sensor BMW 540I 2002 E39 Central Body Electronics ZKE Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 2002, Model line: 540I, Model: BMW 540I 2002 E39Pages: 80, PDF Size: 4.14 MB

Page 38 of 80

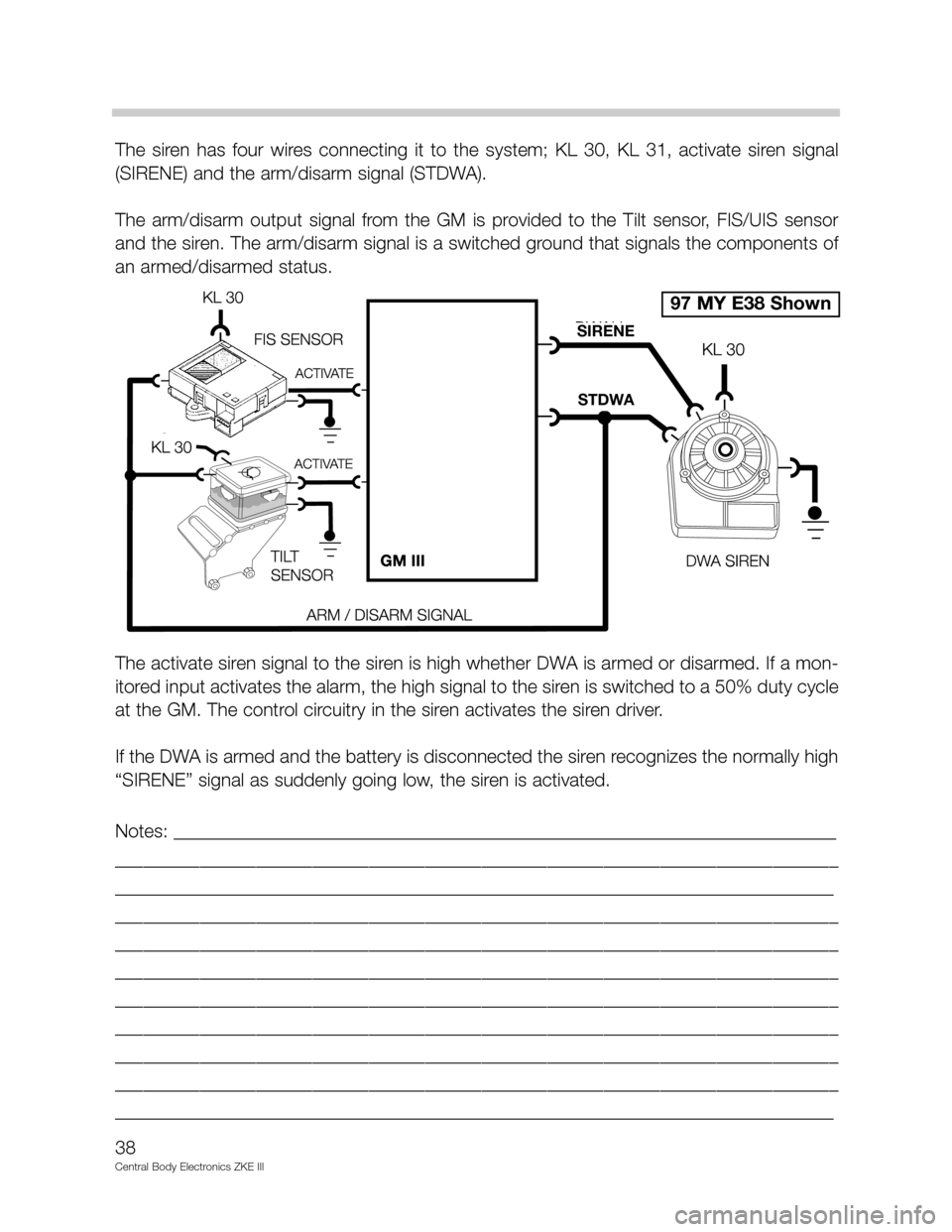

The siren has four wires connecting it to the system; KL 30, KL 31, activate siren signal

(SIRENE) and the arm/disarm signal (STDWA).

The arm/disarm output signal from the GM is provided to the Tilt sensor, FIS/UIS sensor

and the siren. The arm/disarm signal is a switched ground that signals the components of

an armed/disarmed status.

The activate siren signal to the siren is high whether DWA is armed or disarmed. If a mon-

itored input activates the alarm, the high signal to the siren is switched to a 50% duty cycle

at the GM. The control circuitry in the siren activates the siren driver.

If the DWA is armed and the battery is disconnected the siren recognizes the normally high

“SIRENE” signal as suddenly going low, the siren is activated.

Notes: _______________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

38

Central Body Electronics ZKE III

SIRENE

STDWA

97 MY E38 Shown

Page 40 of 80

Principle of Operation

DWA Arming/Disarming

• The DWA is armed every time the vehicle is locked from the outside with the door lock

cylinder or FZV key.

