driveshaft BMW 540i 2000 E39 Workshop Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 2000, Model line: 540i, Model: BMW 540i 2000 E39Pages: 1002

Page 3 of 1002

Downloaded from www.Manualslib.com manuals search engine

YOU are now in Volume I

I

Foreword ................... .. ........................................................................\

.......... v

Index

........................ .. ................................................................ rear of manual

General, 001 General Warnings and Cautions 002 Vehicle Identification and VIN Decoder

Maintenance OiO 020 Maintenance

Engine

100 Engine-General 110 Engine Removal and Installation

113 Cylinder Head Removal and

Installation

116 Cyiinder Head and Valvetrain 117 Camshaft Timing Chain

119 Lubrication System

200 Transmission-General

2 Transmission 210 clutch 230 ManualTransmission

I20 Ignition System

121 Battery, Starter, Alternator

130 Fuel Injection

160 Fuel Tank and Fuel Pump 170 Radiator and Cooling System

180 Exhaust System

240 Automatic Transmission

250 Gearshift Linkage 260 Driveshaft

Suspension, 300 Suspension, Steering and 330 Rear Suspension

Brakes-General 331 Final Drive

Steering and No Front Suspension 340 Brakes

320 Steering and Wheel Alignment

400 Body-General

410 Fenders, Engine Hood 411 Doors

412 Trunk Lid, Tailgate

510 Exterior Trim, Bumpers 512 Door Windows

Equipment 513 Interior Trim

7

Equipment and 720 seat Belts

Accessories 721 Airbag System (SRS)

OBD On-Board Diagnostics

. ............ ..

515 Central Lociting and

Anti-Theft

520 Seats 540 Sunroof

.................................................................... Foreword .............................. .. v

Index ................... .. ................................................................ rear of manual

Electrical

6 system

600 Electrical System-General 620 Instruments

610 Electrical Comoonent Locations 630 Liohts

611 wipers and washers 612 Switches eati in^ and Air Conditioning

Radio

. ........... ........ .........................

Electrical Wiring Diagrams

Page 62 of 1002

Downloaded from www.Manualslib.com manuals search engine

020-30

Maintenance

fluid use and the most-up-to-date information regarding

transmission operating fluids.

The automatic transmission is not equipped with a dipstick.

Therefore, checking the ATF level is an involved procedure

which includes measuring and maintaining a specified ATF

temperature during the checking procedure.

For more complete

ATF service information, including

checking

ATF level and ATF filter replacement procedures,

see

240 Automatic Transmission.

Transmission service, manual

Manual transmission service consists of inspecting for leaks

and checking the fluid. Evidence of transmission leaks is

like-

ly to be seen around the driveshaft mounting flange and at the

bottom of the bellhousing.

NOTE-

For more information on identifying oil

leaks and their

causes, see 230 Manual Transmission and210 Clutch.

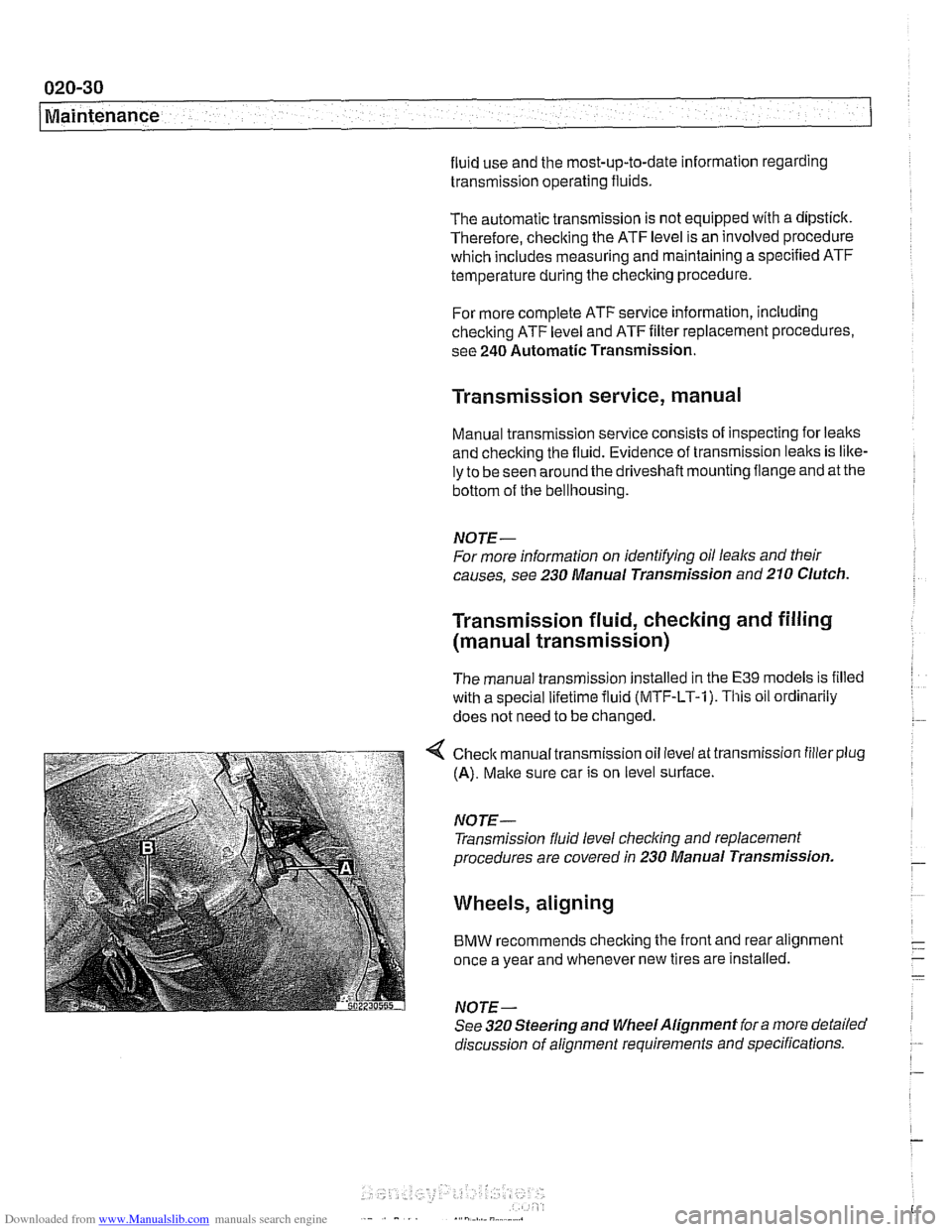

Transmission fluid, checking and filling

(manual transmission)

Tne manual transmss'on inslalleo 'n rne E39 models s f;lled

with a special liierime iluid (ivlTF-LT-I). oi. ordinarily

does

not need to be changed.

