ignition coil BMW 540i 2001 E39 Workshop Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 2001, Model line: 540i, Model: BMW 540i 2001 E39Pages: 1002

Page 53 of 1002

Downloaded from www.Manualslib.com manuals search engine

020-21

Maintenance

Spark plugs, replacing

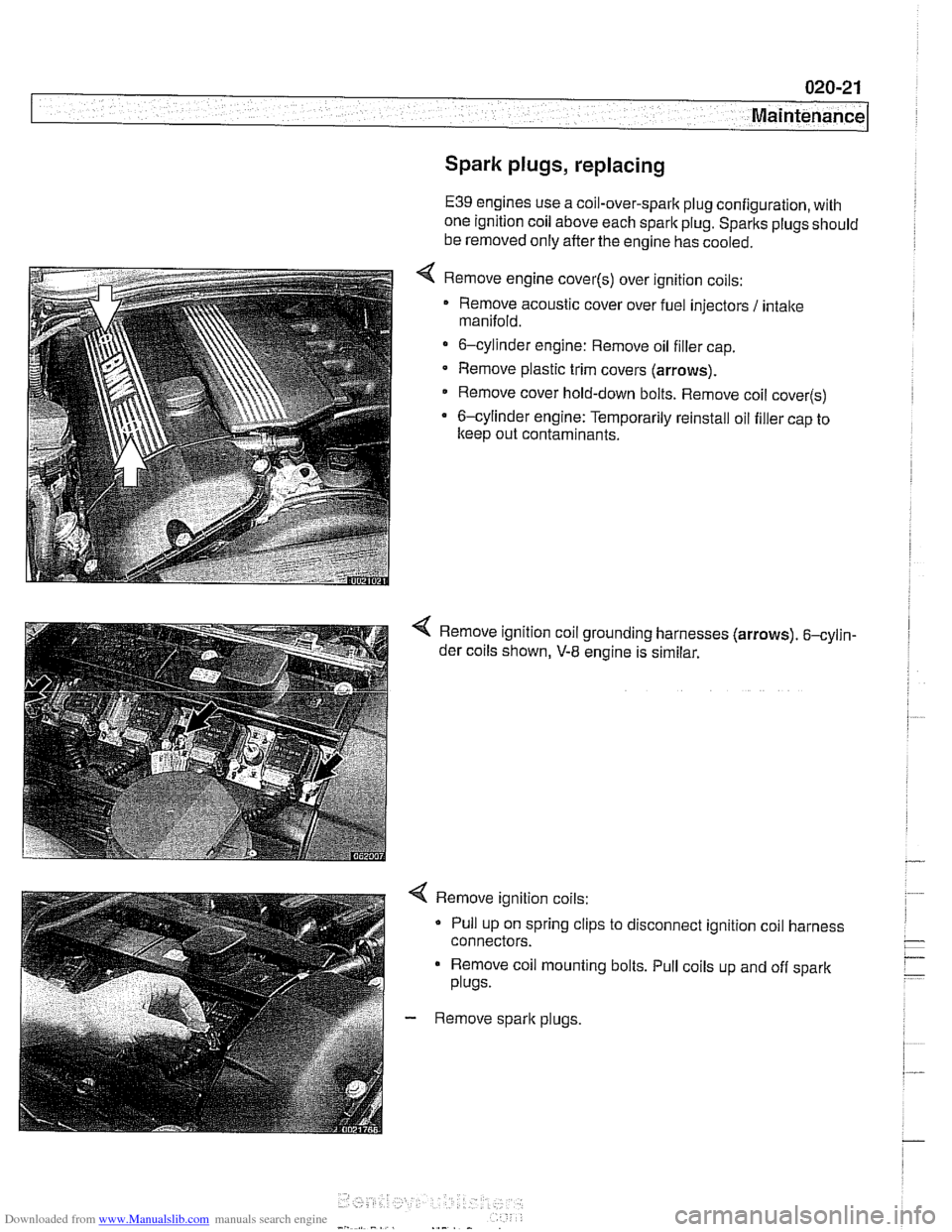

E39 engines use a coil-over-spark plug configuration, with

one ignition coil above each spark plug. Sparks plugs should

be removed only after the engine has cooled.

Remove engine

cover(s) over ignition coils:

Remove acoustic cover over fuel injectors

I intake

manifold.

6-cylinder engine: Remove oil filler cap.

Remove plastic trim covers (arrows).

Remove cover hold-down bolts. Remove coil

cover(s)

6-cylinder engine: Temporarily reinstall oil filler cap to

keep out contaminants.