• The DWA LED flashes as an acknowledgment along with the exterior lights and a

momentary chirp from the siren.

• The GM monitors all required input signals for closed status (door closed, luggage com-

partment closed, etc.) The inputs must be in a closed status for a minimum of 3 sec-

onds for the GM to include them as an activation component. If after 3 seconds any

input signal not in the closed status is excluded (this is acknowledged by the DWA LED)

preventing false alarm activations. The hood switch can be “lifted” to the service posi-

tion to test the alarm with the hood open.

• If the DWA is armed a second time within 10 seconds, the tilt sensor and interior pro-

tection sensor are excluded as alarm activation components. This function is useful if

the vehicle is transported on a train or flat bed truck to prevent false alarm activations.

• While armed, the trunk can be opened with out the alarm being triggered as follows:

- If opened with the trunk remote button via the FZV, the GM prevents the alarm from

activating. (This feature is customizable under the Car Memory function).

- If opened with the key at the trunk lock cylinder the trunk key position switch sig-

nals the GM and in the same manner prevents the alarm from activating.

In either case, when the trunk is returned to the closed position, it is no longer con-

sidered as an activation signal.

Panic Mode Operation: When the trunk button is pressed and held, the GM is signaled

to activate the siren for the Panic Mode. The panic mode is function with either an armed

or disarmed DWA system.

Emergency Disarming: Emergency disarming occurs automatically if a key is used to turn

the ignition switch on and the EWS accepts it. The EWS signals the GM to unlock the doors

and deactivate the DWA.

40

Central Body Electronics ZKE III

Page 47 of 80

Sunroof

Purpose of the System

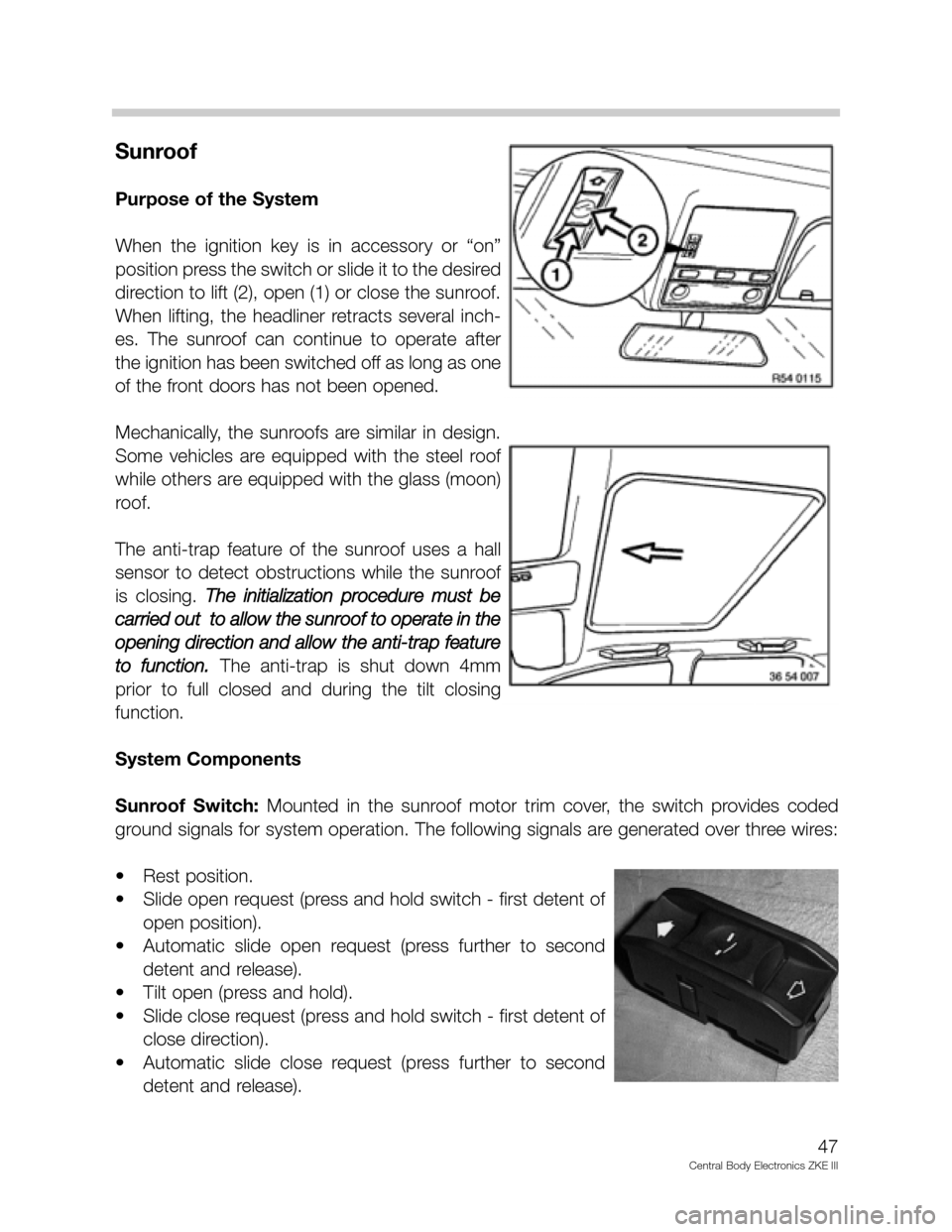

When the ignition key is in accessory or “on”

position press the switch or slide it to the desired

direction to lift (2), open (1) or close the sunroof.

