sensor BMW 540I 2002 E39 Central Body Electronics ZKE Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 2002, Model line: 540I, Model: BMW 540I 2002 E39Pages: 80, PDF Size: 4.14 MB

Page 16 of 80

Workshop Hints

Windshield Wiper Blade Service

To access the wiper blades for cleaning or replacement,the following is required:

• With the ignition switched on (KL15), switch the wiper stalk to the “Intermittant” wipe

mode.

• Switch the ignition off when the wiper arms are in the “upright” position.

CAUTION: Do not allow the wiper arm to spring back against the windshield, glass

breakage will occur!

Rain Sensor Equipped Vehicles

Make sure the wiper blades are in perfect condition. Only use window cleaner to clean the

windows. Dirty windows can cause the Rain Sensor control module to set a fault

due to the end limits of its adaptation abilities.

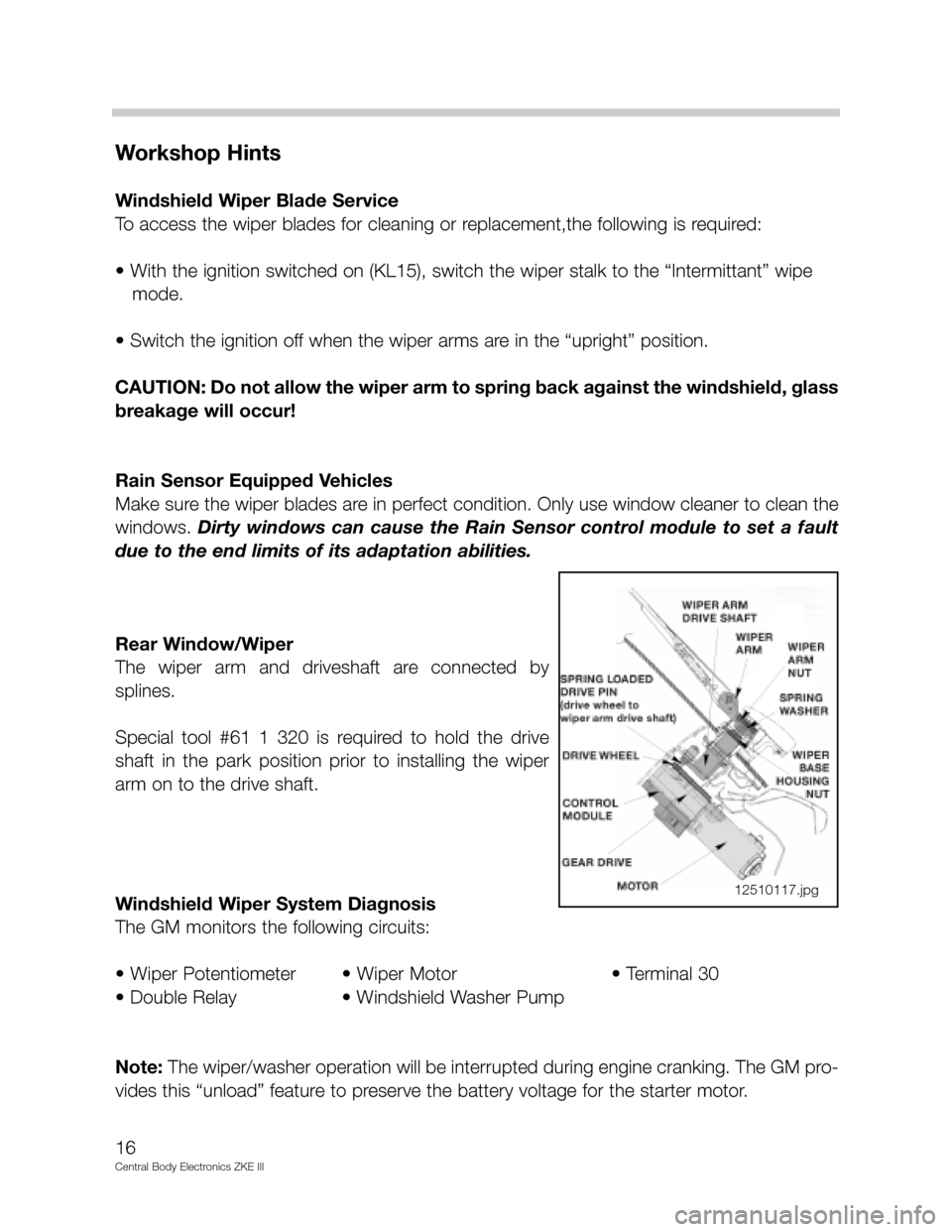

Rear Window/Wiper

The wiper arm and driveshaft are connected by

splines.

Special tool #61 1 320 is required to hold the drive

shaft in the park position prior to installing the wiper

arm on to the drive shaft.

Windshield Wiper System Diagnosis

The GM monitors the following circuits:

• Wiper Potentiometer • Wiper Motor • Terminal 30

• Double Relay • Windshield Washer Pump

Note: The wiper/washer operation will be interrupted during engine cranking. The GM pro-

vides this “unload” feature to preserve the battery voltage for the starter motor.

16

Central Body Electronics ZKE III

12510117.jpg

Page 21 of 80

Luggage Comparment Remote Unlock: The luggage com-

parment can be opened from inside the vehicle with the

remote release button. This feature is also functions when the

doors are locked from the central button.

The GM will disregard the remote release button input when

the luggage comparment is mechanically locked with the

Master Key (valet setting).

The GM will also disregard the release input if the vehicle

speed is > 4 MPH.

The E53 remote release button is located in the center con-

sole. This input will release the rear liftgate following the same

criteria stated above.

