height BMW 745LI 2002 E66 Level Control System Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 2002, Model line: 745LI, Model: BMW 745LI 2002 E66Pages: 57, PDF Size: 1.89 MB

Page 38 of 57

38

Level Control Systems

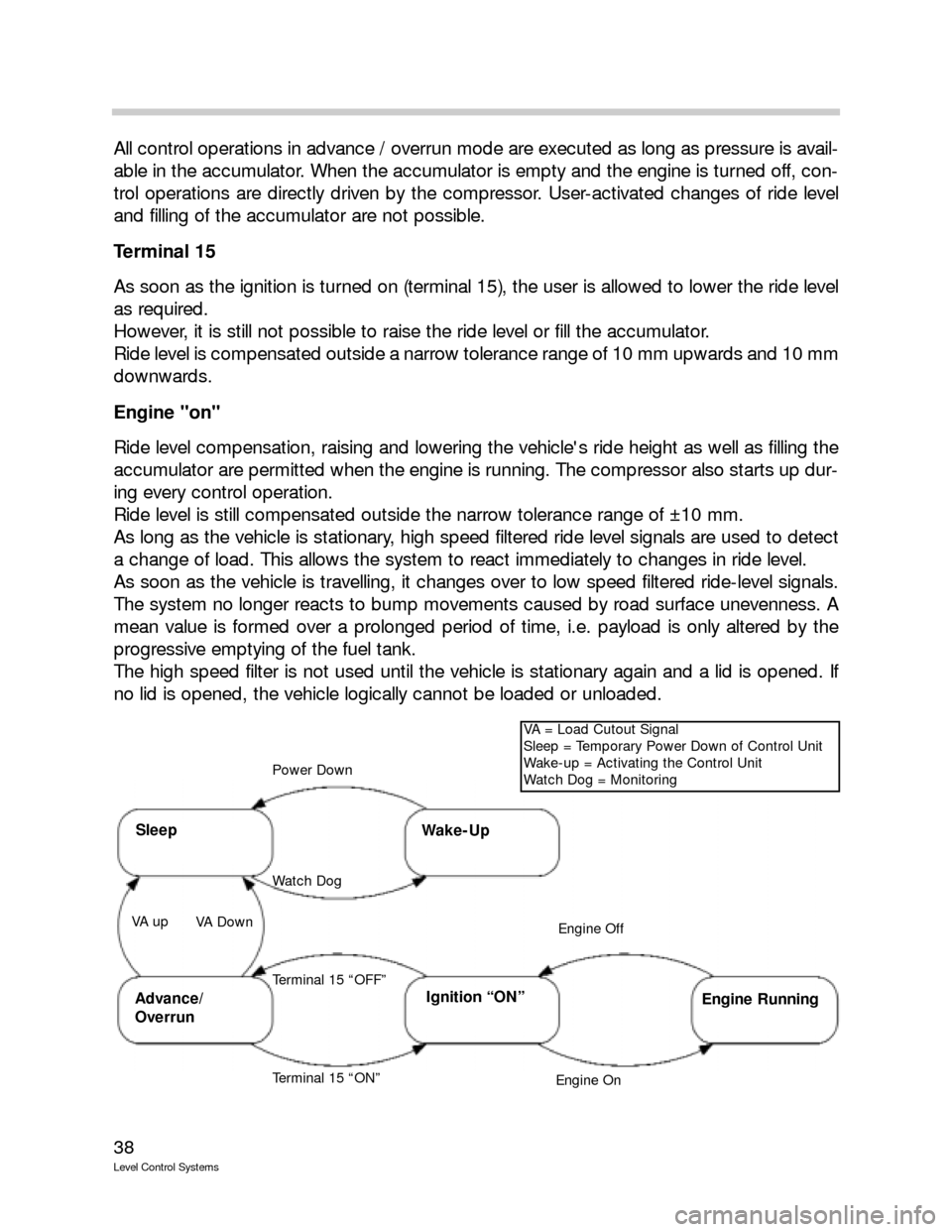

All control operations in advance / overrun mode are executed as long as pressure is avail-

able in the accumulator. When the accumulator is empty and the engine is turned off, con-

trol operations are directly driven by the compressor. User-activated changes of ride level

and filling of the accumulator are not possible.

Terminal 15

As soon as the ignition is turned on (terminal 15), the user is allowed to lower the ride level

as required.