When lifting, the headliner retracts several inch-

es. The sunroof can continue to operate after

the ignition has been switched off as long as one

of the front doors has not been opened.

Mechanically, the sunroofs are similar in design.

Some vehicles are equipped with the steel roof

while others are equipped with the glass (moon)

roof.

The anti-trap feature of the sunroof uses a hall

sensor to detect obstructions while the sunroof

is closing. The initialization procedure must be

carried out to allow the sunroof to operate in the

opening direction and allow the anti-trap feature

to function.

The anti-trap is shut down 4mm

prior to full closed and during the tilt closing

function.

System Components

Sunroof Switch:Mounted in the sunroof motor trim cover, the switch provides coded

ground signals for system operation. The following signals are generated over three wires:

• Rest position.

• Slide open request (press and hold switch - first detent of

open position).

• Automatic slide open request (press further to second

detent and release).

• Tilt open (press and hold).

• Slide close request (press and hold switch - first detent of

close direction).

• Automatic slide close request (press further to second

detent and release).

47

Central Body Electronics ZKE III

Page 48 of 80

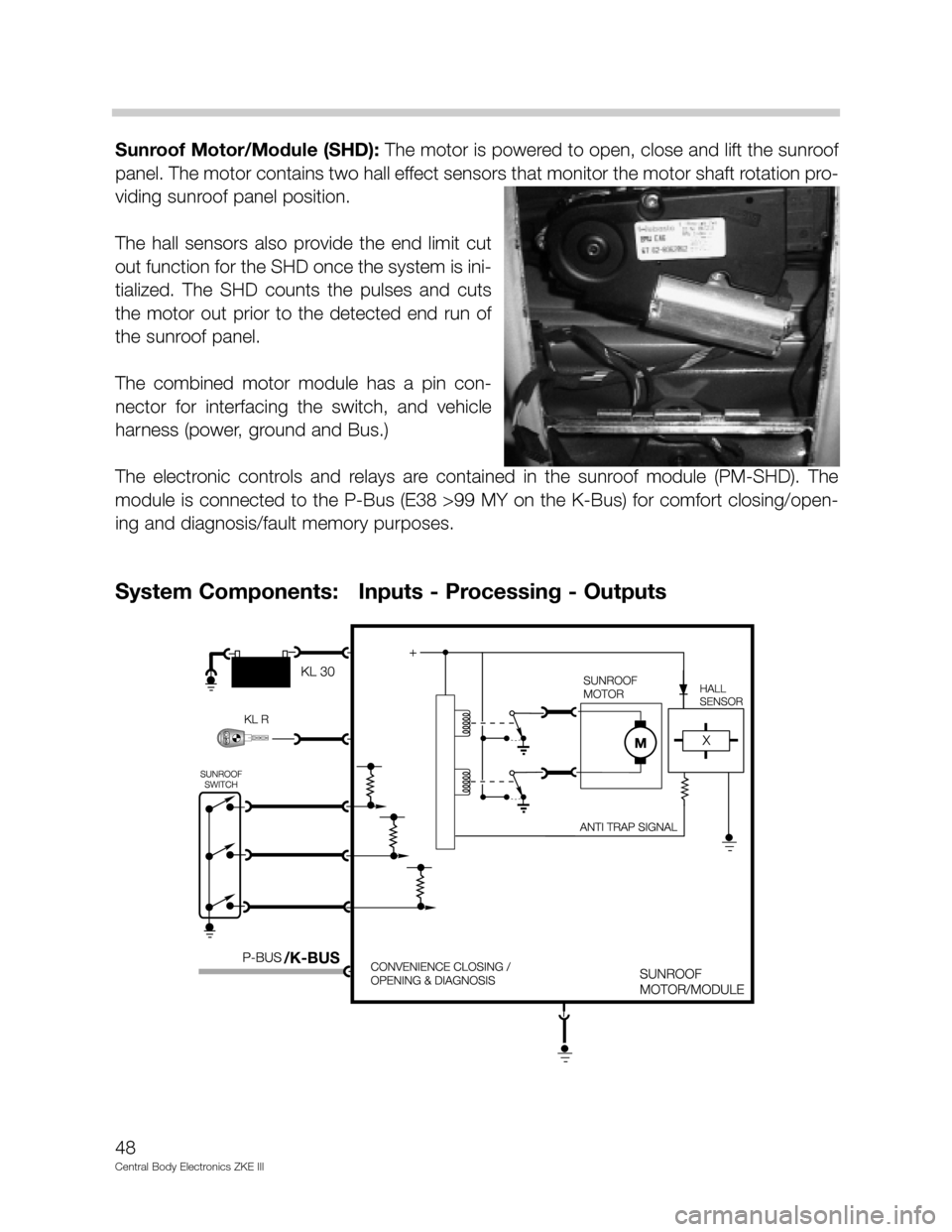

Sunroof Motor/Module (SHD): The motor is powered to open, close and lift the sunroof

