heater BMW M3 1992 E36 User Guide

[x] Cancel search | Manufacturer: BMW, Model Year: 1992, Model line: M3, Model: BMW M3 1992 E36Pages: 759

Page 76 of 759

113-10

CYLINDER

HEAD

REMOVAL

AND

INSTALLATION

Tightening

Torques

"

Coolant

drain

plug

to

cylinder

block

.

.

25

Nm

(18

ft-1b)

"

Intake

manifold

support

to

manifold

.

.

15

Nm

(11

ft-Ib)

"

Lower

intake

manifold

to

cylinder

head

.

..........

.

..

...

15

Nm

(11

ft-Ib)

"

Lower

intake

manifold

to

upper

manifold

..........

.

..

...

15

Nm

(11

ft-Ib)

"

Radiator

cooling

fan

to

coolant

pump

.

40

Nm

(30

ft-Ib)

"

Radiator

drain

screw

to

radiator

...

.

2

.5

Nm

(22

in-lb)

CYLINDER

HEAD,

6-CYLINDER

For

ease

of

use

this

procedure

is

broken

into

subsections,

as

follows

:

General

Coolingsystem,

draining

Cyiinder

head

cover,

removing

Intake

manifold,

removing

Timing

chains,

uncoupling

Cylinder

head

assembly,

removing

WARNING

-

Allow

the

engine

to

cool

before

beginning

this

pro-

cedure

.

General

1

.

Working

inside

luggage

compartment,

disconnect

neg-

ative

(-)

battery

cable

.

CAUTION-

"

Prior

to

disconnectiog

the

battery,

read

the

bat-

tery

disconnection

cautions

given

at

the

front

of

this

manual

on

page

vi¡¡

.

"

Disconnecting

the

battery

may

erase

fault

code(s)

stored

in

control

module

memory

.

Check

for

fault

codes

using

special

BMW

diagnostic

equipment

2

.

Remove

front

exhaust

pipes

from

manifolds

.

Discard

nuts

.

3

.

Remove

air

filter

housing

complete

with

mass

air

flow

sensor

and

intake

air

ducting

.

Disconnect

vacuum

hos-

es

from

throttle

housing

.

4

.

On

M52

and

S52US

engines

:

Remove

secondary

air

injection

check-valve

from

front

of

engine

and

set

aside

.

CYLINDER

HEAD,

6-CYLINDER

Coolingsystem,

draining

5

.

Drain

engine

coolant

and

Rmove

coolant

hoses

from

thermostat

housing

.

Drain

engine

block

by

removing

block

drain

.

See

170

Radiator

and

Cooling

System

.

NOTE-

The

block

drain

is

on

the

exhaust

side

of

the

engine,

near

cylinder

no

.

5

.

6

.

Remove

radiator

cooling

fan

and

fan

shroud

.

See

170

Radiator

and

Cooling

System

.

NOTE-

The

radiator

cooling

fannut(32

mm

wrench)

has

left-

hand

threads

.

Cylinder

head,

removing

(6-cylinder

engine)

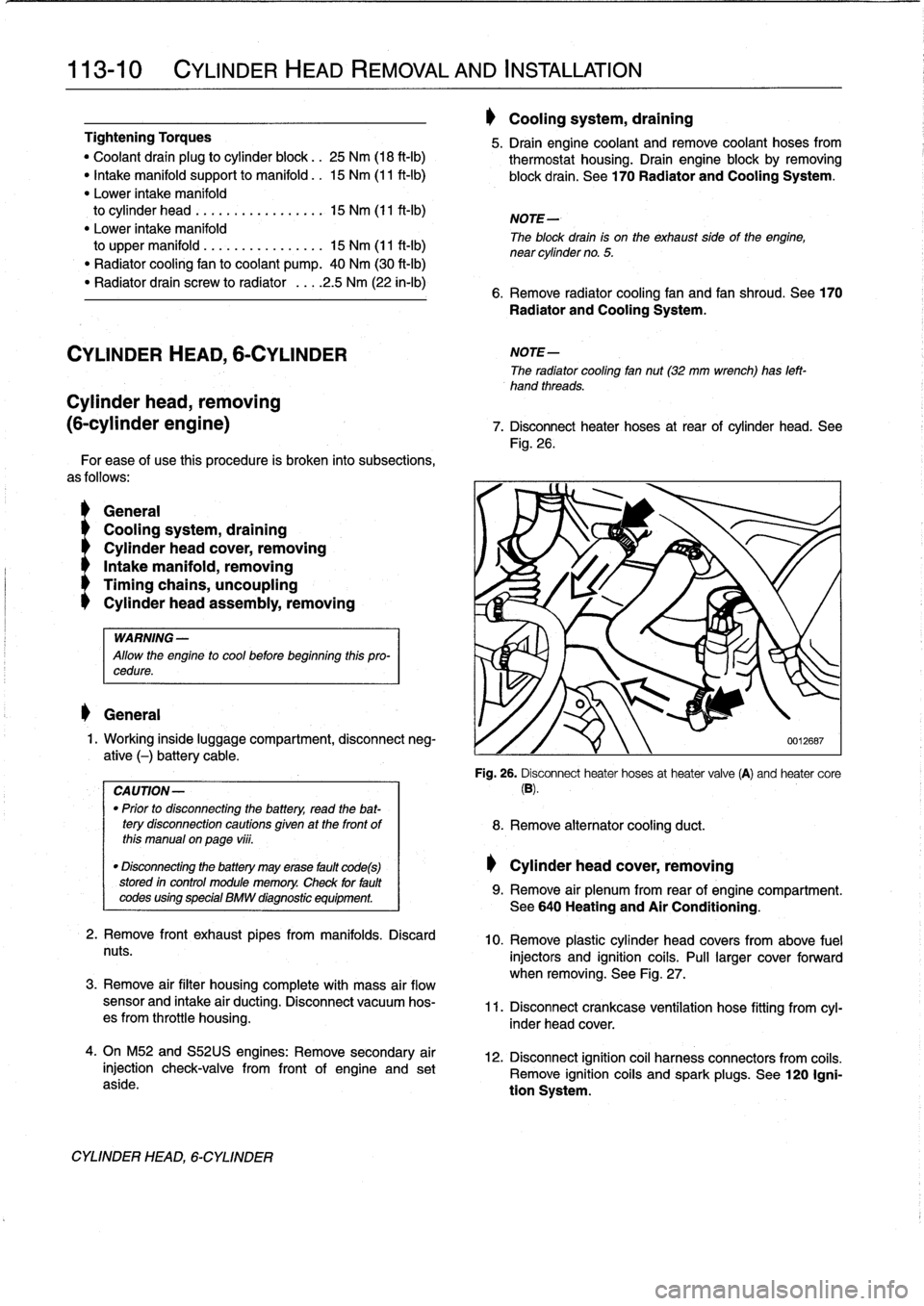

7

.

Disconnect

heater

hoses

at

rear

of

cylinder

head

.

See

Fig

.

26

.

'i

8

.

Remove

alternator

cooling

duct

.

Cylinder

head

cover,

removing

0012687

Fig

.

26

.

Disconnect

heater

hoses

at

heater

valve

(A)

and

heater

core

(B)

.

9

.

Remove

air

plenum

from

rear

of

engine

compartment

.

See640

Heating

and

Air

Conditioning

.

10

.

Remove

plastic

cylinder

head

covers

from

above

fuel

injectors

and

ignition

coils

.

Pull

larger

cover

forward

when

removing

.

See

Fig

.

27

.

11

.

Disconnect

crankcase

ventílation

hose

fitting

from

cyl-

inder

head

cover

.

12

.

Disconnect

ignition

coil

harness

connectors

from

coiis

.

Remove

ignition

coiis

and

spark

plugs

.

See

120

Igni-

tion

System

.

Page 78 of 759

113-12

CYLINDER

HEAD

REMOVAL

AND

INSTALLATION

18

.

Working

from

underside

of

intake

manifold,

disconnect

21

.

Detach

oil

dipstick

guide

tube

from

manifold

.

Disconharness

connectors,

vent

hoses,

and

air

bypass

nectvent

hose

at

base

of

dipstick

.

hoses)

.

22

.

Remove

intake

manifold

from

engine

byremoving

sev-19

.

Working

at

rear

of

intake

manifold,

label

and

disconnect

en

mounting

nuts

from

above

andtwo

support

bracket

fuel

supply

and

fuel

return

lines

.

Remove

fuelline

hold

bolts

from

below

.

See

Fig

.

32

.

down

bracket

to

free

lines

.

See

Fig

.

31

.

NOTE-

On

M52IS52US

engines,

a

special

fitting

is

used

to

re-tain

the

fuel

fines

to

the

fuel

rail

.

Use

BMW

special

tool

no

.

16

1

050

to

expand

the

locking

clip

inside

the

end

of

the

fuellíne

fittings

.

