ind BMW M3 1993 E36 Workshop Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 1993, Model line: M3, Model: BMW M3 1993 E36Pages: 759

Page 116 of 759

119-2

LUBRICATION

SYSTEM

NOTE-

Component

Location

If

the

light

does

not

go

out,

thewiring

to

theswitch

is"

Oil

pressure

switch

most

likely

grounded

somewhere

between

the

switch

all

engines

.......

...

.

..

......

ora

oil

filter

housing

terminal

and

the

warning

light

.

Sea

Electrical

Wiring

Diagrams

atrearof

manual

for

electrical

schematics

.

CAUTION-

Some

oil

may

drain

out

as

the

oil

pressure

switch

is

removed

.

Use

a

rag

to

soak

up

any

spills

.

2

.

Install

pressure

gauge

in

place

of

switch

.

3

.

With

gauge

instalied,

start

engine

and

allow

to

reach

operating

temperature

.

Check

oil

pressureboth

cold

and

hot

.

NOTE-

For

the

most

accurate

test

results,

the

engine

oil

(and

filter)

shouldbe

newand

of

the

correct

grade

.

Oil

Pressure

"

¡dle

(mínimum)

..

.

.

..............

.

.

0

.5

bar

(7psi)

"

Regulated

pressure

(elevated

engine

speed)

4-cylinder

engines

..

......

4

.3

±

0

.2

bar

(63

t3

psi)

6-cylinder

engines

.

.

.............

.

4

.0

bar

(59

psi)

4

.

Remove

pressure

gauge

and

reinstall

pressure

switch

.

If

testing

shows

low

oil

pressure,

one

or

more

of

the

follow-

ing

conditions

may

be

indicated

:

OIL

PAN

"

Worn

or

faulty

oii

pump

.

"

Worn

or

faulty

engine

bearings

The

oil

pancan

be

removed

with

the

engine

instalied,

al-

Severe

engine

wear

.

though

specíal

enginesupport

equipment

will

be

needed

.

Al¡

of

these

conditionsindicate

the

need

for

major

repairs

.

Oil

pressure

warning

system,

testing

When

the

ignition

is

tumed

ora,

the

oil

pressure

warning

light

comes

ora

.

When

the

engine

ís

started

and

the

oil

pressure

ris-

es

slightly,

the

oil

pressure

switch

opens

and

thewarning

light

goes

out

.

Make

sure

the

oil

leve¡

is

correct

before

making

tests

.

1

.

Turra

ignition

switch

ora

.

"

Warning

light

ora

instrument

panel

must

light

up

.

2

.

Remove

connector

from

oil

pressure

switch

.

"

Warning

light

ora

instrument

panel

must

go

out

.

OIL

PAN

3

.

If

warning

light

does

not

light

when

ignition

is

ora,

re-

move

connector

from

oil

pressure

switch

anduse

a

jumper

wire

to

ground

connector

terminal

to

a

clean

metal

surface

.

NOTE

-

If

the

warning

light

comes

ora,

check

the

switch

as

de-

scríbed

in

the

nextstep

.

If

the

warning

light

does

not

come

ora,

thewiring

to

the

instrument

cluster

or

to

the

light

itself

isfaulty

.

4

.

To

test

switch,

connect

ara

ohmmeter

between

terminal

in

switch

body

and

ground

.

With

engine

off,

these

should

be

continuity

.

With

engine

running,

oil

pressure

should

opera

switch

and

there

should

beno

continuity

Replace

a

faulty

switch

.

WARNING

-

Keep

in

mind

that

low

oil

pressure

may

be

prevent-

ing

the

switch

from

tuming

the

light

out

.

If

the

light

remains

ora

while

the

engine

is

running,

check

the

oil

pressure

asdescribed

earlier

.

Do

not

drive

the

car

until

the

problem

is

corrected

.

Theengine

may

be

severely

damaged

.

Oil

pan,

removing

and

installing

(4-cylinder

engines)

1

.

Raise

car

arad

place

securely

ora

jackstands

.

2

.

Remove

splash

shíeld(s)

from

under

engine,

where

ap-

plicable

.

3

.

Drain

engine

oil

as

described

in

020

Maintenance

Pro-

gram

.

4

.

Disconnect

vacuum

hose

adapter

from

vacuum

brake

booster

at

rear

of

engine

compartment

.

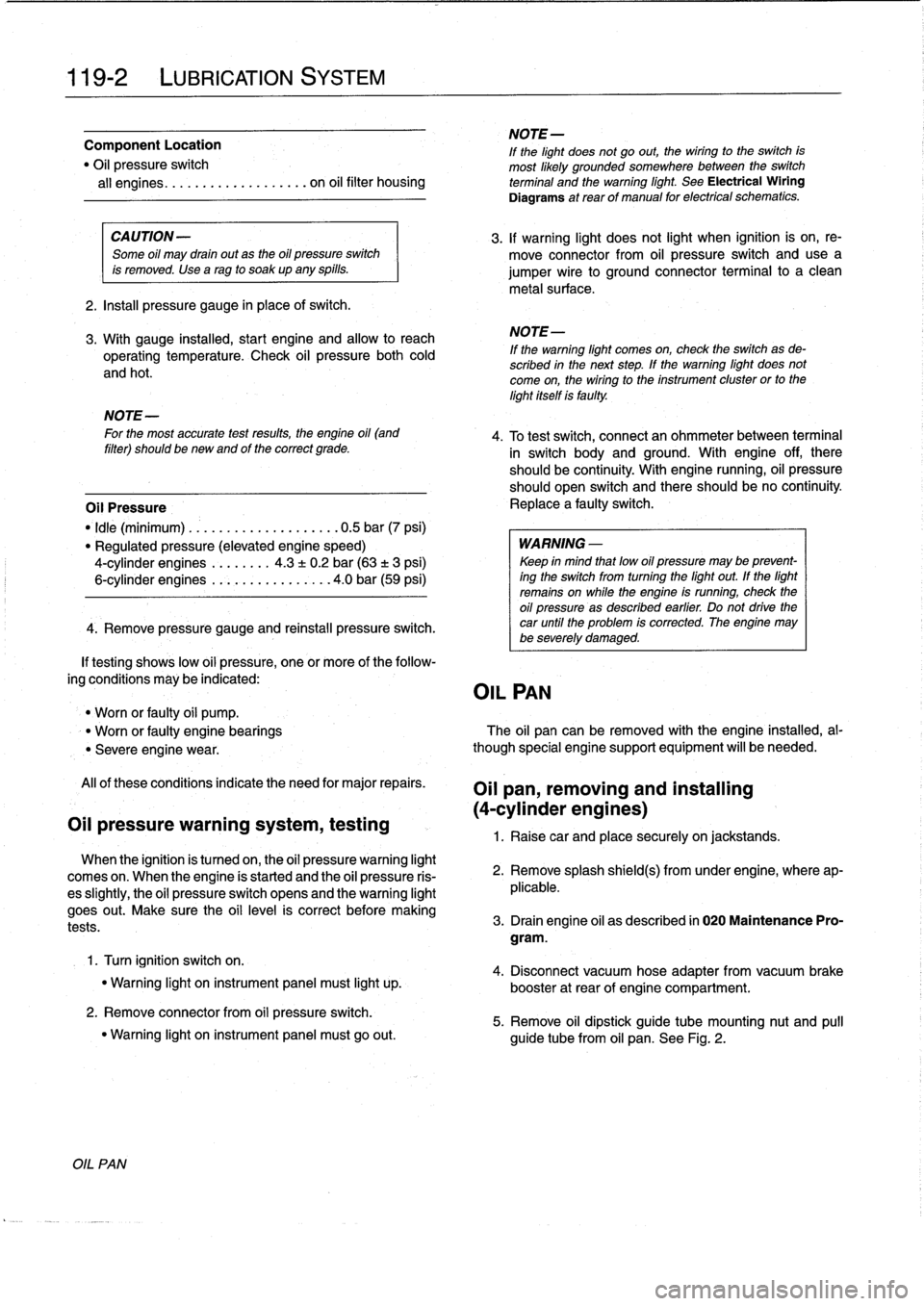

5

.

Remove

oil

dipstick

guide

tube

mounting

nut

and

pull

guide

tube

from

oil

pan

.

See

Fig

.

2

.

Page 117 of 759

NOTE

-

The

guide

tube

is

sealed

in

the

pan

with

an

O-ring

.

Check

that

theO-ring

comes

out

with

the

tube

.

Use

a

new

O-ring

when

installing

the

tube

.

Fig

.

2

.