However, it is still not possible to raise the ride level or fill the accumulator.

Ride level is compensated outside a narrow tolerance range of 10 mm upwards and 10 mm

downwards.

Engine "on"

Ride level compensation, raising and lowering the vehicle's ride height as well as filling the

accumulator are permitted when the engine is running. The compressor also starts up dur-

ing every control operation.

Ride level is still compensated outside the narrow tolerance range of ±10 mm.

As long as the vehicle is stationary, high speed filtered ride level signals are used to detect

a change of load. This allows the system to react immediately to changes in ride level.

As soon as the vehicle is travelling, it changes over to low speed filtered ride-level signals.

The system no longer reacts to bump movements caused by road surface unevenness. A

mean value is formed over a prolonged period of time, i.e. payload is only altered by the

progressive emptying of the fuel tank.

The high speed filter is not used until the vehicle is stationary again and a lid is opened. If

no lid is opened, the vehicle logically cannot be loaded or unloaded.

SleepWake-Up

Power Down

Watch Dog

Ignition “ON”Advance/

Overrun

VA = Load Cutout Signal

Sleep = Temporary Power Down of Control Unit

Wake-up = Activating the Control Unit

Watch Dog = Monitoring

Engine Off

Engine On

Engine Running

Terminal 15 “ON” VA up

VA Down

Terminal 15 “OFF”

Page 39 of 57

39

Level Control Systems

Workshop Hints

If a threshold level is exceeded on all 4 wheels when the vehicle is stationary, the control

unit assumes that the vehicle has been raised on a workshop platform.

There are three possible reset conditions for workshop platform recognition:

The original level values are undershot at all four wheels,

A selection is made by button,

A speed of >40 km/h is recognized for 3 s.

Vehicle jack

If the lowering speed at a wheel is too low during the lowering operation, the system

assumes that the wheel is jacked up. However, the downward velocity must be less than

a certain preprogrammed speed threshold. If the system detects a jacked wheel, it stores

the height of this wheel.

Car jack recognition is reset when the stored ride height is again undershot. When a trav-

elling speed of 40 km/h is maintained for at least 3 s, another control attempt is performed.

The car jack recognition can also be reset by button selection.

Please note that the system also controls ride height in diagnostic mode. For this reason,

Belt Mode must be activated before carrying out work on the system or before setting the

vehicle ride height.

Belt Mode:

Heights are fixed and are not compensated. If Belt Mode is set, the function LED is off. The

text message "ride-height control system inactive" appears in the instrument cluster.

Transport Mode:

The Transport Mode setting is for transportation purposes. When the ignition is turned on,

the message "ride-height control system inactive" appears. Heights are increased or

decreased depending on ignition key status, e.g. ride height is reduced when the vehicle is

lashed to a ship or train and raised when the "Engine on" signal is generated and when the

vehicle is transported on a transporter truck.

The correct ride height is set to ± 5 mm via "Activate components." The left and right ride

levels are set separately at the rear axle. The ride levels are then set at the front axle. The

left and right air springs are adjusted jointly for this purpose.

Following this, the new ride height for the front and rear axles is stored via the "Offset func-

tion."

Before replacing components, the system must be depressurized! This is done in the diag-

nostics via "control unit functions," "Component activation," "Pressure-relieve front axle/rear

axle." Repeat the activation procedure 6 times.

Page 41 of 57

41

Level Control Systems

Single Axle Air Suspension (E65/E66)