WARNING

-

"

The

fuel

system

is

desígned

to

retan

pressure

even

wheh

the

ignition

is

off

.

When

working

with

the

fuel

system,

loosen

the

fuel

lines

slowly

toal-

low

residual

fuel

pressure

to

dissipate

gradually

.

Avoid

spraying

fuel

.

"

Fuel

is

highly

flammable

.

When

working

around

fuel,

do

not

disconnect

any

wires

that

could

cause

electrfcal

sparks

.

Do

not

smoke

orwork

near

heaters

or

other

fire

hazards

.

"

Always

unscrew

the

fuel

tank

cap

to

release

pres-

sure

in

the

tank

before

working

on

the

tank

or

lines

.

20

.

Remove

mountingscrews

and

release

wiring

harness

duct

at

rear

bulkhead

and

move

aside

.

Remove

wiring

harness

brackets

frombulkhead

.

CYLINDER

HEAD,

6-CYLINDER

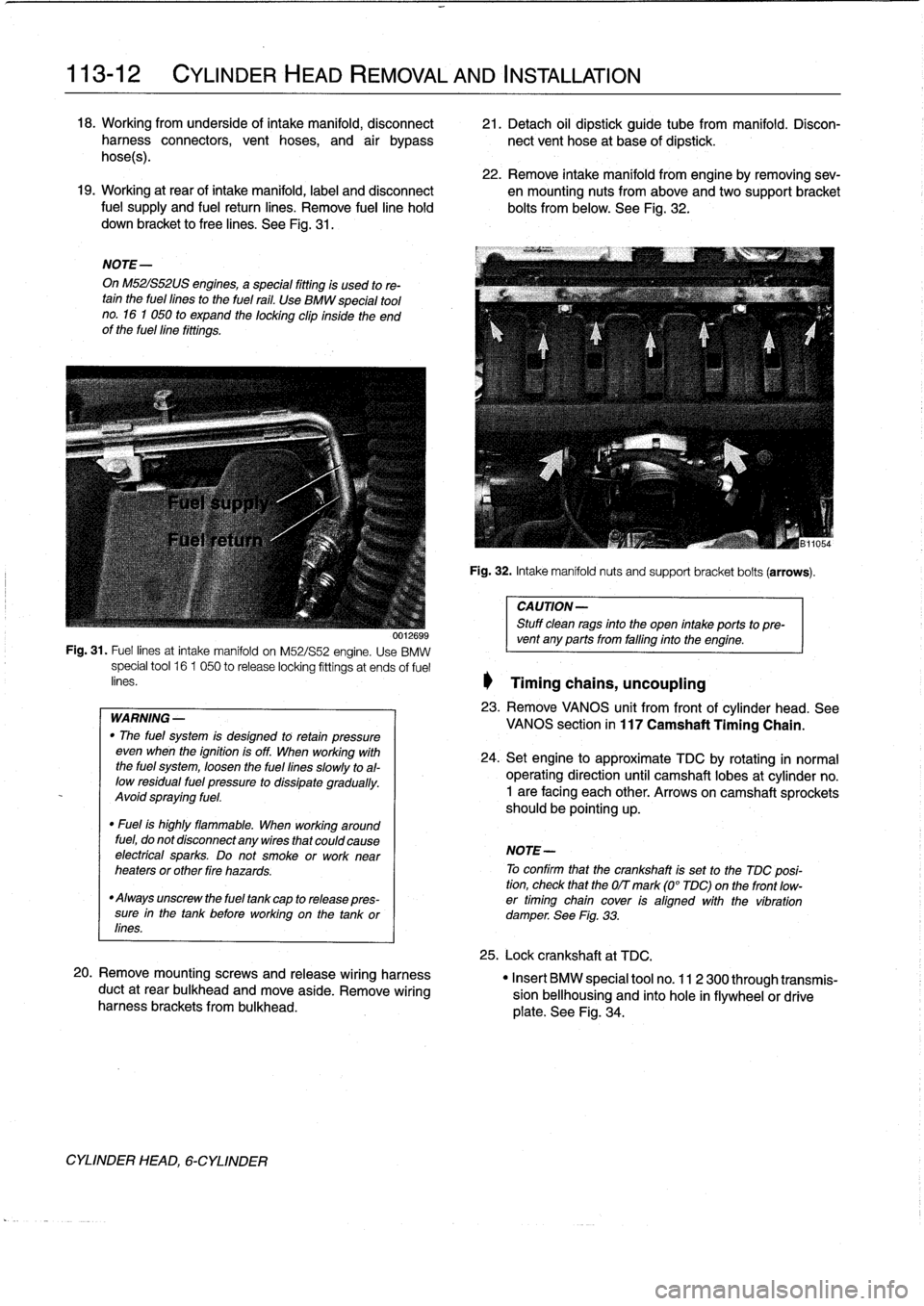

Fig

.

32

.

Intake

manifoldnuts

and

support

bracket

bolts

(arrows)

.

CAUTION-

Stuff

clean

rags

into

the

open

intake

ports

topre-

001269s

vent

any

ports

from

falfing

into

the

engine

.

Fig

.

31

.

Fuel

lines

at

intake

manifold

on

M52/S52

engine

.

Use

BMW

special

tool

16

1

050

to

release

locking

fittings

at

ends

of

fuel

enes

.

1

Timing

chains,

uncoupling

23

.

Remove

VANOS

unit

from

frontof

cylinder

head

.

See

VANOS

section

in

117

Camshaft

Timing

Chain

.

24

.

Setengine

to

approximate

TDC

by

rotating

in

normal

operating

direction

until

camshaft

lobes

at

cylinder

no

.

1

are

facing

each

other

.

Arrows

on

camshaft

sprockets

should

be

pointing

up

.

NOTE-

To

confirm

that

the

crankshaft

is

set

to

the

TDC

posi-

tion,

check

that

the

OIT

mark

(0°

TDC)on

the

front

low-

er

timing

chain

cover

ís

aligned

with

the

víbration

damperSee

Fig

.

33

.

25

.

Lock

crankshaft

at

TDC

.

"

Insert

BMW

special

tool

no

.

11

2

300

through

transmis-

sion

bellhousing

and

finto

hole

in

flywheelor

drive

plate

.

See

Fig

.

34

.

Page 152 of 759

130-

6

FUEL

INJECTION

Warnings

and

Cautions

For

personal

safety,

as

well

as

the

protection

of

sensitive

electronic

components,

the

following

warnings

and

cautions

should

be

adhered

to

when

working

on

the

engine

manage-

ment

system

.

GENERAL

WARNING

-

"

The

ignition

system

produces

high

voltages

that

can

be

fatal

.

Avoid

contact

with

exposed

termi-

nals

.

Use

extreme

caution

when

working

onacar

with

the

ignition

switched

on

or

the

engine

run-

ning

.

"

Do

not

touch

or

disconnect

any

high

voltage

ca-

bles

from

the

coils

or

spark

plugs

while

the

engine

is

running

or

beingcranked

by

the

starter

.

"

Connect

and

disconnect

the

DME

system

wiring

and

test

equipment

leads

only

when

the

ignition

is

switched

off

.

"

Gasoline

is

highly

flammable

and

fts

vaporsare

explosive

.

Do

not

smoke

or

work

on

a

car

near

heaters

or

other

fire

hazards

when

diagnosing

and

repalring

fuel

system

problems

.

Have

a

tire

extinguisher

avaílable

in

case

of

an

emergency

.

"

When

working

onan

open

fuel

system,

wear

suit-

able

hand

protection,

asprolonged

contact

wfth

fuel

can

cause

illnesses

and

skin

disorders

.

"

Renew

fuel

system

hoses,

clamps

and

O-rings

any

timethey

are

removed

.

"

Before

makingany

electrical

tests

that

require

the

engine

to

be

cranked

using

the

starter,

disable

the

ignition

system

as

described

in

120

Ignition

System

.

CAUTION-

"

Prior

to

disconnecting

the

battery,

read

the

bat-

tery

disconnectinn

cautions

given

at

the

front

of

this

manual

onpage

vifi

.

"

Do

not

connect

any

test

equipment

that

delivers

a

12-volt

power

supply

to

terminal

15

(+)

of

the

ig-

nitioncoil

.

The

current

flow

may

damage

the

ECM

.

In

general,

connect

test

equipment

only

as

speclfied

by

BMW,

this

manual,

or

the

equipment

maker

.

"

Only

use

a

digital

multlmeter

for

electrical

test

.

"

Only

use

an

LED

test

light

for

quick

tests

.

"

Disconnecting

the

battery

may

erase

fault

code(s)

stored

in

memory

.

Check

for

fault

codes

prior

to

disconnecting

the

battery

cables

.

ff

the

Check

Engine

light

ís

illuminated,

see100En-

gine-General

for

DME

fault

code

information

.

ff

any

other

system

faults

have

been

detected

(indi-

catedbyan

illuminated

warning

light),

see

an

au-

thorized

BMW

dealer

.