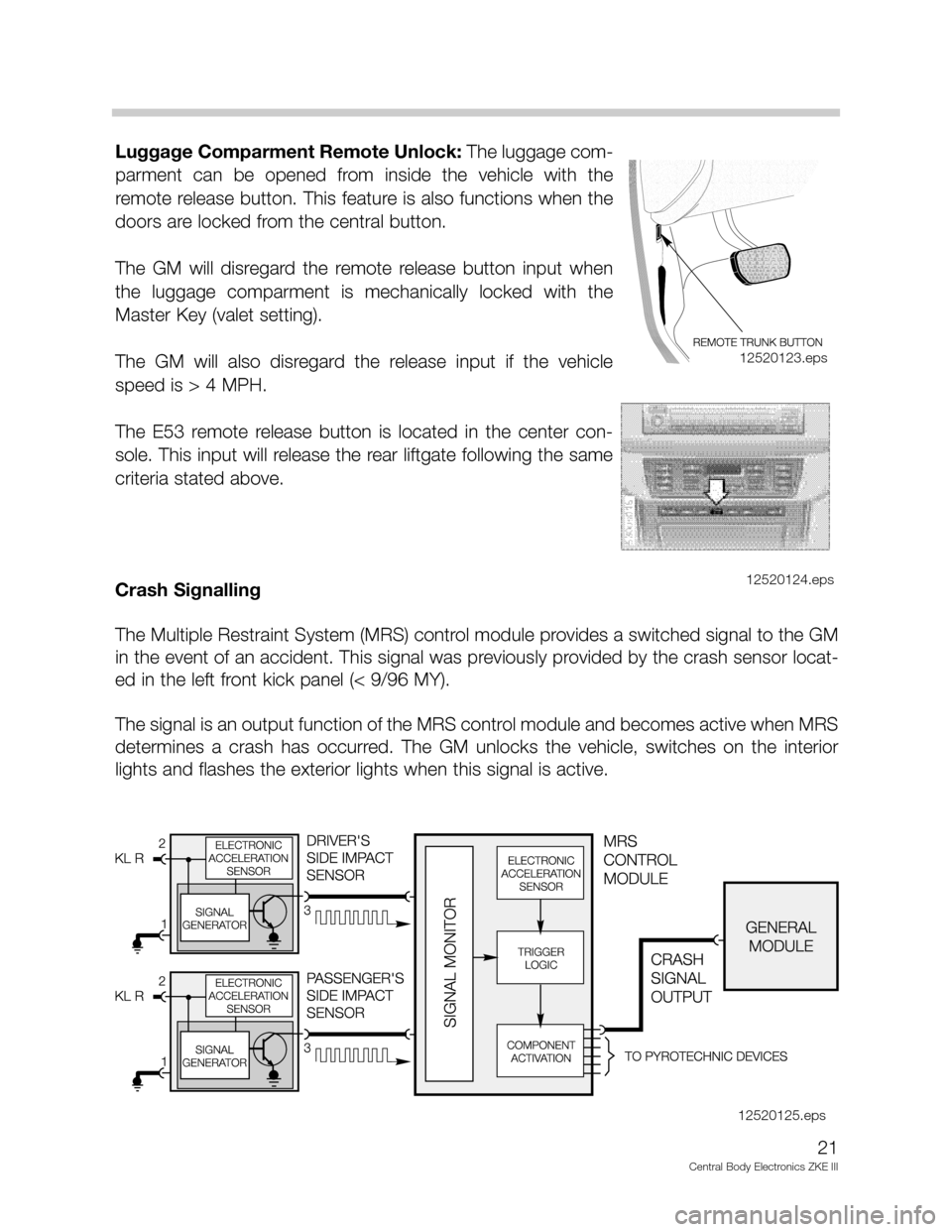

Crash Signalling

The Multiple Restraint System (MRS) control module provides a switched signal to the GM

in the event of an accident. This signal was previously provided by the crash sensor locat-

ed in the left front kick panel (< 9/96 MY).

The signal is an output function of the MRS control module and becomes active when MRS

determines a crash has occurred. The GM unlocks the vehicle, switches on the interior

lights and flashes the exterior lights when this signal is active.

21

Central Body Electronics ZKE III

12520123.eps

12520124.eps

12520125.eps

Page 23 of 80

Door Lock Actuators: A door lock actuator contains an electric motor and an integrated

microswitch (position switch). The rotary motor movement through the gear drive mechan-

ically moves the locking latch.

When the lock actuator is operating, the motor is powered until the position switch signals

the “locked” position. If the vehicle is locked from the exterior, the motor is powered further

and the the gear mechanism is moved beyond the locked position into the “double lock”

position. The motors must be powered (in reverse) to release the double lock. The inside

door handles will not unlock a “double locked” vehicle.

E53 Door Lock Mechanism: The E53 utilizes a door latch combined with dual actuator

motors. This type of actuator is sealed, self contained units with no replaceable parts. The

door lock actuators use hall effect sensors in place of pin contacts/microswitches to pro-

vide:

• Door lock key position (driver’s door only)

• Door open/closed status (replaces door jamb

switch).

The GM monitors the lock cylinder positions over two

wires. The signals are generated by two hall effect

sensors (Hall Sensor 1 & 2) located in the actuator.

When the key is turned, a plastic cylinder in the lock

actuator is simultaneously rotated by the lock tumbler

extension rod.

An asymmetrical shaped magnet is incorporated in the plastic cylinder, which when rotat-

ed changes the magnetic influence on the hall sensors. The presence of a magnet in close

proximity to the sensing surface of either hall sensor creates a coded input over the two

wires that the GM uses to determine the key position.