Purpose of the System

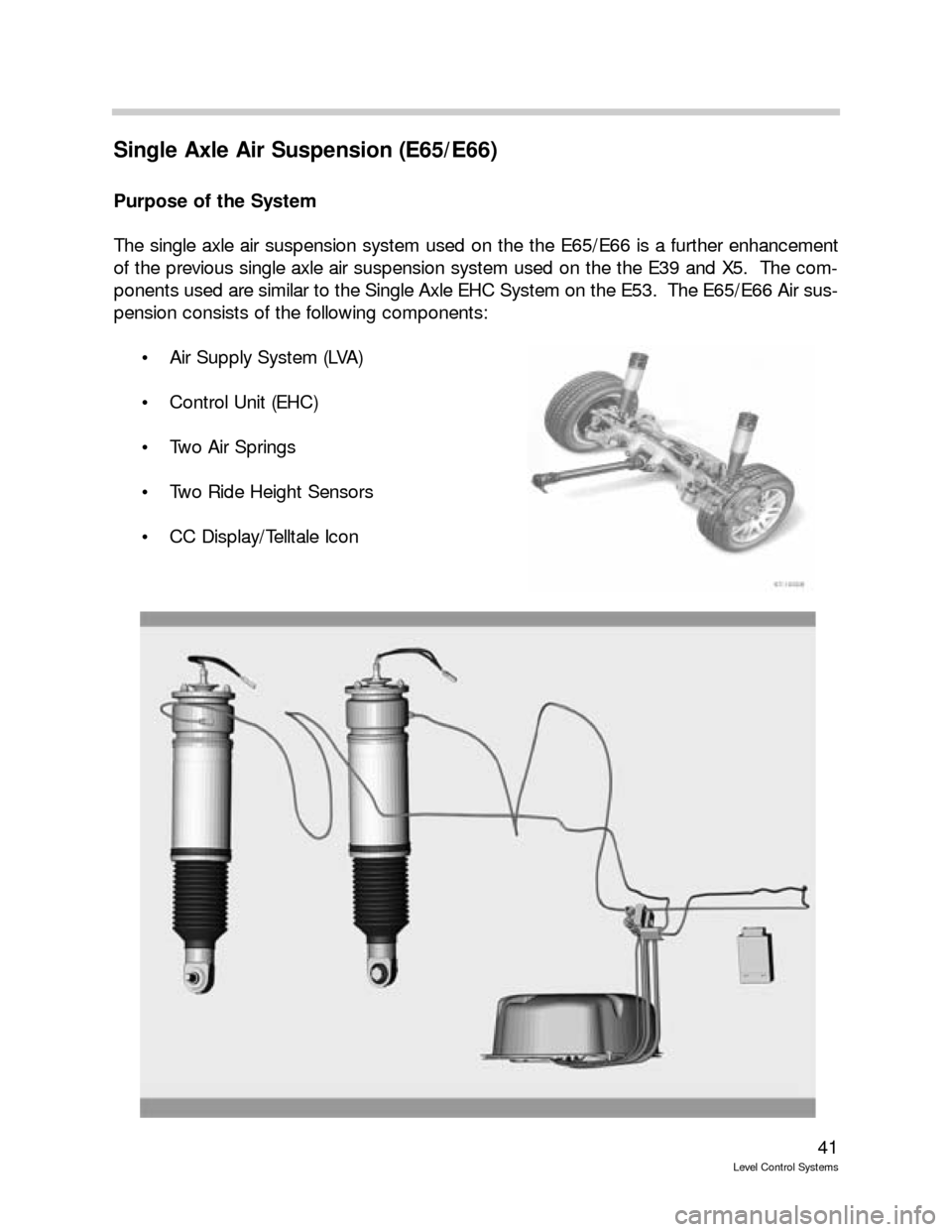

The single axle air suspension system used on the the E65/E66 is a further enhancement

of the previous single axle air suspension system used on the the E39 and X5. The com-

ponents used are similar to the Single Axle EHC System on the E53. The E65/E66 Air sus-

pension consists of the following components:

Air Supply System (LVA)

Control Unit (EHC)