Oil

dipstick

guide

tube

mounting

nut

(arrow)

on

M44

engine

.

Use

new

O-ring

at

base

of

tube

during

installatidn

.

6

.

Install

engine

lifting

equipment

at

front

engine

lifting

point

and

raise

engine

approximately

5

mm

(

1

/4

inch)

until

engineweight

is

supported

.

7

.

Workingbeneath

car,

separate

steering

column

shaft

from

steeringrack

at

universal

joint

.

"

Point

wheels

straight

ahead

before

disconnecting

shaft

from

rack

.

Mark

steering

column

shaft

joint

to

steering

rackspíndle

.

See

320

Steering

and

Wheel

Align-

ment

.

CAUTION

-

In

order

to

avoíd

the

need

for

front-end

realign-

ment,

do

notunbolt

power

steering

rack

from

sus-

pension

crossmember

.

8

.

Supportsuspension

crossmember

(subframe)

from

be-

low

usingappropriate

jacking

equipment

.

9

.

At

left

and

right

sides,

unbolt

control

arm

bushing

carri-

ers

from

body

.

Disconnect

stabilizer

bar

links

fromcon-

trol

arms

.

See

Fig

.

3

.

LUBRICATION

SYSTEM

119-

3

0011960

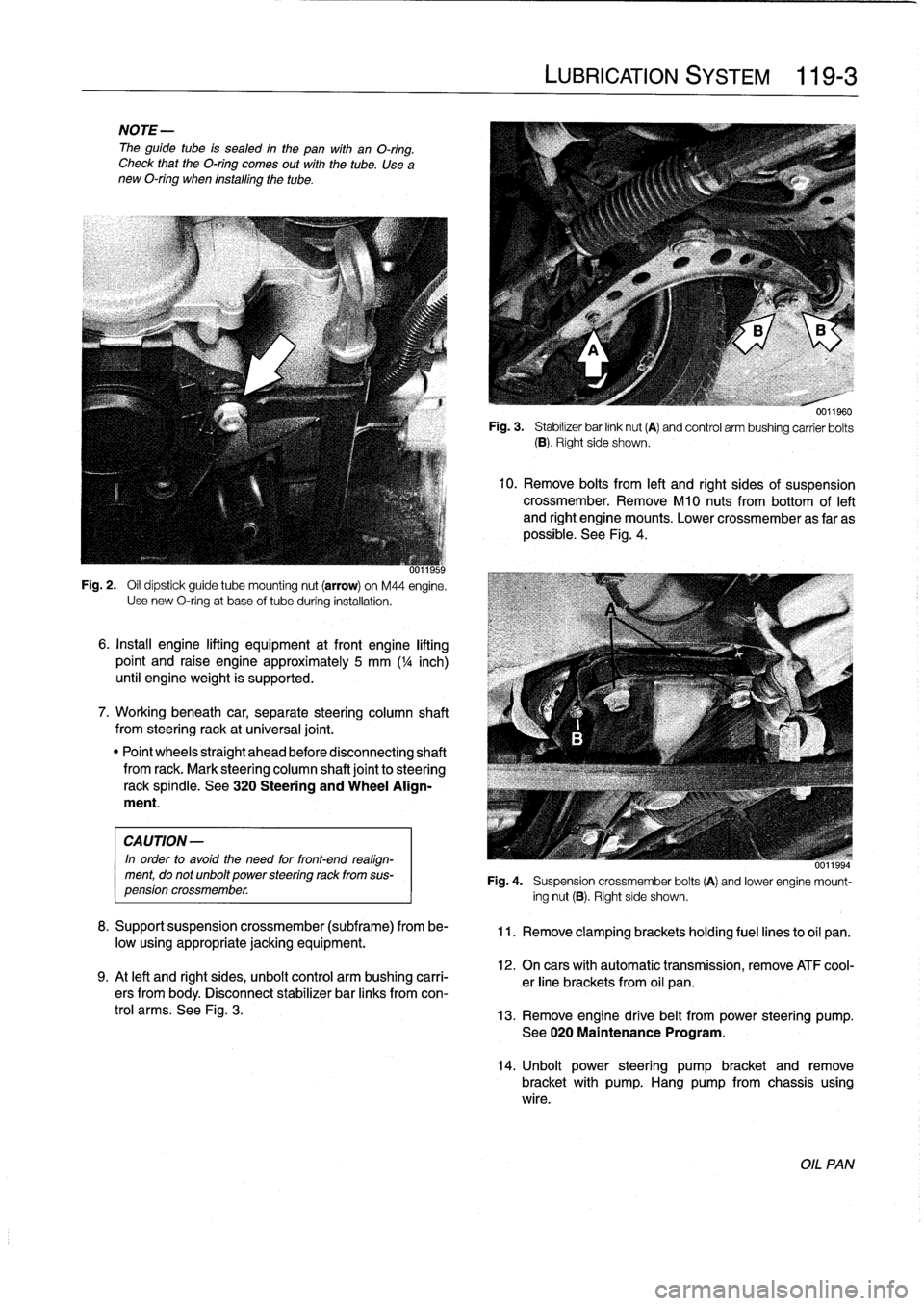

Fig

.

3

.

Stabilizer

bar

link

nut

(A)

and

control

arm

bushing

carrier

bolts

(B)

.

Right

side

shows

.

10

.

Remove

bolts

from

left

and

right

sides

of

suspension

crossmember

.

RemoveM10

nuts

from

bottom

of

left

and

right

engine

mounts

.

Lower

crossmember

as

far

as

possible

.

See

Fig

.

4

.

uu1ibb4

Fig

.

4

.

Suspension

crossmember

bolts

(A)

and

lower

engine

mount-

ing

nut

(B)

.

Right

side

shows

.

11

.

Remove

clamping

brackets

holding

fuel

lines

to

oil

pan

.

12

.

On

cars

with

automatic

transmission,

remove

ATF

cool-

er

line

brackets

from

oil

pan

.

13

.

Remove

engine

drive

belt

from

power

steering

pump

.

See020

Maintenance

Program

.

14

.

Unbolt

power

steering

pumpbracket

andremove

bracket

with

pump

.

Hang

pump

from

chassis

using

wire

.

OIL

PAN

Page 118 of 759

119-

4

LUBRICATION

SYSTEM

15

.

Remove

oil

pan

screws

.

Lower

andremove

oil

pan

to-

ward

rear

.

Tightening

Torques

"

Control

arm

bushing

carrier

CAUTION-

to

body(M10

bolt)

...............

42

Nm

(31

ft-Ib)

'

lf

the

oil

pan

does

not

separate

easily

from

the

en-

"

Engine

mount

to

gine

cylinder

block,

make

sure

all

mounting

bolis

suspension

crossmember

(M10

nut)

.

42

Nm

(31

ft-Ib)

have

been

removed

.

If

necessary,

a

few

tapswith

"

Front

suspension

crossmember

a

rubber

mallet

shouldbreak

it

free

.

Never

pry

the

to

body

.

.

..

...

..

.

....

See

310

Front

SusPension

oil

pan

loose

.

"

Oil

pan

to

engine

block

(M6

bolt)

8

.8

grade

..

....

.

...

...

.

........

10

Nm

(89

in-lb)

16

.

Installation

is

reverse

of

removal

.

10

.9

grade

...

..

.

....

..

.

.

.

.......

12

Nm

(9

ft-Ib)

"

Thoroughly

clean

all

old

gasket

material

from

mating

"

Power

steering

pump

to

bracket

surfaces

anduse

a

new

gasket

.

(self-locking

nuts)

....

..

.

....

..

.

..

22

Nm

(16

ft-Ib)

"

Applya

small

amount

of

non-hardening

sealer

(3-

"

Power

steering

pump

bracket

to

engine

Bond

O

l209

or

equivalent)

to

oil

pan

gasket

directly

block

or

oil

pan

(self-locking

nuts)

..

.

22

Nm

(16

ft-Ib)

below

joints

for

end

cover

and

front

timing

case

cover

.

"

Stabilizer

bar

link

to

control

arm

See

Fig

.

5

.

M8

nut

.................

...

.

...

22

Nm

(17

ft-Ib)

"

When

installing

oil

pan

to

engine,

tighten

forward

M10

nut

.....................

..

42

Nm

(31

Ib-ft)

screws

first,

then

tightenrear

.

"

Steering

column

universal

joint

"

Fill

engine

with

oil

as

described

in

020

Maintenance

to

steering

rack

spindle

(M8

bolt)

....

19

Nm

(14

ft-ib)

Program

.