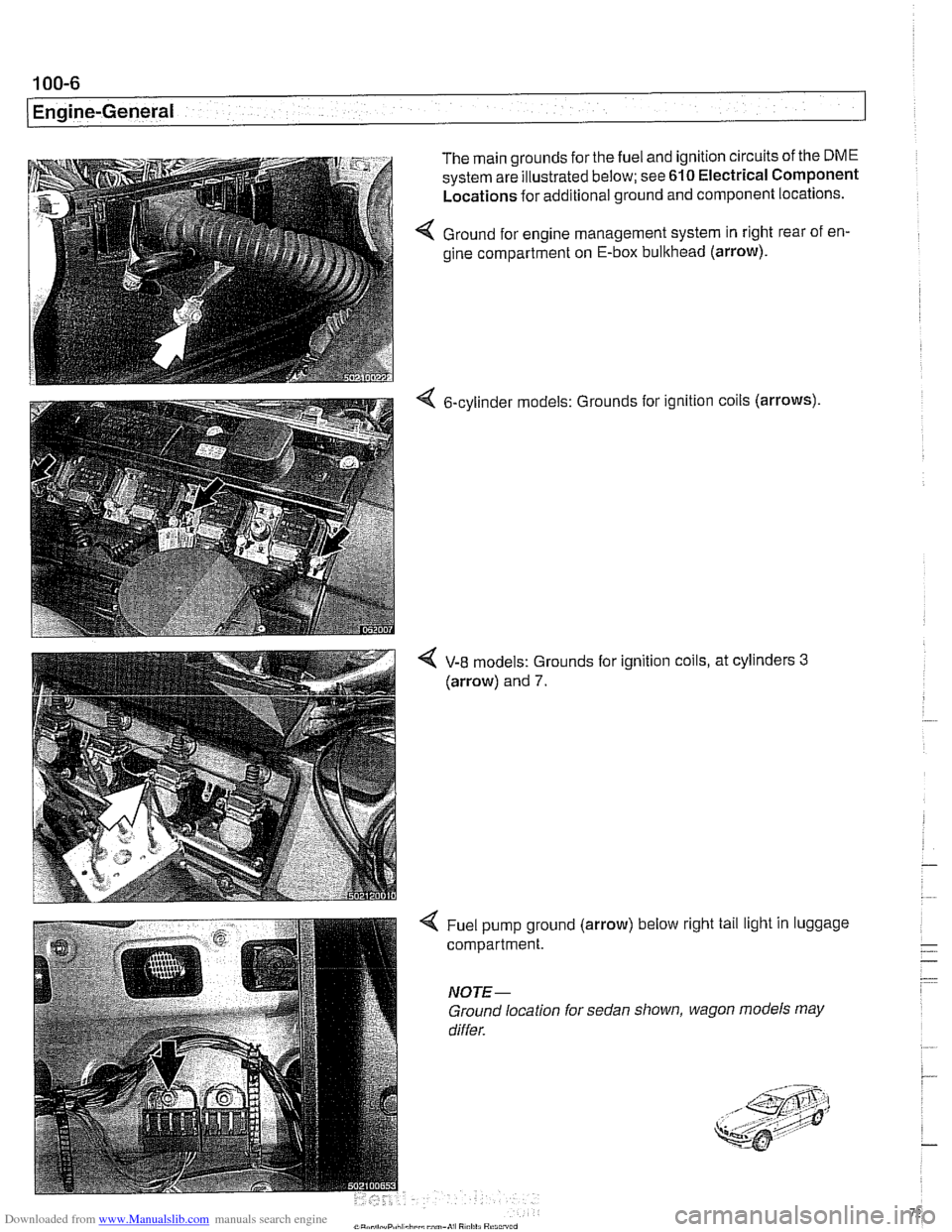

Remove ignition coil grounding harnesses (arrows). 6-cylin-

der coils shown,

V-8 engine is similar.

< Remove ignition coils:

Pull up on spring clips to disconnect ignition coil harness

connectors.

Remove coil mounting bolts. Pull coils up and off spark

plugs.

- Remove spark plugs.

Page 72 of 1002

Downloaded from www.Manualslib.com manuals search engine

100-6

( Engine-General

The main grounds for the fuel and ignition circuits of the DME

system are illustrated below; see 610 Electrical Component

Locations for additional ground and component locations.

4 Ground for engine management system in right rear of en-

gine compartment on E-box bulkhead (arrow).

6-cylinder models: Grounds

for ignition coils (arrows)

4 V-8 models: Grounds for ignition coils, at cylinders 3

(arrow) and 7.

4 Fuel pump ground (arrow) below right tail light in luggage

compartment.

NOTE-

Ground location for sedan shown, wagon models may

differ.

Page 100 of 1002

Downloaded from www.Manualslib.com manuals search engine

11 3-6

Cylinder Head Removal and Installation

- Disable ignition system by removing DME main relay. See

610 Component Locations for relay location.

WARNING-

. The ignition system produces high voltages that can be fa-

tal. Avoid contact with exposed terminals and use

exfreme

caution when working on a car with the ignition switched on

or the engine running.

Do not touch or disconnect ignition

components while

the engine is running or being cranked by the starter.

Failure to remove the DME main relay or attempting to

disa-

bie the fuel andignition systems by other methods may result

in damaoe to the enoine control module

(ECM).

