jack points BMW 540i 2000 E39 Owner's Guide

[x] Cancel search | Manufacturer: BMW, Model Year: 2000, Model line: 540i, Model: BMW 540i 2000 E39Pages: 1002

Page 774 of 1002

Downloaded from www.Manualslib.com manuals search engine

340-1 2

Brakes Brake pads, checking and replacing

Brake pads can be replaced without disconnecting the brake

fluid hose from the caliper or having to bleed the brakes. The

rotors can be replaced without disassembling wheel hub and

bearing. Always machine or replace rotors in pairs. Replace

pads in sets.

Front and rear brake pad replacement procedures are identical.

WARNING -

* Altllough semi-metallic andmetallic brale friction materials

in brake pads or shoes no longer contain asbestos, they

produce dangerous dust.

Treat all

brale dust as a hazardous material.

Do not create dust by grinding, sanding, or cleaning

brake friction surfaces with compressed air.

CAUTION--

Pressing caliper piston in may cause brake fluid reservoir to

overflow To prevent this, use a clean syringe to first remove

some fluid

from reservoir.

Raise car and remove wheels,

WARNING-

Make sure that the car is firmly supported on jack stands de-

signed for the purpose. Place jack stands beneath structural

chassis points. Do not place jack stands under suspension

parts.

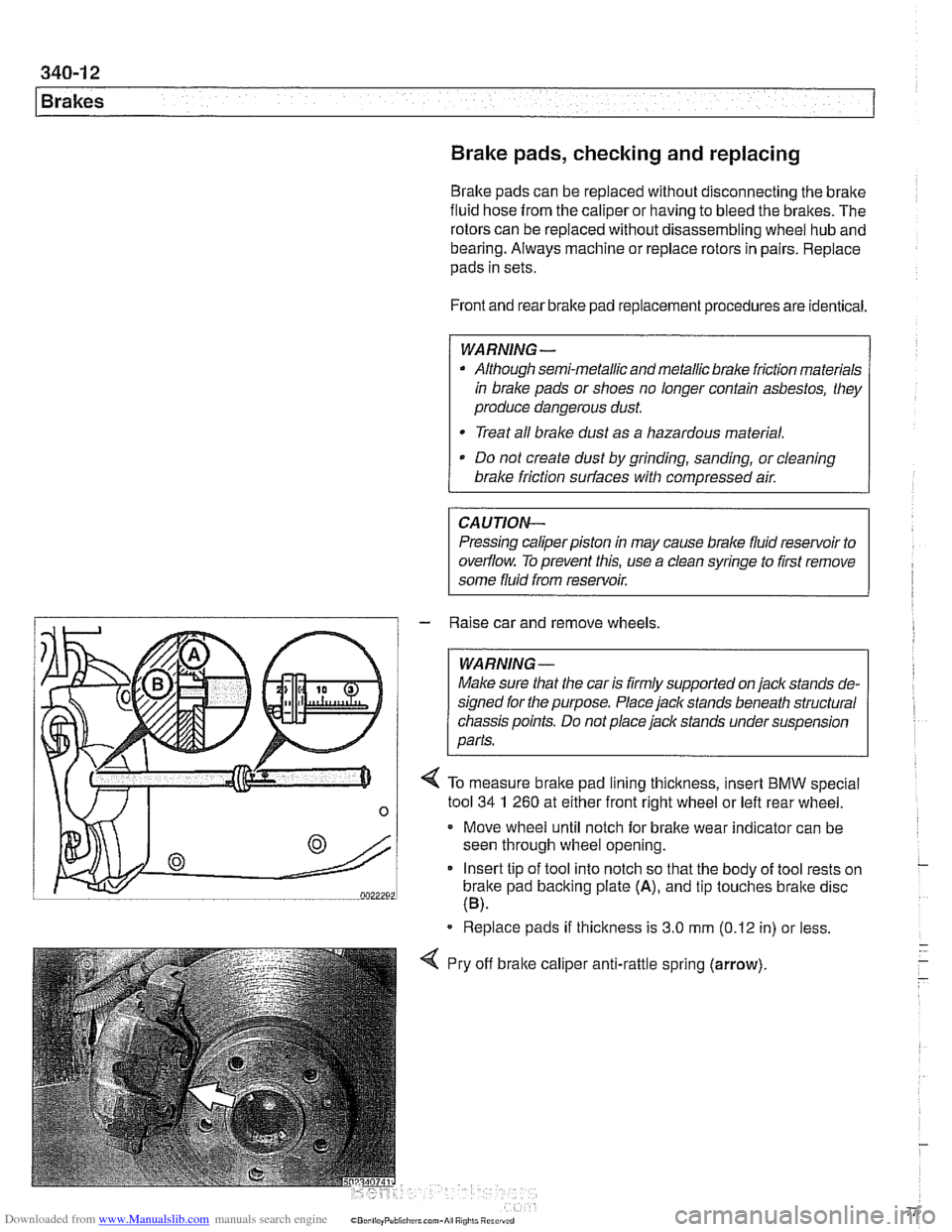

/ 4 To measure brake pad lining thickness, insert BMW special

n 1 tool 34 1 260 at either frontilght wheel or left rear wheel -

Move wheel until notch for brake wear indicator can be

seen through wheel opening.

Insert tip of tool into notch so that the body of tool rests on

brake pad backing plate

(A), and tip touches bralte disc

(B).

Replace pads if thickness is 3.0 mm (0.12 in) or less.

Pry off

bralte calipe~ , anti-rattle spring (arrow).

Page 777 of 1002

Downloaded from www.Manualslib.com manuals search engine

340-1 5

Brakes

- Remainder of installation is reverse of removal.