< Check manual transmission oil level at transmission filler plug

(A). Make sure car is on level surface.

NOTE- Transmission fluid level

checking and replacement

procedures are covered in 230 Manual Transmission.

Wheels, aligning

BMW recommends checking the front and rear alignment

once a year and whenever new tires are installed.

NOTE-

See 320 Steering and Wheel Alignment for a more detailed

discussion of alignment requirements and specifications.

Page 491 of 1002

Downloaded from www.Manualslib.com manuals search engine

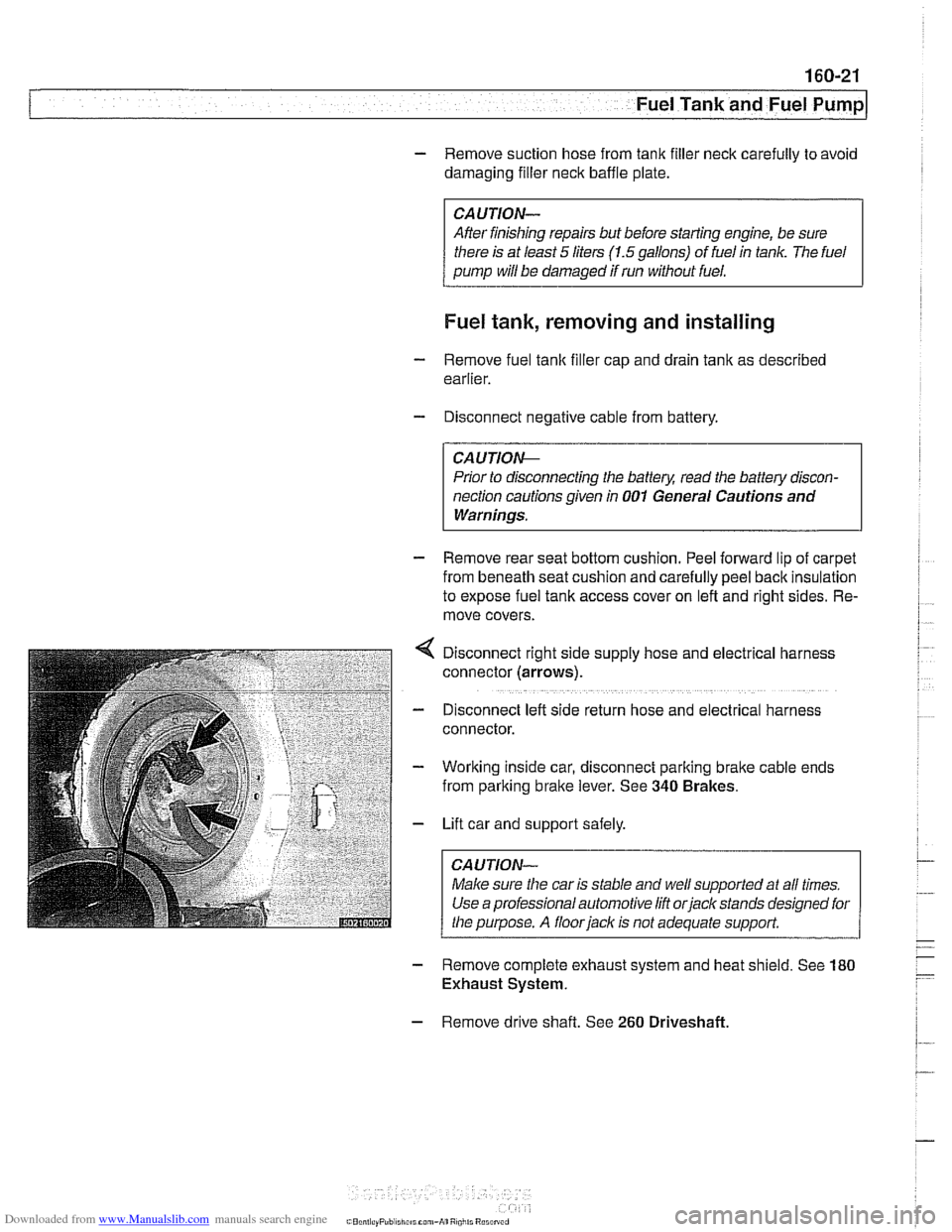

Fuel Tank and Fuel pump/

- Remove suction hose from tank filler neck carefully to avoid

damaging filler neck baffle plate.

CAUTION-

After finishing repairs but before starling engine, be sure

there is at least

5 liters (1.5 gallons) of fuel in tanlc. The fuel

pump will be damaged if run without fuel.

Fuel tank, removing and installing

- Remove fuel tank filler cap and drain tank as described

earlier.

- Disconnect negative cable from battery.

CAUTION-

Prior to disconnecting the battea read the battery discon-

nection cautions given in

001 General Cautions and

Warnings.

- Remove rear seat bottom cushion. Peel forward lip of carpet

from beneath seat cushion and carefully peel back insulation

to expose fuel tank access cover on left and right sides. Re-

move covers.

Disconnect right side supply hose and

electr~cal harness

connector (arrows).

D~sconnect left side return hose and electrical harness

connector.

Working inside car, disconnect parking

bralte cable ends

from parking brake lever. See

340 Brakes.

Lift car and support safely.

Make sure the car is stable and

we/ supported at all times.

Use a professional automotive lift

orjack stands designed for

the purpose. A floorjaclc is not adequate support.