panel. The motor contains two hall effect sensors that monitor the motor shaft rotation pro-

viding sunroof panel position.

The hall sensors also provide the end limit cut

out function for the SHD once the system is ini-

tialized. The SHD counts the pulses and cuts

the motor out prior to the detected end run of

the sunroof panel.

The combined motor module has a pin con-

nector for interfacing the switch, and vehicle

harness (power, ground and Bus.)

The electronic controls and relays are contained in the sunroof module (PM-SHD). The

module is connected to the P-Bus (E38 >99 MY on the K-Bus) for comfort closing/open-

ing and diagnosis/fault memory purposes.

48

Central Body Electronics ZKE III

System Components: Inputs - Processing - Outputs

/K-BUS

Page 49 of 80

Principle of Operation

Initialization: Initialization is required for the SHD to learn the end positions of the motor's

travel. The hall sensors provide pulses for motor rotation, the SHD counts the pulses and

determines where the panel is by memorizing the stored pulses.

If the system is not initialized, the sunroof will only operate in the tilt up and slide close posi-

tions. Initialize as follows:

• Press and hold the sunroof switch in either the tilt up or slide close positions for 15 sec-

onds.

• The sunroof motor operates momentarily signifying initialization acceptance.

The SHD memorizes the pulses from the hall sensors on the next activation of the motor

by driving the panel to its end run positions. The SHD senses an amperage increase and

determines the end run position. The counted number of pulses is then used as the basis

for calculating the panel position.

Anti-Trap Feature: The anti-trap feature of the sunroof uses a hall sensor to detect

obstructions while the sunroof is closing (pulse frequency slowed down) in the automatic

close function. The anti-trap feature is shut down prior to full closing (4mm from full closed)

to allow the sunroof to seat into the seal.

Note: The anti-trap feature is not functional when the switch is held in the manual close

position.

Notes: _______________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

49

Central Body Electronics ZKE III

Page 50 of 80

Workshop Hints

SHD Self Diagnosis

The SHD monitors operation and stores fault codes if a defect is determined. The SHD

monitors the following conditions:

• SHD motor relays:The relays are checked for sticking contacts (plausibility) and non

functional contacts.

• Hall effect position sensors:The SHD must detect a pulse frequency from the hall

effect sensor(s) during operation.

• Sunroof Switch: The SHD monitors the signal plausibility of the coded signaling from

the sunroof switch.

Sunroof Fault Response Characteristics

If a fault occurs with any of these functions, the SHD responds as follows:

• Overrides the end run detection.

• Switches the motor off if the relay contacts stick for more than 500 ms.

• Switches the motor off if pulses are not received.

Emergency Operation of the Sunroof

If the sunroof motor does not respond to the switch signals, the hex key in the trunk lid tool

kit is used to manually turn the motor shaft drive.

50

Central Body Electronics ZKE III

Page 53 of 80

System Components

Door Contacts: As mentioned in the Central Locking Section, the existing door contacts

opened/closed are also an input for the interior lighting function. The E53 uses the Hall

effect sensors for the purpose of monitoring door open/closed status (located directly

behind the rotary latch plate encased in the actuator). The sensor is activated by the rotary

latch plate's position.

• Door closed, the rotary latch plate is in the latched position. Current flow through the

hall sensor is < 5 mA.

• Door open, the rotary latch plate is in the open position. Current flow through the hall

sensor is > 12 mA.

A change in current flow informs the General module when a door is opened or closed.