- Clean brake caliper mounting bolts (7 mm Allen). Replace

ones which are not in perfect condition. Do not grease.

Top up brake fluid to MAX marking.

- Before driving car, pump bralte pedal several times so that

brake pads contact brake rotors.

Check that brake fluid level is correct. Top up if necessary.

Hold ignition key for at least

30 seconds in accessory po-

sition without starting engine. This clears any fault codes in

memory and turns off brake pad warning light.

Tightening torques Brake caliper to pad carrier

(7 mm Allen)

Front caliper

30 Nm (22 It-lb)

- Rear caliper 28 Nm (21 It-lb)

Road wheel to hub

120i 10 Nm (89i7 ft-lb)

Brake rotors, removing and installing

- Raise car and remove wheels

WARNING-

Male sure that the car is firmly supported on jack stands de-

signed for the purpose. Place jack stands beneath structural

chassis points. Do not place jack stands under suspension

parts.

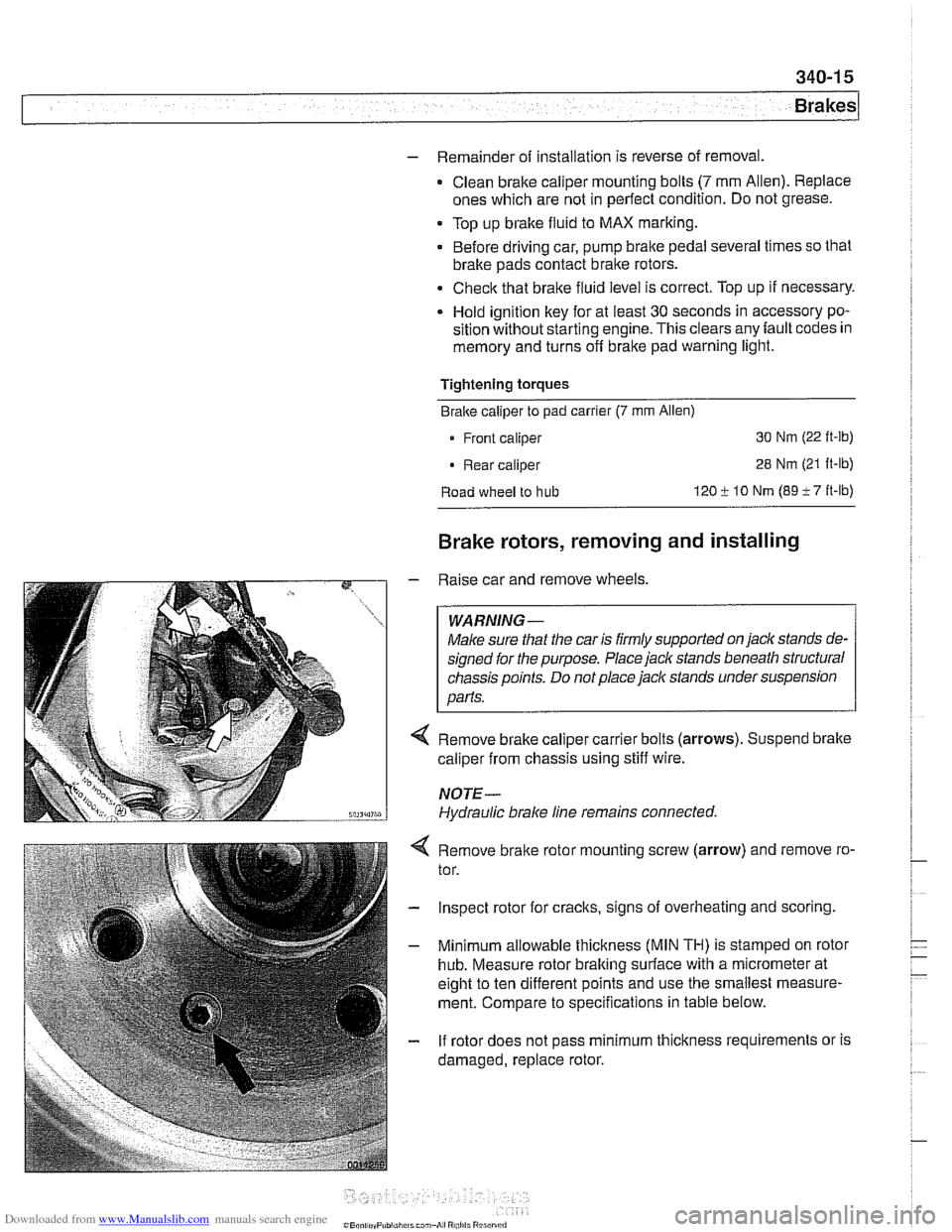

Remove brake caliper carrier bolts (arrows). Suspend brake

caliper from chassis using stiff wire.

NOTE-

Hydraulic brake line remains connected.

4 Remove bralte rotor mounting screw (arrow) and remove ro-

tor.

- Inspect rotor for cracks, signs of overheating and scoring.

- Minimum allowable thickness (MIN TH) is stamped on rotor

hub. Measure rotor braking surface with a micrometer at

eight to ten different points and use the smallest measure-

ment. Compare to specifications in table below.

- If rotor does not pass minimum thickness requirements or is

damaged, replace rotor.

Page 785 of 1002

Downloaded from www.Manualslib.com manuals search engine

340-23

Brakes

- Using flat-bladed screwdriver, reach into brake drum through

lug bolt hole. Turn brake adjuster until wheel no longer turns.

Back adjuster off

12 notches.

Parking brake adjusting (initial)

Back

off adjuster through wheel

lug bolt hole 12 notches

- Working inside car, set parking brake several times to seat

cable. Then pull parking brake

lever up two notches. Tighten

cable adjusting nuts until it is just possible to turn rear wheels

with slight resistance.

