relay BMW 760LI 2001 E66 Level Control System Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 2001, Model line: 760LI, Model: BMW 760LI 2001 E66Pages: 57, PDF Size: 1.89 MB

Page 18 of 57

18

Level Control Systems

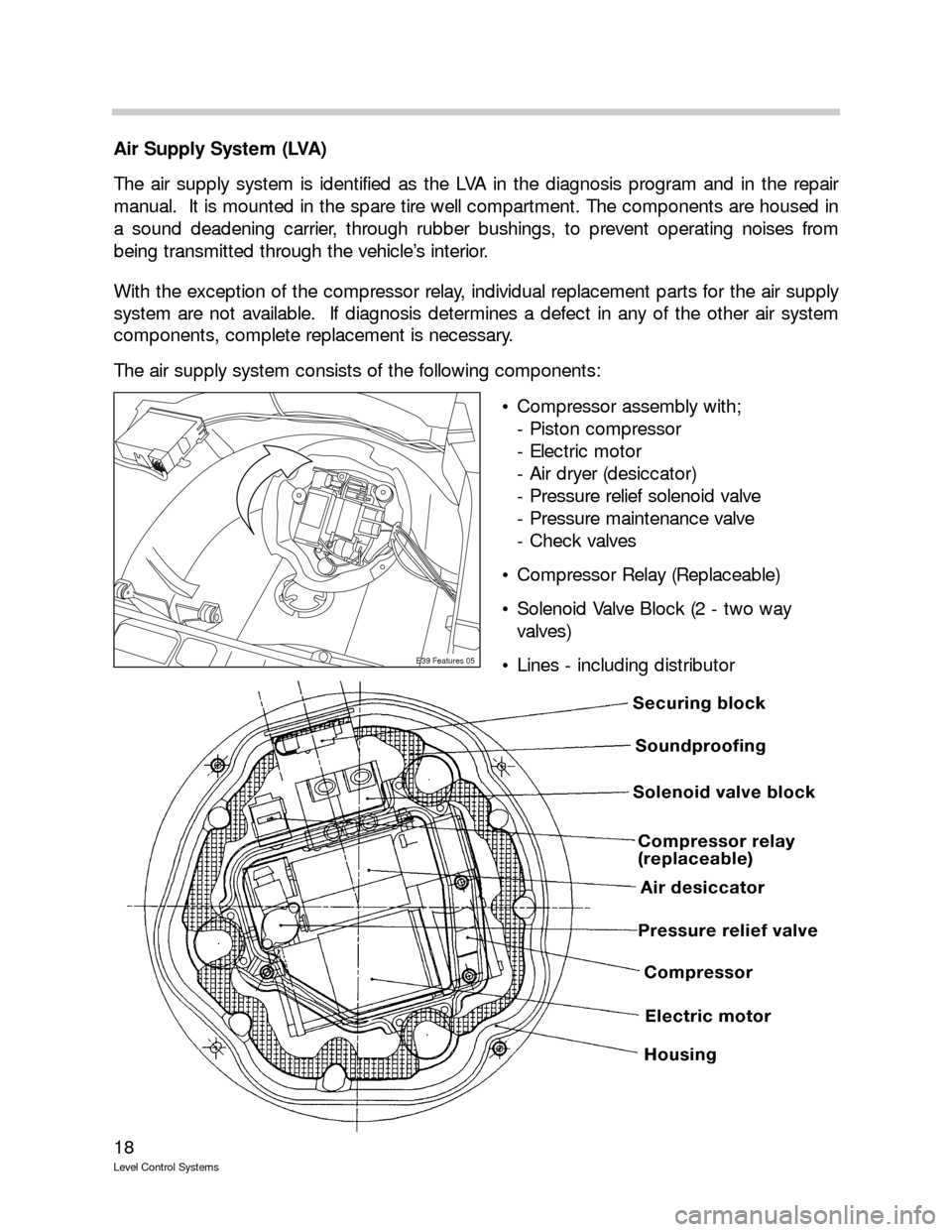

Air Supply System (LVA)

The air supply system is identified as the LVA in the diagnosis program and in the repair

manual. It is mounted in the spare tire well compartment. The components are housed in

a sound deadening carrier, through rubber bushings, to prevent operating noises from

being transmitted through the vehicle’s interior.

With the exception of the compressor relay, individual replacement parts for the air supply

system are not available. If diagnosis determines a defect in any of the other air system

components, complete replacement is necessary.

