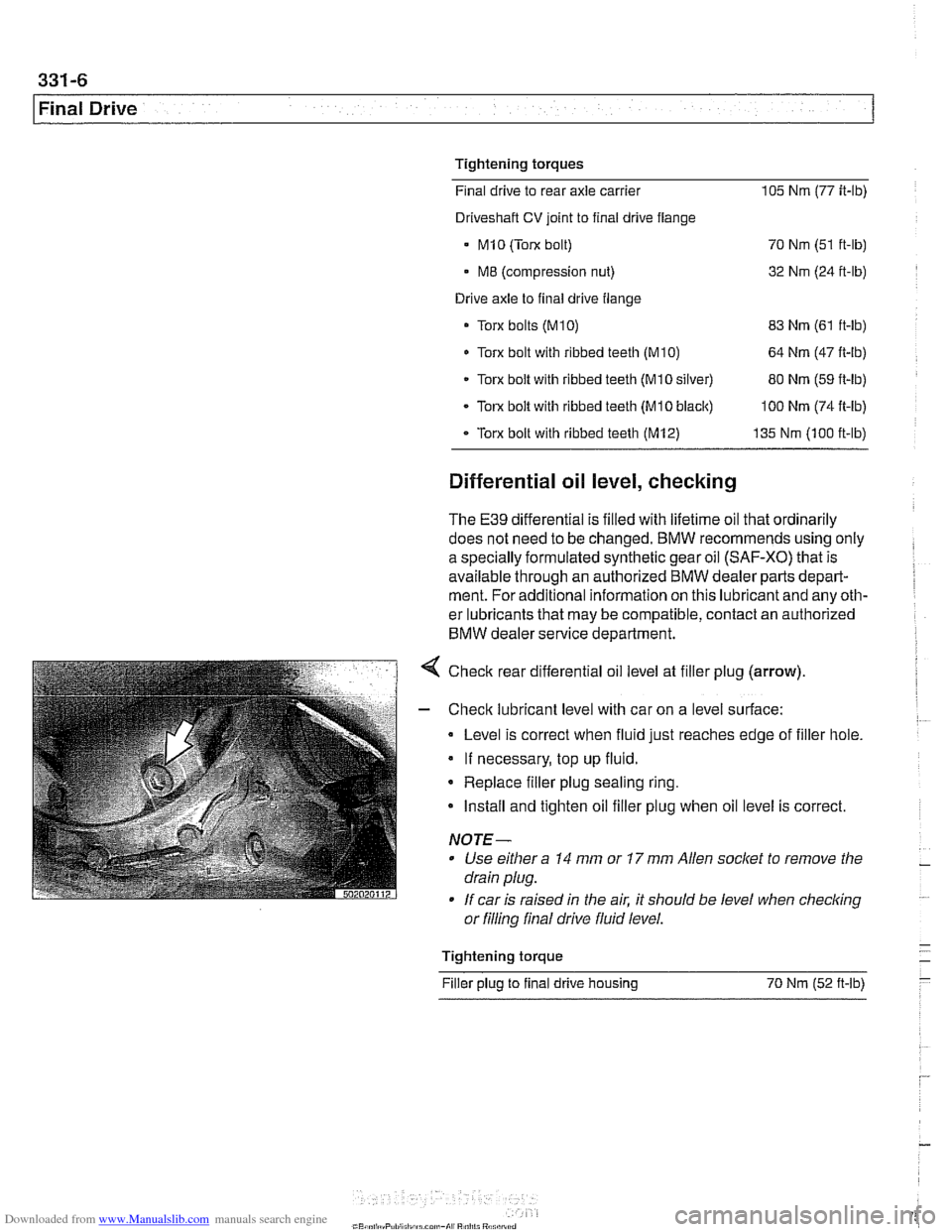

< Check rear differential oil level at filler plug (arrow).

- Check lubricant level with car on a level surface:

Level is correct when fluid just reaches edge of filler hole.

If necessary, top up fluid.

* Replace filler plug sealing ring.

Install and tighten oil filler plug when oil level is correct.

NOTE-

Use either a 14 mm or 17 mm Allen socket to remove the

drain plug.