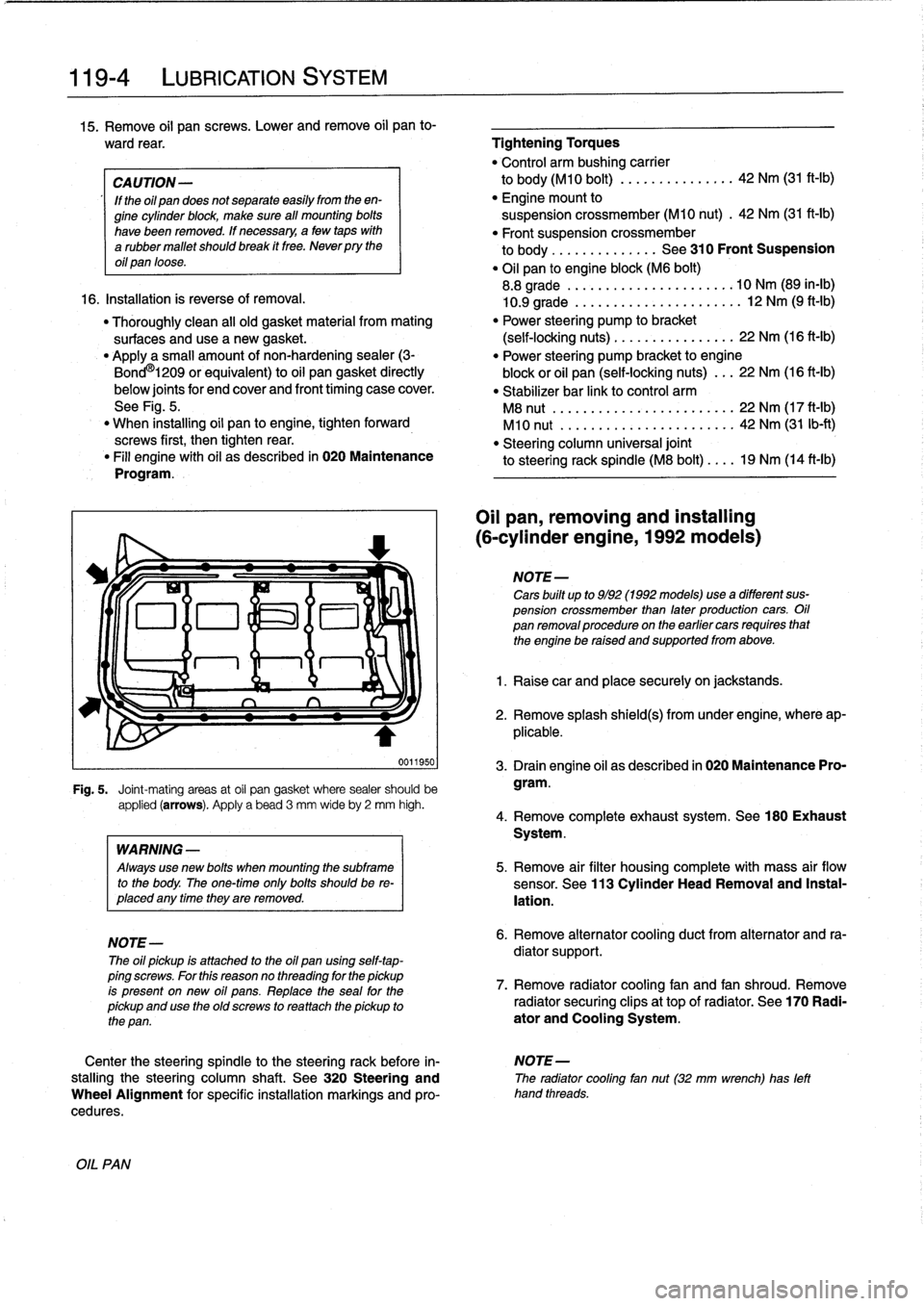

0011950

Fig

.

5

.

Joint-mating

areas

at

oil

pan

gasket

where

sealer

should

be

applied

(arrows)

.

Apply

a

bead

3

mm

wideby

2

mm

high

.

OIL

PAN

WARNING

-

Always

use

new

bolis

when

mounting

the

subframe

to

the

body

.

The

one-timeonly

bolis

shouldbe

re-

placed

any

timethey

are

removed

.

NOTE-

The

oil

pickup

is

attached

to

the

oil

pan

using

self-tap-

ping

screws

.

For

this

reasonno

threading

for

the

pickup

is

present

on

new

oil

pans

.

Replace

the

seal

for

the

pickup

and

use

the

oíd

screws

to

rea

ttach

the

pickup

to

the

pan

.

Oil

pan,

removing

and

installing

(6-cylinder

engine,

1992models)

NOTE-

Cars

built

up

to

9/92

(1992models)usea

different

sus-

pension

crossmember

than

later

production

cars

.

Oil

pan

removalprocedureon

the

earlier

cars

requires

that

the

engine

be

raised

and

supportedfrom

above

.

1

.

Raise

car

and

place

securely

on

jackstands

.

2

.

Remove

splash

shield(s)

from

under

engine,

where

ap-

plicable

.

3

.

Drain

engine

oil

as

described

in

020

Maintenance

Pro-

gram

.

4

.

Remove

complete

exhaust

system

.

See180

Exhaust

System

.

5

.

Remove

air

filter

housing

complete

with

mass

air

flow

sensor

.

See

113

Cylinder

Head

Removal

and

Instal-

lation

.

6

.

Remove

alternator

cooling

duct

from

alternator

and

ra-

diator

support

.

7

.

Remove

radiator

cooling

fan

and

fan

shroud

.

Remove

radiator

securing

clips

at

top

of

radiator

.

See

170

Radi-

ator

and

Cooling

System

.

Center

the

steering

spindle

to

the

steering

rack

before

in-

NOTE-

stalling

the

steering

column

shaft

.

See

320

Steering

and

The

radiator

cooling

fan

nut(32

mm

wrench)

has

left

Wheel

Alignment

for

specific

installation

markings

and

pro-

hand

threads

.

cedures

.

Page 119 of 759

8

.

Remove

air

plenum

from

rear

of

engine

compartment

.

See

640

Heating

and

Air

Conditioning

.

9

.

Release

drive

belt

tension

and

remove

alternator

drive

belt

.

Remove

A/C

compressor

drive

belt

.

See

Fig

.

6

.