• Magnet in front of sensor, current flow through the sensor is <5 mA (0).

• Magnet rotated away from sensor, current flow through the sensor is >12 mA (1).

Hall effect sensors improve the actuators reliability since they are impervious to moisture

and there are no wear contacts.

23

Central Body Electronics ZKE III

12520127 lock-4

Page 24 of 80

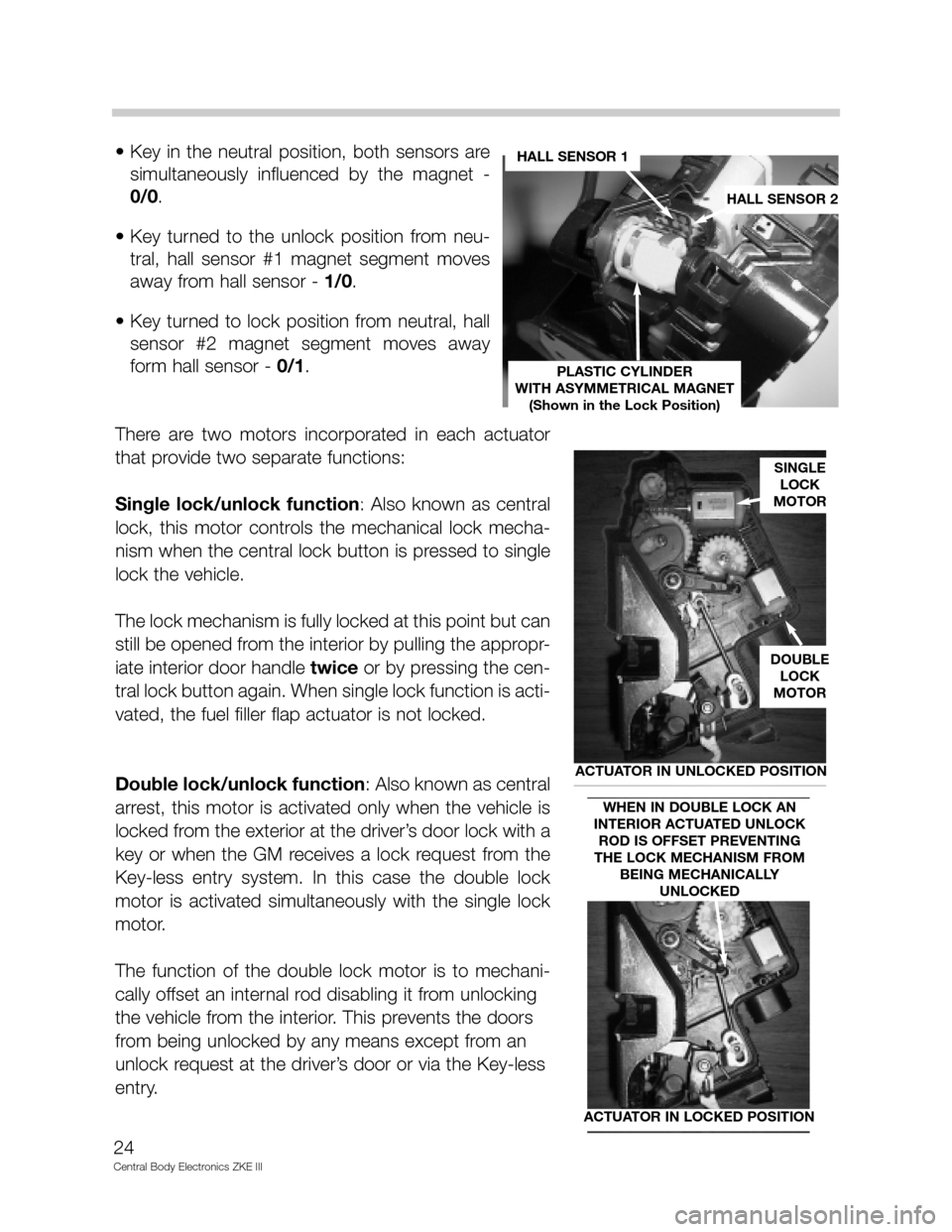

• Key in the neutral position, both sensors are

simultaneously influenced by the magnet -

0/0.

• Key turned to the unlock position from neu-

tral, hall sensor #1 magnet segment moves

away from hall sensor - 1/0.

• Key turned to lock position from neutral, hall

sensor #2 magnet segment moves away

form hall sensor - 0/1.

There are two motors incorporated in each actuator

that provide two separate functions:

Single lock/unlock function: Also known as central

lock, this motor controls the mechanical lock mecha-

nism when the central lock button is pressed to single

lock the vehicle.

The lock mechanism is fully locked at this point but can

still be opened from the interior by pulling the appropr-

iate interior door handle twice or by pressing the cen-

tral lock button again. When single lock function is acti-

vated, the fuel filler flap actuator is not locked.

Double lock/unlock function: Also known as central

arrest, this motor is activated only when the vehicle is

locked from the exterior at the driver’s door lock with a

key or when the GM receives a lock request from the

Key-less entry system. In this case the double lock

motor is activated simultaneously with the single lock

motor.

The function of the double lock motor is to mechani-

cally offset an internal rod disabling it from unlocking

the vehicle from the interior. This prevents the doors

from being unlocked by any means except from an

unlock request at the driver’s door or via the Key-less

entry.