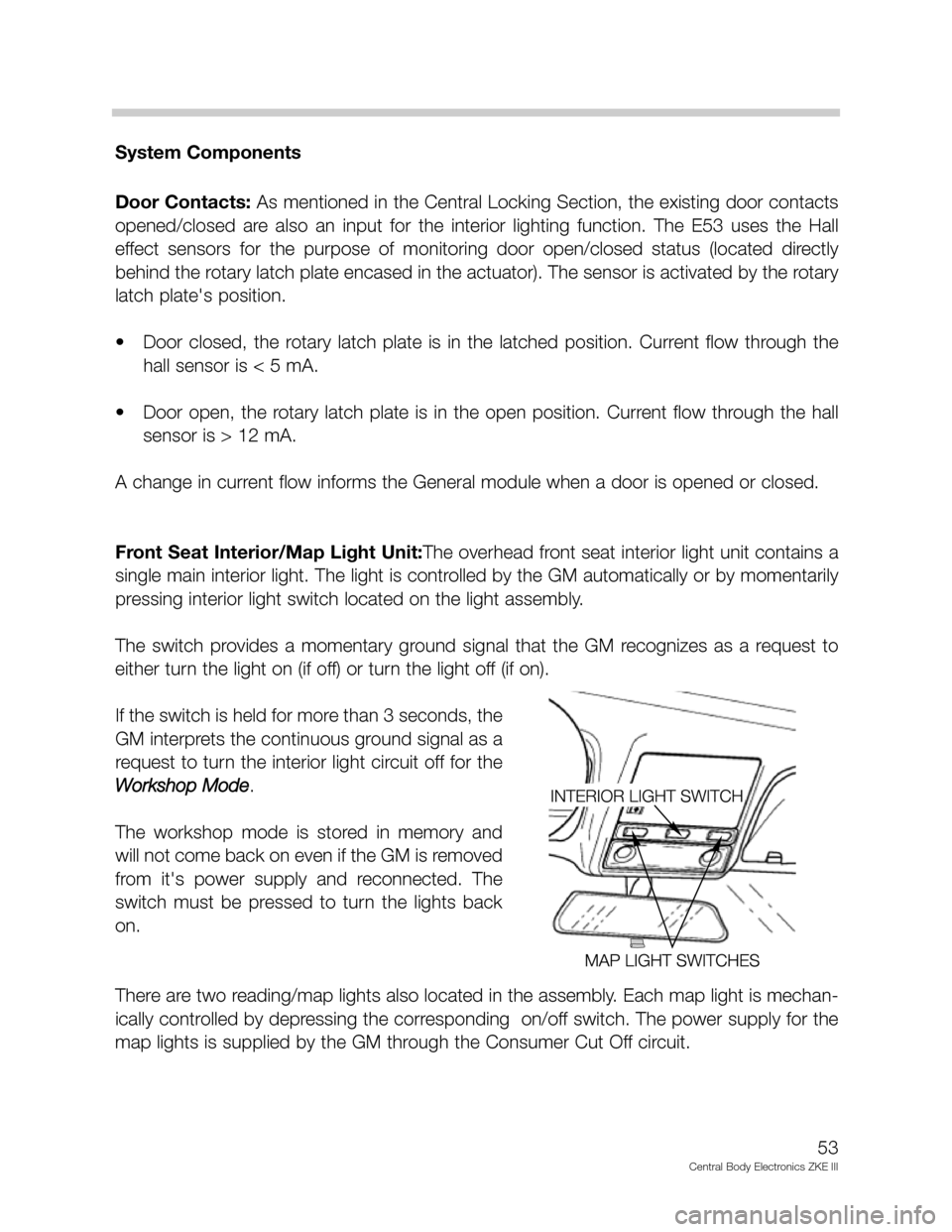

Front Seat Interior/Map Light Unit:The overhead front seat interior light unit contains a

single main interior light. The light is controlled by the GM automatically or by momentarily

pressing interior light switch located on the light assembly.

The switch provides a momentary ground signal that the GM recognizes as a request to

either turn the light on (if off) or turn the light off (if on).

If the switch is held for more than 3 seconds, the

GM interprets the continuous ground signal as a

request to turn the interior light circuit off for the

Workshop Mode

.

The workshop mode is stored in memory and

will not come back on even if the GM is removed

from it's power supply and reconnected. The

switch must be pressed to turn the lights back

on.

There are two reading/map lights also located in the assembly. Each map light is mechan-

ically controlled by depressing the corresponding on/off switch. The power supply for the

map lights is supplied by the GM through the Consumer Cut Off circuit.