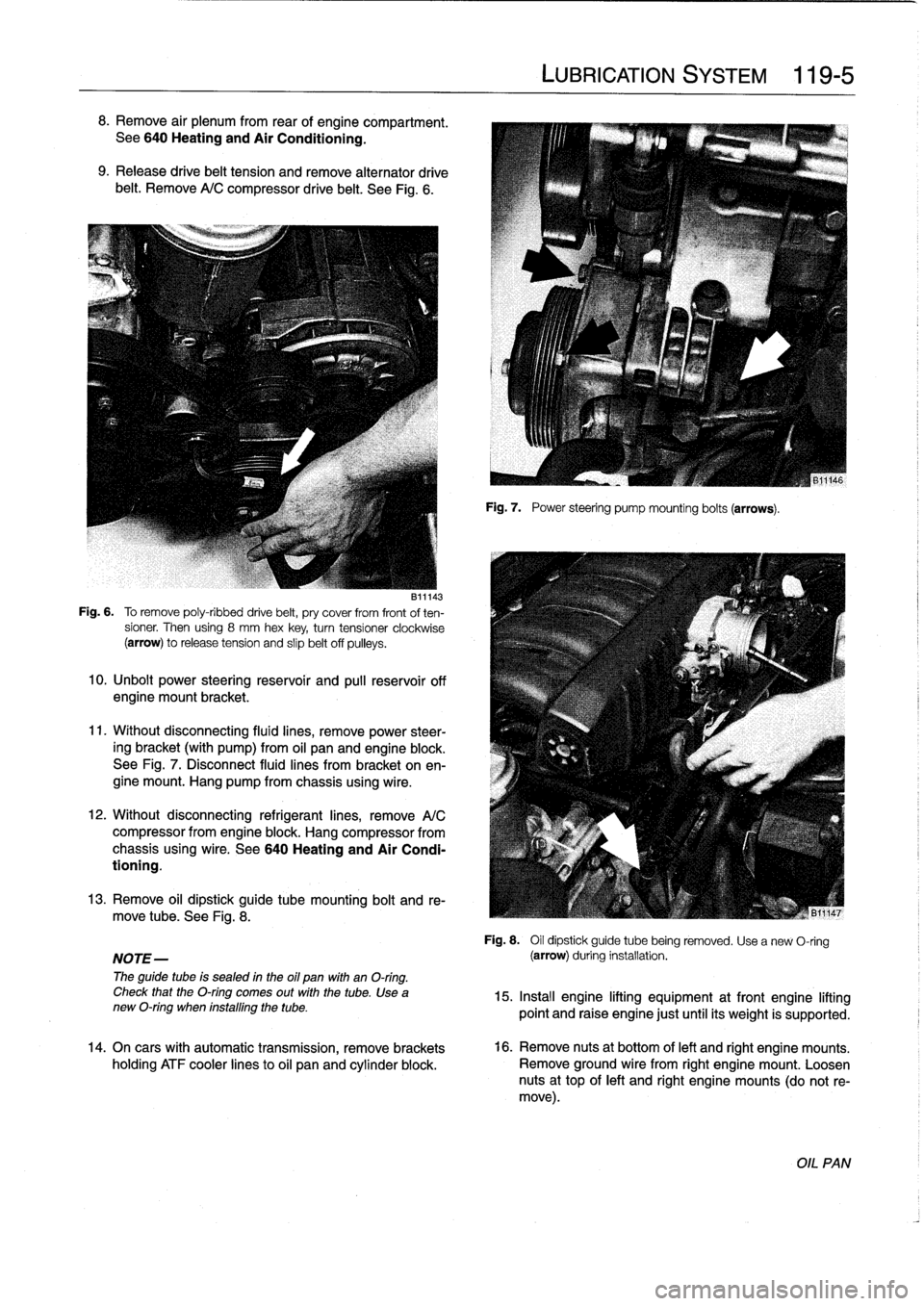

B11143

Fig

.

6

.

To

remove

poly-ribbed

drive

belt,

pry

cover

from

front

of

ten-

sioner

.

Then

using

8

mm

hex

key,

turntensioner

clockwise

(arrow)

torelease

tension

and

slip

belt

off

pulleys

.

10

.

Unbolt

power

steering

reservoir

and

pull

reservoir

off

engine

mount

bracket

.

11

.

Without

disconnecting

fluid

lines,

remove

power

steer-

ing

bracket

(with

pump)

from

oil

panand

engine

block

.

See

Fig

.

7

.

Disconnect

fluid

lines

from

bracket

on

en-

gine

mount

.

Hang

pump

from

chassis

using

wire

.

12

.

Without

disconnecting

refrigerant

lines,

remove

A/C

compressor

from

engine

block

.

Hang

compressor

from

chassis

using

wire

.

See

640

Heating

and

Air

Condi-

tioning

.

13

.

Remove

oil

dipstick

guide

tube

mounting

bolt

and

re-

move

tube

.

See

Fig

.

8

.

NOTE-

The

guide

tube

is

sealed

in

the

oil

pan

with

an

O-ring

.

Check

that

the

O-ring

comes

out

with

the

tube

.

Use

anew

O-ring

when

installing

the

tube

.

14

.

On

cars

with

automatic

transmission,

remove

brackets

holding

ATF

cooler

linesto

oil

pan

and

cylinder

block

.

LUBRICATION

SYSTEM

119-

5

Fig

.

7

.

Power

steering

pump

mounting

bolts

(arrows)

.

Fig

.

8

.

Oil

dipstick

guide

tube

being

removed

.

Usea

new

O-ring

(arrow)

during

installation

.

15

.

Insta¡¡

engine

lifting

equipment

at

front

engine

lifting

point

and

raise

engine

just

until

its

weight

is

supported

.

16

.

Remove

nuts

at

bottom

of

left

and

right

engine

mounts

.

Remove

ground

wire

from

right

engine

mount

.

1-oosen

nuts

at

top

of

left

and

right

engine

mounts

(do

not

re-

move)

.

OIL

PAN

Page 120 of 759

119-

6

LUBRICATION

SYSTEM

17

.

Raise

engine

as

much

as

possible

.

Check

carefully

for

22

.

Installation

is

reverse

of

removal

.

obstructions,

wiring

harness

clearance

and

pinched

hoses

or

lines

as

engine

is

raised

.

"

When

installing

oil

pan,

apply

a

b

d

of

non-hardening

sealing

compound

(3-Bond

1209

0

or

equivalent)

to

18

.

Remove

oil

pan

mounting

bolts

and

lower

oil

pan

to

front

and

rear

end

cover

seam

areas

on

block

.

subframe

crossmember

.

"

Position

oil

pump

pickup

tube

and

oil

pan

onto

block

and

install

pickup

tube

using

a

new

gasket

.

"

Be

sure

tab

on

gasket

faces

down

towards

intake

of

NOTE-

pickup

tube

.

If

the

oil

pan

does

not

separate

easily

from

the

engine

"

Tightenforward

oil

pan

screws

first,

then

tighten

rear

.

cylinder

block,

afew

taps

with

arubber

mallet

should

"

Fill

engine

with

oil

as

described

in

020

Maintenance

break

it

free

.

Do

not

pry

the

oil

pan

loose

.

Program

.

"

After

adding

engine

oil,

start

and

run

engine

.

Raise

en-

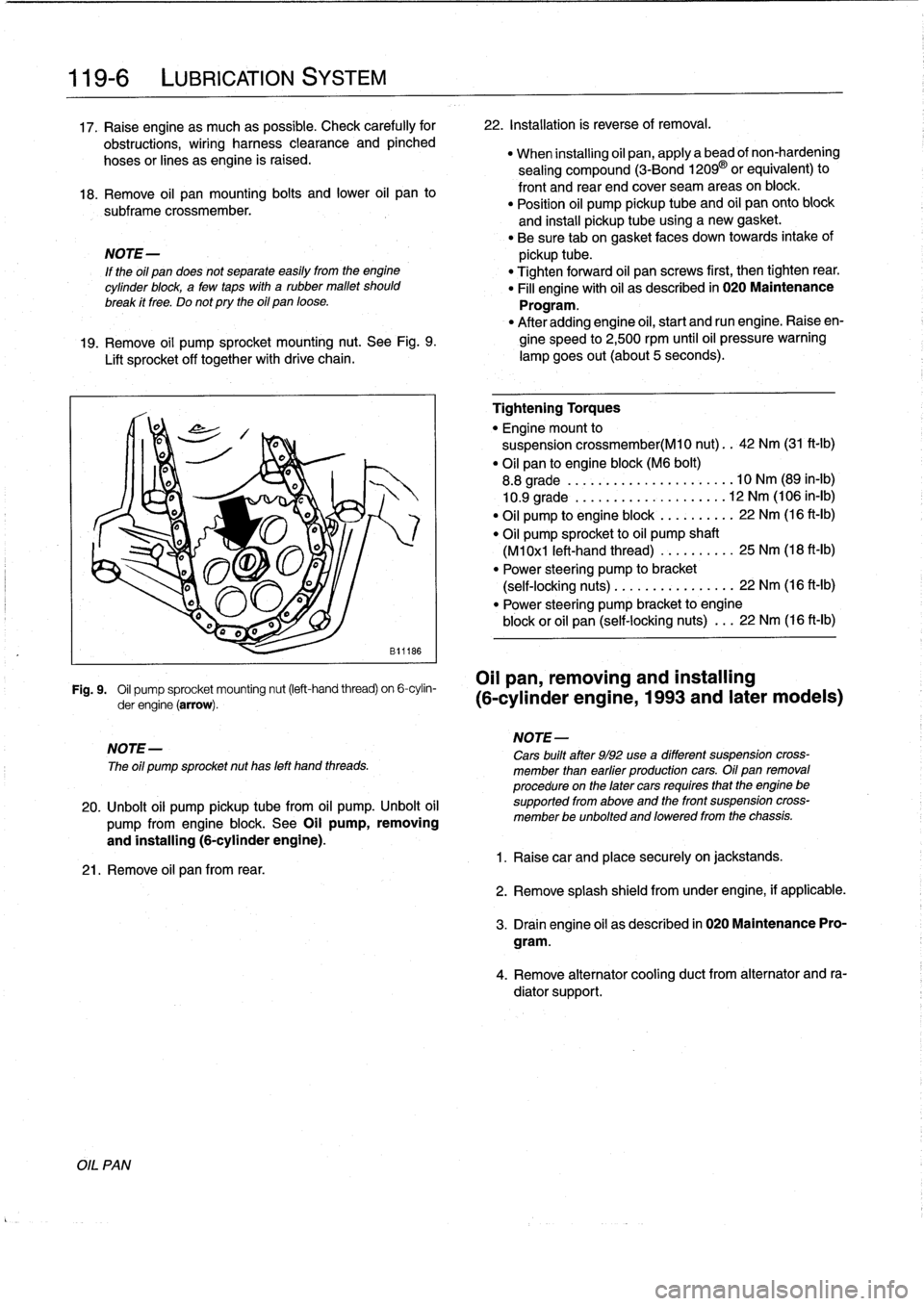

19

.