The air supply system consists of the following components:

Compressor assembly with;

- Piston compressor

- Electric motor

- Air dryer (desiccator)

- Pressure relief solenoid valve

- Pressure maintenance valve

- Check valves

Compressor Relay (Replaceable)

Solenoid Valve Block (2 - two way

valves)

Lines - including distributor

E39 Features 05

Page 19 of 57

19

Level Control Systems

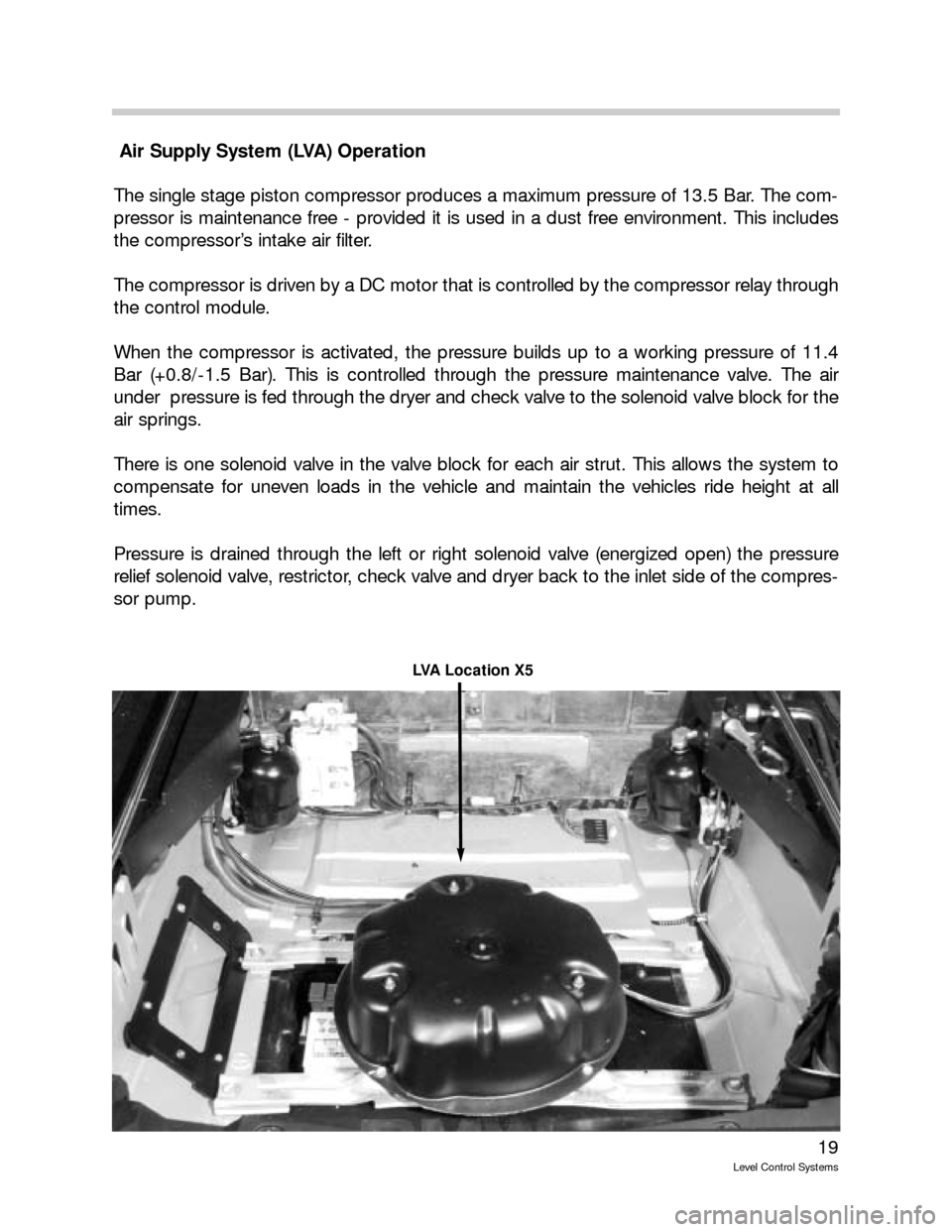

Air Supply System (LVA) Operation

The single stage piston compressor produces a maximum pressure of 13.5 Bar. The com-

pressor is maintenance free - provided it is used in a dust free environment. This includes

the compressor’s intake air filter.

The compressor is driven by a DC motor that is controlled by the compressor relay through

the control module.

When the compressor is activated, the pressure builds up to a working pressure of 11.4

Bar (+0.8/-1.5 Bar). This is controlled through the pressure maintenance valve. The air

under pressure is fed through the dryer and check valve to the solenoid valve block for the

air springs.

There is one solenoid valve in the valve block for each air strut. This allows the system to

compensate for uneven loads in the vehicle and maintain the vehicles ride height at all

times.