24

Central Body Electronics ZKE III

HALL SENSOR 1

HALL SENSOR 2

PLASTIC CYLINDER

WITH ASYMMETRICAL MAGNET

(Shown in the Lock Position)

SINGLE

LOCK

MOTOR

DOUBLE

LOCK

MOTOR

ACTUATOR IN UNLOCKED POSITION

ACTUATOR IN LOCKED POSITION

WHEN IN DOUBLE LOCK AN

INTERIOR ACTUATED UNLOCK

ROD IS OFFSET PREVENTING

THE LOCK MECHANISM FROM

BEING MECHANICALLY

UNLOCKED

Page 25 of 80

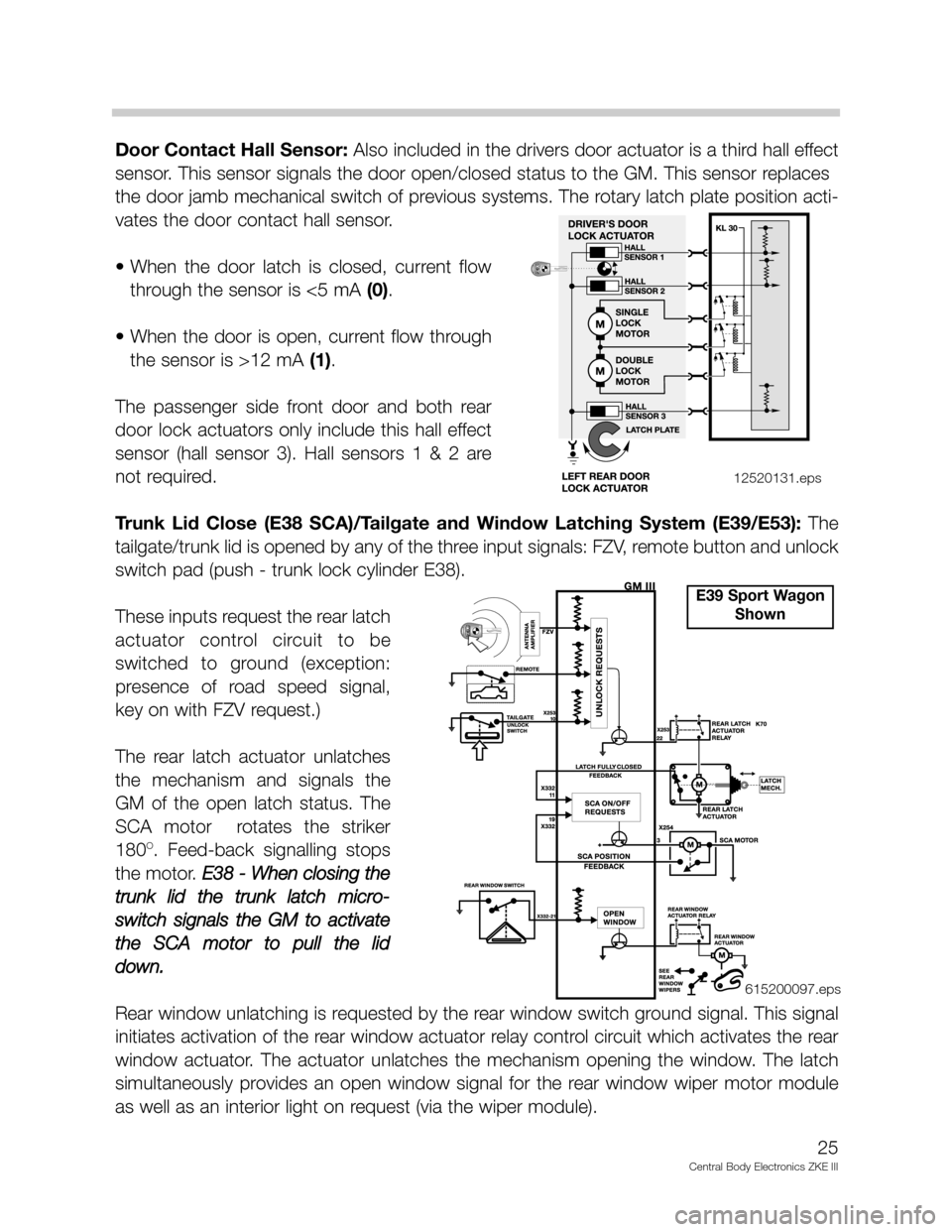

Door Contact Hall Sensor: Also included in the drivers door actuator is a third hall effect

sensor. This sensor signals the door open/closed status to the GM. This sensor replaces

the door jamb mechanical switch of previous systems. The rotary latch plate position acti-

vates the door contact hall sensor.

• When the door latch is closed, current flow

through the sensor is <5 mA (0).

• When the door is open, current flow through

the sensor is >12 mA (1).

The passenger side front door and both rear

door lock actuators only include this hall effect

sensor (hall sensor 3). Hall sensors 1 & 2 are

not required.

Trunk Lid Close (E38 SCA)/Tailgate and Window Latching System (E39/E53): The

tailgate/trunk lid is opened by any of the three input signals: FZV, remote button and unlock

switch pad (push - trunk lock cylinder E38).

These inputs request the rear latch

actuator control circuit to be

switched to ground (exception:

presence of road speed signal,

key on with FZV request.)

The rear latch actuator unlatches

the mechanism and signals the

GM of the open latch status. The

SCA motor rotates the striker

180

O. Feed-back signalling stops

the motor. E38 - When closing the

trunk lid the trunk latch micro-

switch signals the GM to activate

the SCA motor to pull the lid

down.

Rear window unlatching is requested by the rear window switch ground signal. This signal

initiates activation of the rear window actuator relay control circuit which activates the rear

window actuator. The actuator unlatches the mechanism opening the window. The latch

simultaneously provides an open window signal for the rear window wiper motor module

as well as an interior light on request (via the wiper module).