Remove

oil

pump

sprocket

mounting

nut

.

See

Fig

.

9

.

gine

speed

to

2,500

rpm

until

oil

pressure

warning

Lift

sprocket

off

together

with

drive

chain

.

lampgoes

out(about

5seconds)

.

Fig

.

9

.

Oil

pump

sprocket

mounting

nut

(left-hand

thread)

on

6-cylin-

OII

pan,

removing

and

installing

derengine(arrow)

.

(6-cylinder

engine,

1993

and

later

modeis)

NOTE-

The

oíl

pump

sprocket

nut

has

left

hand

threads

.

20

.

Unbolt

oil

pump

pickup

tubefrom

oil

pump

.

Unbolt

oil

pump

from

engine

block

.

See

Oil

pump,

removing

and

installing

(6-cylinder

engine)

.

21

.

Remove

oil

pan

from

rear

.

Tightening

Torques

"

Engine

mount

to

suspension

crossmember(M10

nut)

..

42

Nm

(31

ft-Ib)

"

Oil

pan

to

engine

block

(M6

bolt)

8

.8

grade

....

..

.

...

...

.

........

10

Nm

(89

in-lb)

10

.9

grade

.

.

..

.

..

...

.

.

.

.

.

.....

12

Nm

(106

in-lb)

"

Oil

pump

to

engine

block

.

...

...

.

..

22

Nm

(16

ft-Ib)

"

Oil

pump

sprocket

to

oil

pump

shaft

(M1

0x1

left-hand

thread)

...

..

.

.

..

.

25

Nm

(18

ft-Ib)

"

Power

steering

pump

to

bracket

(self-locking

nuts)

.....

.

....

..

.

...

22

Nm

(16

ft-lb)

"

Power

steering

pump

bracket

to

engine

block

or

oil

pan

(self-locking

nuts)

.

..

22

Nm

(16

ft-Ib)

NOTE-

Cars

built

after

9/92

use

a

different

suspension

cross-

member

¡han

earfier

productíon

cars

.

Oil

pan

removal

procedure

on

the

later

cars

requíres

that

the

engine

be

supported

from

aboye

and

the

front

suspension

cross-

member

be

unbolted

and

loweredfrom

the

chassis

.

1

.

Raisecar

and

place

securely

on

jackstands

.

2

.

Remove

splash

shield

fromunder

engine,

if

applicable

.

3

.

Drain

engine

oil

as

descríbed

in

020

Maintenance

Pro-

gram

.

4

.

Remove

alternator

cooling

duct

from

alternator

and

ra-

diator

support

.

Page 121 of 759

5

.

Remove

air

filter

housingcomplete

with

mass

air

flow

sensor

.

See113

Cylinder

HeadRemoval

and

Instal-

lation

.

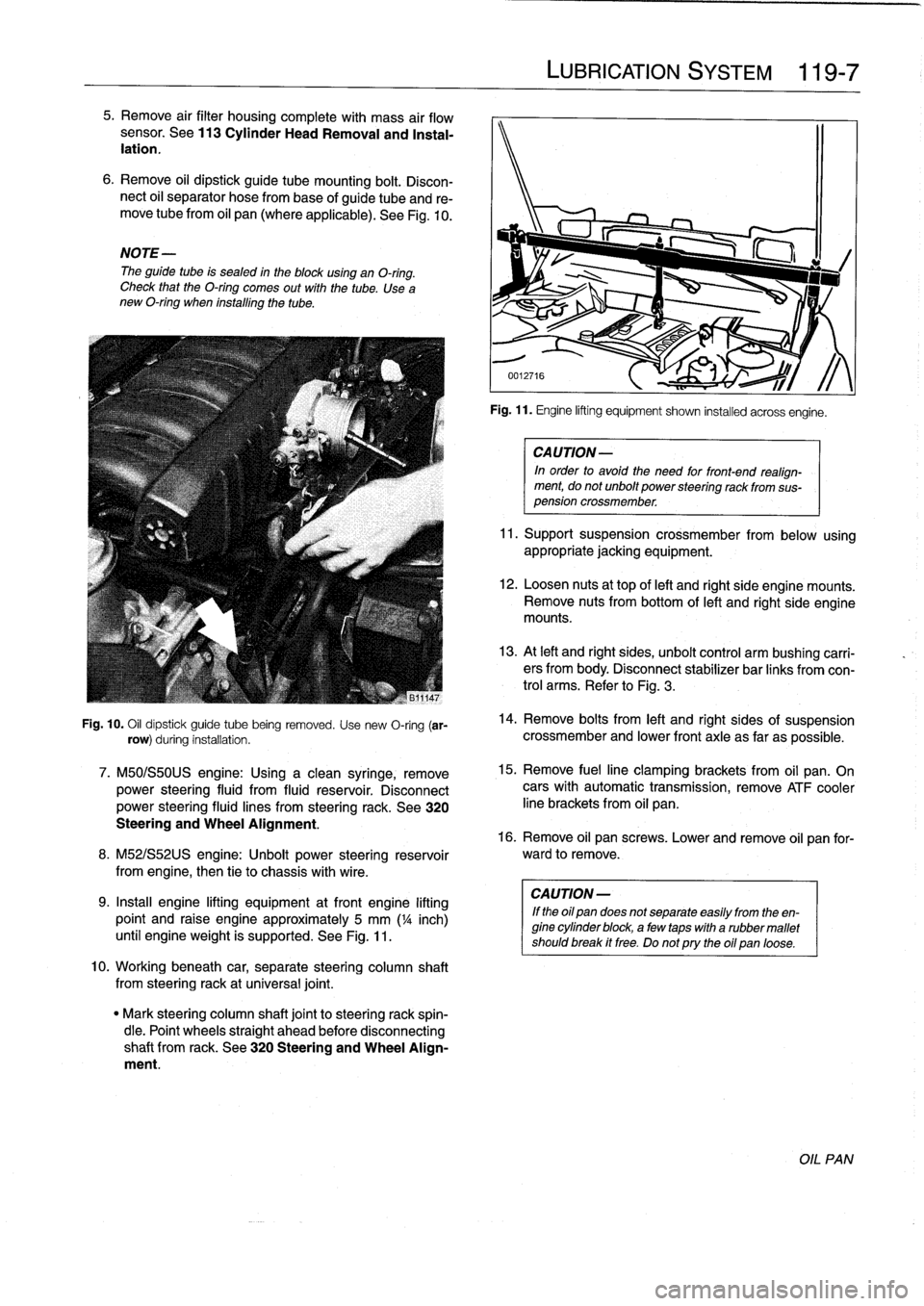

6

.

Remove

oil

dipstick

guide

tube

mounting

bolt

.

Discon-

nect

oil

separator

hose

frombase

of

guide

tube

and

re-

move

tubefrom

oil

pan

(where

applicable)

.

See

Fig

.

10

.

NOTE-

The

guide

tube

is

sealed

in

the

blockusing

an

O-ring

.

Check

that

the

O-ring

comes

out

with

the

tube

.

Use

a

new

O-ring

when

installing

the

tube

.

Fig

.

10

.

Oil

dipstick

guide

tube

being

removed

.

Use

new

O-ring

(ar-

row)

during

installation

.

7

.

M50/S50US

engine

:

Using

a

clean

syringe,

remove

power

steering

fluid

from

fluid

reservoir

.

Disconnect

power

steering

fluid

lines

from

steering

rack

.

See

320

Steering

and

Wheel

Alignment

.

8

.

M52/S52US

engine

:

Unbolt

power

steering

reservoir

from

engíne,

then

tie

to

chassis

with

wire

.