Two Air Springs

Two Ride Height Sensors

CC Display/Telltale Icon

Page 44 of 57

44

Level Control Systems

Control Unit

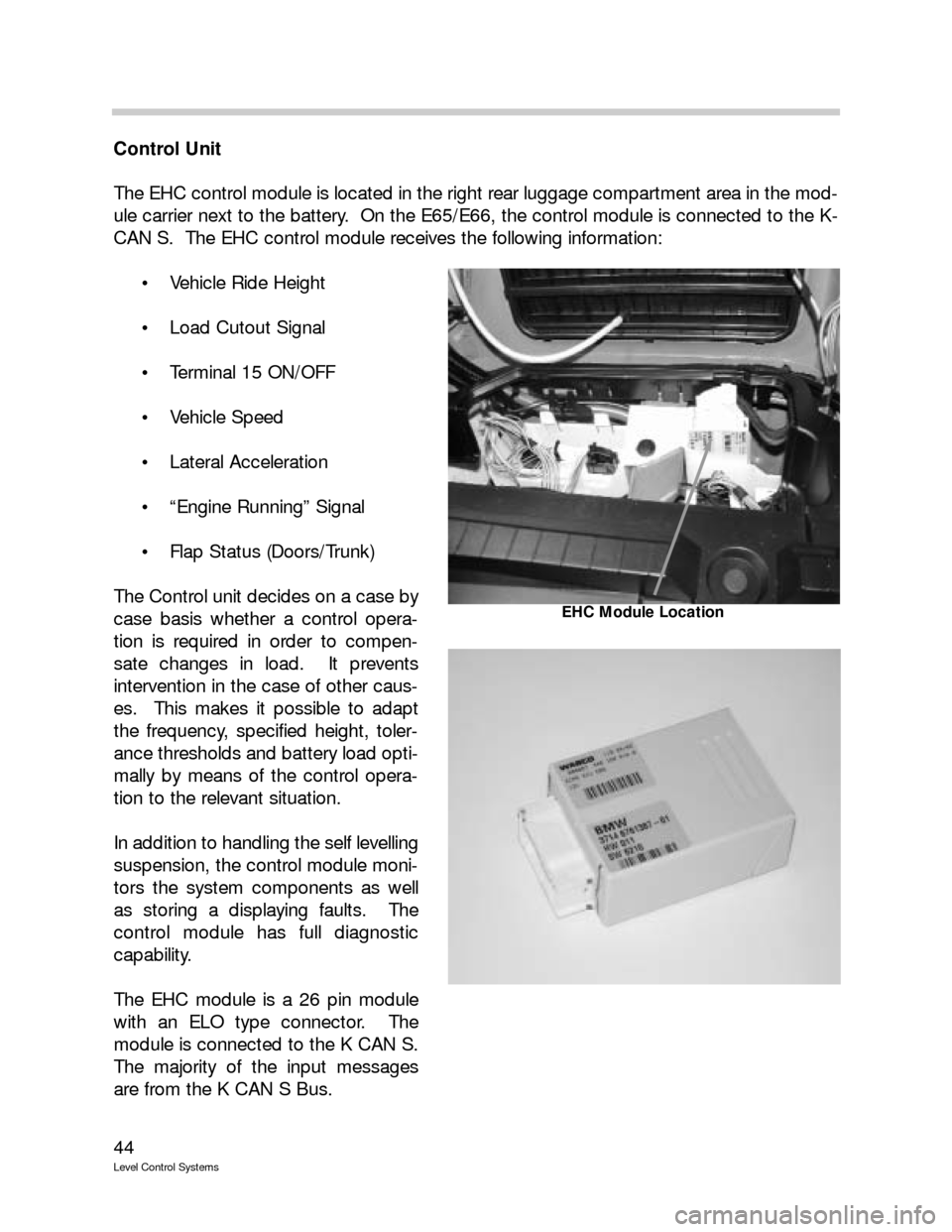

The EHC control module is located in the right rear luggage compartment area in the mod-

ule carrier next to the battery. On the E65/E66, the control module is connected to the K-

CAN S. The EHC control module receives the following information:

Vehicle Ride Height

Load Cutout Signal

Terminal 15 ON/OFF

Vehicle Speed

Lateral Acceleration

“Engine Running” Signal

Flap Status (Doors/Trunk)

The Control unit decides on a case by

case basis whether a control opera-

tion is required in order to compen-

sate changes in load. It prevents

intervention in the case of other caus-

es. This makes it possible to adapt

the frequency, specified height, toler-

ance thresholds and battery load opti-

mally by means of the control opera-

tion to the relevant situation.

In addition to handling the self levelling

suspension, the control module moni-

tors the system components as well

as storing a displaying faults. The

control module has full diagnostic

capability.

The EHC module is a 26 pin module

with an ELO type connector. The

module is connected to the K CAN S.

The majority of the input messages

are from the K CAN S Bus.