If car is raised in the air. it should be level when

checkino " or filling final drive fluid level.

- Tightening torque -

Filler plug to final drive housing 70 Nm (52

ft-lb) -

Page 753 of 1002

Downloaded from www.Manualslib.com manuals search engine

331-9

Final Drive

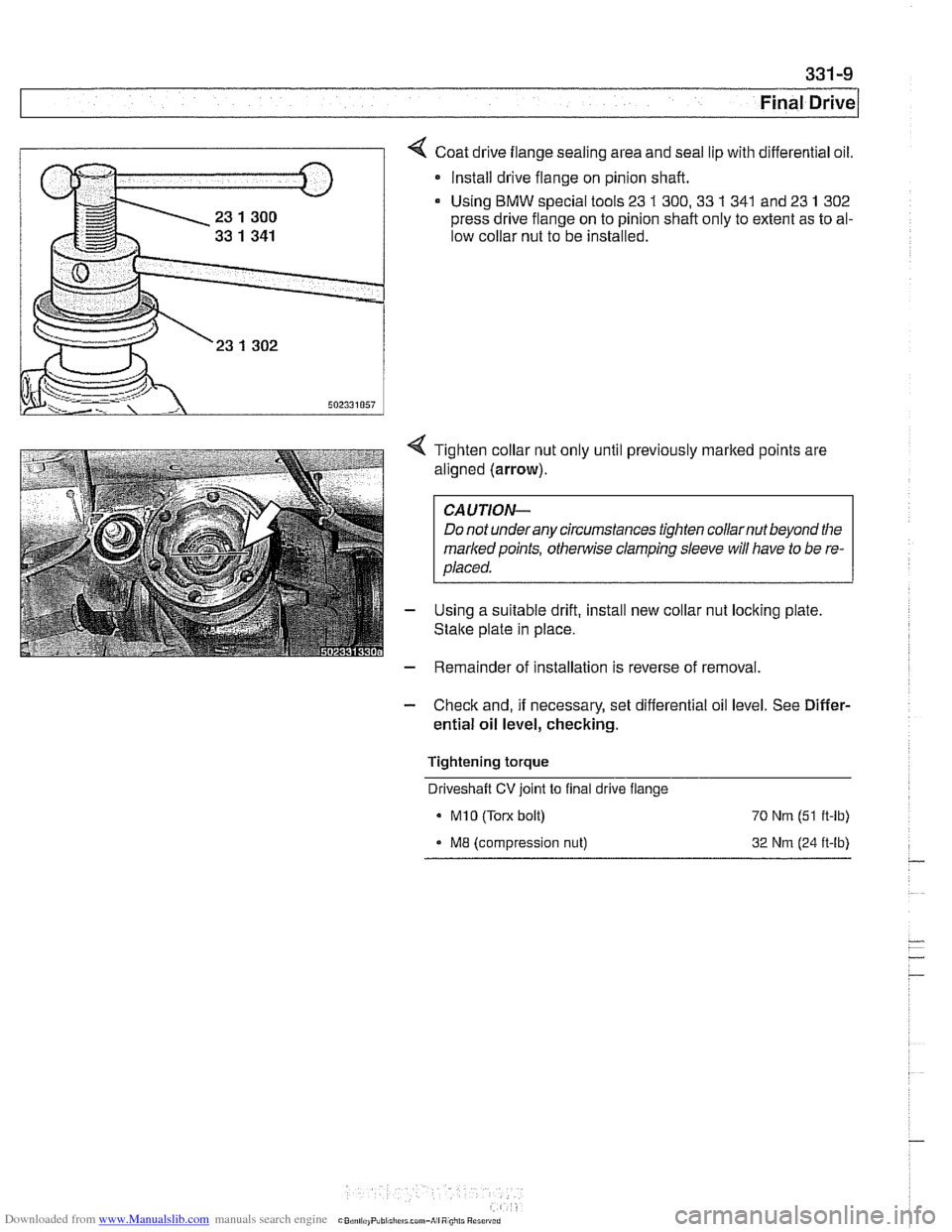

Coat drive flange sealing area and seal lip with differential oil.

* Install drive flange on pinion shaft.