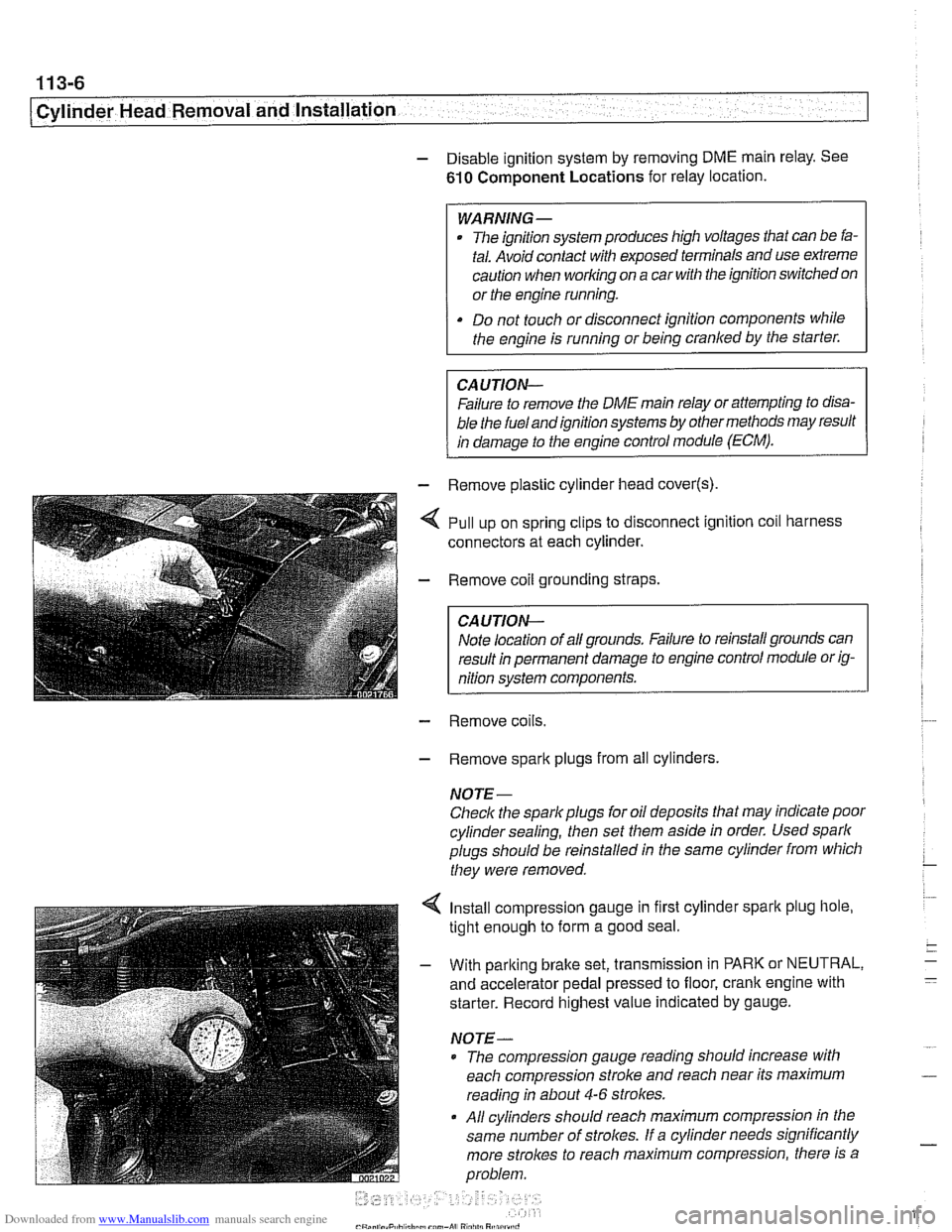

- - Remove plastic cylinder head cover(s)

,,I . ,. .*,.,,&- - Remove coil grounding straps.

I CAUTION-

I nition system components. I

- Remove coils.

- Remove spark plugs from all cylinders.

NOTE-

Check the spark plugs for oil deposits that may indicate poor

cylinder sealing, then set them aside in order. Used spark

plugs should be reinstalled in the same cylinder from which

they were removed.

4 Install compression gauge in first cylinder spark plug hole,

tight enough to form a good seal.

- With parking brake set, transmission in PARK or NEUTRAL,

and accelerator pedal pressed to floor, crank engine with

starter. Record highest value indicated by gauge.

NOTE-

* The compression gauge reading should increase with

each compression stroke and reach near its maximum

reading in about

4-6 strokes.

All cylinders should reach maximum compression in the

same number of

strolces. If a cylinder needs significantly

more strokes to reach

maximum compression, there is a

problem.

Page 101 of 1002

Downloaded from www.Manualslib.com manuals search engine

. .- . --

Lr -- - - - -- Cylinder Head Removal and Installation I -

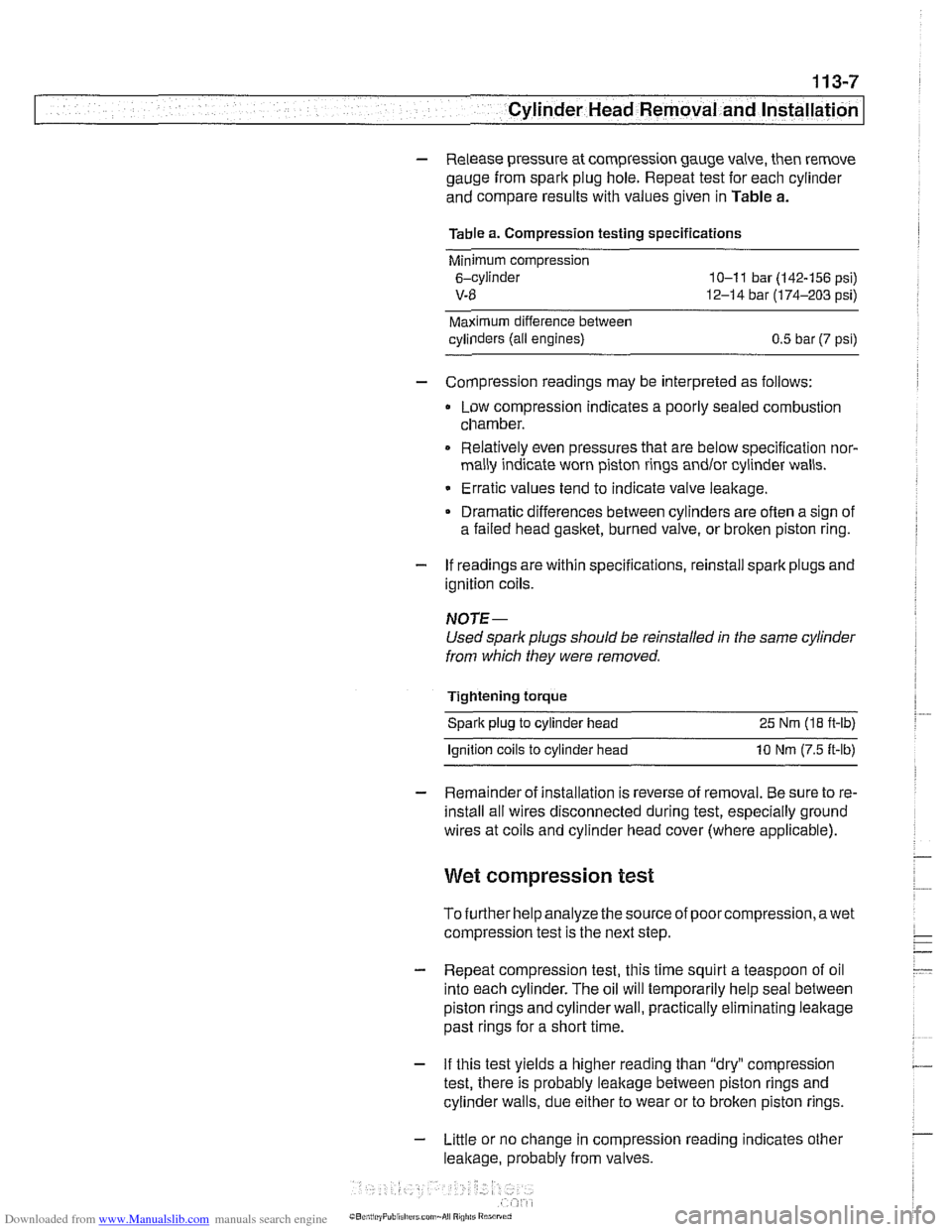

- Release pressure at compression gauge valve, then remove

gauge from spark plug hole. Repeat test for each cylinder

and compare results with values given in Table a.