- Remove complete exhaust system and heat shield. See 180

Exhaust System.

- Remove drive shaft. See 260 Driveshaft

Page 540 of 1002

Downloaded from www.Manualslib.com manuals search engine

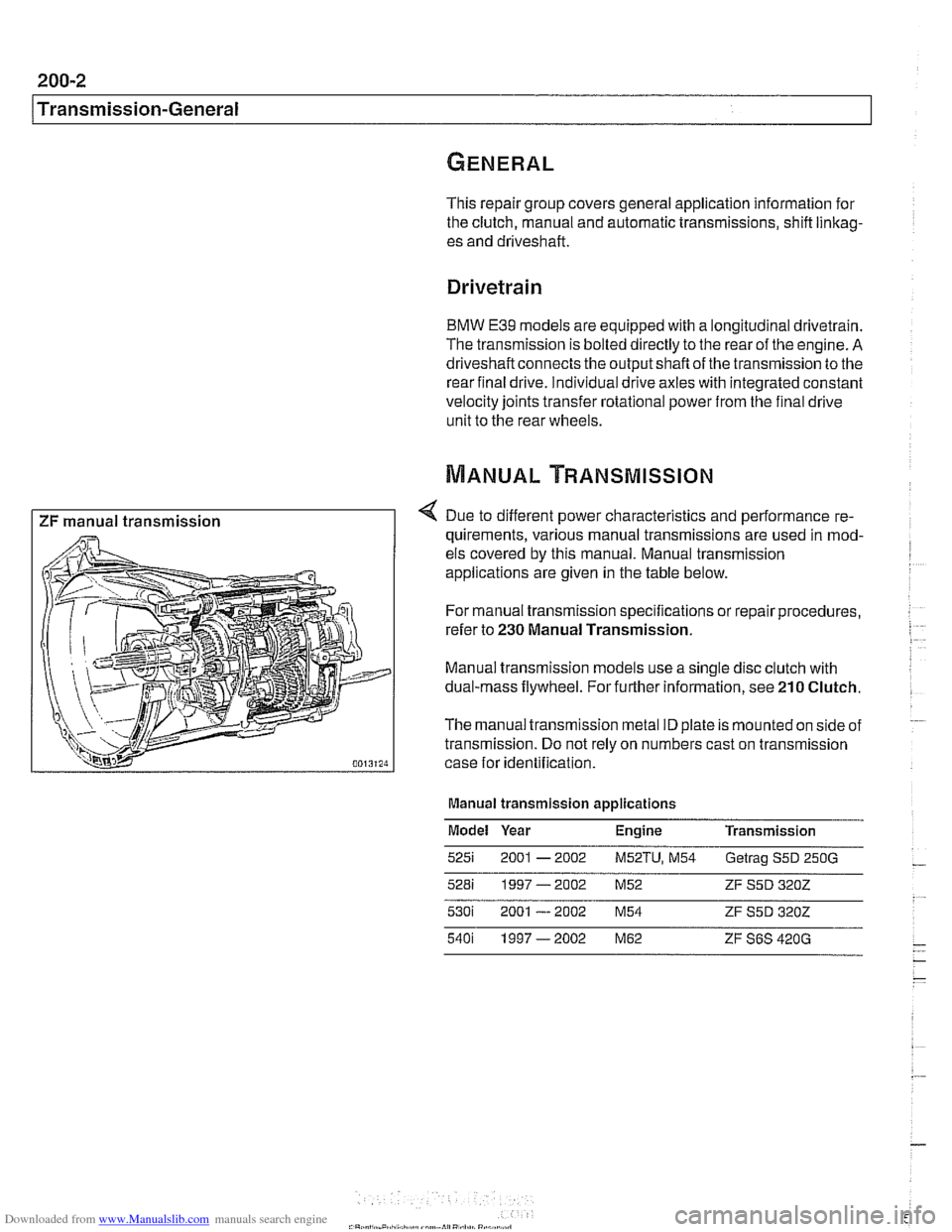

This repair group covers general application information for

the clutch, manual and automatic transmissions, shift linkag-

es and driveshaft.

Drivetrain

I ZF manual transmission I

BMW E39 models are equipped with a longitudinal drivetrain.

The transmission is bolted directly to the rear of the engine.

A

driveshaft connects the output shaft of the transmission to the

rear final drive. Individual drive axles with integrated constant

velocity joints transfer rotational power from the final drive

unit to the rear wheels.

4 Due to different power characteristics and performance re-

quirements, various manual transmissions are used in mod-

els covered by this manual. Manual transmission

applications are given in the table below.

For manual transmission specifications or repair procedures,

refer to

230 Manual Transmission.

Manual transmission models use a single disc clutch with

dual-mass flywheel. For further information, see

210 Clutch.

The manual transmission metal ID plate is mounted on side of

transmission. Do not rely on numbers cast on transmission

case for identification.

Manual transmission applications

Model Year Engine Transmission

5251 2001 - 2002 M52TU, M54 Getrag S5D 250G

528i 1997-2002 M52 ZF S5D 3202

Page 572 of 1002

Downloaded from www.Manualslib.com manuals search engine

Manual Transmission Selector shaft seal, replacing

(transmission installed)

- Put transmission into second gear.

- Raise and safely support vehicle.

WARNING-

Make sure the car is stable and well supported at all times.

Use a professional automotive lift

orjack stands designed for

the purpose.

A floorjack is not adequate support

- 6-speed transmission: Remove rear engine splash shield

- Remove exhaust system and heat shields. See 180 Exhaust

System.

- Support transmission with transmission jack.