53

Central Body Electronics ZKE III

Page 66 of 80

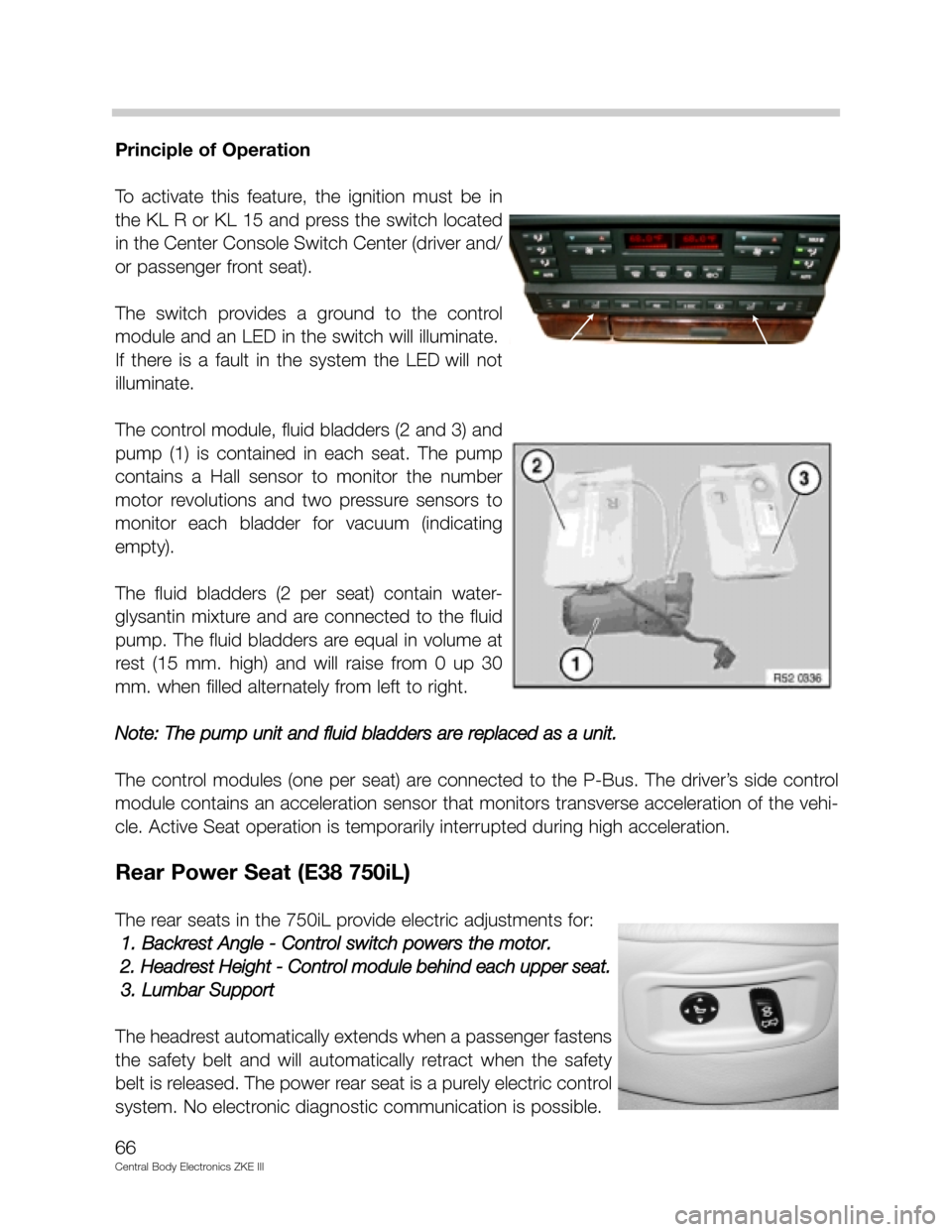

Principle of Operation

To activate this feature, the ignition must be in

the KL R or KL 15 and press the switch located

in the Center Console Switch Center (driver and/

or passenger front seat).

The switch provides a ground to the control

module and an LED in the switch will illuminate.

If there is a fault in the system the LED will not

illuminate.

The control module, fluid bladders (2 and 3) and

pump (1) is contained in each seat. The pump

contains a Hall sensor to monitor the number

motor revolutions and two pressure sensors to

monitor each bladder for vacuum (indicating

empty).

The fluid bladders (2 per seat) contain water-

glysantin mixture and are connected to the fluid

pump. The fluid bladders are equal in volume at

rest (15 mm. high) and will raise from 0 up 30

mm. when filled alternately from left to right.

Note: The pump unit and fluid bladders are replaced as a unit.

The control modules (one per seat) are connected to the P-Bus. The driver’s side control

module contains an acceleration sensor that monitors transverse acceleration of the vehi-

cle. Active Seat operation is temporarily interrupted during high acceleration.

Rear Power Seat (E38 750iL)

The rear seats in the 750iL provide electric adjustments for:

1. Backrest Angle - Control switch powers the motor.

2. Headrest Height - Control module behind each upper seat.

3. Lumbar Support

The headrest automatically extends when a passenger fastens

the safety belt and will automatically retract when the safety

belt is released. The power rear seat is a purely electric control

system. No electronic diagnostic communication is possible.