Using

BMW special tools 23 1 300,33 1 341 and 23 1 302

press drive flange on to pinion shaft only to extent as to al-

low collar nut to be installed.

4 Tighten collar nut only until previously marked points are

aligned (arrow).

CAUTION-

Do not underany circumstances tighten collarnut beyond the

markedpoints,

othe~lise clamping sleeve will have to be re-

placed.

- Using a suitable drift, install new collar nut locking plate

Stalte plate in place.

- Remainder of installation is reverse of removal.

- Check and, if necessary, set differential oil level. See Differ-

ential oil level, checking.

Tightening torque Driveshaft

CV joint to final drive flange

MI0 (Torx bolt) 70 Nrn (51 ft-lb)

ME (compression nut) 32 Nrn (24 ft-lb)

Page 755 of 1002

Downloaded from www.Manualslib.com manuals search engine

331-1 1

Final rive(

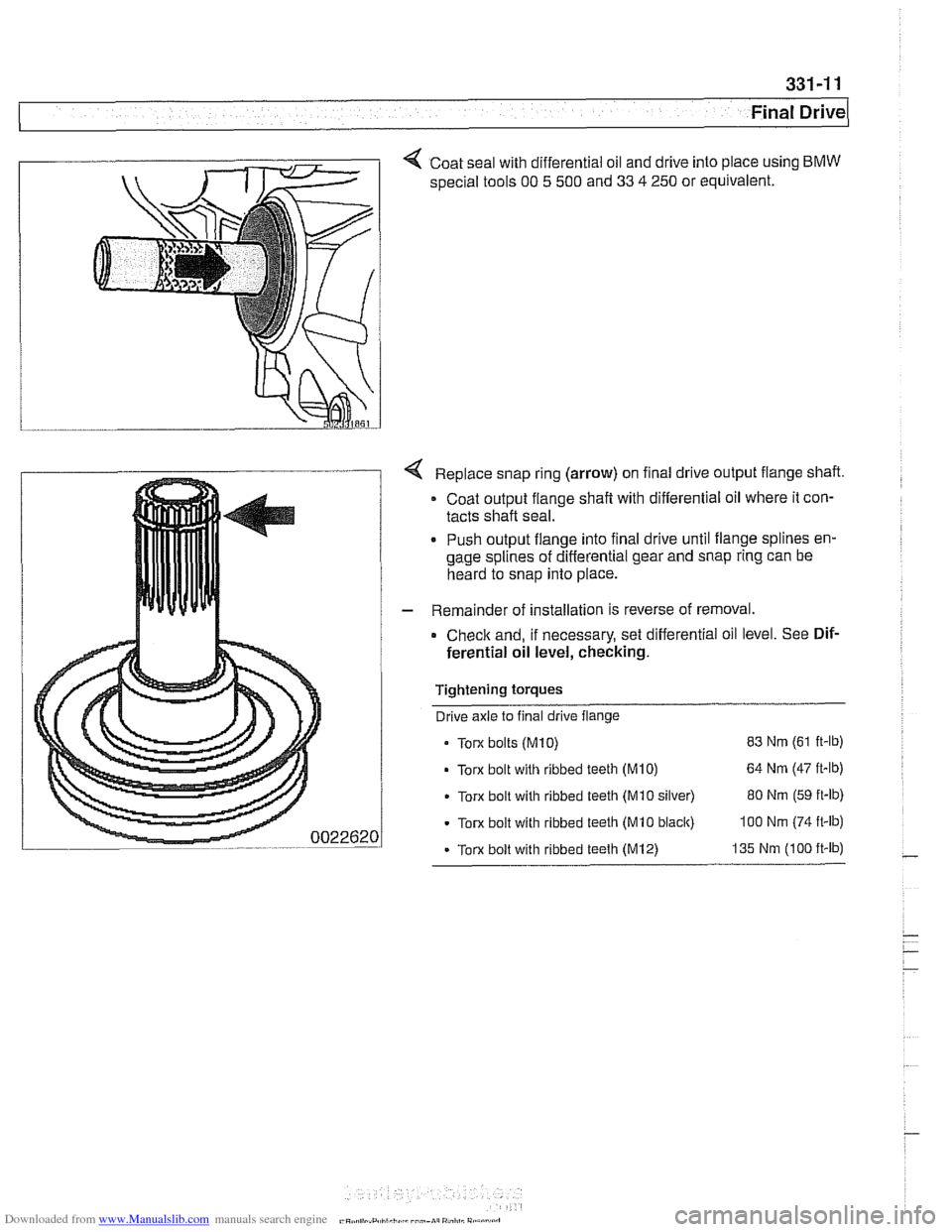

< Coat seal with differential oil and drive into place using BMW

special tools 00 5 500 and 33 4 250 or equivalent.

Replace snap ring (arrow) on final drive output flange shaft.

Coat output flange

shaft with differential oil where it con-

tacts shaft seal.

. Push output flange into final drive until flange splines en-

gage splines of differential gear and snap ring can be

heard to snap into place.

- Remainder of installation is reverse of removal.

Check and, if necessary, set differential oil level. See Dif-

ferential oil level, checking.

Tightening torques Drive axle to final drive flange

Torx bolts

(M10) 83 Nm (61 ft-lb)

Torx bolt with ribbed teeth (M10) 64 Nm (47 it-lb)

Torx bolt with ribbed teeth (Mi0 silver) 80 Nm (59 ft-lb)

Torx bolt with ribbed teeth (MI0 black) 100 Nm (74 ft-lb)

- Torx bolt with ribbed teeth (M12) 135 Nm (100 ft-lb)