- Disconnect driveshaft at transmission and tie to side. See

260 Driveshaft.

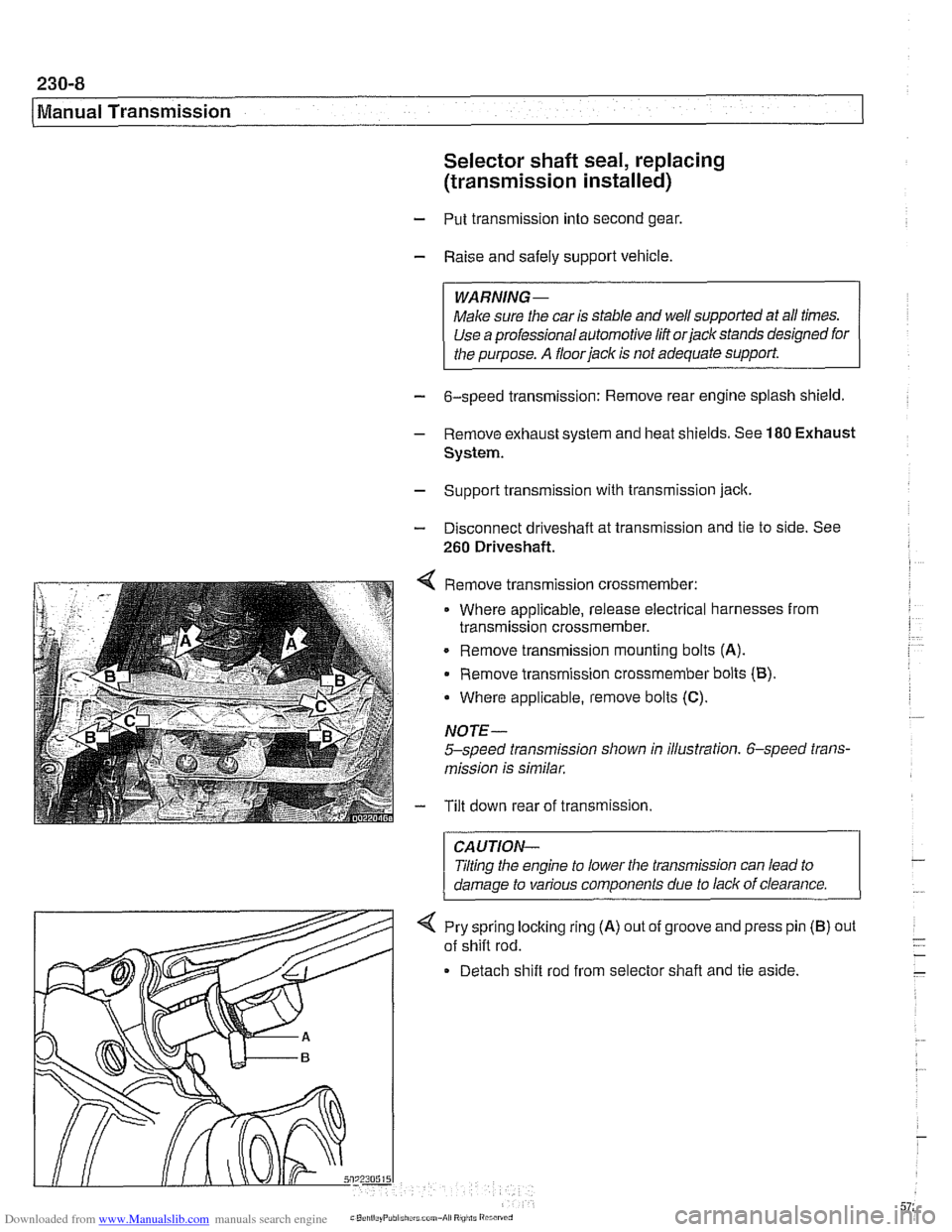

4 Remove transmission crossmember:

Where applicable, release electrical harnesses from

transmission crossmember.

. Remove transmission mounting bolts (A).

Remove transmission crossmember bolts (B).

Where applicable, remove bolts

(C).

NOTE-

5-speed transmission shown in illustration. 6-speed trans-

mission is similar.

- Tilt down rear of transmission.

CAUTION-

Jilting the engine to lower the transmission can lead to

damaae to various components due to lack of clearance.