Additional

systems

with

self-diagnostic

capabilities

include,

ABS

(Anti-

lock

brakes),

SRS

(Airbags),

EML

and

ASC+T

and

AST

(Traction

Control)

.

"

Do

not

run

the

engine

wfth

any

of

the

spark

plug

wires

dlsconnected

.

Catalytic

converter

damage

may

result

.

"

Always

waitat

least

40

seconds

afterturning

off

the

ignition

before

removing

the

engine

control

module

(ECM)

connector

.

ff

the

connector

isre-

moved

before

this

time,

residual

power

in

the

sys-

tem

relay

may

damage

the

control

module

.

"

Cleanliness

is

essential

when

working

onan

open

fuel

system

.

Thoroughly

clean

fuel

line

con-

nections

and

surroundlng

areas

before

loosen-

ing

.

Avoid

moving

the

car

.

Only

fnstall

cleanparts

.

"

Fuel

system

cleaners

and

other

chemical

addi-

tives

other

than

those

specifically

recommended

by

BMW

may

damage

the

catalytic

converter,

the

oxygensensor

or

other

fuel

supply

components

.

Page 154 of 759

130-

8

FUEL

INJECTION

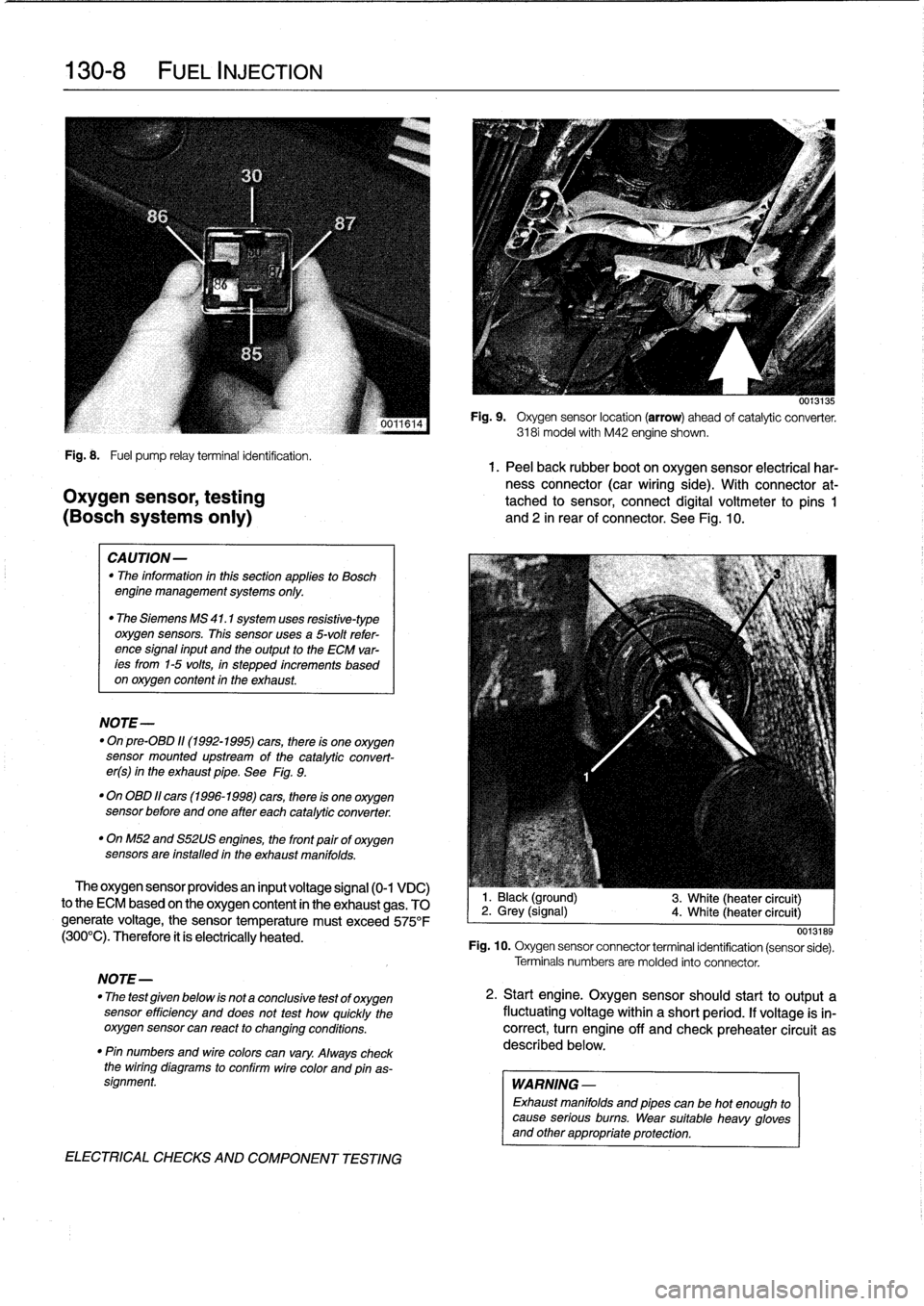

Fig

.

8

.

Fuel

pump

relayterminal

identification

.

1.

Peel

back

rubber

boot

on

oxygen

sensor

electrical

har-

ness

connector

(car

wiring

side)

.

With

connector

at-

Oxygen

sensor,

testing

tached

to

sensor,

connect

digital

voltmeter

to

pins

1

(BOSch

systems

only)

and

2

in

rear

of

connector

.

See

Fig

.

10

.

CAUTION-

"

The

information

inthis

sectionapplies

to

Bosch

engine

management

systems

only

.

"

The

Siemens

MS

41

.1

system

uses

resistive-type

oxygen

sensors

.

This

sensor

uses

a

5-volt

refer-

ence

signal

input

and

the

output

to

the

ECM

var-

ees

from

1-5

volts,

in

stepped

increments

based

on

oxygen

content

in

the

exhaust

.

NOTE-

"

On

pre-08D

11(1992-1995)

cars,

there

is

one

oxygen

sensor

mounted

upstream

of

the

catalytic

convert-

er(s)

in

the

exhaust

pipe

.

See

Fig

.

9

.

"

On

OBD

11

cars

(1996-1998)

cars,

there

is

one

oxygen

sensor

before

andone

after

each

catalytic

converter

.

"

OnM52

and

S52US

engines,

the

front

pairof

oxygen

sensors

are

installed

in

the

exhaust

manifolds

.

The

oxygen

sensor

providesan

input

voltage

signal

(0-1

VDC)

to

the

ECM

based

on

the

oxygen

content

in

the

exhaust

gas

.

TO

generate

voltage,

the

sensor

temperature

must

exceed

575°F

(300°C)

.

Therefore

it

ís

electrically

heated

.

NOTE-

"

The

test

given

below

is

not

a

conclusive

test

of

oxygen

sensor

efficiency

and

does

not

test

how

quickly

the

oxygensensor

can

react

to

changing

conditions

.

"

Pin

numbers

and

wirecolors

can

vary

.

Always

check

the

wiring

diagrams

to

conflrm

wire

color

and

pinas-

signment

.

ELECTRICAL

CHECKS

AND

COMPONENT

TESTING

0013135

Fig

.

9

.

Oxygen

sensor

location

(arrow)

ahead

of

catalytic

converter

.

3181

model

with

M42

engine

shown

.

1

.

Black

(ground)

2

.

Grey

(signal)

4

.

White

(heater

circuit)

3

.

White

(heater

circuit)

0013189

Fig

.

10

.

Oxygen

sensor

connector

terminal

identification

(sensor

sede)

.

Terminals

numbers

are

molded

into

connector

.

2

.

Start

engine

.

Oxygen

sensorshould

start

to

output

a

fluctuating

voltage

within

a

short

period

.

If

voltage

is

in-

correct,

turn

engine

off

and

check

preheater

circuit

as

described

below

.

WARNING

-

Exhaust

manifolds

and

pipes

can

be

hot

enough

to

cause

serious

burns

.

Wear

suitable

heavy

gloves

and

other

appropriate

protection

.

Page 155 of 759

Oxygen

Sensor

FUEL

DELIVERY

TESTS

FUEL

INJECTION

130-

9

"

Voltage

at

¡dle

..

.

..

..

....

0

.2

to

0

.8

VDC,

fluctuating

Checking

fuel

delivery

is

afundamental

part

of

trouble-

shooting

and

diagnosing

the

engine

management

system

.

Fuel

pressure

directly

influences

fuel

delivery

.

An

accurate

NOTE-

fuel

pressure

gauge

will

be

needed

to

make

the

tests

.

To

check

sensorresponse

to

lean

and

rich

mixtures,

createenairleak,

orpull

vacuumhoseofffue¡

pressure

There

are

three

significant

fuel

delivery

values

to

be

mea-

regulator

to

increase

fuel

pressure

.

sured

:

3

.