25

Central Body Electronics ZKE III

12520131.eps

E39 Sport Wagon

Shown

615200097.eps

Page 33 of 80

Anti-Theft (DWA) System

Purpose of the System

The DWA alarm system offers vehicle protection by monitoring the doors, hood, interior,

luggage compartment and vehicle tilting. When activated, DWA deters theft by sounding

an alarm siren for 30 seconds, flashing the low beam headlights (high beam on Xenon

equipped models) and four way flashers for 5 minutes.

The control electronics for DWA are integrated in the general module. The DWA - LED

indicator is located in the rear view mirror (E38 in the top center IHKA grille).

The system is “armed/disarmed” from the driver’s door lock cylinder, remote transmitter or

luggage compartment lock cylinder. The alarm is immediately deactivated when disarmed

with the key in the driver’s door lock cylinder (may be deactivated in Conversion) or remote

transmitter.

The GM utilizes existing components and/or circuits as part of the DWA system:

• Door latch switch/sensor contacts (door open/closed).

• Trunk lid switch contact (monitored for closed trunk).

• Trunk lock key position switch (located on the trunk lock, this switch signal prevents

DWA from activating if armed when the trunk is opened with the key).

• Hood switch (monitored for closed hood, located under the hood).

• DWA status LED (part of rear view mirror).

The additional components required are:

• Interior Sensor • DWA Siren • Tilt sensor

33

Central Body Electronics ZKE III

615200102.eps

Page 34 of 80

System Components

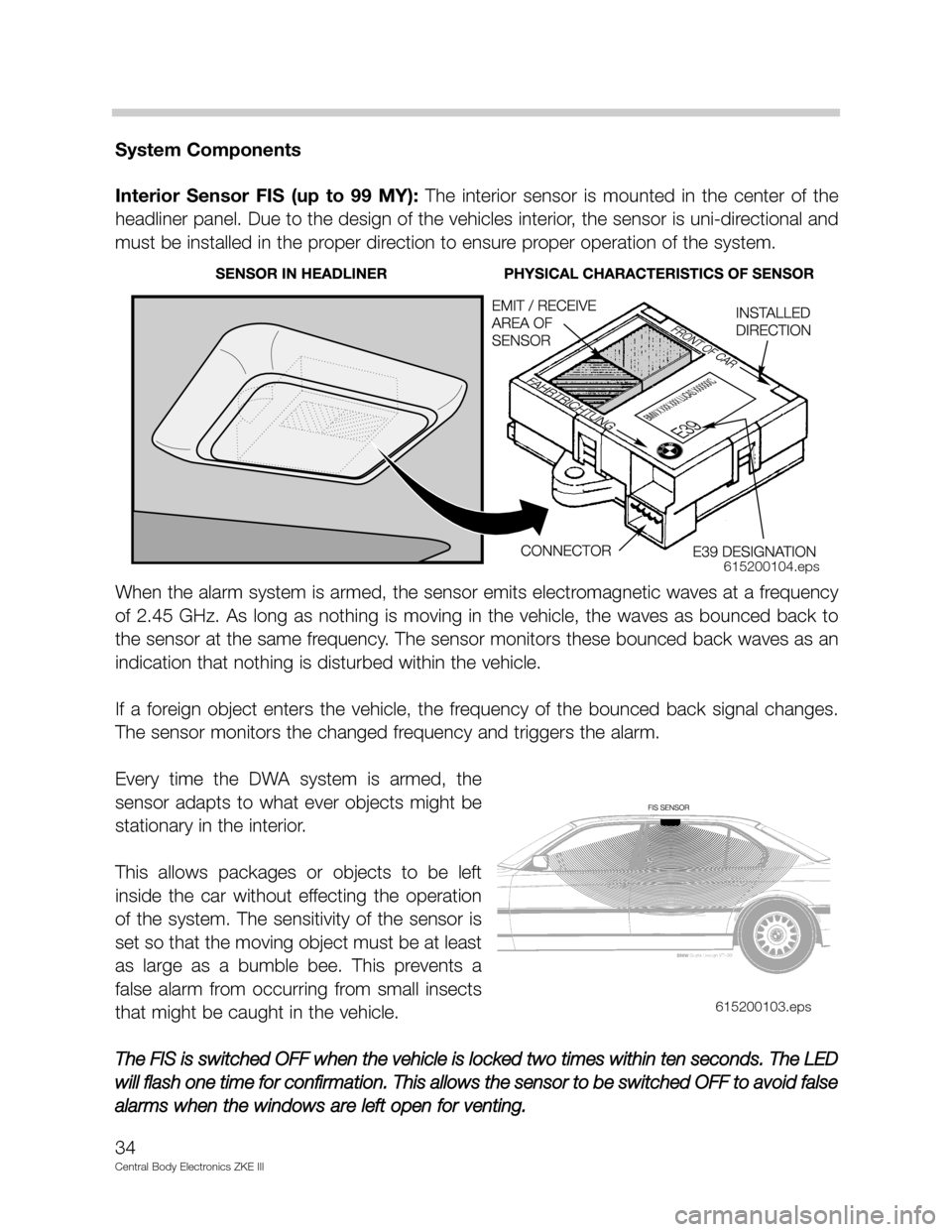

Interior Sensor FIS (up to 99 MY): The interior sensor is mounted in the center of the

headliner panel. Due to the design of the vehicles interior, the sensor is uni-directional and

must be installed in the proper direction to ensure proper operation of the system.