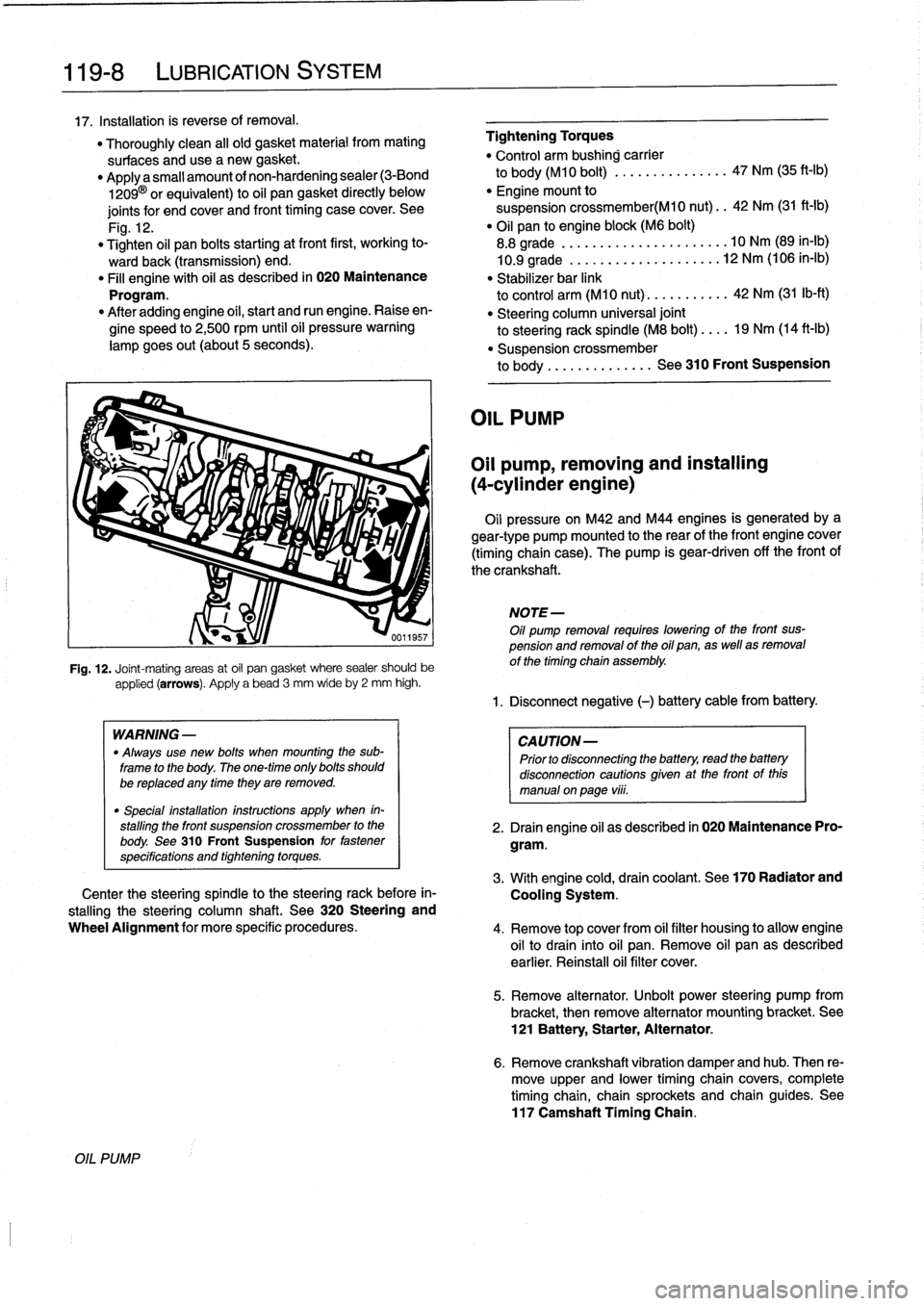

9

.

Insta¡¡

engine

lifting

equipment

atfront

engine

lifting

point

and

raise

engine

approximately

5

mm

('/a

inch)

until

engineweight

is

supported

.

See

Fig

.

11

.

10

.

Workingbeneath

car,

separate

steering

column

shaft

from

steeringrack

at

universal

joint

.

"

Mark

steering

column

shaft

jointto

steering

rack

spin-

dle

.

Point

wheels

straight

ahead

before

disconnecting

shaft

from

rack

.

See

320

Steering

and

Wheel

Align-

ment

.

LUBRICATION

SYSTEM

119

Fig

.

11

.

Engine

lifting

equipment

shown

installed

acrossengíne

.

CA

UTION-

In

order

to

avoid

the

need

for

front-end

realign-

ment,

donot

unbolt

power

steering

rack

from

sus-

pension

crossmember

.

11

.

Support

suspension

crossmember

from

below

using

appropriate

jacking

equipment

.

12

.

Loosen

nuts

at

top

of

left

and

right

side

engine

mounts

.

Remove

nuts

from

bottom

of

left

and

right

side

engine

mounts

.

13

.

At

left

and

right

sides,

unbolt

control

arm

bushíng

carri-

ers

from

body

.

Disconnect

stabilizer

bar

links

fromcon-

trol

arms

.

Refer

to

Fig

.

3

.

14

.

Remove

bolts

from

left

and

right

sides

of

suspension

crossmember

and

lower

front

axle

as

far

as

possible

.

15

.

Remove

fuelline

clamping

brackets

from

oil

pan

.

On

cars

with

automatic

transmission,

remove

ATF

cooler

line

brackets

from

oil

pan

.

16

.

Remove

oil

pan

screws

.

Lower

and

remove

oil

pan

for-

ward

to

remove

.

CA

UTION-

If

the

oil

pan

does

not

separate

easily

from

the

en-

gine

cylinder

block,

a

few

taps

with

a

rubber

mallet

shouldbreak

it

free

.

Do

notpry

the

oil

pan

loose

.

OIL

PAN

Page 122 of 759

119-

8

LUBRICATION

SYSTEM

17

.

Installation

is

reverse

of

removal

.

"

Thoroughly

clean

all

old

gasket

material

from

mating

surtaces

anduse

a

new

gasket

.

"

Applya

small

amount

of

non-hardening

sealer

(3-Bond

1209

0

or

equivalent)

to

oil

pan

gasket

directly

below

joints

for

and

cover

and

front

timing

case

cover

.

See

Fig

.

12

.

"

Tighten

oil

pan

bolts

starting

at

front

first,

working

to-

wardback

(transmission)

end

.

"

Fill

engine

with

oil

as

described

in

020

Maintenance

Program

.

"

After

addingengine

oil,

start

and

run

engine

.

Raiseen-

gine

speed

to

2,500

rpm

until

oíl

pressure

warning

lampgoes

out

(about

5seconds)

.