Separate

sensorharness

connector

from

sensor

.

Check

for

battery

voltage

between

terminals

3

and

4

(green

wire

and

brown

wire)

in

main

wiring

harness

side

of

con-

nector

with

engine

running

.

If

voltage

is

not

present,

check

oxygen

sensor

heater

relay

.

See610

Electrical

Component

Locations

.

4

.

Check

heater

element

resistance

between

terminals

3

and

4

in

sensor

side

of

connector

.

If

element

is

electri-

cally

open

(no

continuity),

replace

sensor

.

NOTE-

The

oxygen

sensor

heater

relay

is

mounted

in

the

main

power

distributfon

box

in

the

left

rear

of

the

engine

com-

partment

.

Refer

to

Fig

.

6

.

The

heater

relay

is

energized

wíth

positive

(+)

battery

voltage

from

the

main

relayanda

switched

ground

from

the

ECM

.

See

Electrical

Wir-

ing

Diagrams

.

"

Oxygen

sensor

to

exhaust

pipe

...

..

55

Nm

(41

ft-Ib)

"

System

pressure-created

by

the

fuel

pump

and

main-

tained

by

the

pressure

regulator

.

"

Fuel

delivery

volume-created

by

the

fuel

pump

and

af-

fected

by

restrictions,

suchasclogged

fuel

filter

.

"

Residual

pressure-the

pressure

maintained

in

the

closed

system

after

the

engine

and

fuel

pump

are

shut

off

.

Procedures

for

measuring

the

first

two

quantities

arede-

scribed

in

160

Fuel

Tank

and

Fuel

Pump

.

Residual

fuel

pres-

sure

is

checked

using

the

procedure

detailed

later

in

this

group

.

Operating

fuel

pump

fortests

To

operate

the

fuel

pump

for

testing

purposes

without

hav-

íng

to

runthe

engine,

the

fuel

pump

relay

can

be

bypassed

to

power

the

pump

directly

.

Fuel

pump

relay

location

is

shown

in

Fig

.

6

.

5

.

¡f

oxygen

sensor

doesn't

produce

a

fluctuating

voltage

To

runthe

fuel

pump,

remove

the

fuel

pump

relay

and

con-

and

preheater

circuit

is

OK,

replace

sensor

.

nect

the

socket

for

relayterminal

30

to

the

socket

for

relay

ter-

mina¡

87

with

a

fused

jumper

wire

.

After

completing

the

tests,

NOTE-

remove

the

jumper

wire

.

If

not

already

applied,

coat

the

oxygen

sensor

threads

with

an

anti-seize

compound

before

installation

.

Do

not

CAUTION-

getthe

compound

on

the

sensor

tip

.

"

Relay

locations

may

vary

.

Use

care

when

identi-

fying

relays

and

making

electrical

checks

at

the

fuselrelay

panel

.

See

610

Electrical

Compo

Tightening

Torque

nent

Locations

for

additional

relay

information

.

"

The

fuel

pump

relay

has

a

1

.5

mm2

red

wire

at

ter-

minal

30

in

the

relay

socket

.

Terminal

87

has

a

1

.5

mm

2

greenlviolet

wire

.

See

Electrical

Wiring

Di-

agrams

for

additional

wiring

information

.

NOTE-

Thejumper

wire

should

be

1.5

mm2

(14

ga

.)

and

in-

clude

an

in-line

tuse

holder

with

a15

amp

tuse

.

To

avoid

fuselrelay

panel

damage

from

repeated

connect-

ing

and

disconnecting,

also

include

a

toggle

switch

.

A

heavy-duty

jumper,

BMW

tool

no

.

61

3

050,

is

also

available

from

an

authorized

BMW

dealer

.

FUEL

DELIVERYTESTS

Page 156 of 759

130-

1

0

FUEL

INJECTION

Relleving

fuel

pressure

and

connecting

fuel

pressure

gauge

WARNING

-

"

Gasoline

is

highly

flammable

and

its

vaporsare

explosive

.

Do

not

smoke

orwork

on

acarnear

heaters

or

other

fire

hazards

when

diagnosing

and

repairing

fuel

system

problems

.

Have

a

fire

extinguisher

available

in

case

of

an

emergency

.

"

When

working

onanopen

fuel

system,

wear

suit-

able

hand

protection

.

Prolonged

contact

with

fuel

can

cause

illnesses

and

skin

disorders

.

To

prevent

fuel

from

spraying

on

a

hot

engine,

system

fuel

pressure

should

be

relieved

before

disconnecting

fuel

lines

.

One

method

is

to

tightly

wrap

a

shop

towel

around

a

fuelline

fit-

ting

and

loosenor

disconnect

the

fitting

.

Cleanliness

is

essential

when

working

with

fuelcircuit

com-

ponents

.

Thoroughly

clean

theunionsbefore

disconnecting

fuellines

.

NOTE-

"

OnM44

engines,

a

Schrmder

valve

is

integrated

in

the

fuel

rail

.

Compressed

air

pressure

canbe

applied

at

the

valve

to

force

the

fuel

in

the

system

back

into

the

tank

.

See

Fig

.

11

.

0012503

Fig

.

11

.

Fuel

rail

showing

location

of

Schraeder

valve

fitting

on

M44

engine

(arrow)

.

NOTE-

B~

specifies

a

special

gauge

and

special

connecting

adapters

to

measure

fuel

pressure

.

If

the

special

tools

arenot

available,

a

length

of

fuel

fine

and

a

T-fitting

canbe

installed

to

the

inlet

fuel

fine

and

connected

to

a

fuel

gauge

.

On

some

vehicles,

thisis

not

possible

without

cutting

finto

a

fuel

lino

.

In

these

lnstances,

it

Is

recom-

mended

that

fuel

pressure

be

checked

at

theoutput

sidoof

the

fuel

pump

.

See

160

Fuel

Tankand

Fuel

Pump

.

FUELDELIVERY

TESTS

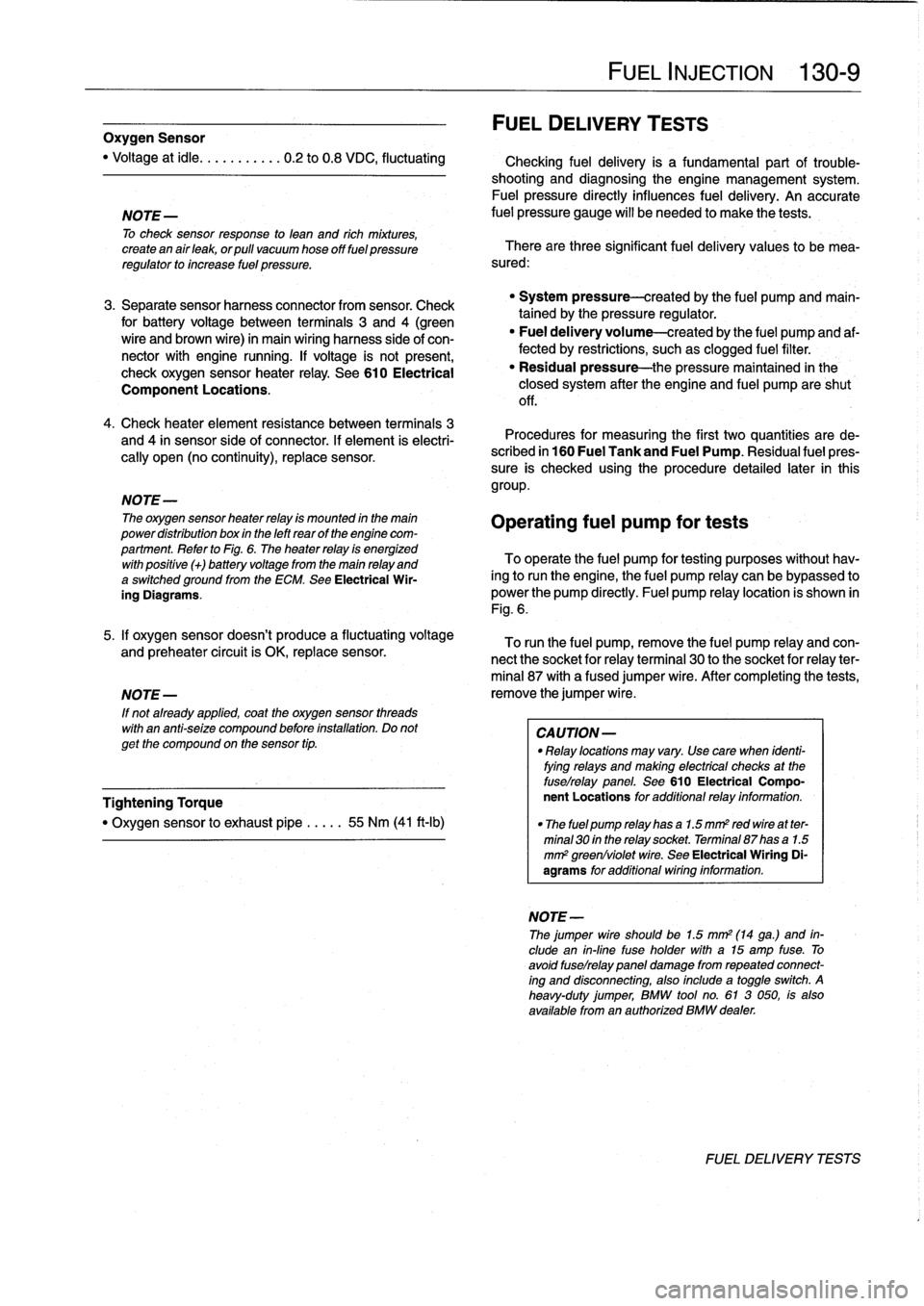

On

OBD

II

6-cylinder

engines,

the

fuel

lines

use

a

special

locking

fitting

.