Page 756 of 1002

Downloaded from www.Manualslib.com manuals search engine

331-12

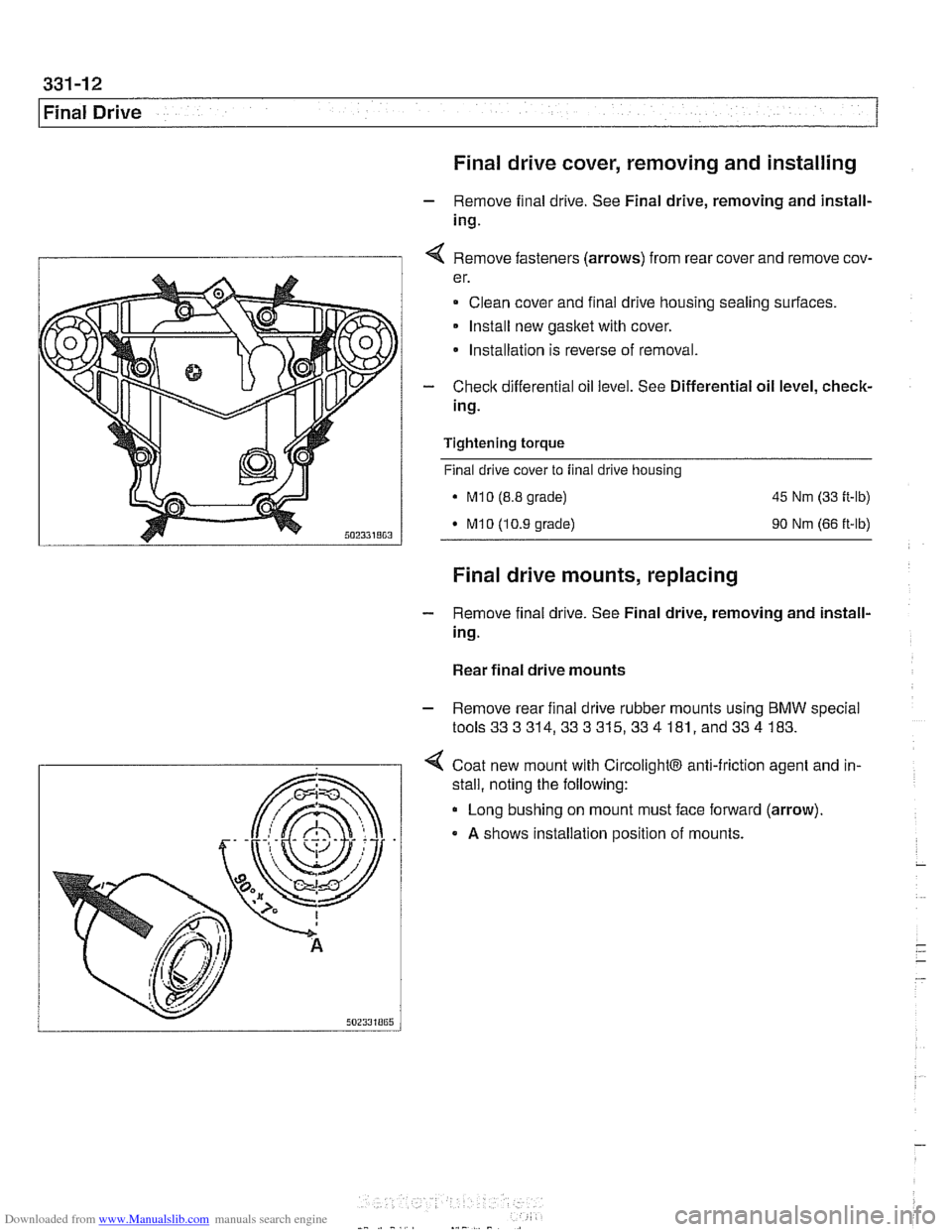

Final Drive Final drive cover, removing and installing

- Remove final drive. See Final drive, removing and install-

ing.

I 1 4 Remove fasteners (arrows) from rear cover and remove cov-

er.

Clean cover and final drive housing sealing surfaces.

Install new

gasket with cover.

* Installation is reverse of removal.

- Check differential oil level. See Differential oil level, check-

ing.

Tightening

torque

Final drive cover to final drive housing

. M10 (8.8 grade) 45 Nm (33 ft-lb)

M10 (10.9 grade) 90 Nm (66 ft-lb)

Final drive mounts, replacing

- Remove final drive. See Final drive, removing and install-

ing.

Rear final drive mounts

- Remove rear final drive rubber mounts using BMW special

tools333314,333315,334 181, and334 183.

4 Coat new mount with CircolightB anti-friction agent and in-

.

stall, noting the following:

Long bushing on mount must face forward (arrow).

A shows installation position of mounts.