EHC Module Location

Page 46 of 57

46

Level Control Systems

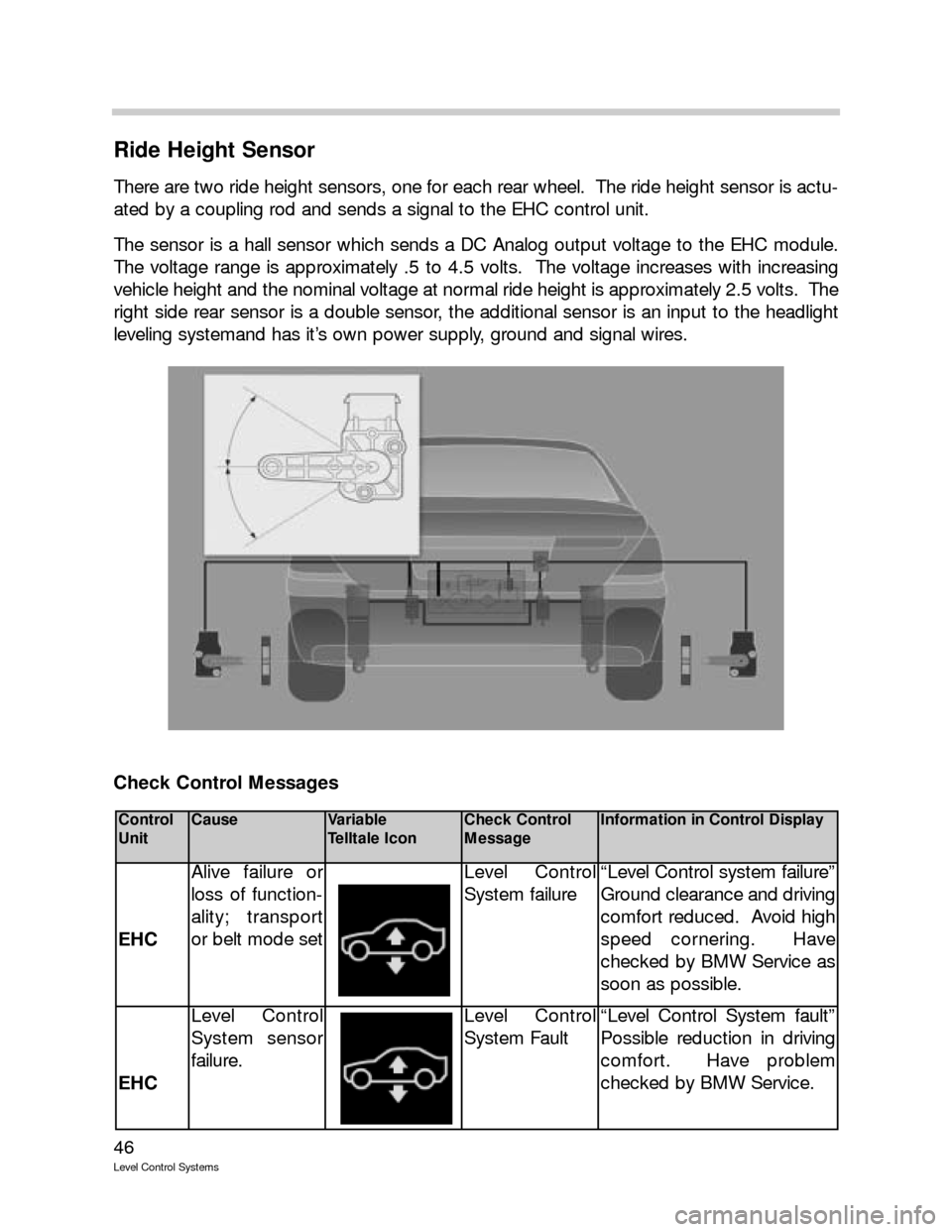

Ride Height Sensor

There are two ride height sensors, one for each rear wheel. The ride height sensor is actu-

ated by a coupling rod and sends a signal to the EHC control unit.

The sensor is a hall sensor which sends a DC Analog output voltage to the EHC module.

The voltage range is approximately .5 to 4.5 volts. The voltage increases with increasing

vehicle height and the nominal voltage at normal ride height is approximately 2.5 volts. The

right side rear sensor is a double sensor, the additional sensor is an input to the headlight

leveling systemand has it’s own power supply, ground and signal wires.