Use

BMW

special

tool

16

1

050

to

release

the

fittings

and

connect

the

fuel

gauge

.

See

Fig

.

12

.

0012699

Fig

.

12

.

Fuel

linos

at

rear

of

intake

manifold

on

M52

engine

.

Use

BMW

special

tool

16

1

050

torelease

fittings

.

WARNING

-

"

Gasoline

is

highly

flammable

and

its

vapors

are

explosive

.

"

The

fuel

pressure

gauge

must

be

securely

con-nected

to

prevent

it

from

coming

loose

under

pressure

.

NOTE-

"

The

fuel

pressure

gauge

should

have

arangoof

0

to

5

bar

(0

to

75

psi)

.

"

On

6-cylinder

engine,

thetop

left-sido

engine

cover

will

have

to

be

removed

to

access

the

fuel

rail

.

Residual

fuel

pressure,

testing

For

quick

restarts

and

to

avoid

vapor

lock

when

the

engine

is

hot,

the

fuel

injection

system

is

designed

to

retain

fuel

pres-

sure

after

the

engine

has

been

turned

off

.

Thís

residualpres-

sure

is

primarily

maíntained

by

a

check

valve

at

the

fuel

pump

outiet

and

the

fuel

pressure

regulator

.

The

fuel

pump

check

valve

is

not

serviceable

asan

individual

part

.

1.

Relieve

fuel

pressure

and

connect

a

pressure

gauge

as

described

earlier

.

WARNING

-

Fuel

will

be

discharged

.

Wrap

a

shop

towel

around

the

fuellino

fitting

when

disconnecting

the

fuel

fine

.

Do

not

smoke

or

worknear

heaters

or

other

fire

hazards

.

Keep

an

approved

fire

extinguisher

handy

.

2

.

Operate

fuel

pump

for

approximately

one

minuto

by

by-

passing

fuel

pump

relay

as

described

earlier

.

Observe

fuel

pressure

.

Page 158 of 759

130-

1

2

FUEL

INJECTION

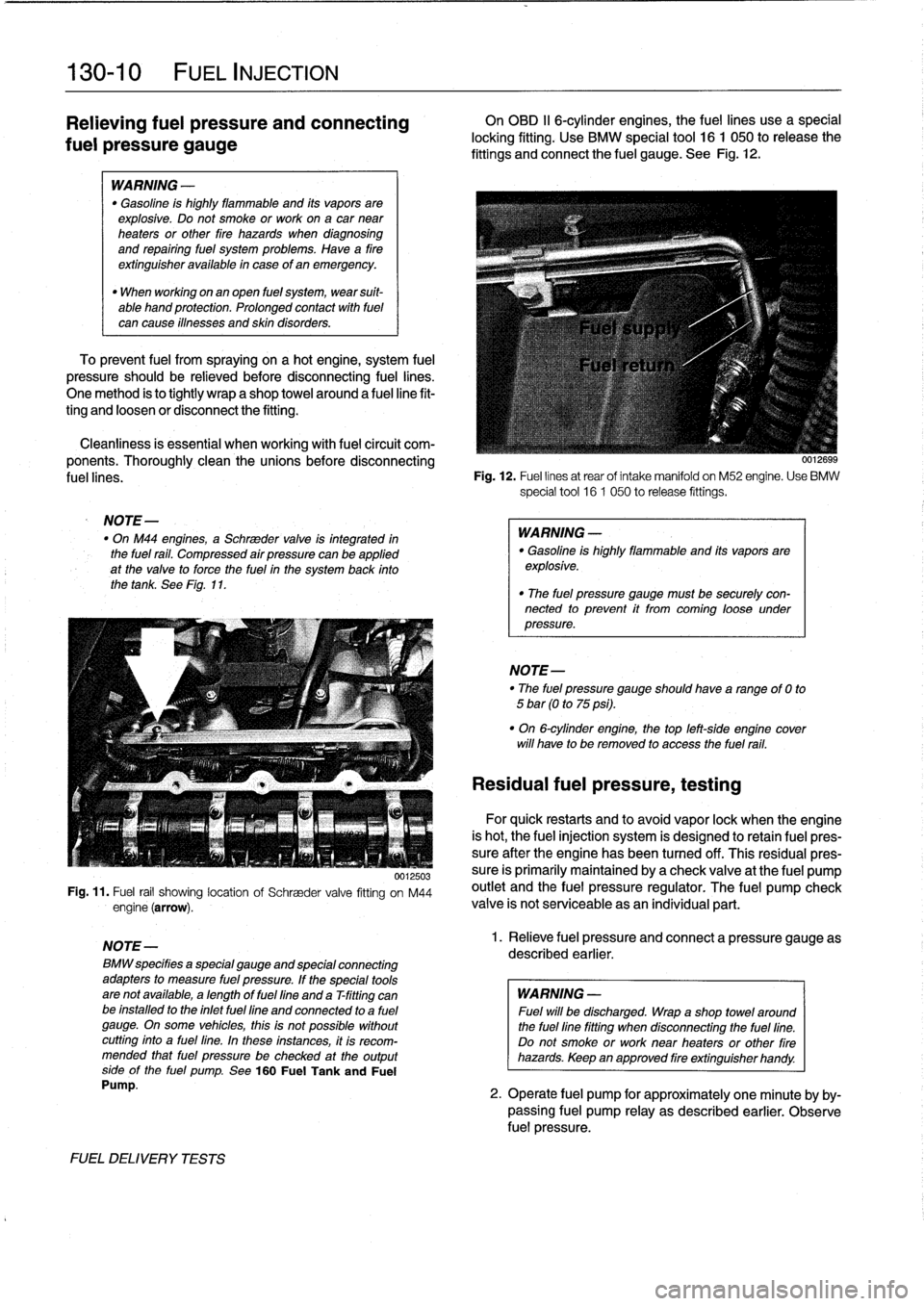

Fig

.

14

.

Voitmeter

connected

across

fuel

injector

connector

with

en-

gine

running

.

M50

engine

shown

.

2

.

If

no

signal

is

present,

check

for

b+

power

to

injectors

.

There

should

be

battery

voltage

(+)

at

red/whitewire

of

each

injector

connector

with

the

ignition

key

on

.

If

volt-

age

is

not

present,

check

main

relay

output

.

Injector

b+

power

comes

from

main

relay

(terminal

87)

.

NOTE-

If

there

is

positive

(+)

batteryvoltage

at

injectors

but

there

was

no

pulsedresponse

at

voltmeter,

check

the

wire(s)

from

the

ECM

to

the

injectors

.

If

no

wiring

faults

can

be

found,

the

pulsed

ground

signal

from

the

control

module

may

be

missing

.

Check

the

outputs

from

the

ECM

.

Fuel

rail

and

injectors,

replacing

1

.

Disconnect

negative

(-)

battery

cable

.

CAUTION-

Prior

to

disconnectiog

the

battery,

read

the

battery

disconnection

cautions

given

at

the

tront

of

this

manual

on

page

viii

.

2

.

M42

and

M50/S50US

engines

:

Working

at

end

offuel

rail,

disconnect

small

vacuum

hose

from

fuel

pressure

regulator

.

3

.

M50/S50US

engines

:

Remove

two

nuts

from

injector

duct

.

Carefully

pry

injector

wiring

duct

off

ínjectors

.

See

Fig

.

15

.

4

.

On

4-cylinder

cars,

remove

upper

intake

manifold

to

ac-

cess

the

fuel-rail

and

injectors

.

See

113

Cylinder

Head

Removal

and

Installation

.

FUELDELIVERYTESTS

Fig

.

15

.

Injector

wiring

harness

duct

being

removed

from

M50

engine

.

NOTE

-

Late-model

M42

and

all

M44

fuel

injectors

are

afr-

shrouded

.