Pressure is drained through the left or right solenoid valve (energized open) the pressure

relief solenoid valve, restrictor, check valve and dryer back to the inlet side of the compres-

sor pump.

LVA Location X5

Page 33 of 57

33

Level Control Systems

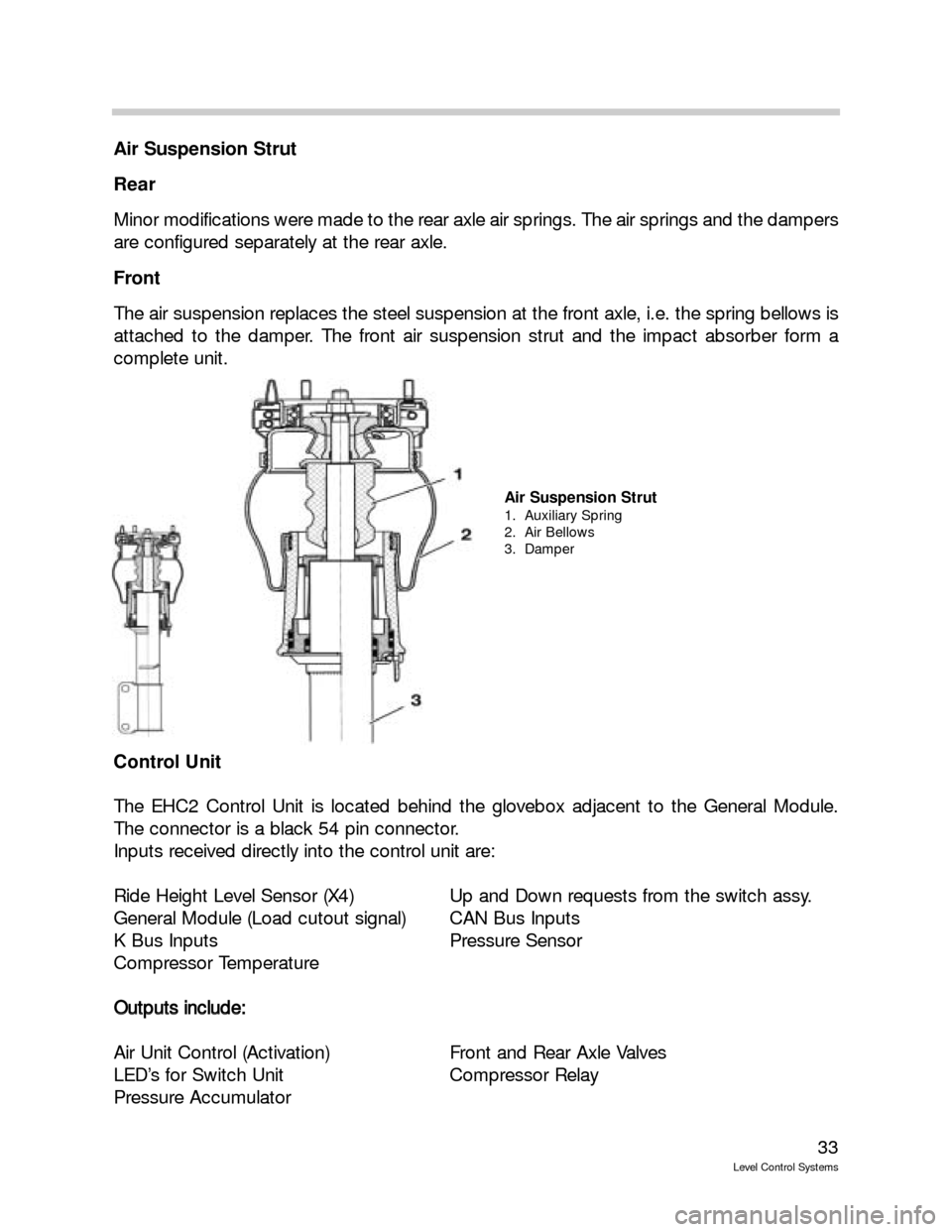

Air Suspension Strut

Rear

Minor modifications were made to the rear axle air springs. The air springs and the dampers

are configured separately at the rear axle.

Front

The air suspension replaces the steel suspension at the front axle, i.e. the spring bellows is

attached to the damper. The front air suspension strut and the impact absorber form a

complete unit.

Control Unit

The EHC2 Control Unit is located behind the glovebox adjacent to the General Module.

The connector is a black 54 pin connector.

Inputs received directly into the control unit are:

Ride Height Level Sensor (X4) Up and Down requests from the switch assy.