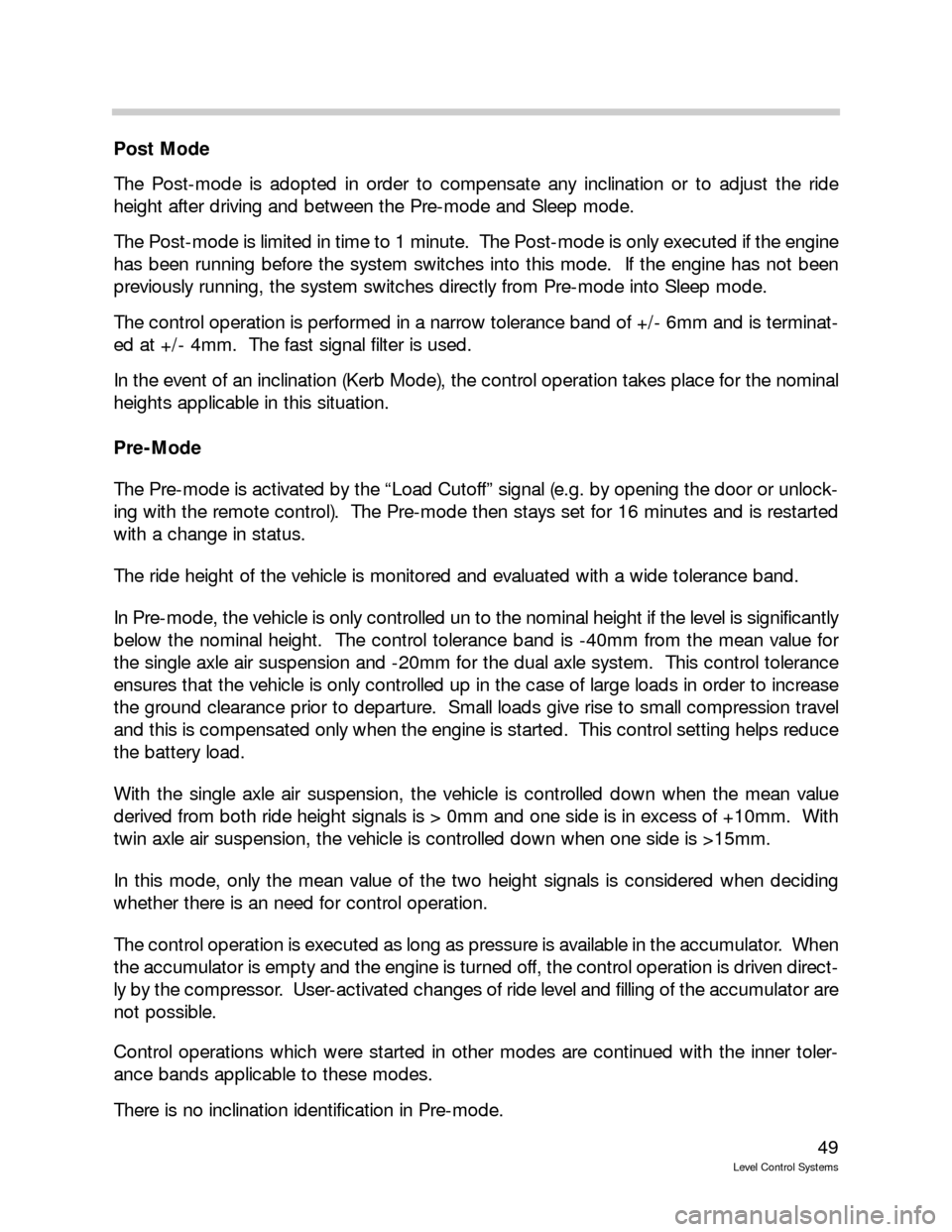

Check Control Messages

Control

UnitCauseVariable

Telltale IconCheck Control

MessageInformation in Control Display

EHC

Alive failure or

loss of function-

ality; transport

or belt mode setLevel Control

System failure“Level Control system failure”

Ground clearance and driving

comfort reduced. Avoid high

speed cornering. Have

checked by BMW Service as

soon as possible.

EHC

Level Control

System sensor

failure.Level Control

System Fault“Level Control System fault”

Possible reduction in driving

comfort. Have problem

checked by BMW Service.

Page 49 of 57

49

Level Control Systems

Post Mode

The Post-mode is adopted in order to compensate any inclination or to adjust the ride

height after driving and between the Pre-mode and Sleep mode.

The Post-mode is limited in time to 1 minute. The Post-mode is only executed if the engine

has been running before the system switches into this mode. If the engine has not been

previously running, the system switches directly from Pre-mode into Sleep mode.