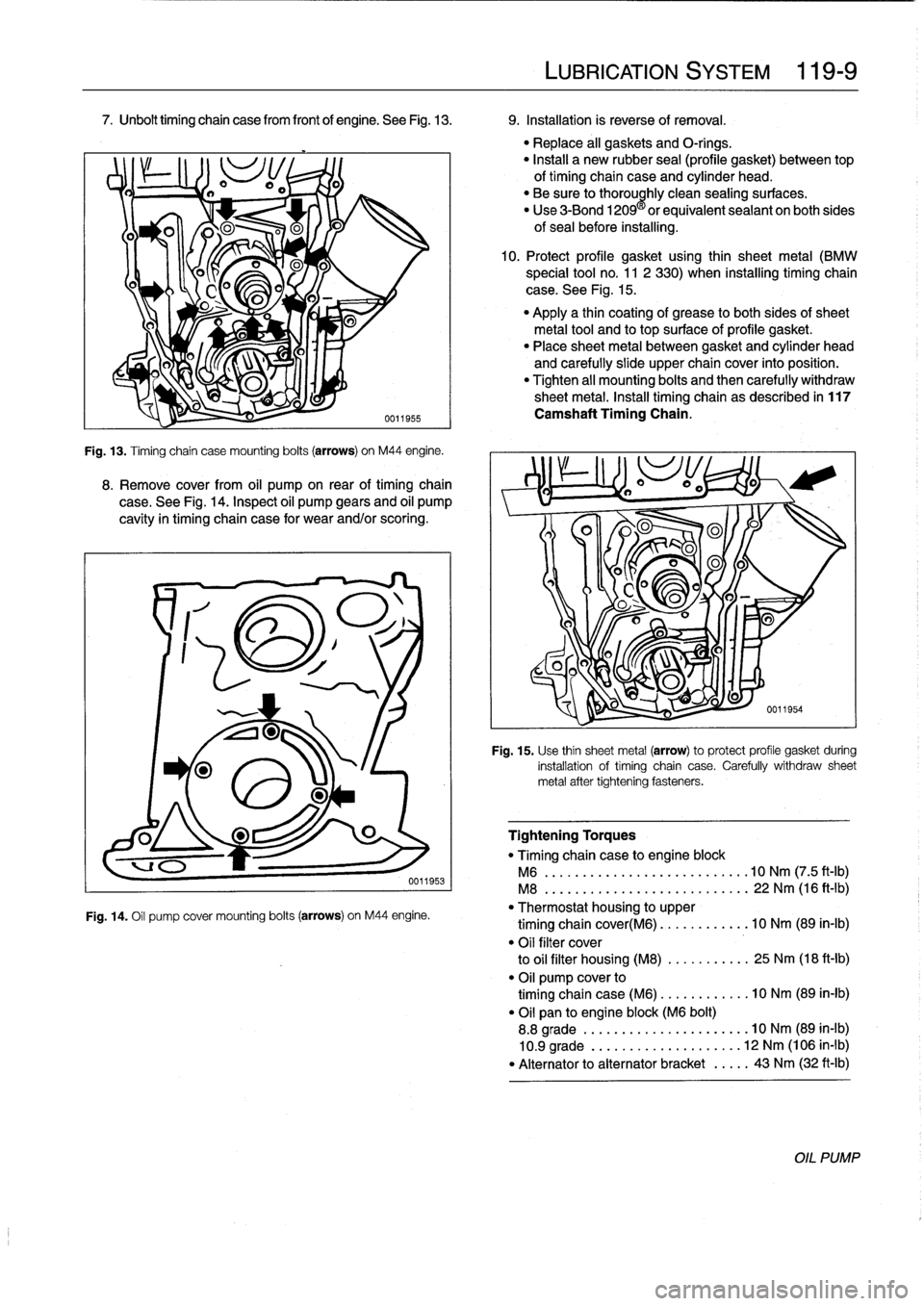

OIL

PUMP

applied

(arrows)

.

Apply

a

bead

3

mm

wideby

2

mm

high

.

WARNING

-

"

Always

use

new

bolts

when

mounting

the

sub-

frame

to

the

body

.

The

one-time

only

bolts

should

be

replaced

any

timethey

are

removed

.

"

Special

installation

instructions

apply

when

in-

stalling

the

front

suspension

crossmember

to

the

body

.

See

310

Front

Suspension

for

fastener

specifications

and

tightening

torques

.

Fig

.

12

.

Joint-mating

areas

at

oil

pan

gasket

where

sealer

should

be

Center

the

steering

spindle

to

the

steering

rack

before

in-

stalling

the

steering

column

shaft

.

See

320

Steering

and

Wheel

Alignment

for

more

specific

procedures

.

Tightening

Torques

"

Control

arm

bushing

carrier

to

body

(M10

bolt)

...............

47

Nm

(35

ft-Ib)

"

Engine

mount

to

suspension

crossmember(M10

nut)

..

42

Nm

(31

ft-Ib)

"

Oil

pan

to

engine

block

(M6

bolt)

8

.8

grade

...........

.......

....

10

Nm

(89

in-lb)

10

.9

grade

...........

..

...

...

.

12

Nm

(106

in-lb)

"

Stabilizer

bar

link

to

control

arm

(M10

nut)

.......

....

42

Nm

(31

Ib-ft)

"

Steering

column

universal

joint

to

steering

rack

spindle

(M8

bolt)

....

19

Nm

(14

ft-Ib)

"

Suspensíon

crossmember

to

body

...

...

.

...

..

.

.

See

310

Front

Suspension

OIL

PUMP

Oil

pump,

removing

and

installing

(4-cylinder

engine)

Oil

pressure

on

M42

and

M44

engines

is

generatedbya

gear-type

pump

mounted

to

the

rear

of

the

front

engine

cover

(timing

chaincase)

.

The

pump

is

gear-driven

off

the

front

of

the

crankshaft

.

NOTE-

Oil

pump

removal

requires

lowering

of

the

front

sus-

pension

and

removal

of

the

oil

pan,

as

well

asremoval

of

the

timing

chain

assembly

.

1

.

Disconnect

negative

(-)

battery

cable

from

battery

.

CAUTION-

Prior

to

disconnectiog

the

battery,

read

the

battery

disconnection

cautions

given

at

the

front

of

this

manual

on

paga

vÍii

.

2

.

Drain

engine

oil

as

described

in

020

Maintenance

Pro-

gram

.

3

.

Withengine

cold,

drain

coolant

.

See

170

Radiator

and

Cooling

System

.

4

.

Remove

top

cover

from

oil

filter

housing

to

allow

engine

oil

to

drain

into

oil

pan

.

Remove

oil

pan

as

described

earlier

.

Reinstall

oil

filter

cover

.

5

.

Remove

alternator

.

Unbolt

power

steering

pump

from

bracket,

then

remove

alternator

mountíng

bracket

.

See

121

Battery,

Starter,

Alternator

.

6

.

Remove

crankshaft

vibration

damper

andhub

.

Then

re-

move

upper

and

lower

timing

chain

covers,

complete

timingchain,

chain

sprockets

and

chain

guides

.

See

117

Camshaft

Tíming

Chain

.

Page 123 of 759

7

.

Unbolt

timing

chain

casefrom

frontof

engine

.

See

Fig

.

13

.

9

.

Installation

is

reverse

of

removal

.

Fig

.

13

.

Timing

chain

case

mounting

bolts

(arrows)

on

M44

engine

.

8

.

Remove

cover

from

oil

pump

on

rear

of

timing

chain

case

.

See

Fig

.

14

.

Inspect

oil

pump

gears

and

oil

pump

cavity

in

timing

chain

case

for

wear

andlor

scoring

.

Fig

.

14

.

Oil

pump

cover

mounting

bolts

(arrows)

on

M44

engine

.

LUBRICATION

SYSTEM

119-

9

"

Replace

al¡

gaskets

and

O-rings

.

"

Install

a

new

rubber

sea¡

(profile

gasket)

between

top

of

timing

chain

case

and

cylinder

head

.

"

Be

sure

to

thoroughly

clean

sealing

surfaces

.

-Use

3-Bond

1209

orequivalent

sealant

on

both

sides

of

sea¡

before

installing

.

10

.

Protect

profile

gasket

using

thin

sheet

metal

(BMW

special

tool

no

.

11

2

330)

when

installing

timing

chain

case

.

See

Fig

.

15

.

"

Applya

thin

coating

of

grease

to

both

sides

of

sheet

metal

tool

and

to

top

surface

of

profile

gasket

.

"

Placesheet

metal

between

gasket

and

cylinder

head

and

carefully

slíde

upper

chain

cover

into

position

.

"

Tighten

al¡

mounting

bolts

and

then

carefully

withdraw

sheet

metal

.

Install

timing

chain

as

described

in

117

Camshaft

Timing

Chain

.

Fig

.

15

.

Use

thin

sheetmetal

(arrow)

toprotect

profile

gasket

during

installation

of

timing

chain

case

.

Carefully

withdraw

sheetmetal

after

tightening

fasteners

.

Tightening

Torques

"

Timing

chain

case

to

engine

block

M6

..

.

...

...

.

..

.............

.

.10

Nm

(7

.5

ft-Ib)

M8

........

.

..

..

..............

22

Nm

(16

ft-Ib)

"

Thermostathousing

to

upper

timing

chain

cover(M6)

............

10

Nm

(89

in-lb)

"

OH

filter

cover

to

oil

filter

housing

(M8)

.

.

.........

25

Nm

(18

ft-lb)

"

Oil

pump

cover

to

timing

chain

case

(M6)

...

..

.......

10

Nm

(89

in-lb)

"

Oil

pan

to

engine

block

(M6

bolt)

8

.8

grade

.........

.

.

..

.........

10

Nm

(89

in-lb)

10

.9

grade

............

.

.......

12

Nm

(106

in-lb)

"

Alternator

to

alternator

bracket

.....

43

Nm

(32

ft-Ib)

OIL

PUMP

Page 124 of 759

119-

1

0

LUBRICATION

SYSTEM

Oil

pump,

removing

and

installing

(6-cylinder

engine)

Oil

pressure

on

the

6-cylinder

engines

is

generated

by

a

gear-type

pump

bolted

to

the

bottom

of

the

engine

block

.

The

oil

pump

is

chain

driven

off

the

front

of

the

crankshaft

.

NOTE-

Oil

pump

removal

requires

raising

the

engine

(cars

built

up

to

9-92)

or

lowering

the

front

suspension

crossmem-

ber

(cars

built

from

9-92)

to

remove

the

oil

pan

.

1.

Drain

oil

as

described

in

020

Maintenance

Program

.

2

.

Remove

oil

pan

as

described

earlier

.