- Release lever and make sure rear wheels turn freely

- Turn on ignition. Pull up parlting brake lever 1 notch and

make sure that parking bralte warning light comes on. if not,

adjust parking bralte warning light contact switch.

- Install parking brake lever boot. Install road wheel lug bolts.

Tightening torque Road

wheel to hub 120 i. 10 Nrn (89 i- 7 ft-lb)

Parking brake shoes, removing and

installing

- Raise rear of car and remove road wheels.

WARNING-

Make sure that the car is firmly supported on jack stands de-

signed for

the purpose. Place jack stands beneath structural

chassis points. Do not place

jaclc stands under suspension

parts.

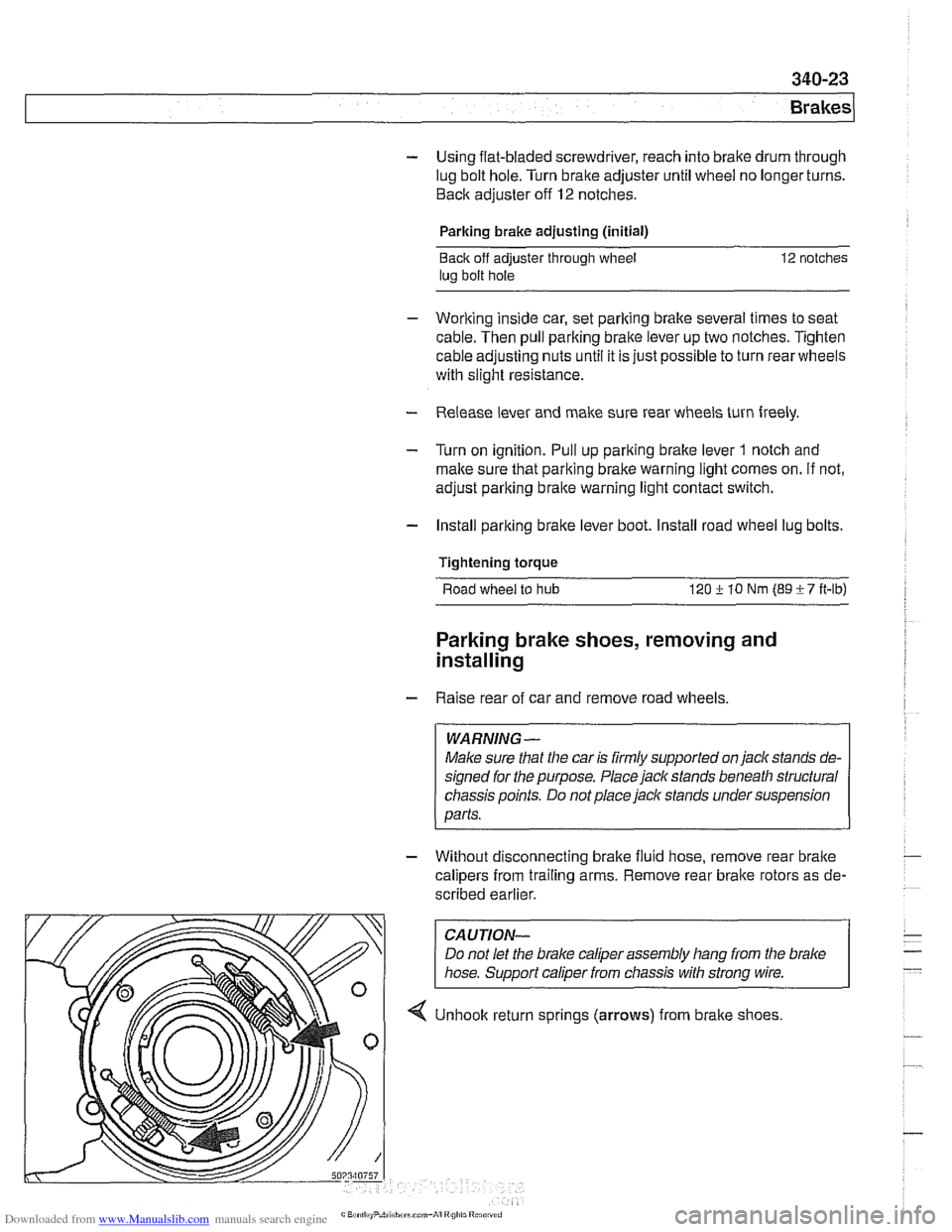

- Without disconnecting brake fluid hose, remove rear bralte

calipers from trailing arms. Remove rear brake rotors as de-

scribed earlier.

CAUTION-

Do not let the brake caliper assembly hang from the brake

hose. Support caliper from chassis with strong wire.