Table a. Compression testing specifications

Minimum compression

6-cylinder

10-1 1 bar (142-156 psi)

V-8 12-14 bar (174-203 psi)

Maximum difference between

cylinders (all engines)

0.5 bar (7 psi)

- Compression readings may be interpreted as follows:

Low compression indicates a poorly sealed combustion

chamber.

0 Relatively even pressures that are below specification nor-

mally indicate worn piston rings

andlor cylinder walls.

Erratic values tend to indicate valve leakage.

Dramatic differences between cylinders are often a sign of

a failed head

gasket, burned valve, or broken piston ring.

- If readings are within specifications, reinstall spark plugs and

ignition coils.

NOTE-

Used spark plugs should be reinstalled in the same cylinder

from which they were removed.

Tightening torque Spark plug to cylinder head 25 Nm

(18 ft-lb)

lanition coils to cylinder head 10 Nm (7.5 ft-lb)

- Remainder of installation is reverse of removal. Be sure to re-

install all wires disconnected during test, especially ground

wires at coils and cylinder head cover (where applicable).

Wet compression test

To further help analyze the source of poorcompression,awet

compression test is the next step.

- Repeat compression test, this time squirt a teaspoon of oil

into each cylinder. The oil will temporarily help seal between

piston rings and cylinder wall, practically eliminating leakage

past rings for a short time.

- If this test yields a higher reading than "dry" compression

test, there is probably leakage between piston rings and

cylinder walls, due either to wear or to broken piston rings.

- Little or no change in compression reading indicates other

leakage, probably from valves.

Page 106 of 1002

Downloaded from www.Manualslib.com manuals search engine

-

Cylinder Head Removal and Installation c

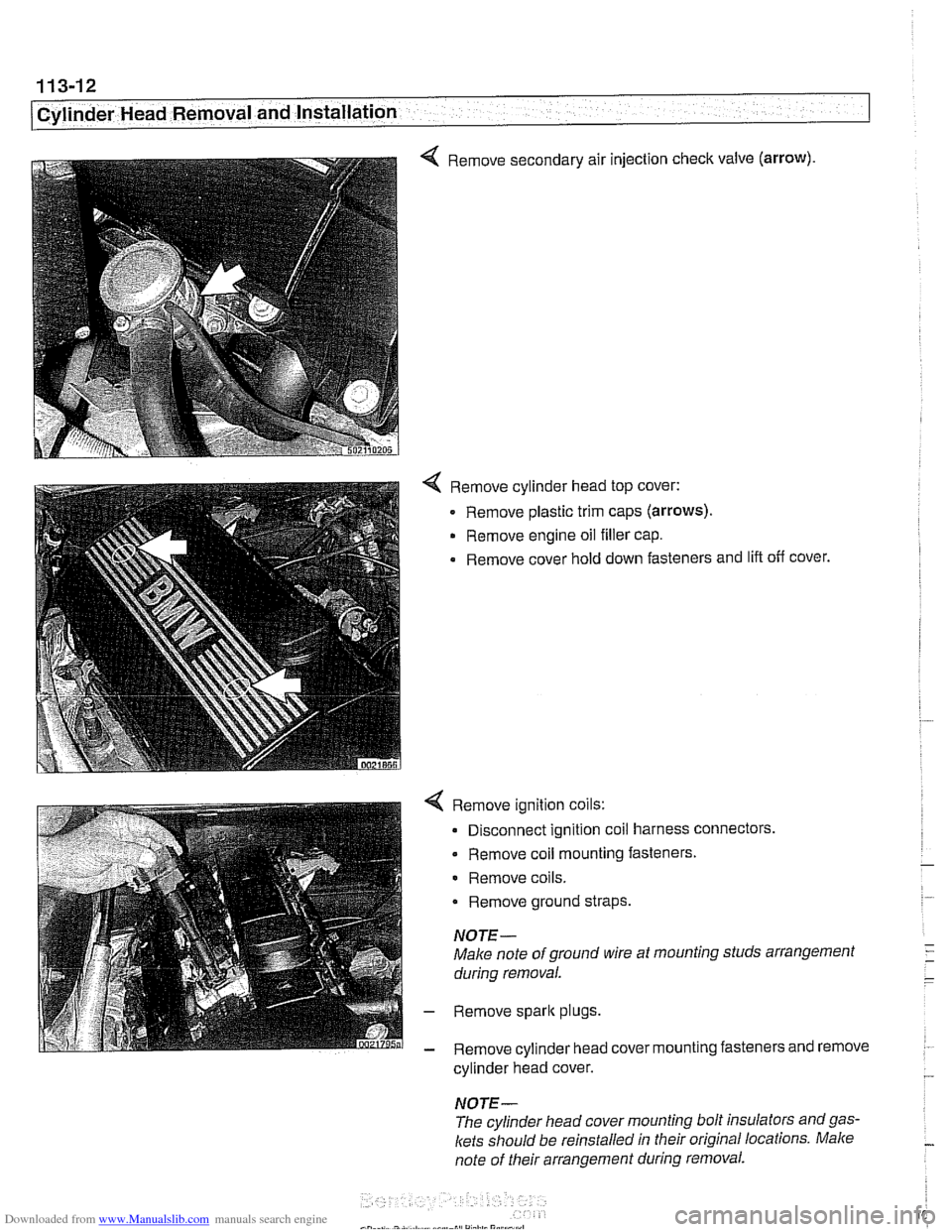

q Remove secondary air inject~on check valve (arrow).

4 Remove cylinder head top cover:

Remove plastic trim caps (arrows).

Remove engine oil filler cap.