-

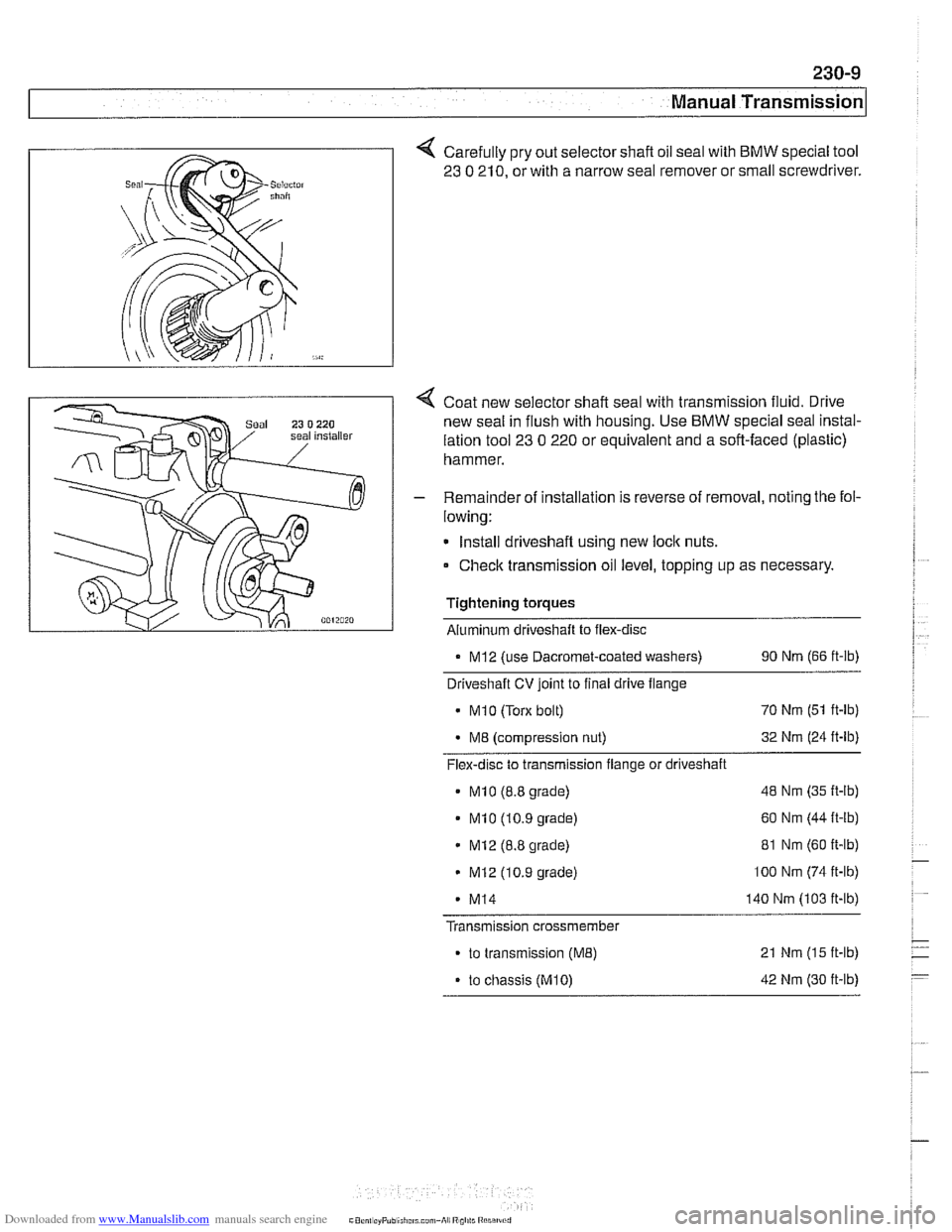

4 Pry sprlng locking rlng (A) out of groove and press pin

of

sh~fl rod.

Detach

sh~ft rod from selector shafl and tie as~de.

(B) out

Page 573 of 1002

Downloaded from www.Manualslib.com manuals search engine

230-9

Manual ~ransmissionl

Carefully pry out selector shaft oil seal with BMW special tool

23

0 210, or with a narrow seal remover or small screwdriver.

Coat new selector shaft seal with transmission fluid. Drive

new seal in flush with housing. Use

BMW special seal instal-

lation tool

23 0 220 or equivalent and a soft-faced (plastic)

hammer.

- Remainder of installation is reverse of removal, noting the fol-

lowing:

Install driveshaft using new

loclc nuts.

Check transmission oil level, topping up as necessary.

Tightening torques Aluminum driveshaft to flex-disc

. MI2 (use Dacromet-coated washers) 90 Nm (66 ft-lb)

Driveshaft CV joint to final drive flange

MI 0 (Torx bolt) 70

Nm (51 ft-lb)

M8 (compression nut) 32

Nm (24 ft-lb)

Flex-disc to transmission flange or driveshaft

MI0 (8.8 grade) 48 Nm (35 ft-lb)

MI0 (10.9 grade) 60

Nm (44 it-lb)

MI2 (8.8 grade) 81

Nm (60 ft-lb)

MI2 (10.9 grade) lo0 Nm (74 ft-lb)

- MI4 140 Nm (103 ft-lb)

Transmission crossmember

to transmission (ME) 21 Nm (15 ft-lb)

. to chassis (M10) 42 Nm (30 ft-lb)

Page 574 of 1002

Downloaded from www.Manualslib.com manuals search engine

230-1 0

I Manual Transmission

Output shaft seal, replacing (5-speed

transmission) (transmission installed)

- Raise and safely support vehicle.

WARNING -

Make sure the car is stable and well supported at all times.

Use a professional automotive

lilt orjack stands designed

for the purpose.

A floorjack is not adequate support.

- Remove exhaust system and heat shields. See 180 Exhaust

System

Support transmission with transmission jack.