See

Fig

.

16

.

When

removing

the

fuel

rail

it

is

necessary

to

remove

the

air

shroud

feeder

hose

from

the

intake

manifold

ducting

.

Fig

.

16

.

Cutaway

view

of

fuelinjector

usedon

M42

or

M44

engine

.

5

.

Disconnect

fuel

supply

line

and

fuel

retum

line

from

fuel

rail

ends

.

WARNING

-

"

Clamp

off

the

fuel

lines

and

then

wrapa

clean

shop

towei

around

the

lines

before

removing

them

.

Residual

fuel

pressure

is

present

in

the

lines

.

"

Fuel

will

be

discharged

.

Do

not

disconnect

any

wires

that

could

cause

electrical

sparks

.

Do

not

smoke

or

worknear

heaters

or

other

fire

hazards

.

Keepan

approved

fire

extinguisher

handy

.

Page 159 of 759

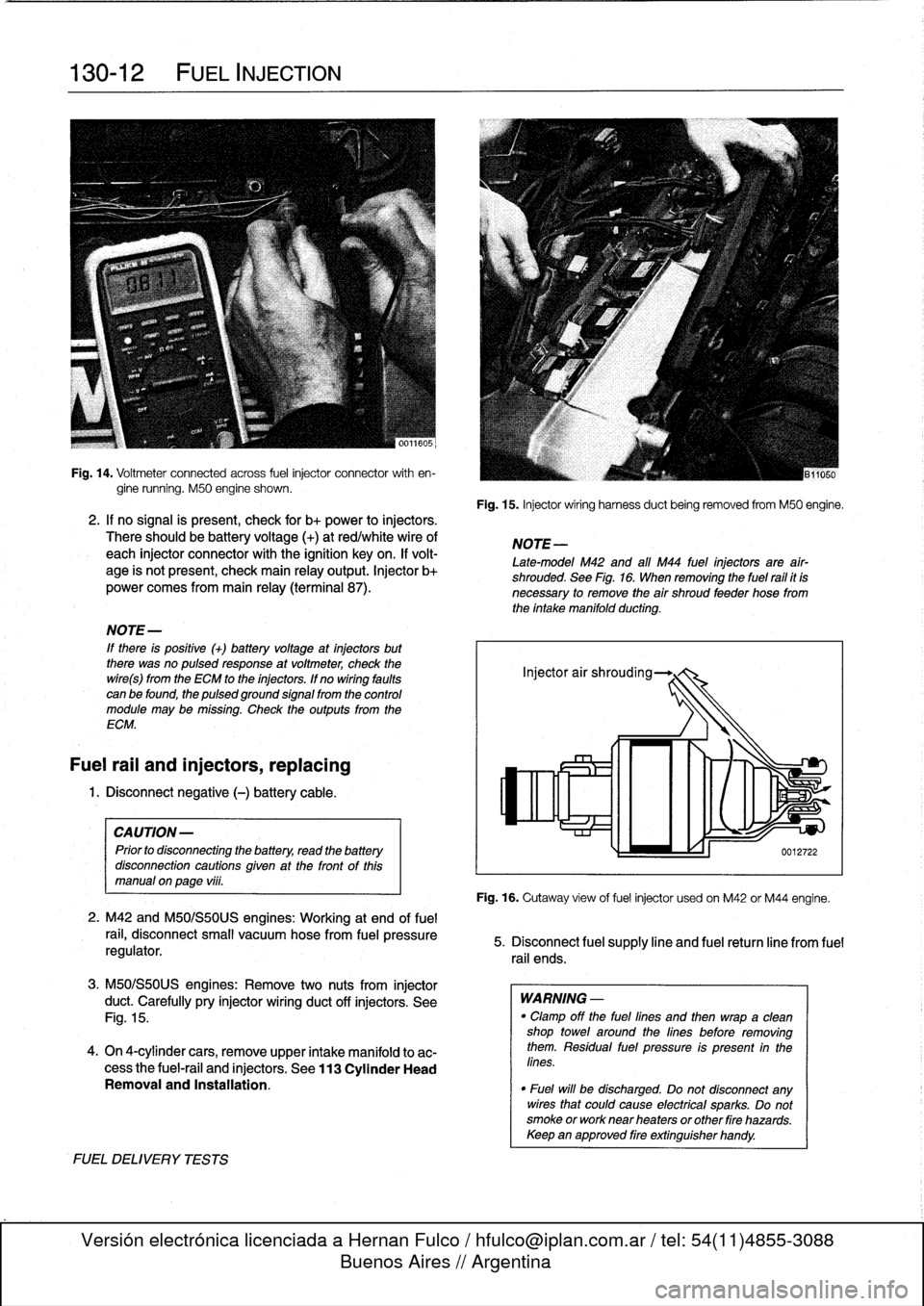

6

.

Remove

fuel

rail

mounting

bolts

.

See

Fig

.

17

.

0012504

Fig

.

17

.

Location

of

fuel

rail

mounting

bolts

(A)

and

fuel

inlet

and

return

lines

(B)

on

M44

engine

.

Upper

manifold

has

been

removed

.

7

.

Pull

upon

fuel

rail

and

remove

injector

rail

with

injec-tors

.

Remove

individualinjectors

by

removing

injector

retaining

clip

and

pullinginjector

from

rail

.

See

Fig

.

18

.

Fig

.

18

.

Pry

retaining

clip

from

injector

(1),

then

pull

injector

from

rail

(2)

.

8

.

Installation

is

reverse

of

removal

.

Tightening

Torque

"

Fuel

rail

to

cylinder

head

..

.

..

..

...

10

Nm

(89

in-lb)

FUEL

INJECTION

130-

1

3

Fuel

Pressure

Regulator

The

fuel

pressure

regulator

location

on

E36

models

is

mounted

in

one

of

two

locations

:

Fuel

Pressure

Regulator

Location

"

4-cylinder

engines

1992-

January

1997

............

...

..

on

fuel

rail

January

1997-

on

...............

..

...

under

car

"

6-cylinderengines

1992-1995

.

.

...

...

.

...........

...

..

on

fuel

rail

1996-on

..

.

..

................

...

...

undercar

Fuel

pressure

regulator,

replacing

(fuel

rail

mount)

WARNING

-

Fuel

will

be

discharged

.

Do

not

disconnect

any

wires

that

could

cause

electrícal

sparks

.

Do

not

smoke

or

work

near

heaters

or

other

fire

hazards

.

Keepan

approved

fire

extinguisher

handy

.

9

.

On

6-cylinder

engines,

remove

top

engine

covers

.