Page 759 of 1002

Downloaded from www.Manualslib.com manuals search engine

Final ~rivel

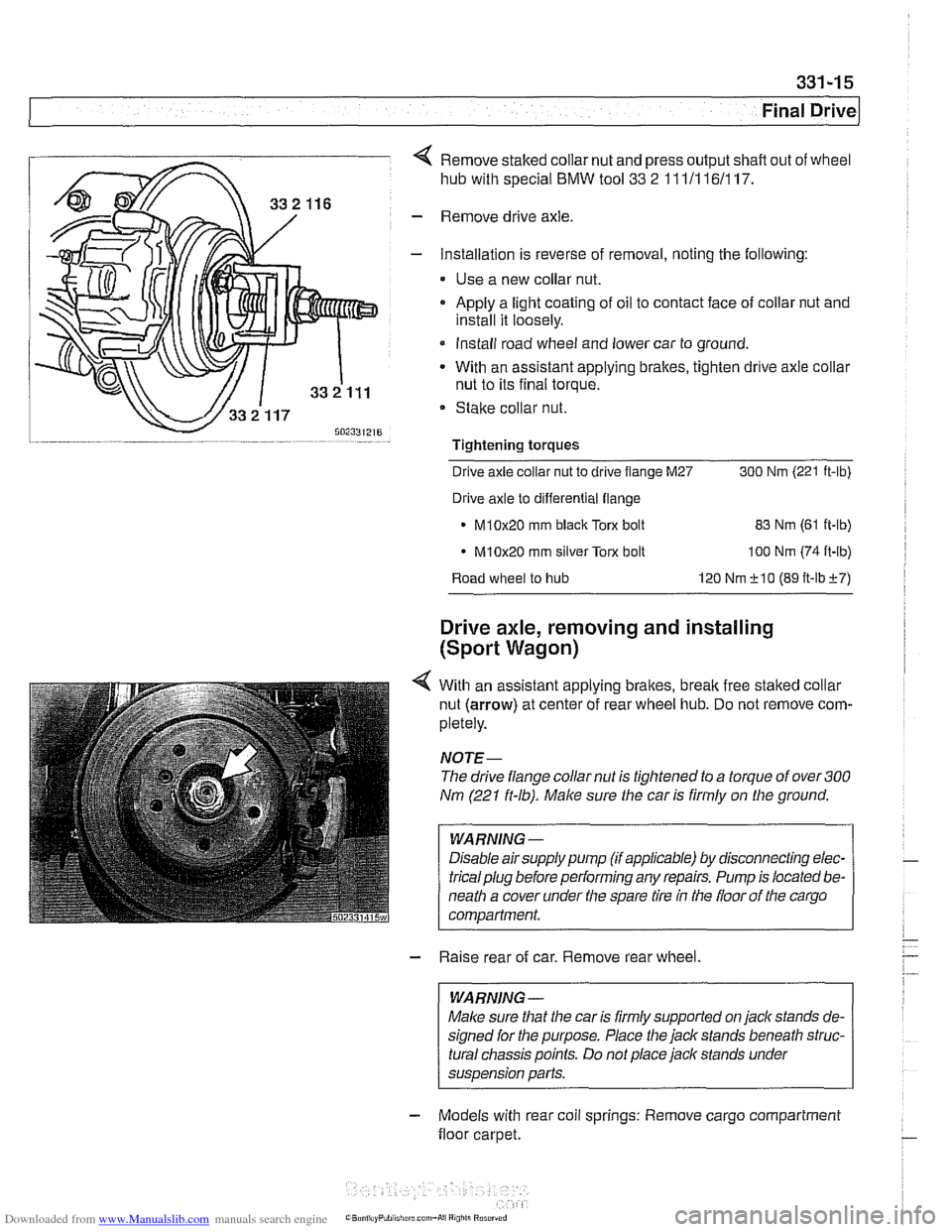

4 Remove staked collar nut and press output shafl out of wheel

hub with special

BMW tool 33 2 111/116/117.

- Remove drive axle.

- Installation is reverse of removal, noting the following:

Use a new collar nut.

a Apply a light coating of oil to contact face of collar nut and

install it loosely.

* Install road wheel and lower car to ground.

- With an assistant applying brakes, tighten drive axle collar

nut to its final torque.

Stake collar nut.

Tightening torques

-

Drive axle collar nut to drive flange M27 300 Nrn (221 ft-lb)

Drive axle to differential flange

* M10x20 rnm black Torx bolt

83 Nrn (61 ft-lb)

M10x20 rnrn silver Torx bolt

100 Nrn (74 ft-lb)

Road wheel to hub 120 Nrn f 10 (89 ft-lbf7)

Drive axle, removing and installing

(Sport Wagon)

4 With an assistant applying brakes, brealc free staked collar

nut (arrow) at center of rear wheel hub. Do not remove com-

pletely.

NOJE-

The drive flange collar nut is tightened to a torque of over 300

Nm (221 ft-lb). Make sure the car is firmly on the ground.

WARNING -

Disable airsupply pump (if applicable) by disconnecting elec-

tricalplug before performing any repairs. Pump is located be-

neath a cover under the spare tire

in the floor of the cargo

compartment.

- Raise rear of car. Remove rear wheel.

WARNING -

Malce sure that the car is firmly supported on jack stands de-

signed for the purpose. Place the jack stands beneath struc-

tural chassis points. Do not place jack stands under

suspension parts.

- Models with rear coil springs: Remove cargo compartment

floor carpet.