Remove cover hold down fasteners and lift off cover.

4 Remove ignition coils:

Disconnect ignition coil harness connectors.

. Remove coil mounting fasteners.

Remove coils.

Remove ground straps.

NOTE-

Make note of ground wire at mounting studs arrangement

during removal.

- Remove sparlc plugs.

- Remove cylinder head cover mounting fasteners and remove

cylinder head cover.

NOTE-

The cylinder head cover mounting bolt insulators and gas-

lets should be reinstalled in their original locations. Make

note of their arrangement during removal.

Page 123 of 1002

Downloaded from www.Manualslib.com manuals search engine

Cylinder Head Removal and Installation

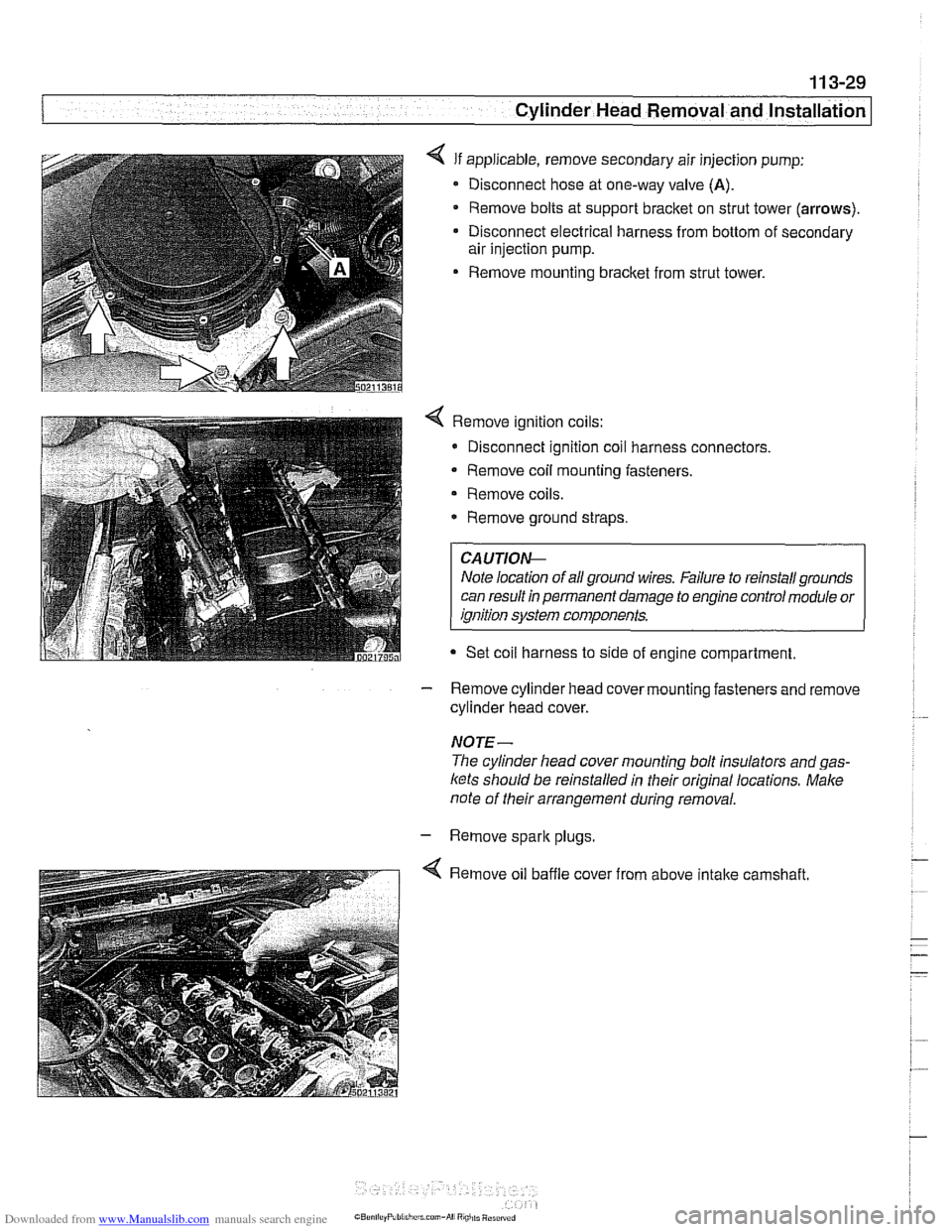

4 If applicable, remove secondary air injection pump:

Disconnect hose at one-way valve

(A).

Remove bolts at support bracket on strut tower (arrows).

Disconnect electrical harness from bottom of secondary

air injection pump.

Remove mounting bracket from strut tower.

4 Remove ignition coils:

* Disconnect ignition coil harness connectors.

Remove coil mounting fasteners.

Remove coils.

* Remove ground straps.

CA UTIOI\C

Note location of all ground wires. Failure to reinstall grounds

can result in permanent damage to engine control module or

ignition system components.

Set coil harness to side of engine compartment

- Remove cylinder head cover mounting fasteners and remove

cylinder head cover.

NOTE-

The cylinder head cover mounting bolt insulators and gas-

ltets should be reinstalled in their original locations. Male

note of their arrangement during removal.