66

Central Body Electronics ZKE III

Page 67 of 80

67

Central Body Electronics ZKE III

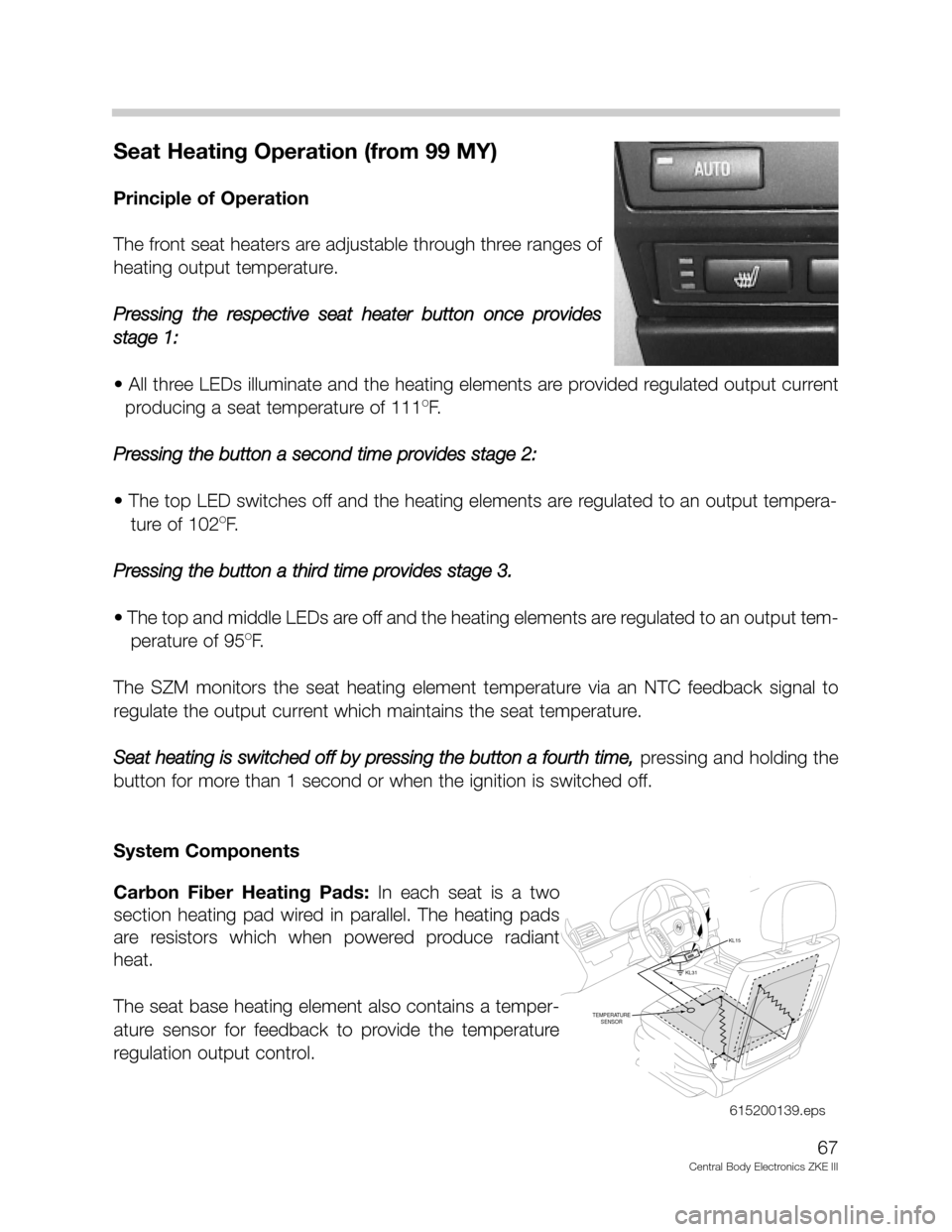

Seat Heating Operation (from 99 MY)

Principle of Operation

The front seat heaters are adjustable through three ranges of

heating output temperature.

Pressing the respective seat heater button once provides

stage 1:

• All three LEDs illuminate and the heating elements are provided regulated output current

producing a seat temperature of 111

OF.

Pressing the button a second time provides stage 2:

• The top LED switches off and the heating elements are regulated to an output tempera-

ture of 102

OF.

Pressing the button a third time provides stage 3.

• The top and middle LEDs are off and the heating elements are regulated to an output tem-

perature of 95

OF.

The SZM monitors the seat heating element temperature via an NTC feedback signal to

regulate the output current which maintains the seat temperature.

Seat heating is switched off by pressing the button a fourth time,

pressing and holding the

button for more than 1 second or when the ignition is switched off.

System Components

Carbon Fiber Heating Pads:In each seat is a two

section heating pad wired in parallel. The heating pads

are resistors which when powered produce radiant

heat.

The seat base heating element also contains a temper-

ature sensor for feedback to provide the temperature

regulation output control.