Page 760 of 1002

Downloaded from www.Manualslib.com manuals search engine

331-16

I Final Drive

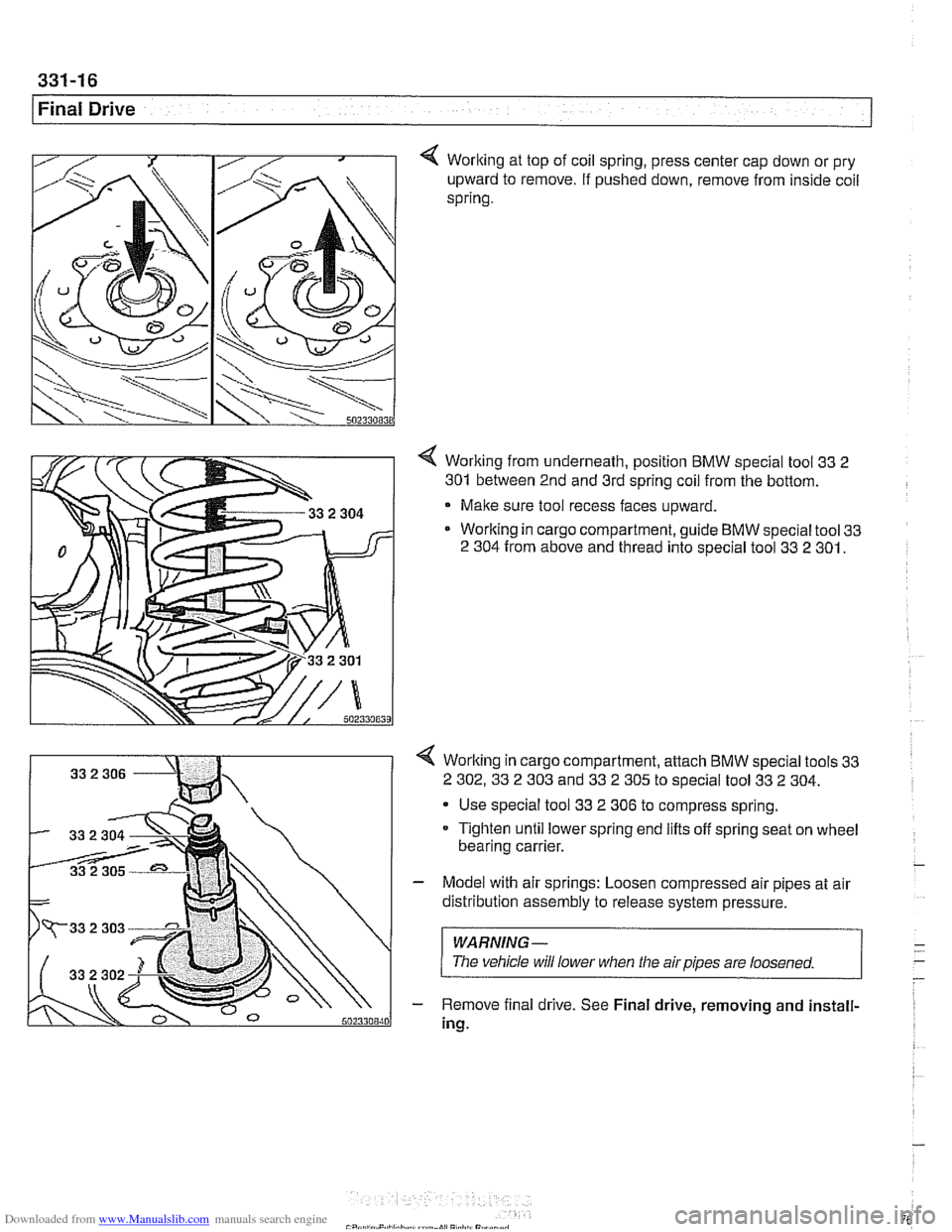

Worlting at top of coil spring, press center cap down or pry

upward to remove. If pushed down, remove from inside coil

spring.

4 Worlting from underneath, position BMW special tool 33 2

301

between 2nd and 3rd spring coil from the bottom.

Make sure tool recess faces upward.

Worlting in cargo compartment, guide BMW special tool

33

2 304

from above and thread into special tool 33 2 301.

4 Worlting in cargo compartment, attach BMW special tools 33

2 302.33

2 303 and 33 2 305 to special tool 33 2 304.

- Use special tool 33 2 306 to compress spring.

Tighten until lower spring end lifts off spring seat on wheel

bearing carrier.

- Model with air springs: Loosen compressed air pipes at air

distribution assembly to release system pressure.

WARNING-

The vehicle will lower when tlie airpipes are loosened.

- Remove final drive. See Final drive, removing and install-

ing.