The control operation is performed in a narrow tolerance band of +/- 6mm and is terminat-

ed at +/- 4mm. The fast signal filter is used.

In the event of an inclination (Kerb Mode), the control operation takes place for the nominal

heights applicable in this situation.

Pre-Mode

The Pre-mode is activated by the “Load Cutoff” signal (e.g. by opening the door or unlock-

ing with the remote control). The Pre-mode then stays set for 16 minutes and is restarted

with a change in status.

The ride height of the vehicle is monitored and evaluated with a wide tolerance band.

In Pre-mode, the vehicle is only controlled un to the nominal height if the level is significantly

below the nominal height. The control tolerance band is -40mm from the mean value for

the single axle air suspension and -20mm for the dual axle system. This control tolerance

ensures that the vehicle is only controlled up in the case of large loads in order to increase

the ground clearance prior to departure. Small loads give rise to small compression travel

and this is compensated only when the engine is started. This control setting helps reduce

the battery load.

With the single axle air suspension, the vehicle is controlled down when the mean value

derived from both ride height signals is > 0mm and one side is in excess of +10mm. With

twin axle air suspension, the vehicle is controlled down when one side is >15mm.

In this mode, only the mean value of the two height signals is considered when deciding

whether there is an need for control operation.

The control operation is executed as long as pressure is available in the accumulator. When

the accumulator is empty and the engine is turned off, the control operation is driven direct-

ly by the compressor. User-activated changes of ride level and filling of the accumulator are

not possible.

Control operations which were started in other modes are continued with the inner toler-

ance bands applicable to these modes.

There is no inclination identification in Pre-mode.

Page 50 of 57

50

Level Control Systems

Normal

The normal mode is the starting point for the vehicle’s normal operating state. It is obtained

by way of the engine running signal.

Ride level compensation, changing the vehicle’s ride height and filling the accumulator are

possible. The compressor starts up as required.

A narrower tolerance band than that in Pre-mode cab be used because the battery capac-

ity does not have to be protected. The fast filter is used with a narrow tolerance band of

+/- 10mm. In this way, ride level compensation takes place outside a narrow band of 10+/-

10mm. The faster filter allows the system to respond immediately to changes in ride level.

Evaluation and control are performed separately for each wheel.

When a speed signal is recognized, the control unit switches into Drive mode. When the

vehicle is stopped, the control unit remains in Drive mode. The system switches back into

Normal mode when a door or the boot (trunk) lid is also opened. If none of the doors or

the boot lid is opened, the vehicle cannot be loaded or unloaded.

This prevents a control operation happening when the vehicle (for example) is stopped at

traffic lights and the ride height is above the mean axle due to the pitching motion on the

rear axle.

Drive

The Drive mode is activated for E39/E53 single axle air suspension when a speed signal of

>4km/h is recognized. The Drive mode is recognized from >1km/h for the E65/E66 single

axle air suspension and for the E53 twin-axle air suspension system.

Low pass filters are used. In this way, only changes in ride height over a prolonged period

of time (1000 seconds) are corrected. These are merely the changes in ride height, caused

by vehicle compression and a reduction in vehicle mass due to fuel consumption. The high

pass (fast) filter is used during the control operation. The slow filters are recognized at the

end of the control operation. The slow filters are re-initialized at the end of the control oper-

ation. The markedly dynamic height signals caused by uneven road surfaces are filtered

out.

Page 51 of 57

51

Level Control Systems

Kerb (Curb) Mode

The Kerb mode prevents the inclination caused by the vehicle mounting an obstacle with

ine wheel from being compensated. Compensation would cause a renewed inclination of

the vehicle and result in a renewed control operation after the vehicle comes off the obsta-

cle.

The Kerb Mode is activated when the height difference between the left and right sides of

the vehicle is > 32mm for the E65/E66 with single axle air suspension and >24mm for the

E39/E53 with single axle air suspension and lasts longer than 0.9s. Twisting (also over both

axles) > 45mm must occur for the E53 with twin axle air suspension.

There must be no speed signal present. The system switches from single wheel control to

axle control.

The Kerb mode is quit when the difference between the left and right sides of the vehicle is

< 28mm for the single axle air suspension and lasts longer than 0.9s when the speed is

greater than > 1km/h.