Disconnect driveshafi at transmission output flange, and

hang driveshaft to side. See

260 Driveshaft.

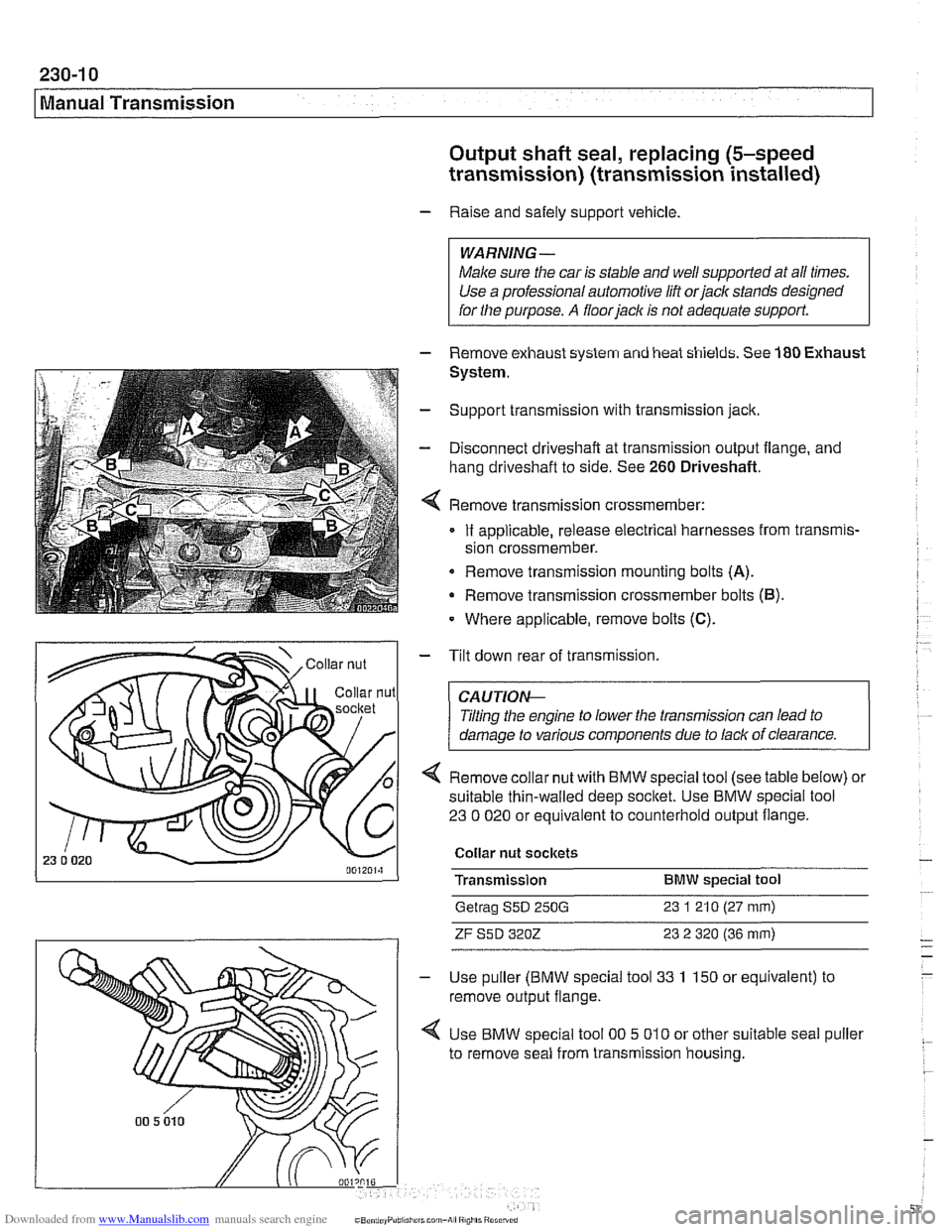

Remove transmission crossmember:

If applicable, release electrical harnesses from transmis-

sion crossmember.

Remove transmission mounting bolts

(A).

Remove transmission crossmember bolts (6).

Where applicable, remove bolts (C).

- Tilt down rear of transmission.

CAUTIOI\C

Tilting the engine to lower the transmission can lead to

damage to various components due to lack of clearance.

4 Remove collar nut with BMW special tool (see table below) or

suitable thin-walled deep

socltet. Use BMW special tool

23 0 020 or equivalent to counterhold output flange.

Collar nut sockets

Transmission

BMW special tool

Getrag S5D 250G 23 1 21 0 (27 mm)

ZF S5D 3202 23 2 320 (36 mm)

Use puller (BMW special tool 33 1 150 or equivalent) to

remove output flange.

Use BMW special tool

00 5 010 or other suitable seal puller

to remove seal from transmission housing.

Page 575 of 1002

Downloaded from www.Manualslib.com manuals search engine

230-1 1

Manual ~ransmissionl

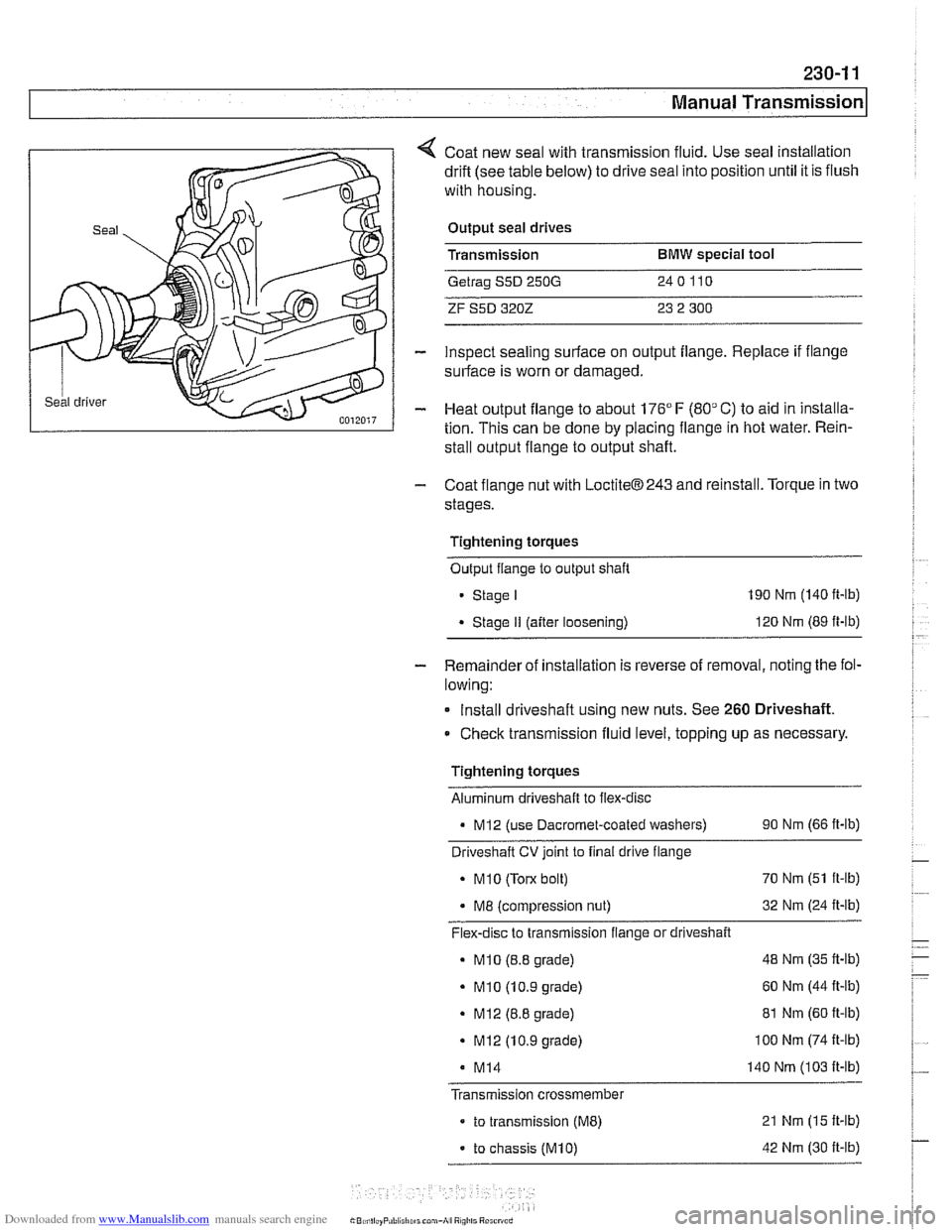

Coat new seal with transmission fluid. Use seal installation

drift (see table below) to drive seal into position until it is flush

with housing.