- Remove spark plugs

4 Remove oil baffle cover from above intake camshaft.

Page 152 of 1002

Downloaded from www.Manualslib.com manuals search engine

Cylinder Head Removal and Installation

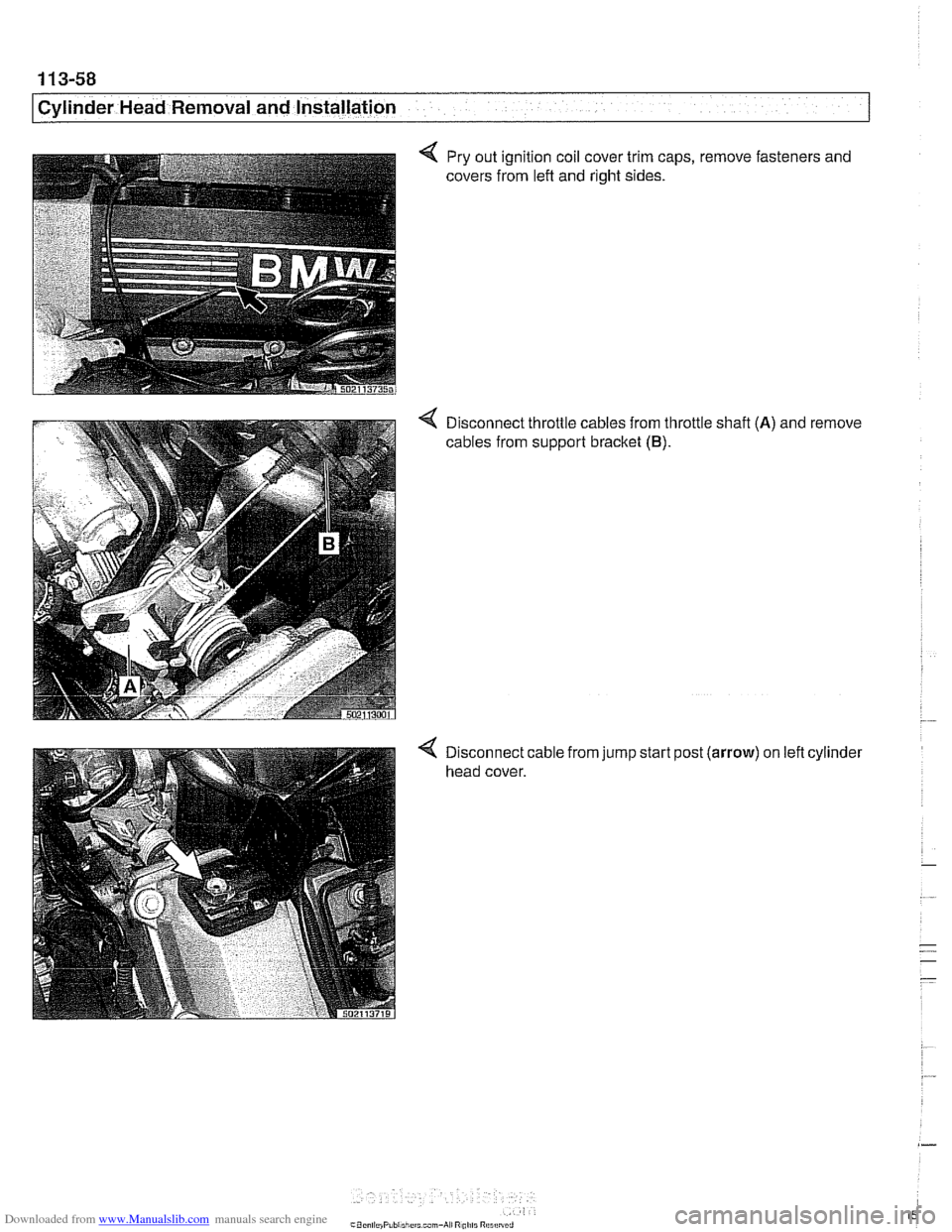

Pry out ignition coil cover trim caps,

covers from lefl and right sides. remove fasteners

and

< Disconnect throttle cables from throttle shafl (A) and remove

cables from support bracket

(B).

< Disconnect cable from jump start post (arrow) on left cylinder

head cover.