4 Unhook return sprlngs (arrows) from brake shoes

Page 786 of 1002

Downloaded from www.Manualslib.com manuals search engine

340-24

Brakes

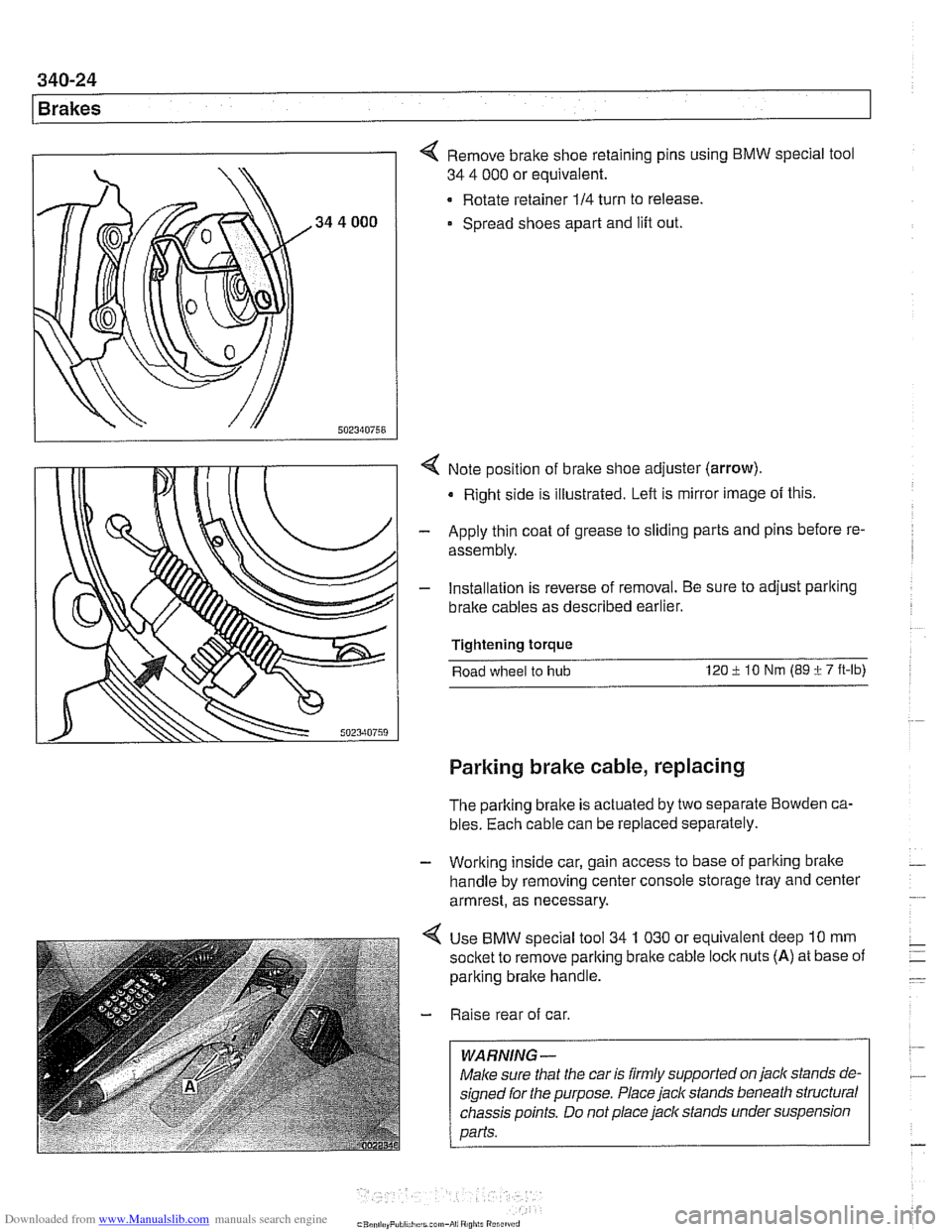

4 Remove brake shoe retaining pins using BMW special tool

34 4 000 or equivalent.

Rotate retainer

114 turn to release.

Spread shoes apart and lift out.

4 Note position of bralte shoe adjuster (arrow).

Right side is illustrated. Left is mirror image of this.

- Apply thin coat of grease to sliding parts and pins before re-

assembly.

- Installation is reverse of removal. Be sure to adjust parlting

bralte cables as described earlier.

Tightening torque

Road wheel to

hub 120 i lo Nm (89 i 7 ft-lb)

Parking brake cable, replacing

The parking brake is actuated by two separate Bowden ca-

bles. Each cable can be replaced separately.

- Working inside car, gain access to base of parking brake -

handle by removing center console storage tray and center

armrest, as necessary.

4 Use BMW special tool 34 1 030 or equivalent deep 10 mm

socket to remove parlting brake cable

loclc nuts (A) at base of

parking brake handle.

- Raise rear of car.

WARNING -

Male sure that the car is firmly supported on jack stands de-

signed for the purpose. Place jack stands beneath structural

chassis points. Do not place jaclc stands under suspension

Darfs.

Page 788 of 1002

Downloaded from www.Manualslib.com manuals search engine

1 Brakes

ABS COMPONENT REPLACEMENT

CA UTIOW-

If the tires on the car are of different makes, the ABS/trac-

tion controlsystem may overreact. Only fit tires of the same

make and treadpattern.

In adverse conditions, such as trying to rock the car out

of deep snow or other soft surface, or when snow

chains are fitted, it is advisable to switch off traction

control and allow

tlie car driveline to operate conven-

tionally.

All E39 vehicles are equipped with

Antilock Braking System

(ABS). Early production models featured ABS with Automatic

Stability Control (ABS

I ASC). Later models came equipped

with ABS and Dynamic Stability Control (ABS

/ DSC). This

manual will refer to these systems as ABS. ASC or DSC will

be specified when necessary.

For ABS system and component descriptions, see

300 Sus-

pension, Steering and Brakes-General.