If the system switches from Kerb mode to Sleep mode, this status is stored in the

EEPROM.

If the vehicle is loaded or unloaded in Kerb mode, the mean value of the axle is calculated

by the control unit. The value is calculated in the control unit from the changes in ride level

of the spring travel on the left and right sides.

A change in ride level is initiated if the mean value of compression or rebound at the axle is

outside the tolerance band of +/- 10mm. The left and right sides of the vehicle are raised

or lowered in parallel. The height difference between the two sides is maintained.

Curve

Since rolling motions have a direct impact on the measured ride level, an unwanted control

operation would be initiated during longer instances of cornering with an appropriate roll

angle in spite of the slow filtering of the Drive mode. The control operations during corner-

ing would cause displacement of the air volume from the outer side to the inner side of the

curve. Once the curve is completed, this would produce an inclination which would result

in a further control operation. The Curve mode prevents this control operation whereby

when cornering is recognized slow filtering is stopped and a potential control operation that

has started is terminated.

The Curve mode is activated for the E65/E66 single axle EHC and for the E53 twin axle

suspension for a lateral acceleration of > 2m/s

2and deactivated at < 1.5 m/s2.

The lateral acceleration is recorded by the rotation rate sensor.

Page 52 of 57

52

Level Control Systems

Lift

The Lift mode is used to prevent control operations when a wheel is changed or during

work on the vehicle while it is on a lifting platform.

This mode is recognized when the permitted rebound travel at one or more wheels is

exceeded. For the E65/E66 the limit is > 55mm.

A “jack” situation is also recognized when the ride level is stored and the lowering speed

drops below the value of 2 mm/s for 3 seconds.

If the vehicle has been raised slightly and the permitted rebound travel has not yet been

achieved, the control operation attempts to readjust the ride height. If the vehicle is not low-

ered, a car jack situation is recognized after a specific period of time and this ride height is

stored.

A reset is performed if the vehicle is again 10 mm below this stored ride height.

Transport

The Transport mode is set and cleared by means of a diagnosis activation. It serves to

increase the ground clearance in order to ensure a safe transportation of vehicles on trans-

porter trucks. The nominal height of the vehicle is raised in this mode by 30 mm.

When the Transport mode is activated, the air suspension symbol is indicated in the vari-

able telltale in the instrument cluster and a text message is output in the Check Control

Display.

Control operations do not take place in this mode because the vehicle mass does not

change during transportation.

Belt

The Belt mode is set for mounting on the belt in order to avoid control operations.

When the Belt mode is activated, the air suspension symbol is indicated in the variable tell-

tale in the instrument cluster and a text message is output in the Check Control display.

The Belt mode is cleared by means of a diagnostic activation only. The Belt mode can no

longer be set.

New control units are supplied with the Belt mode set.

Control operations are not performed, the safety concept only operates with limited effect.

The Belt Mode is also known as “Band Mode” or “Assembly Line Mode”.

Page 53 of 57

53

Level Control Systems

Operating Principle

Initialization/Reset Performance

When the control unit is powered up after a reset (such as an undervoltage < 4.5 V or by a

load cutoff), different tests and initializations are performed. This system is only enabled

after the tests have been successfully completed and starts to execute the control pro-

grams on a cyclical basis.

Occurring faults are stored and displayed.

Control Sequence

In an ongoing control operation, the high pass filter (fast filter) is always used to prevent the

controlled height from overshooting the nominal value. If a low pass filter (slow filter) were

used to calculate the ride height, brief changes of ride height would be consumed. The

low-pass filter is used while the vehicle is driven. This type of filtering filters out vibrations

which are excited by the road surface.

The high pass filter is used to respond quickly to ride level deviations from setpoint. These

take place while the vehicle is stationary in the event of large load changes.

Both sides of the vehicle are controlled individually, i.e. even the setpoint/actual value com-

parison for both sides is carried out individually. Exception: check for undershooting of the

minimum height in Pre-mode and Kerf mode: consideration of the left and right mean val-

ues in each case.

The following stipulations are applicable here:

Raising before lowering

Activation of all valves with control in the same direction

Individual wheel deactivation

To ensure safe closing of the non-return valve in the air drier, the drain valve is actuated

briefly for 200ms after the control operation has ended.

The permissible ON period of the components is monitored while control up operation are

executed.