General Module (Load cutout signal) CAN Bus Inputs

K Bus Inputs Pressure Sensor

Compressor Temperature

O Ou

ut

tp

pu

ut

ts

s

i

in

nc

cl

lu

ud

de

e:

:

Air Unit Control (Activation) Front and Rear Axle Valves

LED’s for Switch Unit Compressor Relay

Pressure Accumulator

Air Suspension Strut

1. Auxiliary Spring

2. Air Bellows

3. Damper

Page 43 of 57

43

Level Control Systems

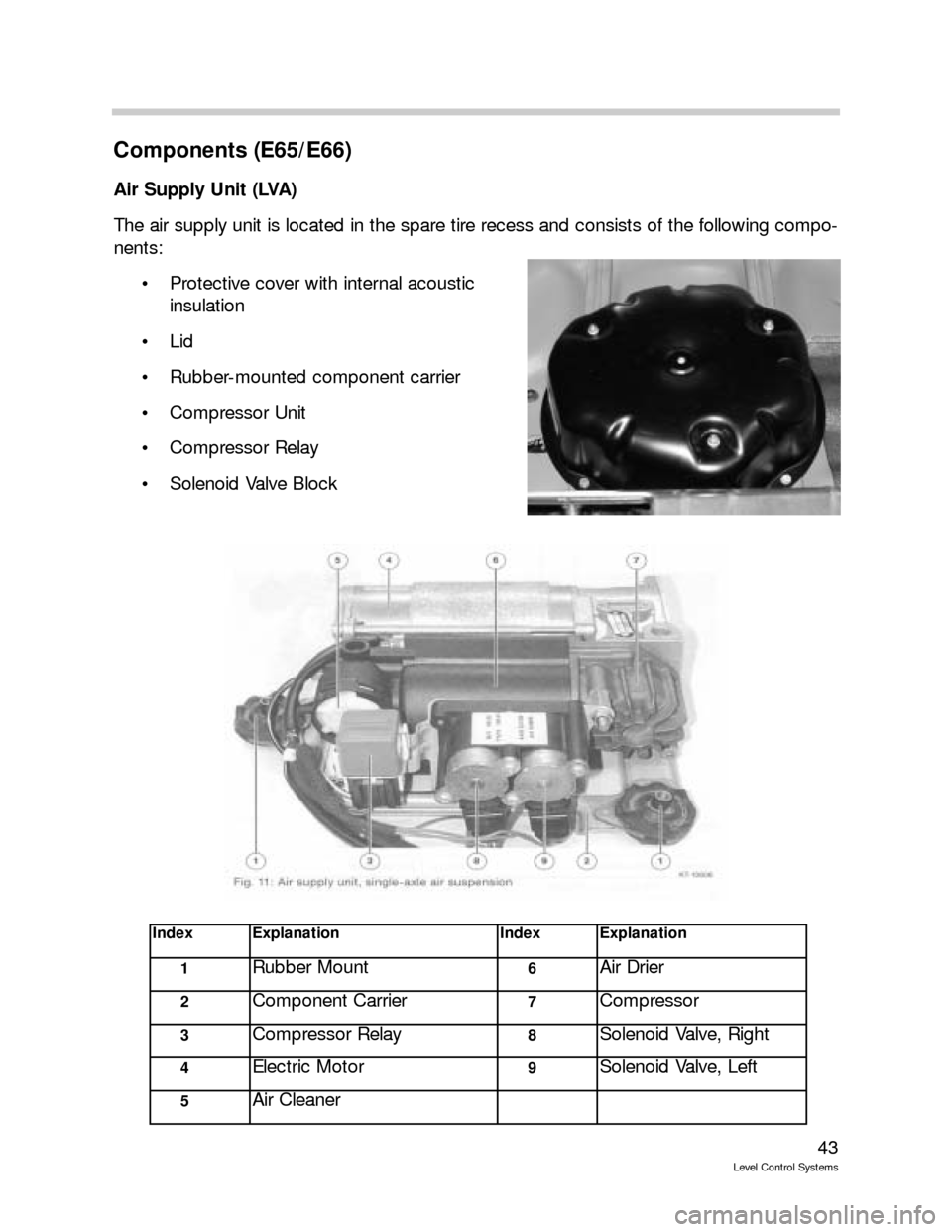

Components (E65/E66)

Air Supply Unit (LVA)

The air supply unit is located in the spare tire recess and consists of the following compo-

nents:

Protective cover with internal acoustic

insulation

Lid

Rubber-mounted component carrier

Compressor Unit

Compressor Relay

Solenoid Valve Block

IndexExplanationIndexExplanation

1Rubber Mount6Air Drier

2Component Carrier7Compressor

3Compressor Relay8Solenoid Valve, Right

4Electric Motor9Solenoid Valve, Left

5Air Cleaner