When the alarm system is armed, the sensor emits electromagnetic waves at a frequency

of 2.45 GHz. As long as nothing is moving in the vehicle, the waves as bounced back to

the sensor at the same frequency. The sensor monitors these bounced back waves as an

indication that nothing is disturbed within the vehicle.

If a foreign object enters the vehicle, the frequency of the bounced back signal changes.

The sensor monitors the changed frequency and triggers the alarm.

Every time the DWA system is armed, the

sensor adapts to what ever objects might be

stationary in the interior.

This allows packages or objects to be left

inside the car without effecting the operation

of the system. The sensitivity of the sensor is

set so that the moving object must be at least

as large as a bumble bee. This prevents a

false alarm from occurring from small insects

that might be caught in the vehicle.

The FIS is switched OFF when the vehicle is locked two times within ten seconds. The LED

will flash one time for confirmation. This allows the sensor to be switched OFF to avoid false

alarms when the windows are left open for venting.

34

Central Body Electronics ZKE III

615200103.eps615200104.eps

Page 35 of 80

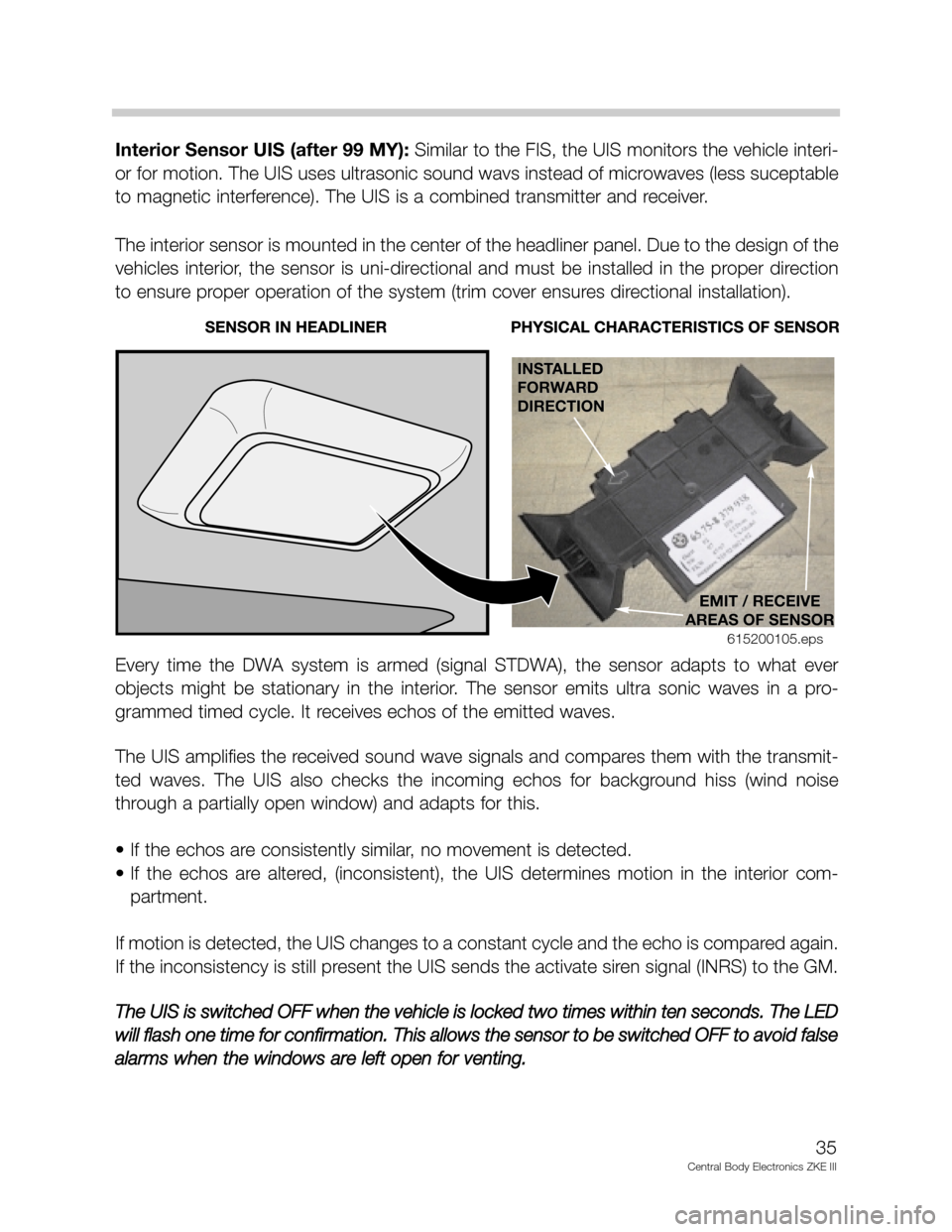

Interior Sensor UIS (after 99 MY):Similar to the FIS, the UIS monitors the vehicle interi-

or for motion. The UIS uses ultrasonic sound wavs instead of microwaves (less suceptable

to magnetic interference). The UIS is a combined transmitter and receiver.

The interior sensor is mounted in the center of the headliner panel. Due to the design of the

vehicles interior, the sensor is uni-directional and must be installed in the proper direction

to ensure proper operation of the system (trim cover ensures directional installation).

Every time the DWA system is armed (signal STDWA), the sensor adapts to what ever

objects might be stationary in the interior. The sensor emits ultra sonic waves in a pro-

grammed timed cycle. It receives echos of the emitted waves.

The UIS amplifies the received sound wave signals and compares them with the transmit-

ted waves. The UIS also checks the incoming echos for background hiss (wind noise

through a partially open window) and adapts for this.

• If the echos are consistently similar, no movement is detected.