Re-

move

fuel

rail

mounting

bolts

and

lift

up

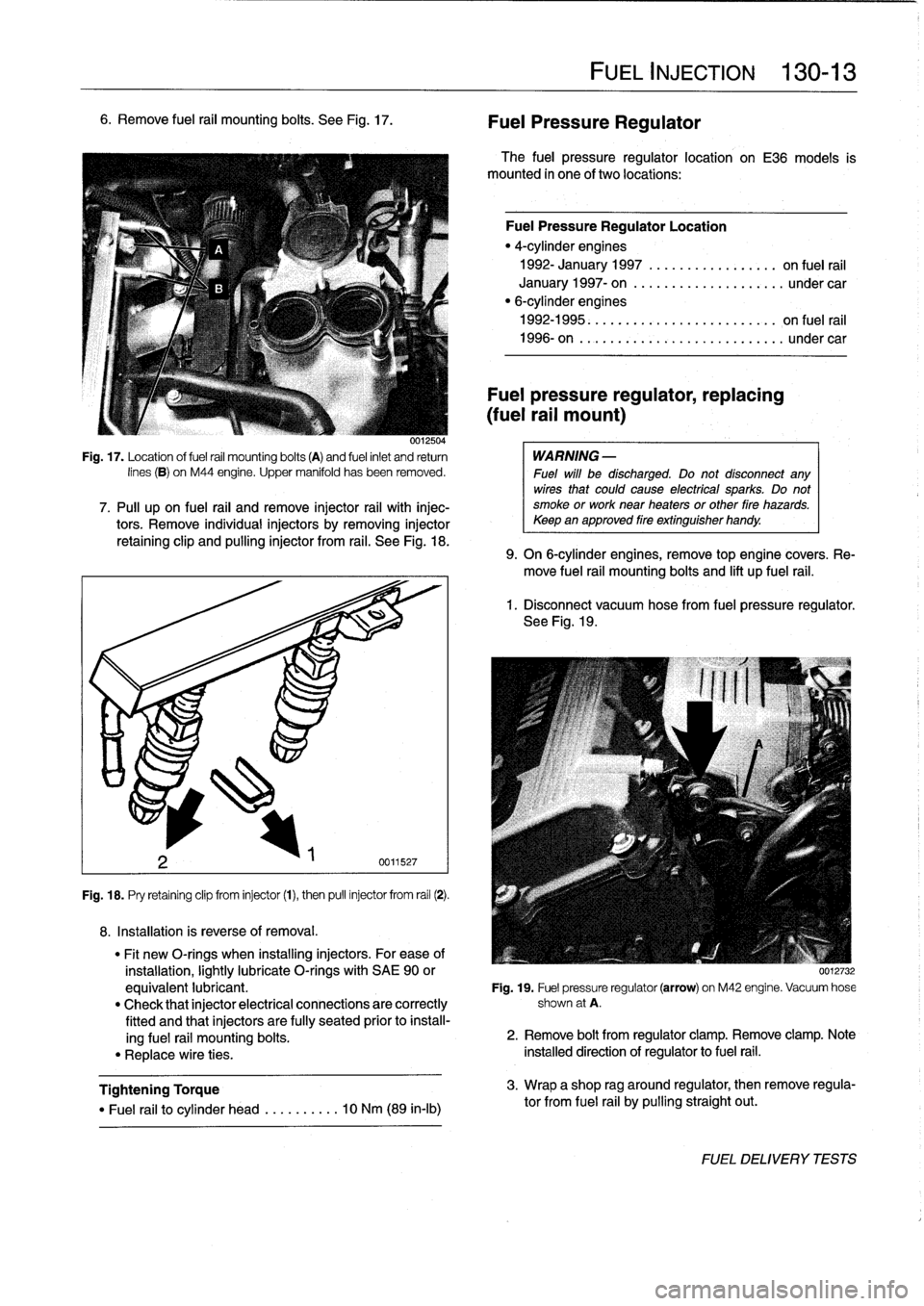

fuel

rail

.

1

.

Disconnect

vacuum

hose

from

fuel

pressure

regulator

.

See

Fig

.

19

.

"

Fit

new

O-rings

when

installing

injectors

.

For

ease

of

installation,

lightly

lubricate

O-rings

with

SAE

90

or

0012732

equivalent

lubricant

.

Fig

.

19

.

Fuel

pressure

regulator

(arrow)

on

M42

engine

.

Vacuum

hose

"

Check

that

injector

electrical

connections

are

correctly

shown

at

A

.

fitted

and

that

injectors

are

fully

seated

prior

to

install-

ing

fuel

rail

mounting

bolts

.

2

.

Remove

bolt

from

regulator

clamp

.

Remove

clamp

.

Note

"

Replace

wire

ties

.

installed

direction

of

regulator

to

fuel

rail

.

3

.

Wrap

a

shop

rag

around

regulator,

then

remove

regula-

tor

from

fuel

rail

by

pulling

straight

out

.

FUELDELIVERYTESTS

Page 160 of 759

130-

1

4

FUEL

INJECTION

NOTE-

Be

sure

to

retrieve

thrust

washer

behind

fuel

pressure

regulator

on

6-cylinder

engine

.

4

.

Installation

is

reverse

of

removal

.

Replace

O-rings

.

Fuel

pressure

regulator,

replacing

(under

car

mount)

WARNING

-

Fuel

will

be

discharged

.

Do

not

disconnect

any

wires

that

could

cause

electrical

sparks

.

Do

not

smoke

or

work

near

heaters

or

other

fire

hazards

.

Keep

an

approved

tire

extinguisher

handy

.

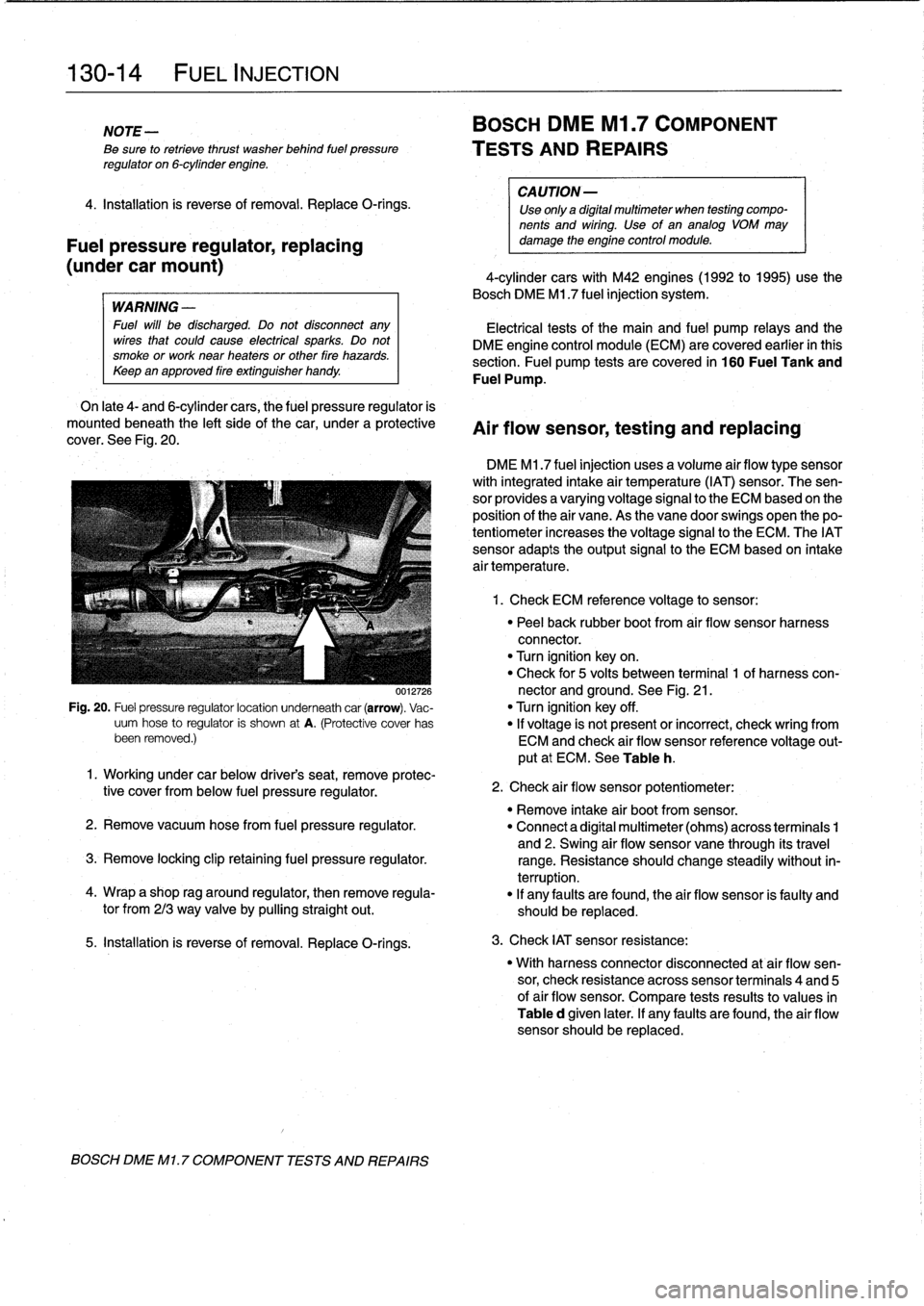

On

late

4-

and

6-cylinder

cars,

the

fuel

pressure

regulator

is

mounted

beneath

the

left

sideof

the

car,

under

a

protective

cover

.

See

Fig

.

20

.

0012726

Fig

.

20

.

Fuel

pressure

regulatorlocation

underneath

car

(arrow)

.

Vac-

uum

hose

to

regulator

is

shown

at

A

.

(Protective

cover

has

been

removed

.)

5

.

Installation

is

reverse

of

removal

.

Replace

O-rings

.

BOSCH

DME

Ml

.

7

COMPONENT

TESTS

AND

REPAIRS

BOSCH

DME

Ml

.7

COMPONENT

TESTS

AND

REPAIRS

CA

UTION-

Use

only

a

digital

multimeter

when

testing

compo-

nents

and

wiring

.

Use

of

an

analog

VOM

may

damage

the

engine

control

module

.

4-cylinder

cars

with

M42

engines(1992

to

1995)use

the

Bosch

DME

M1

.7

fuel

injection

system

.

Electrical

tests

of

the

main

and

fuel

pump

relays

and

the

DME

engine

control

module

(ECM)

are

covered

earlier

in

this

section

.

Fuel

pump

tests

arecovered

in

160

Fuel

Tank

and

Fuel

Pump

.

Air

flow

sensor,

testing

and

replacing

DME

M1

.7

fuel

injection

uses

a

volume

air

flow

type

sensor

with

integrated

intake

air

temperature

(IAT)

sensor

.

The

sen-

sor

provides

a

varyingvoltage

signal

to

the

ECM

based

on

the

position

of

the

air

vane

.

As

the

vane

doorswings

open

thepo-

tentiometer

increases

the

voltage

signal

to

the

ECM

.

The

IATsensor

adapts

theoutput

signal

to

the

ECM

based

on

intake

air

temperature

.