Output seal drives

Transmission

BMW special tool

Getrag S5D 250G 240110

ZF S5D 3202 23 2 300

inspect sealing surface on output flange. Replace if flange

surface is worn or damaged.

Heat output flange to about 176"

F (80" C) to aid in installa-

tion. This can be done by placing flange in hot water. Rein-

stall output flange to output shaft.

- Coat flange nut with LoctiteB243 and reinstall. Torque in two

stages.

Tightening torques Output flange to output shaft

Stage I 190 Nm (140 ft-lb)

Stage II (after loosening) 120

Nm (89 ft-lb)

- Remainder of installation is reverse of removal, noting the fol-

lowing:

Install driveshaft using new nuts. See

260 Driveshaft.

Check transmission fluid level, topping up as necessary

Tightening torques Aluminum driveshaft to flex-disc

- MI2 (use Dacromet-coated washers) 90 Nm (66 ft-lb)

Driveshaft

CV joint to final drive flange

. MI0 (Torx bolt) 70

Nm (51 ft-lb)

. M8 (compression nut) 32

Nm (24 ft-lb)

Flex-disc to transmission flange or driveshaft

- MI0 (8.8 grade) 48

Nm (35 ft-lb)

- MI0 (10.9 grade) 60

Nm (44 It-lb)

. MI2 (8.8 grade) 81 Nm (60 ft-lb)

. MI2 (10.9 grade) I00 Nm (74 It-lb)

M14 140 Nm (103 It-lb)

Transmission crossmember

- to transmission (ME) 21 Nm (15 It-lb)

- to chassis (M10) 42 Nm (30 It-lb)

Page 576 of 1002

Downloaded from www.Manualslib.com manuals search engine

230-12

/ Manual Transmission

Output shaft seal, replacing (6-speed

transmission) (transmission installed)

- Raise and safely support vehicle.

WARNING-

Make sure the car is stable and well supported at all times.

Use a professional automotive lift

orjack stands designed for

the purpose.

A floorjack is not adequate support.

- Remove exhaust system and heat shields. See 180 Exhaust

System.

- Support transmission with transmission jack

- Disconnect driveshaft at transmission output flange, and

hang driveshaft to side. See

260 Driveshaft.

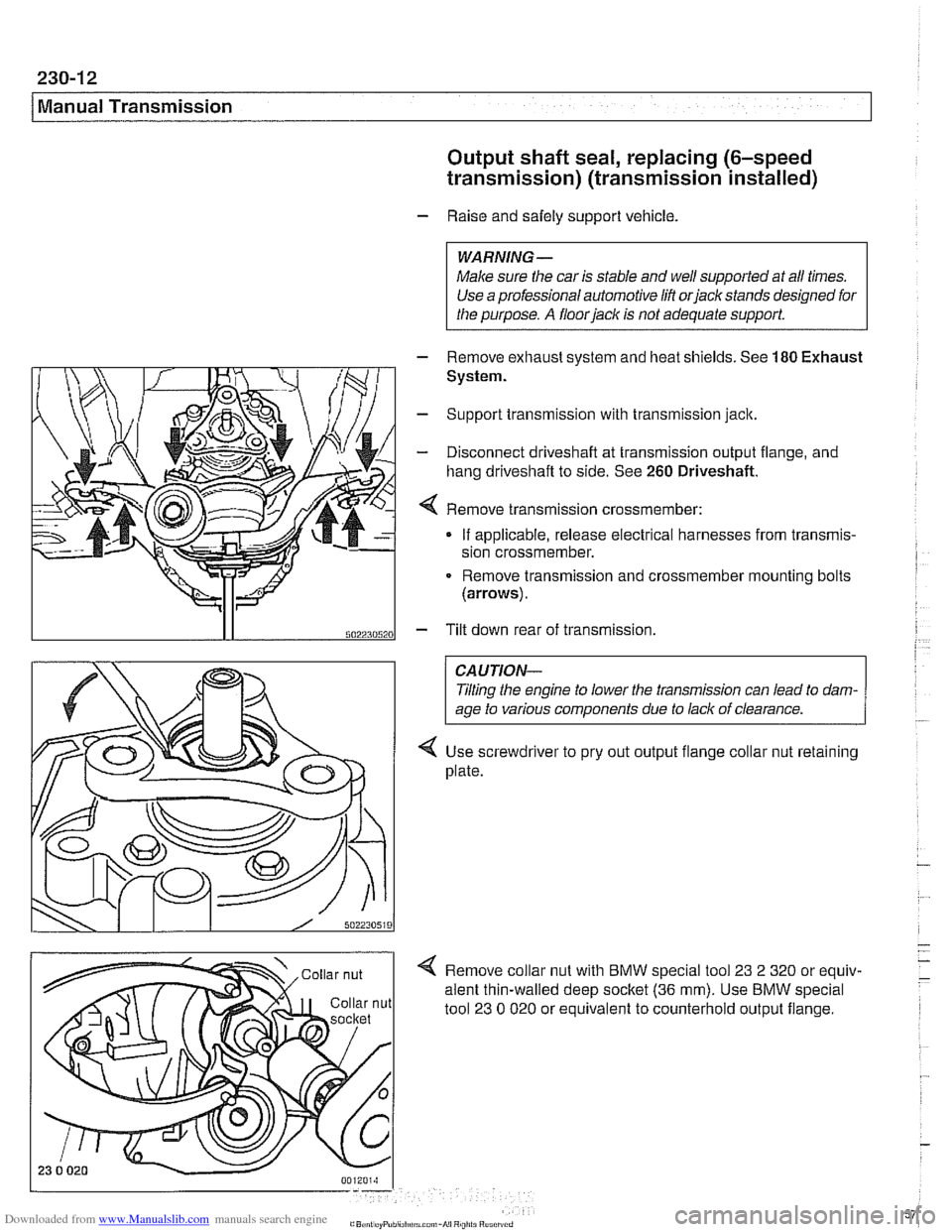

Remove transmission crassmember:

If applicable, release electrical harnesses from transmis-

sion crossmember.

Remove transmission and crossmember mounting bolts

(arrows).