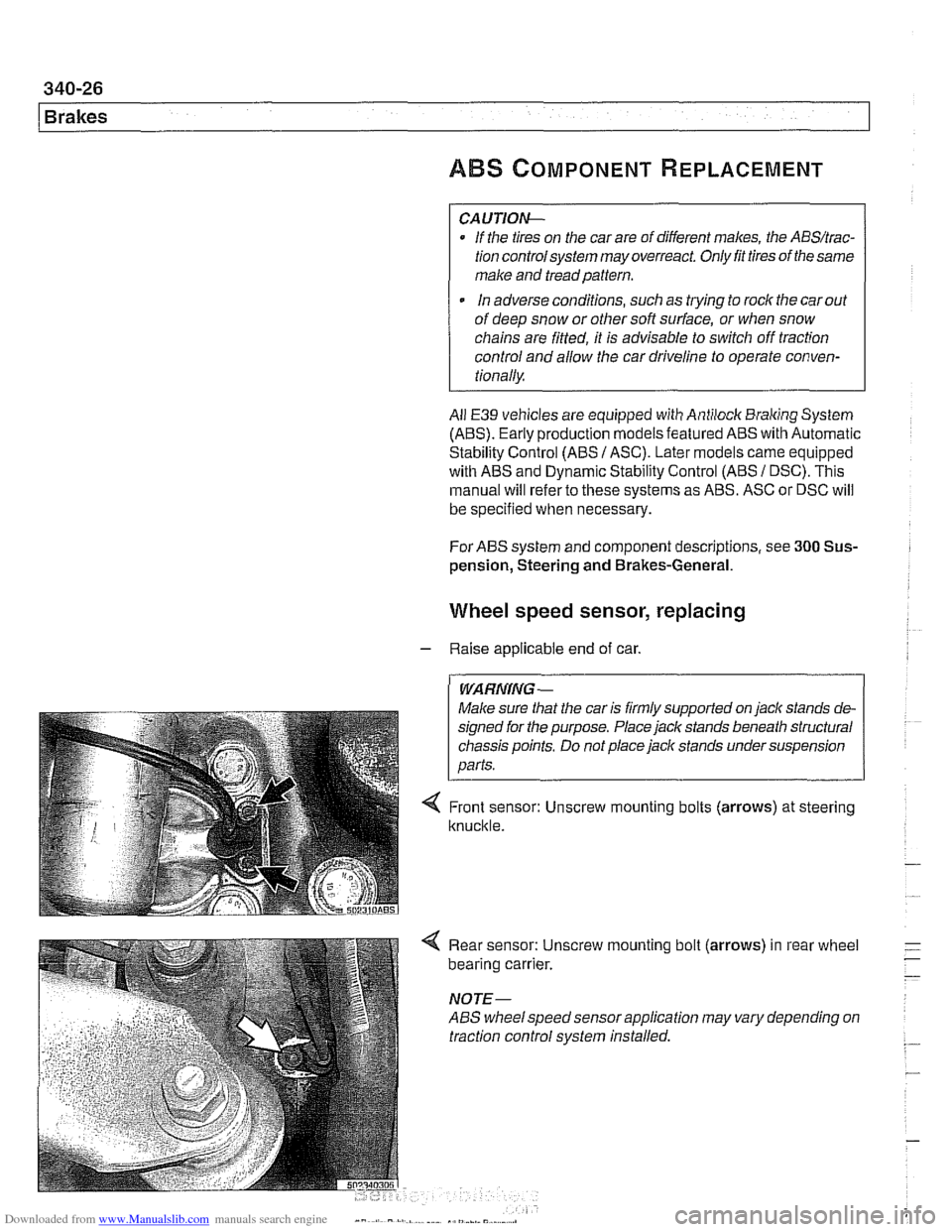

Wheel speed sensor, replacing

- Raise applicable end of car.

Make sure that the car is firmly supported on

jack stands de-

signed for the purpose. Place

jack stands beneath structural

chassis points. Do not place jack stands under suspension

< Front sensor: Unscrew mounting bolts (arrows) at steering

knuckle.

4 Rear sensor: Unscrew mounting bolt (arrows) in rear wheel

bearing carrier.

NOTE-

ABS wheelspeed sensor application may vary depending on

traction control system installed.