• If the echos are altered, (inconsistent), the UIS determines motion in the interior com-

partment.

If motion is detected, the UIS changes to a constant cycle and the echo is compared again.

If the inconsistency is still present the UIS sends the activate siren signal (INRS) to the GM.

The UIS is switched OFF when the vehicle is locked two times within ten seconds. The LED

will flash one time for confirmation. This allows the sensor to be switched OFF to avoid false

alarms when the windows are left open for venting.

35

Central Body Electronics ZKE III

615200105.eps

Page 36 of 80

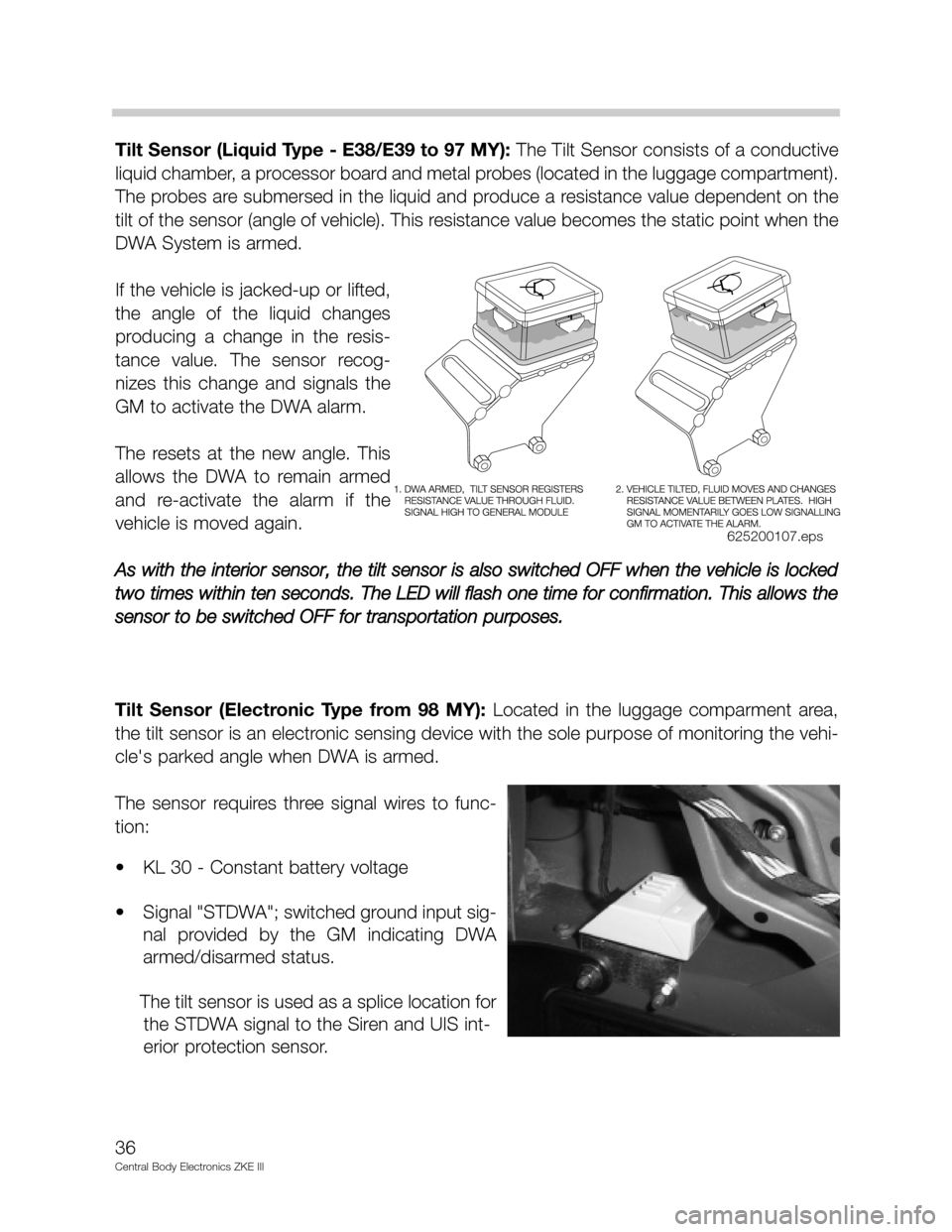

Tilt Sensor (Liquid Type - E38/E39 to 97 MY): The Tilt Sensor consists of a conductive

liquid chamber, a processor board and metal probes (located in the luggage compartment).

The probes are submersed in the liquid and produce a resistance value dependent on the

tilt of the sensor (angle of vehicle). This resistance value becomes the static point when the

DWA System is armed.

If the vehicle is jacked-up or lifted,

the angle of the liquid changes

producing a change in the resis-

tance value. The sensor recog-

nizes this change and signals the

GM to activate the DWA alarm.

The resets at the new angle. This

allows the DWA to remain armed

and re-activate the alarm if the

vehicle is moved again.

As with the interior sensor, the tilt sensor is also switched OFF when the vehicle is locked

two times within ten seconds. The LED will flash one time for confirmation. This allows the

sensor to be switched OFF for transportation purposes.

Tilt Sensor (Electronic Type from 98 MY): Located in the luggage comparment area,

the tilt sensor is an electronic sensing device with the sole purpose of monitoring the vehi-

cle's parked angle when DWA is armed.

The sensor requires three signal wires to func-

tion:

• KL 30 - Constant battery voltage

• Signal "STDWA"; switched ground input sig-

nal provided by the GM indicating DWA

armed/disarmed status.

The tilt sensor is used as a splice location for

the STDWA signal to the Siren and UIS int-

erior protection sensor.