Page 153 of 1002

Downloaded from www.Manualslib.com manuals search engine

- .-

.. Cylinder Head Removal and Installation I -

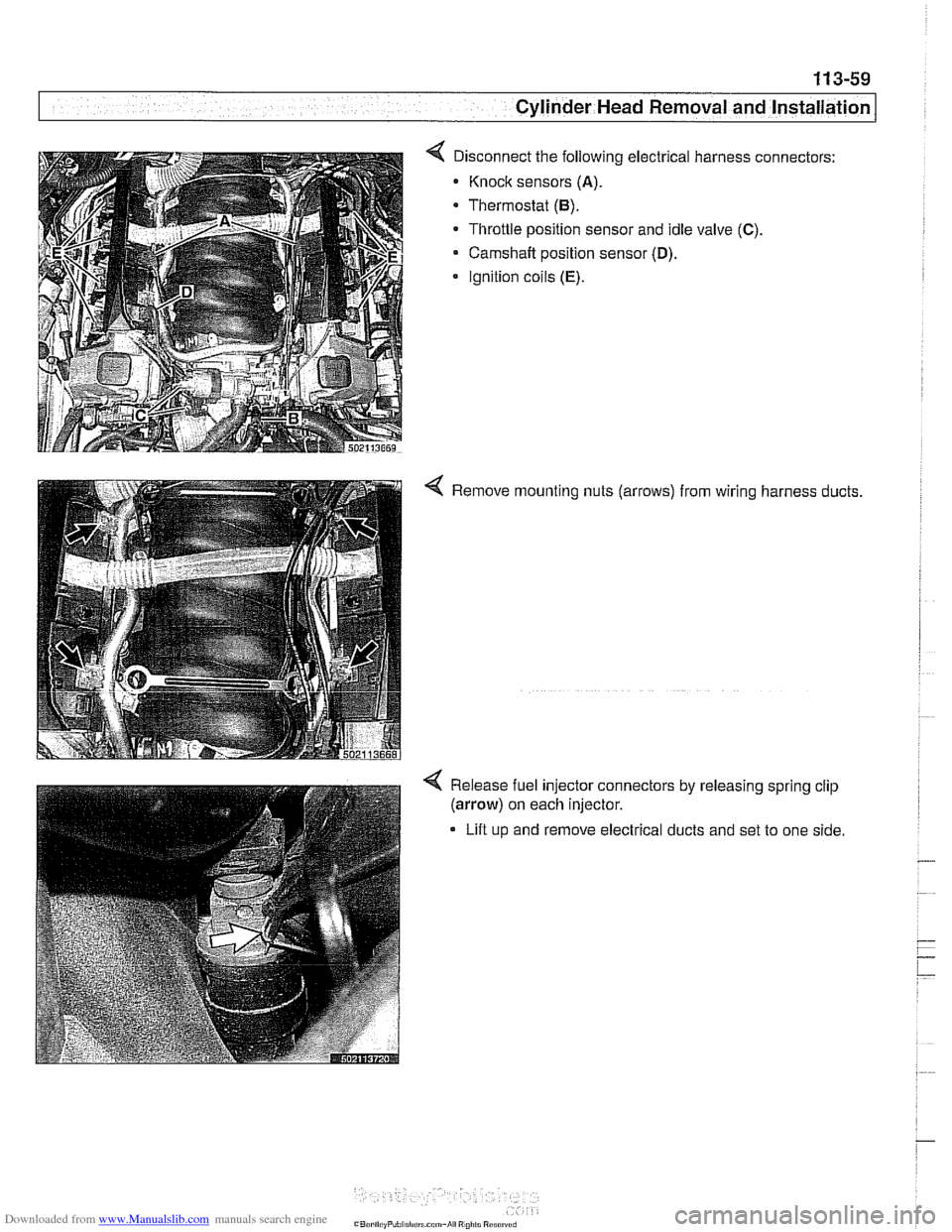

< Disconnect the following electrical harness connectors:

Knock sensors

(A).

Thermostat (6).

Throttle position sensor and idle valve (C).

Camshaft position sensor (D).

Ignition coils (E).

< Remove mounting nuts (arrows) from wiring harness ducts.

4 Release fuel injector connectors by releasing spring clip

(arrow) on each injector.

Lift up and remove electrical ducts and set to one side

Page 155 of 1002

Downloaded from www.Manualslib.com manuals search engine

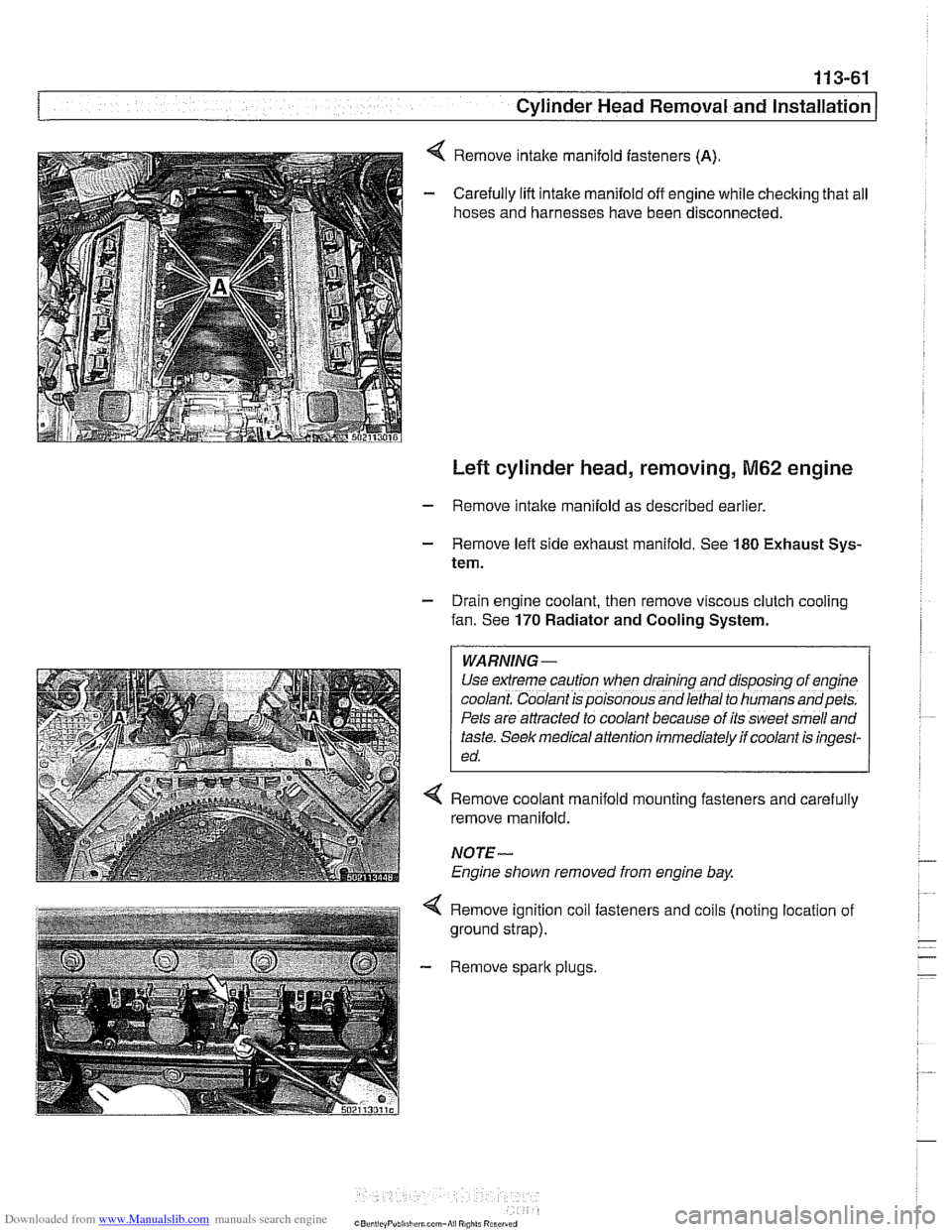

11 3-61

Cylinder Head Removal and installation I

Remove intake manifold fasteners (A).

Carefully lift intake manifold off engine while checking that all

hoses and harnesses have been disconnected.

Left cylinder head, removing, M62 engine

- Remove intake manifold as described earlier

- Remove left side exhaust manifold. See 180 Exhaust Sys-

tem.

- Drain engine coolant, then remove viscous clutch cooling

fan. See

170 Radiator and Cooling System.

WARNING -

Use extreme caution when draining and disposfng of eng~ne

coolant. Coolant is poisonous and lethal to humans andpets.