Page 808 of 1002

Downloaded from www.Manualslib.com manuals search engine

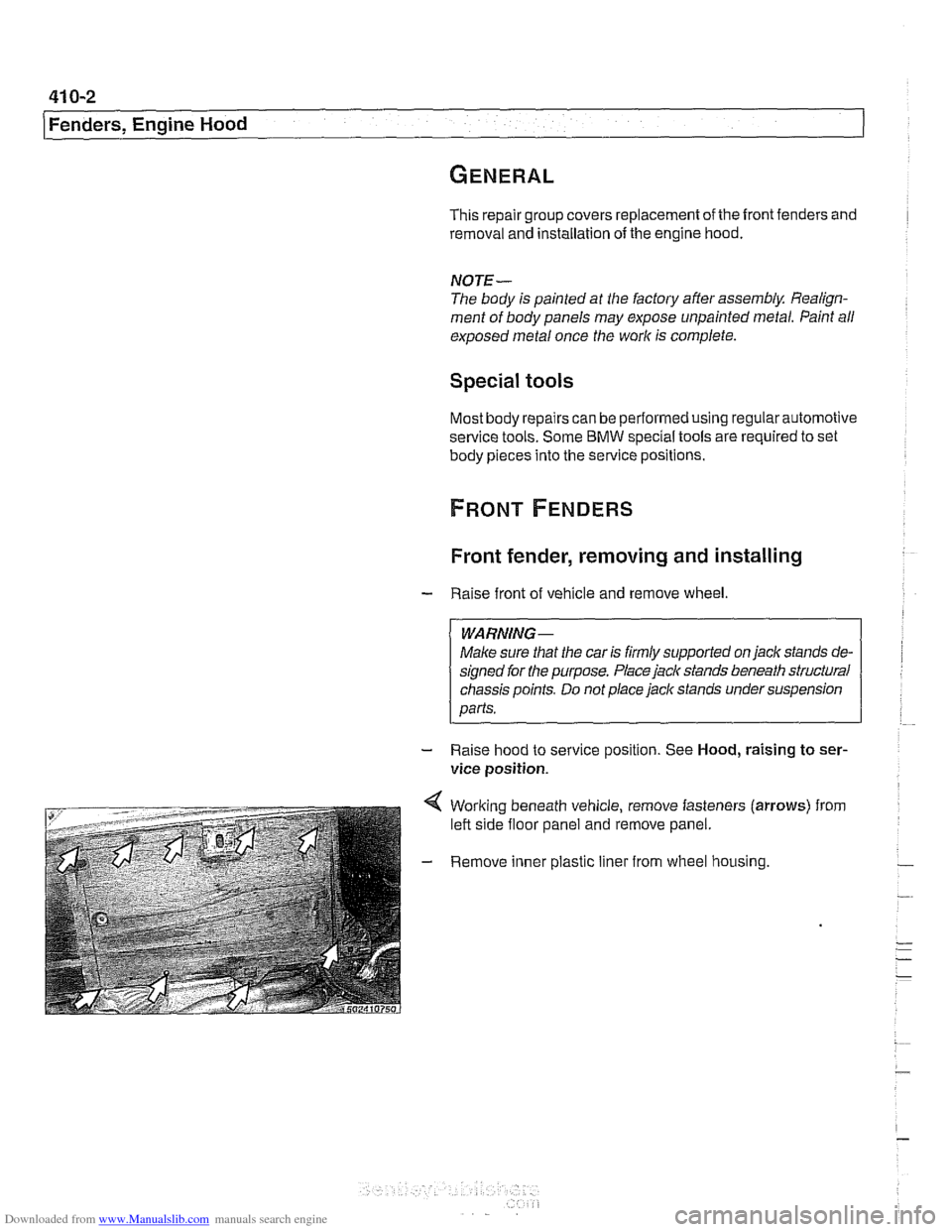

[Fenders, Engine Hood

This repair group covers replacement of the front fenders and

removal and installation of the engine hood.

NOJE-

The body is painted at the factory affer assembly Realign-

ment of body panels may expose unpainted metal. Paint all

exposed metal once the work is complete.

Special tools

Most body repairs can be performed using regular automotive

service tools. Some BMW special tools are required to set

body pieces into the

service positions.

Front fender, removing and installing

- Raise front of vehicle and remove wheel

WARNING-

Make sure that the car is firmly supported on jack stands de-

signed for the purpose.

Placejaclr stands beneath structural

chassis points. Do not place jack stands under suspension

parts.

- Raise hood to service position. See Hood, raising to ser-

vice position.

4 Working beneath vehicle, remove fasteners (arrows) from

left side floor panel and remove panel.

- Remove inner plastic liner from wheel housing.

Page 855 of 1002

Downloaded from www.Manualslib.com manuals search engine

Exterior Trim, ~umpersl

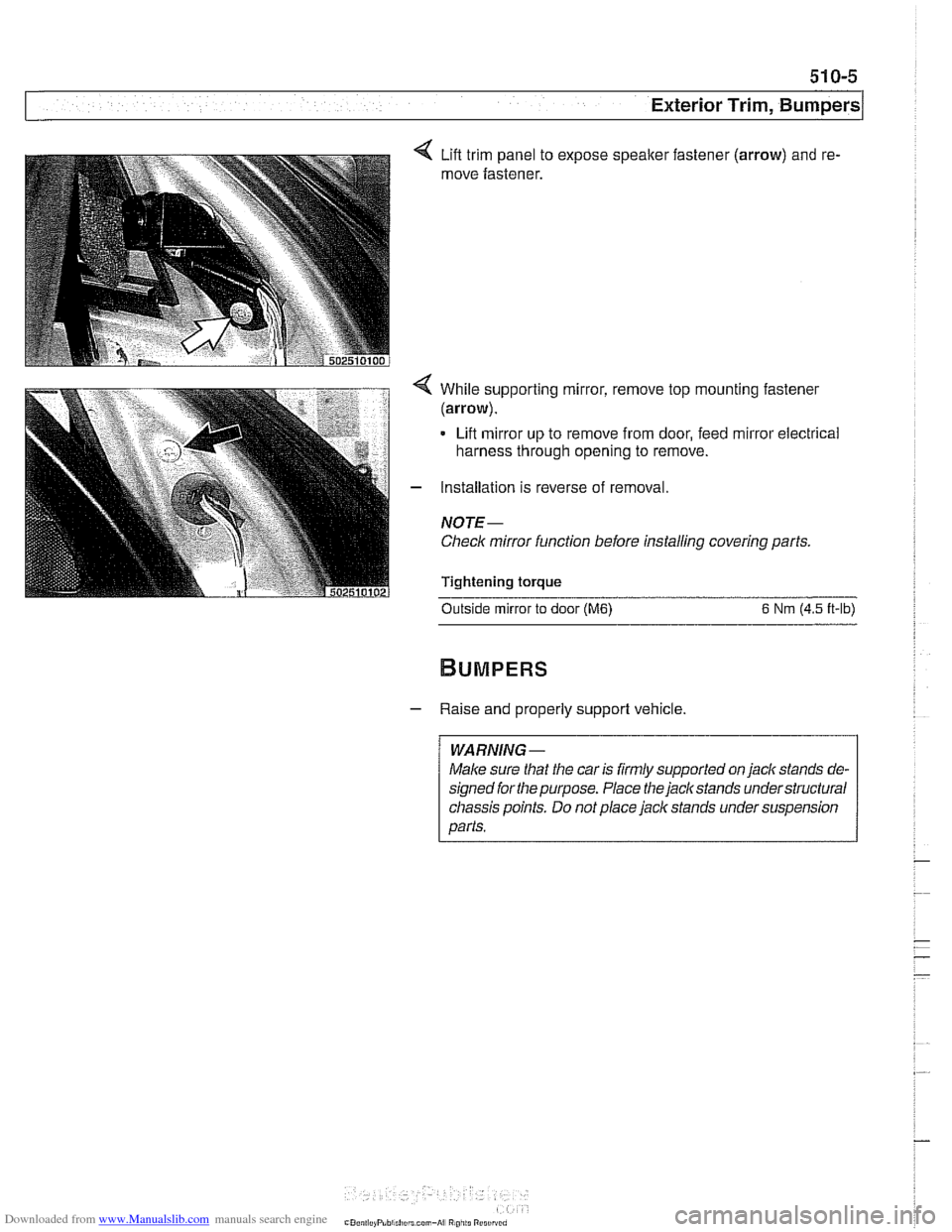

4 While supporting mirror, remove top mounting fastener

(arrow).