KL31

KL15

TEMPERATURE

SENSOR

615200139.eps

Page 68 of 80

68

Central Body Electronics ZKE III

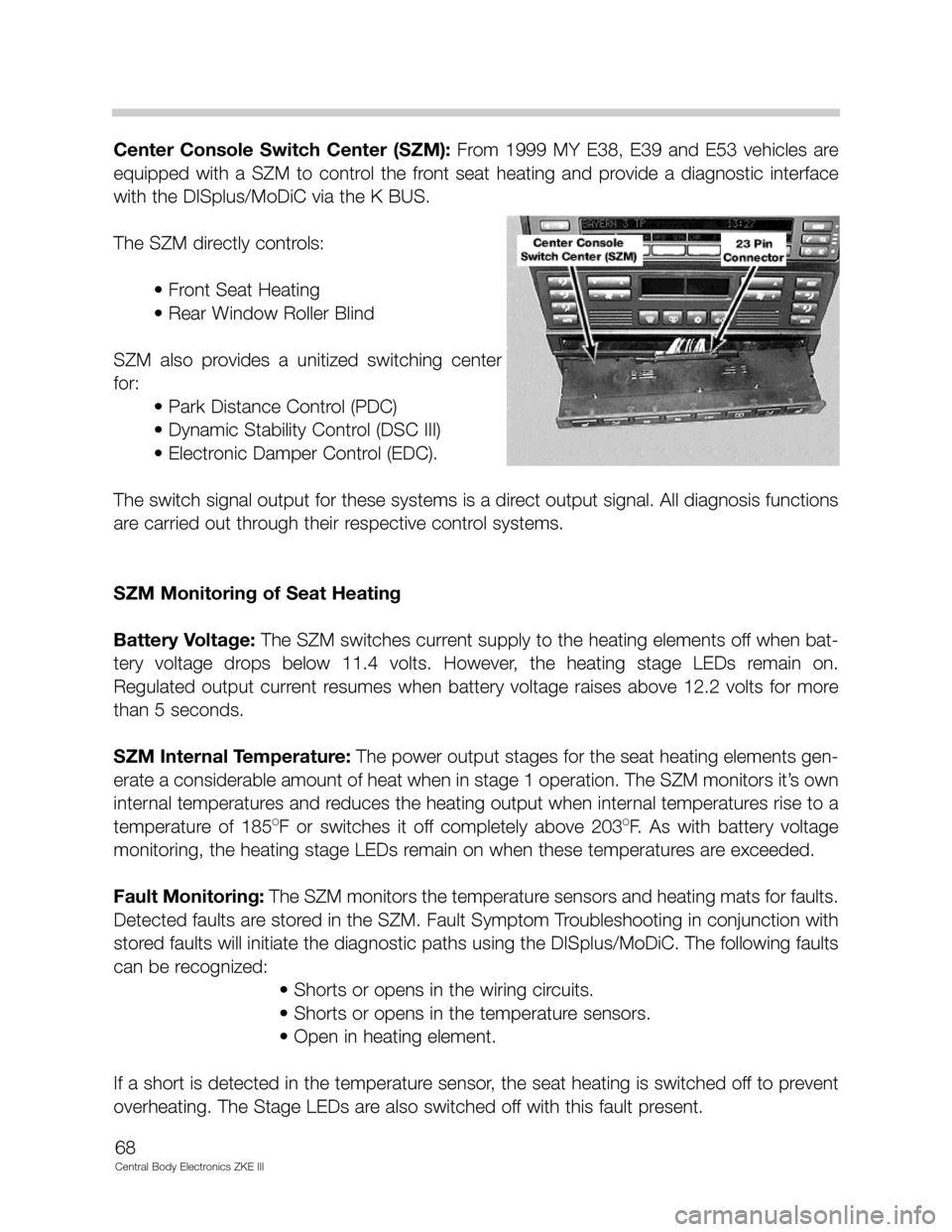

Center Console Switch Center (SZM): From 1999 MY E38, E39 and E53 vehicles are

equipped with a SZM to control the front seat heating and provide a diagnostic interface

with the DISplus/MoDiC via the K BUS.

The SZM directly controls:

• Front Seat Heating

• Rear Window Roller Blind

SZM also provides a unitized switching center

for:

• Park Distance Control (PDC)

• Dynamic Stability Control (DSC III)

• Electronic Damper Control (EDC).

The switch signal output for these systems is a direct output signal. All diagnosis functions

are carried out through their respective control systems.

SZM Monitoring of Seat Heating

Battery Voltage:The SZM switches current supply to the heating elements off when bat-

tery voltage drops below 11.4 volts. However, the heating stage LEDs remain on.

Regulated output current resumes when battery voltage raises above 12.2 volts for more

than 5 seconds.

SZM Internal Temperature: The power output stages for the seat heating elements gen-

erate a considerable amount of heat when in stage 1 operation. The SZM monitors it’s own

internal temperatures and reduces the heating output when internal temperatures rise to a

temperature of 185

OF or switches it off completely above 203OF. As with battery voltage

monitoring, the heating stage LEDs remain on when these temperatures are exceeded.

Fault Monitoring:The SZM monitors the temperature sensors and heating mats for faults.

Detected faults are stored in the SZM. Fault Symptom Troubleshooting in conjunction with

stored faults will initiate the diagnostic paths using the DISplus/MoDiC. The following faults

can be recognized:

• Shorts or opens in the wiring circuits.

• Shorts or opens in the temperature sensors.

• Open in heating element.

If a short is detected in the temperature sensor, the seat heating is switched off to prevent

overheating. The Stage LEDs are also switched off with this fault present.