36

Central Body Electronics ZKE III

625200107.eps

Page 37 of 80

• Signal "NG"; switched ground output signal provided to the GM. The signal is used for

two purposes,

1. As a momentary acknowledgment that the tilt sensor received STDWA and is cur-

rently monitoring the vehicle angle.

2. If the tilt sensor detects a change in the vehicle's angle when DWA is armed, signal

NG is switched to inform the GM to activate the siren.

When the tilt sensor receives the STDWA signal from the GM it memorizes the vehicle's

parked angle. The angle of the vehicle is monitored by the solid state electronics. Once

armed, if the angle changes, the tilt sensor provides a switched ground signal to the GM

to activate DWA.

As with the interior sensor, the tilt sensor is also switched OFF when the vehicle is locked

two times within ten seconds. The LED will flash one time for confirmation. This allows the

sensor to be switched OFF for transportation purposes.

Glass Breakage Sensors (Early E38 - before FIS Sensor): The door windows (includ-

ing the rear quarter glass wire loop) are monitored by inductive sensors mounted on the

inside of the door behind the trim panel. A closed window is recognized by a magnetic plate

on the glass lining up with the sensor.

If the glass is broken, the plate falls away and the signal from the sensor changes and the

GM will activate the alarm.

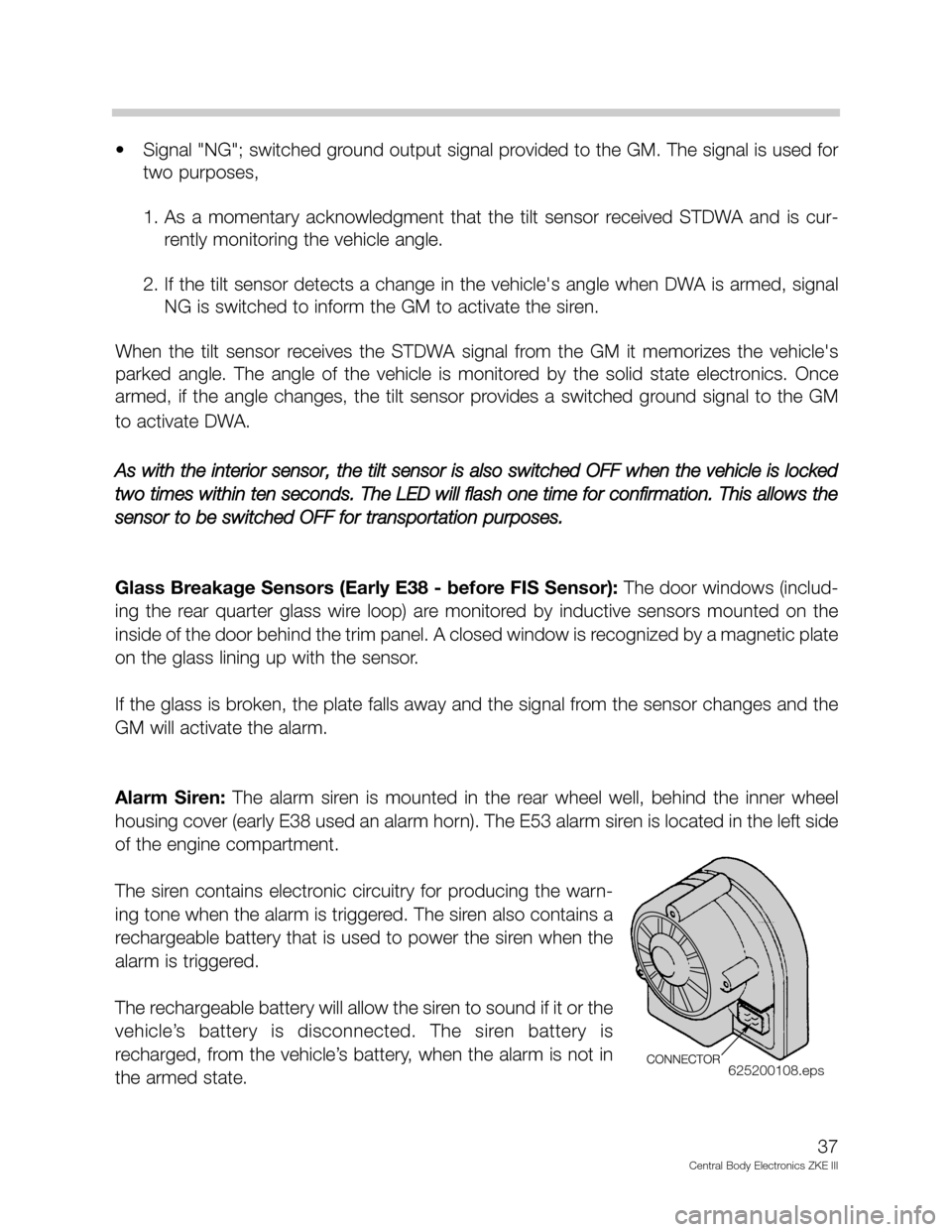

Alarm Siren: The alarm siren is mounted in the rear wheel well, behind the inner wheel

housing cover (early E38 used an alarm horn). The E53 alarm siren is located in the left side

of the engine compartment.

The siren contains electronic circuitry for producing the warn-

ing tone when the alarm is triggered. The siren also contains a

rechargeable battery that is used to power the siren when the

alarm is triggered.

The rechargeable battery will allow the siren to sound if it or the

vehicle’s battery is disconnected. The siren battery is

recharged, from the vehicle’s battery, when the alarm is not in

the armed state.

37

Central Body Electronics ZKE III

625200108.eps