Lifi mirror up to remove from door, feed mirror electrical

harness through opening to remove.

- Installation is reverse of removal.

NOTE-

Checlt mirror function before installing covering parts.

Tightening torque

Outside mirror to door (M6) 6 Nm (4.5 It-lb)

BUMPERS

- Raise and properly support vehicle.

WARNING-

Male sure that the car is firmly supported on jacltstands de-

signed

forthe purpose. Place the jacltstands understructural

cliassis points. Do not place

jack stands under suspension

oarfs.

Page 861 of 1002

Downloaded from www.Manualslib.com manuals search engine

Exterior Trim, Bumpers

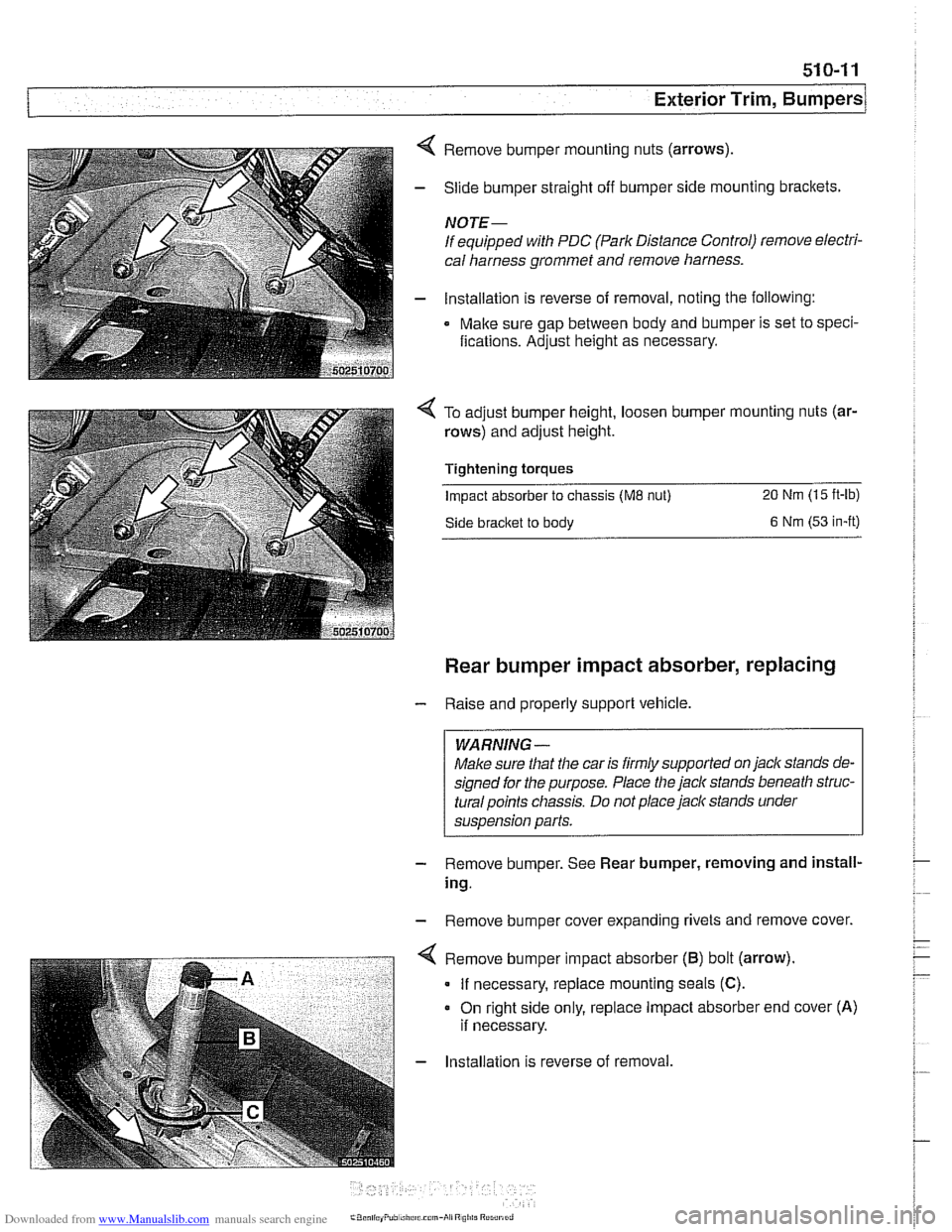

4 Remove bumper mounting nuts (arrows)

- Slide bumper straight off bumper side mounting brackets.

NOTE-

If equipped with PDC (Park Distance Control) remove electri-

cal harness grommet and remove harness.

- lnstallation is reverse of removal, noting the following:

Make sure gap between body and bumper is set to speci-

fications. Adjust height as necessary.

To adjust bumper height, loosen bumper mounting nuts (ar-

rows) and adjust height.