1

.

Check

ECM

reference

voltage

to

sensor

:

"

Peel

back

rubber

boot

from

air

flow

sensor

harness

connector

.

"

Turn

ignition

keyon

.

"

Check

for

5

volts

between

terminal

1

of

harness

con-

nector

and

ground

.

See

Fig

.

21

.

"

Turn

ignition

key

off

.

"

If

voltage

is

not

present

or

incorrect,

check

wring

from

ECM

and

check

air

flow

sensor

reference

voltage

out-

put

at

ECM

.

See

Table

h

.

1

.

Working

under

car

below

driver's

seat,

remove

protec-

tive

cover

from

below

fuel

pressure

regulator

.

"

Remove

intake

air

bootfrom

sensor

.

2

.

Remove

vacuum

hosefrom

fuel

pressure

regulator

.

"

Connect

a

digital

multimeter

(ohms)

across

terminais

1

and

2

.

Swing

air

flow

sensor

vane

through

its

travel

3

.

Remove

locking

clip

retaining

fuel

pressure

regulator

.

range

.

Resistance

should

change

steadily

without

in-

terruption

.

4

.

Wrap

a

shop

rag

around

regulator,

then

remove

regula-

"

If

any

faults

are

found,

the

air

flow

sensor

is

faulty

and

tor

from

213

way

valve

by

pullingstraight

out

.

should

be

replaced

.

2

.

Check

air

flow

sensor

potentiometer

:

3

.

Check

IAT

sensor

resistance

:

"

With

harness

connector

disconnected

at

air

flow

sen-

sor,

check

resistance

across

sensor

terminais

4

and

5

of

air

flow

sensor

.

Compare

tests

results

to

values

in

Table

d

given

later

.

If

any

faults

are

found,

the

air

flow

sensor

should

be

replaced

.

Page 174 of 759

130-

2

8

FUEL

INJECTION

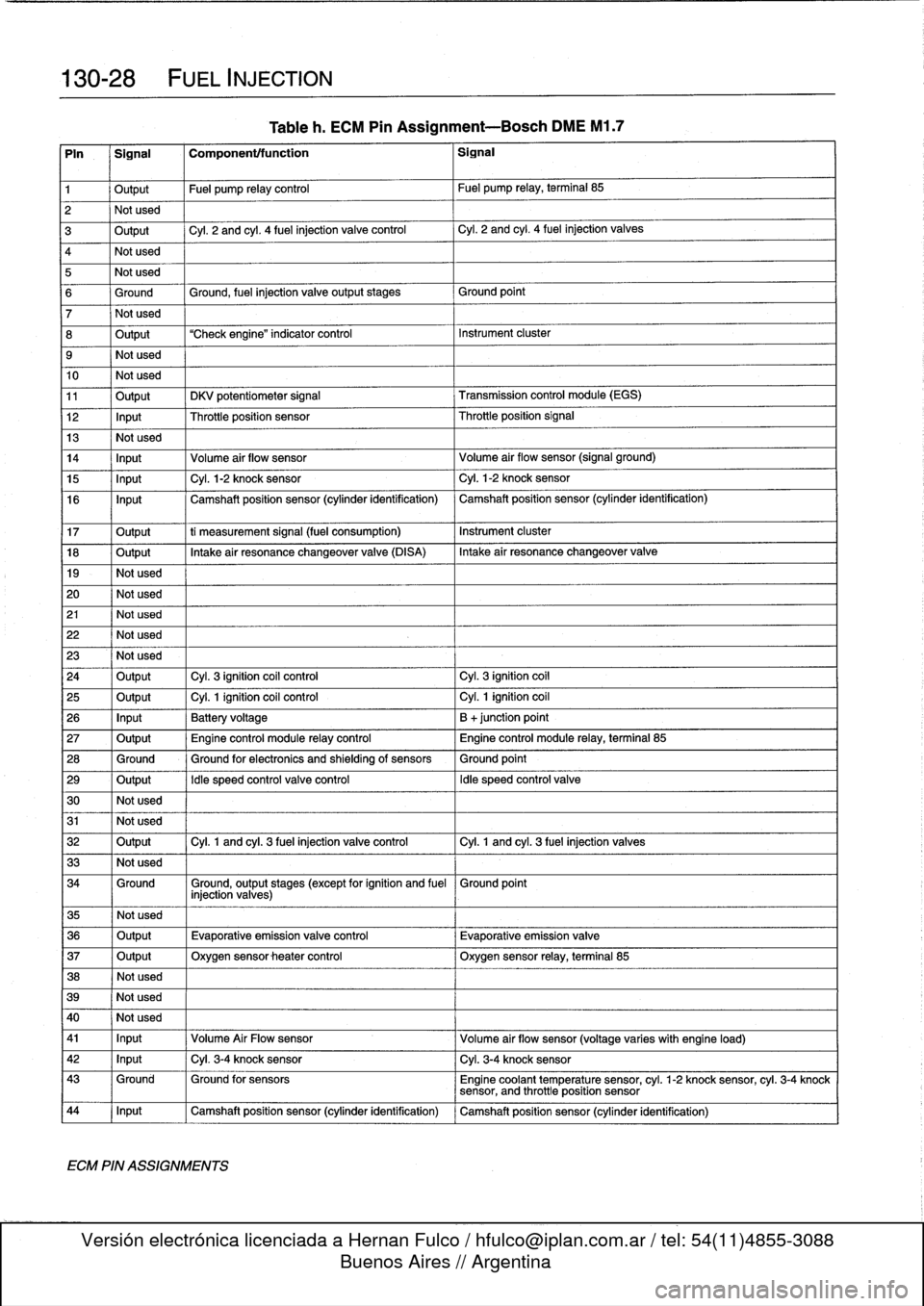

Tableh

.

ECM

Pin

Assignment-Bosch

DME

M1

.7

Pin

Signal

Componenttfunction

Signal

1

Output

Fuel

pump

relay

control

Fuel

pump

relay,

terminal

85

2

Not

used

3

Output

Cyl

.

2

and

cyl

.

4

fuel

injection

valve

control

Cyl

.

2

and

cyl

.

4

fuel

injection

valves

4

Not

used

5

Not

used

6

Ground

Ground,

fuel

injection

valveoutputstages

Ground

point

7

Not

used

8

Output

"Check

engine"

indicator

control

Instrument

cluster

9

Not

used

10

Not

used

11

Output

DKV

potentiometer

signal

Transmission

control

module

(EGS)

12

Input

Throttleposition

sensor

Throttleposition

Signal

13

Not

used

14

Input

Volume

air

flow

sensor

Volume

air

flow

sensor

(signal

ground)

15

Input

Cyl

.

1-2

knock

sensor

Cyl

.

1-2

knock

sensor

16

Input

Camshaft

position

sensor

(cylinder

identification)

Camshaft

position

sensor

(cylinder

identification)

17

Output

ti

measurement

signal

(fuel

consumption)

Instrument

cluster

18

Output

Intakeair

resonance

changeover

valve

(DISA)

Intake

air

resonance

changeover

valve

19

-

Not

used

20

Not

used

21

Not

used

22

Not

used

23

Not

used

24

Output

Cyl

.

3

ignition

coil

control

Cyl

.

3

ignition

coil

25

Output

Cyl

.

1

ignition

coil

control

Cyl

.

1

ignition

coil

26

Input

Battery

voltage

B

+junction

point

27

Output

Engine

control

module

relay

control

Engine

control

module

relay,

terminal

85

28

Ground

Ground

for

electronics

and

shielding

of

sensors

Ground

point

29

Output

Idle

speed

control

valve

control

Idle

speed

control

valve

30

Not

used

31

Not

used

32

Output

Cyl

.

1

and

cyl

.

3

fuel

injection

valve

control

Cyl

.

1

and

cyl

.

3

fuel

injection

valves

33

Not

used

34

Ground

Ground,

output

stages

(except

for

ignition

and

fuel

Ground

point

injection

valves)

35

Not

used

36

Output

Evaporative

emissionvalve

control

Evaporative

emission

valve

37

Output

Oxygen

sensor

heater

control

Oxygen

sensor

relay,

terminal

85

38

Not

used

39

Not

used

40

I

Not

used

41

I

Input

,

Volume

Air

Flow

sensor

Volume

air

flow

sensor

(voltage

varies

with

engine

load)

42

1

Input

1

Cyl

.

3-4

knock

sensor

1

Cyl

.

3-4

knock

sensor

43

Ground

Ground

for

sensors

Engine

coolant

temperature

sensor,

cyl

.

1-2

knock

sensor,

cyl

.

3-4

knock

sensor,

and

throttle

position

sensor

44

1

Input

1

Camshaft

position

sensor

(cylinder

identification)

1

Camshaft

position

sensor

(cylinder

identification)

ECM

PIN

ASSIGNMENTS