Pets are attracted to coolant because of its sweet smell and

taste.

Seek med~cal attention immediately if coolant is ingest-

ed.

4 Remove coolant manifold mounting fasteners and carefully

remove manifold.

NOTE-

Engine shown removed from engine bay

4 Remove ignition coil fasteners and coils (noting location of

ground strap).

- Remove spark plugs.

Page 166 of 1002

Downloaded from www.Manualslib.com manuals search engine

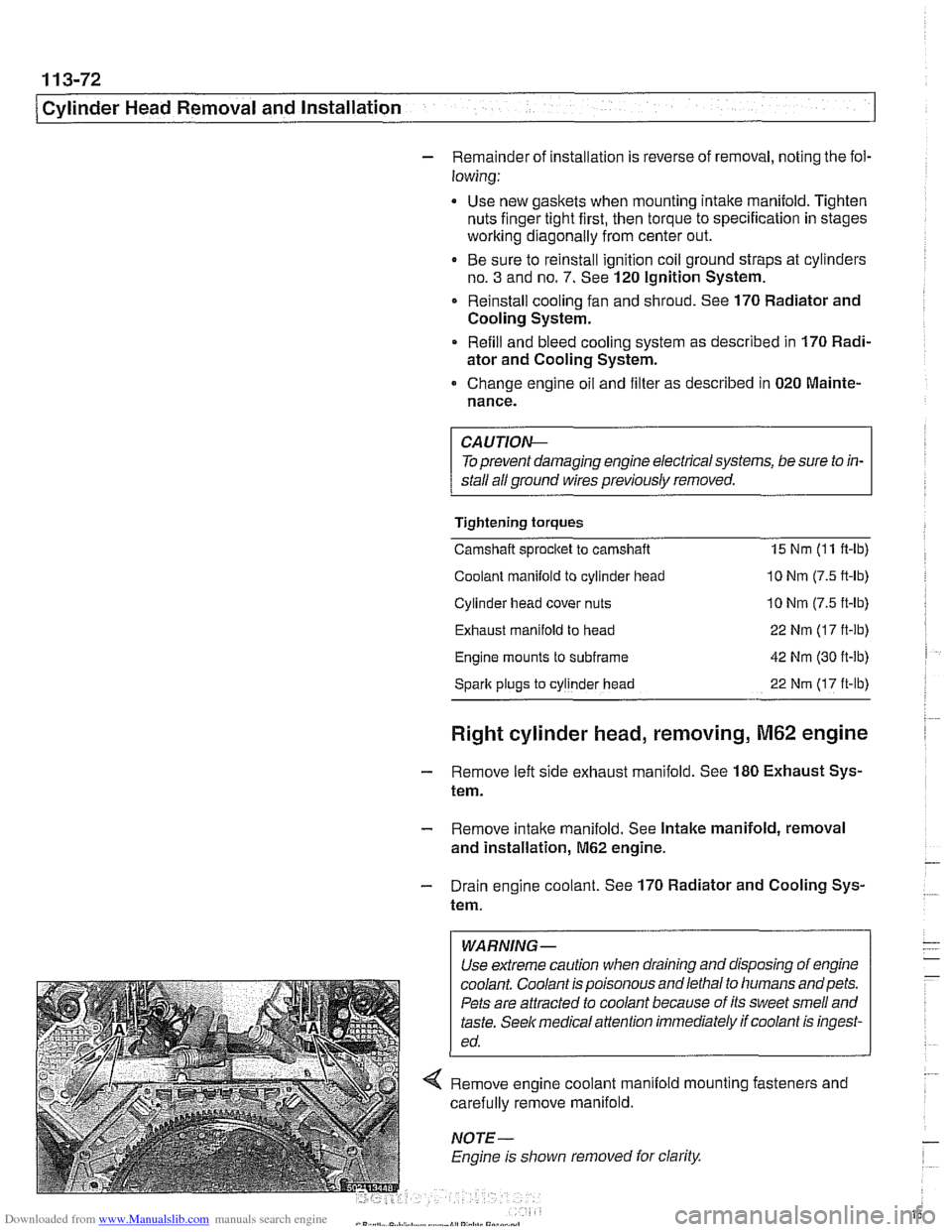

/Cylinder Head Removal and Installation

- Remainder of installation is reverse of removal, noting the fol-

lowing:

Use new gaskets when mounting intake

manifold. Tighten

nuts finger tight first, then torque to specification in stages

working diagonally from center out.

Be sure to reinstall ignition coil ground straps at cylinders

no.

3 and no. 7. See 120 Ignition System.

Reinstall cooling fan and shroud. See

170 Radiator and

Cooling System.

Refill and bleed cooling system as described in

170 Radi-

ator and Cooling System.

Change engine oil and filter as described in

020 Mainte-

nance.

CA UTIOG

To prevent damaging engine electricalsystems, be sure to in-

stall all ground wires previously removed.

Tightening torques

Camshaft sprocket to camshaft 15

Nm (11 H-lb)

Coolant manifold to cylinder head 10 Nm (7.5 H-lb)

Cylinder head cover nuts 10 Nm (7.5 ft-lb)

Exhaust manifold to head 22 Nm (17 ft-lb)

Engine mounts to subirame 42 Nm (30 ft-lb)

Spark plugs to cylinder head 22 Nm (17 ft-lb)

Right cylinder head, removing, M62 engine

- Remove left side exhaust manifold. See 180 Exhaust Sys-

tem.

- Remove intake manifold. See Intake manifold, removal

and installation,

M62 engine.

- Drain engine coolant. See 170 Radiator and Cooling Sys-

tem.

WARNING-

Use extreme caution when draining and disposing of engine

coolant.

Coolanl is poisonous andlellial lo liumans andpels.

Pets are

altracled to coolant because of 11s sfieet smell and

fasle. Seelc medcal anenfion immed~alely if coolant is ingesl-

. .-

< Remove engine coolant manlold mo~nlng fasreners and

carei~lly remove manifo d.

. I

NOTE

Engine 8s slioivn removed lor clarify