Tightening torques

Impact absorber to chassis (ME nut) 20 Nm (15 ft-lb)

Side bracket to body 6 Nm (53 in-it)

Rear bumper impact absorber, replacing

- Raise and properly support vehicle.

WARNING -

Make sure that the car is firmly supported on jack stands de-

signed for the purpose. Place the jack stands beneath

struc-

turalpoints chassis. Do not place jaclc stands under

suspension parts.

- Remove bumper. See Rear bumper, removing and install-

ing.

- Remove bumper cover expanding rivets and remove cover.

. - . . - . . ".-- < Remove b~mper mpact absorber (6) bot (arrow).

I If necessary, replace mounting seals (C).

- Installation is reverse of removal.

Page 862 of 1002

Downloaded from www.Manualslib.com manuals search engine

I Exterior Trim, Bumpers

Tightening torques Impact absorber to chassis

(M8 nut) 20 Nm (15 ft-lb)

Impact absorber to chassis

(M6 nut) 9 Nm (80 In-lb

Bumper bracket to impact absorber 45 Nm (32 ft-lb)

(MI0 bolt)

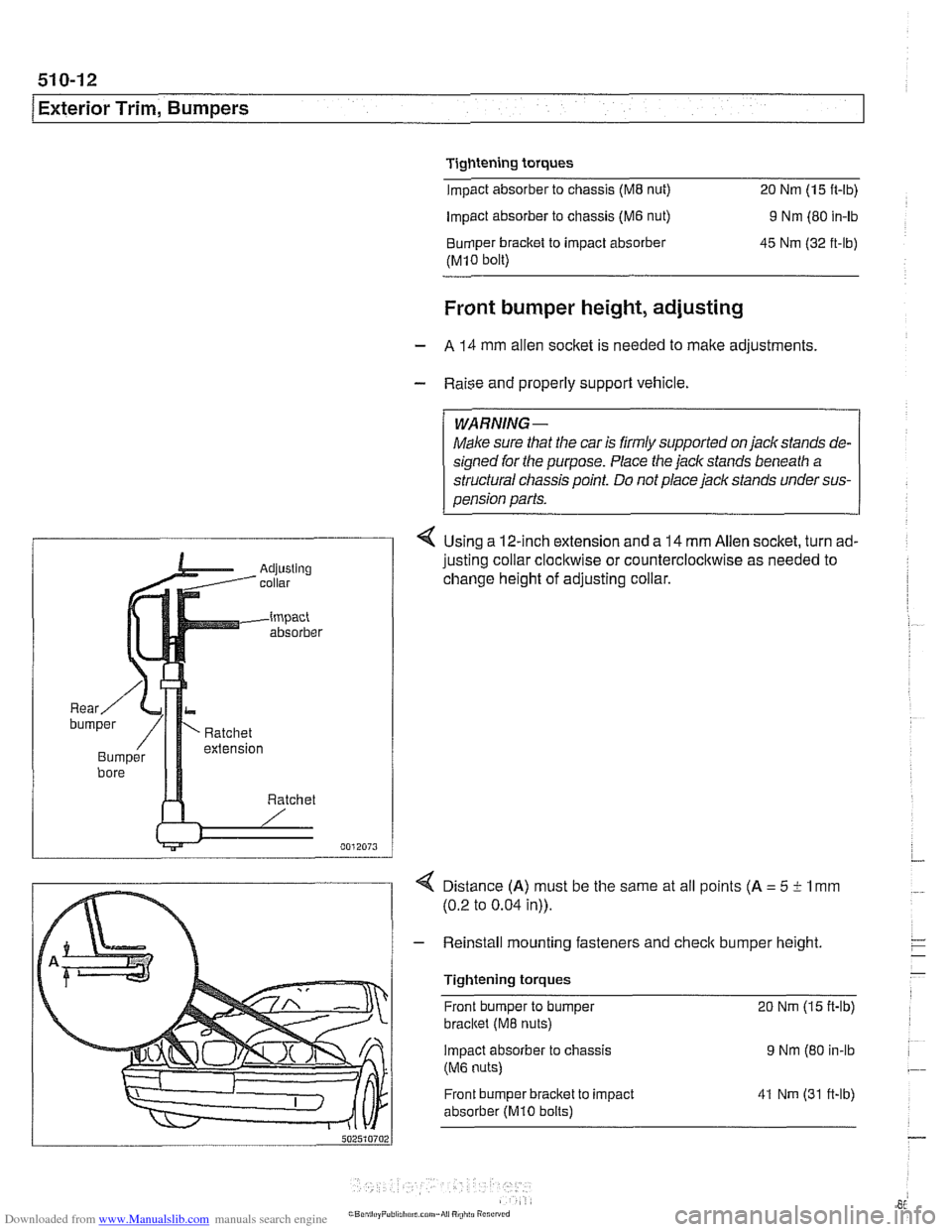

Front bumper height, adjusting

- A 14 mm allen socket is needed to make adjustments

- Raise and properly support vehicle.

WARNING-

Make sure that the car is firmly supported on jackstands de-

signed for the purpose. Place the jack stands beneath a

structural chassis point.

Do not place jack stands under sus-

pension parts.

4 Using a 12-inch extension and a 14 mm Allen socket, turn ad-

justing collar

clocl~wise or counterclocl~wise as needed to

change height of adjusting collar.

4 Distance (A) must be the same at all points (A = 5 i- 1 mm

(0.2 to 0.04 in)).

- Reinstall mounting fasteners and check bumper height

Tightening torques Front bumper to bumper

20 Nm (15 ft-lb)

bracltet (M8 nuts)

Impact absorber

to chassis 9 Nm (80 in-lb

(M6 nuts)

Front bumper bracket to impact

absorber

(MI0 bolts)

41 Nm (31 ft-lb)