5022305201 - Tilt down rear of transmission

CAUTION-

Tlting the engine to lower the transmission can lead to dam-

age to various components due to lack of clearance.

Use screwdriver to pry out output flange collar nut retaining

plate.

Remove collar nut with BMW special tool

23 2 320 or equiv-

alent thin-walled deep socltet

(36 mm). Use BMW special

tool

23 0 020 or equivalent to counterhold output flange.

Page 578 of 1002

Downloaded from www.Manualslib.com manuals search engine

230-14

I Manual Transmission

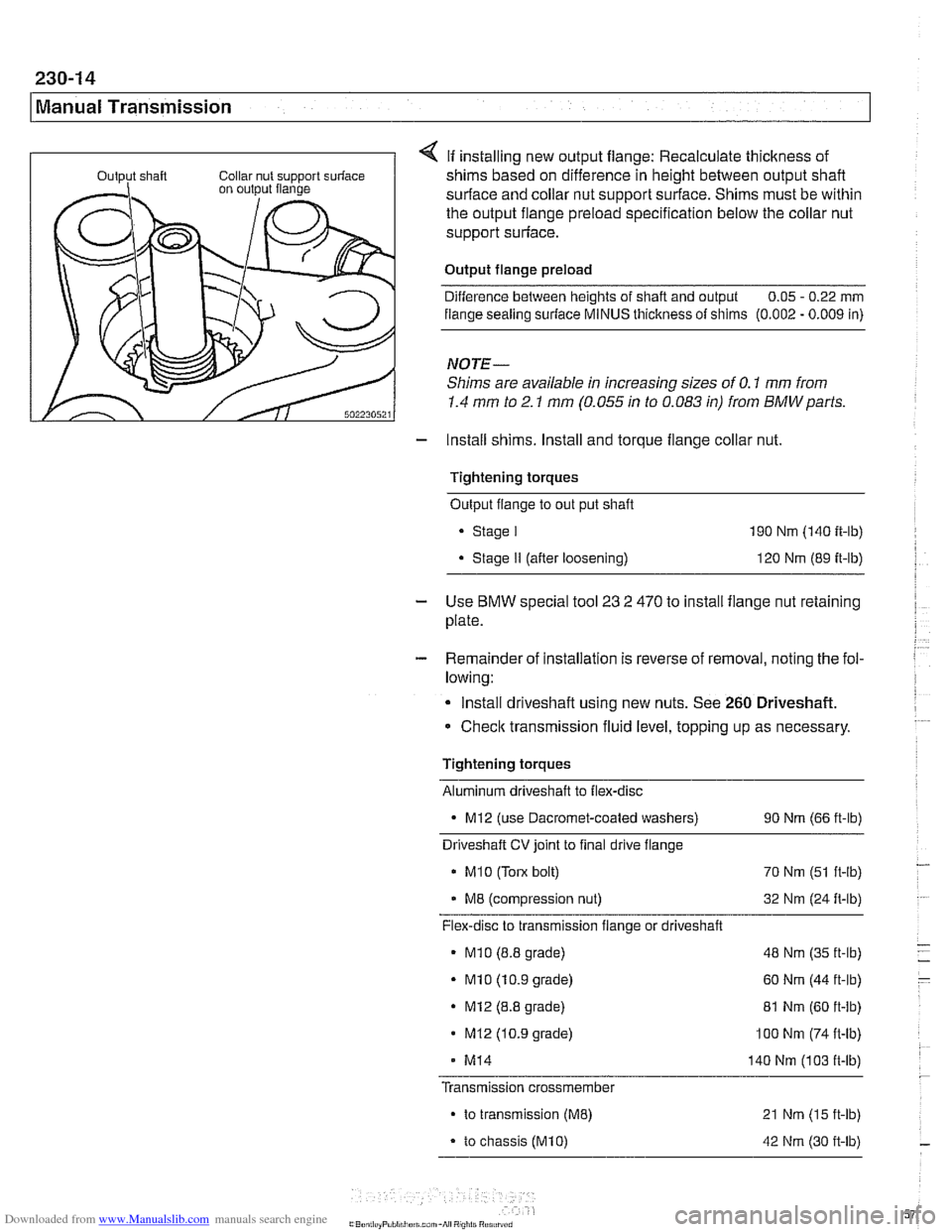

If installing new output flange: Recalculate thickness of

shims based on difference in height between output shaft

surface and collar nut support surface. Shims must be within

the output flange preload specification below the collar nut

support surface.

Output flange preload Difference between heights of shaft and output 0.05

- 0.22 mm

flange sealing

suriace MINUS thickness of shims (0.002 - 0.009 in)

NOTE-

Shims are available in increasing sizes of 0.1 mm from

1.4 mm to 2.1 mm (0.055 in to 0.083 in) from BMWparts.

- Install shims. Install and torque flange collar nut.

Tightening torques Output flange to out put shaft

. Stage I 190 Nm (140 ft-lb)

. Stage II (after loosening) 120 Nm (89 it-lb)

- Use BMW special tool 23 2 470 to install flange nut retaining

plate.

- Remainder of installation is reverse of removal, noting the fol-

lowing:

Install driveshaft using new nuts. See

260 Driveshaft.

Checlc transmission fluid level, topping up as necessary.

Tightening torques

Aluminum driveshaft to flex-disc

- MI2 (use Dacromet-coated washers) 90 Nm (66 ft-lb)

Driveshaft

CV joint to final drive flange

MI0 (Tom bolt)

70 Nm (51 ft-lb)

M8 (compression nut) 32 Nm (24 ft-lb)

Flex-disc to transmission flange or driveshaft

* MI0 (8.8 grade) 48 Nm (35 ft-lb)

- MI0 (10.9 grade) 60 Nm (44 ft-lb)

. MI2 (8.8 grade)

81 Nm (60 ft-lb)

MI2 (10.9 grade) 100 Nm (74 ft-lb)

- MI4 140 Nm (1 03 ft-lb)

Transmission

crossmembe~

to transmission (ME)

to chassis (M10)

21 Nm (15 ft-lb)

42 Nm (30 it-lb)