3

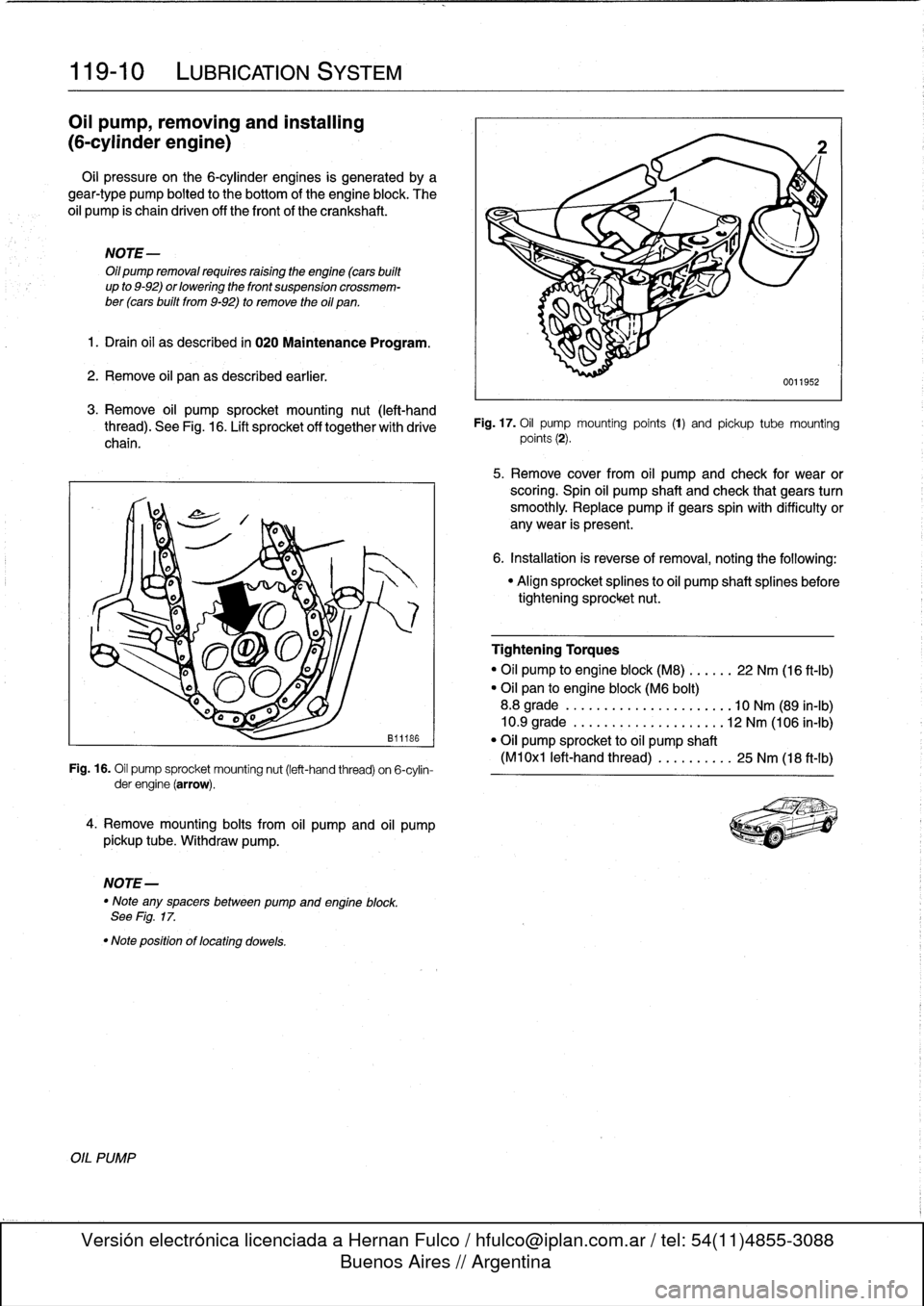

.

Remove

oil

pump

sprocket

mounting

nut

(left-hand

thread)

.

See

Fig

.

16

.

Lift

sprocket

off

together

with

drive

chain

.

Fig

.

16

.

Oil

pump

sprocket

mounting

nut

(left-hand

thread)

on

6-cylin-

der

engine

(arrow)

.

4

.

Remove

mounting

bolts

from

oil

pump

and

oil

pump

pickup

tube

.

Withdraw

pump

.

NOTE-

Note

any

spacers

between

pump

and

engine

block

.

See

Fig

.

17

.

"

Note

position

of

locating

dowels

.

OIL

PUMP

811186

0011952

Fig

.

17

.

Oil

pump

mounting

points

(1)

and

pickup

tube

mountíng

points

(2)

.

5

.

Remove

coverfrom

oil

pump

and

check

for

wear

or

scoring

.

Spin

oil

pump

shaft

and

check

that

gears

turn

smoothly

.

Replace

pump

if

gears

spinwith

difficulty

or

any

wear

is

present

.

6

.

Installation

is

reverse

of

removal,

noting

the

following

:

"

Align

sprocket

splines

to

oil

pump

shaft

splines

before

tightening

sprocket

nut

.

Tightening

Torques

"

Oil

pump

to

engine

block

(M8)

......

22

Nm

(16

ft-Ib)

"

Oil

pan

to

engine

block

(M6

bolt)

8

.8

grade

..

...

.

...

...

.

.........

10

Nm

(89

in-lb)

10

.9

grade

.

...

.

..

....

.

........

12

Nm

(106

in-lb)

"

Oil

pump

sprocket

to

oil

pump

shaft

(M1

0x1

left-hand

thread)

..........

25

Nm

(18

ft-Ib)

Page 125 of 759

GENERAL

.

........

.

...........

.

.

.

.

.

.

.

120-1

Camshaft

Position

(CMP)

Sensor

....

.

.

.

...

120-6

Disabling

Ignition

System

.

.

.

.

.....

.

.

.

.

.

.

.

120-2

Camshaft

position

(CMP)

sensor,

replacing

Warnings

and

Cautions

.

.

.

.

.

.

.....

.

.

.

.

.

.

.

120-2

(4-cylinder

engine)

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

...

120-6

Camshaft

position

(CMP)

sensor,

replacing

IGNITION

SYSTEM

DIAGNOSTICS

.

.

.

.

.

.

120-3

(6-cylinder

engine)

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

120-7

Basic

Troubleshooting

Principles

...

.

.

.

.

.

.

.

120-3

Knock

sensors,

replacing

.

.

...

.

.

.

.

.

.

.

.

.

.

.

.

120-7

Ignition

Firing

Order

.....

.

...

.

.

.

.....

.

.

.

.120-7

IGNITION

SYSTEM

SERVICE

.

.........

.

120-3

Checking

for

Spark

..

.

.

.

.

.

.

.

.

.

.......

.

.

.

120-3

Ignition

coil,

testing

and

replacing

(4-cylinder

engine)

.

.

.

.

.

.

.

.

.

.

.........

.

120-3

Ignition

coil,

testing

and

replacing

(6-cylinder

engine)

.........

.

..........

120-4

Crankshaft

Positionlrpm

Sensor

.......

.

...

120-5

Crankshaft

position/rpm

sensor,

testing

and

replacing

(front

mounted)

.........

.

.

.

.

.

.

120-6

Crankshaft

position/rpm

sensor,replacing

(rear

mounted)

.....

.

.....

.

.....

.

.

.

.

.

.

120-6

GENERAL

Troubleshooting

and

testing

of

the

engine

management

system

should

be

carried

out

using

the

BMW

specialized

ser

This

repair

group

covers

repair

andcomponent

replace-

vice

tester

(scan

tool)

.

ment

information

for

the

ignition

system

.

All

engines

use

a

distributorless

ignition

system

with

indívid-

ual

ignitioncoils

for

each

cylinder

.

There

is

no

distributor

cap

NOTE-

or

ignition

rotor

.

Each

coil

can

be

selectively

controlled

by

the

"

Spark

plug

replacement

is

covered

in

020

Mainte-

engine

control

module

on

a

cylinder-by-cylinder

basis

.

On

later

nance

Program

.

systems,

knock

sensors

are

used

to

monitor

and

control

igni-

"

For

fuel

related

troubleshooting

and

testing,

see

130

tion

knock

(ping)

and

adjusttiming

accordingly

.

Fuel

lnjection

.

Ignition

timing

is

electronically

controlled

and

not

adjust-

All

engines

covered

by

this

manual

use

an

advanced

en-

able

.

The

engine

control

module

(ECM)

usesengine

load,

en-

gine

management

system

.

The

engine

management

system

gine

speed,

coolant

temperature,

and

intake

air

temperature

incorporates

on-board

diagnostics,

fuel

injection,

ignition

and

as

the

basic

inputs

for

timing

control

.

Knock

detection

is

also

other

advanced

engine

control

functions

.

an

input

to

the

control

module,

where

applicable

.

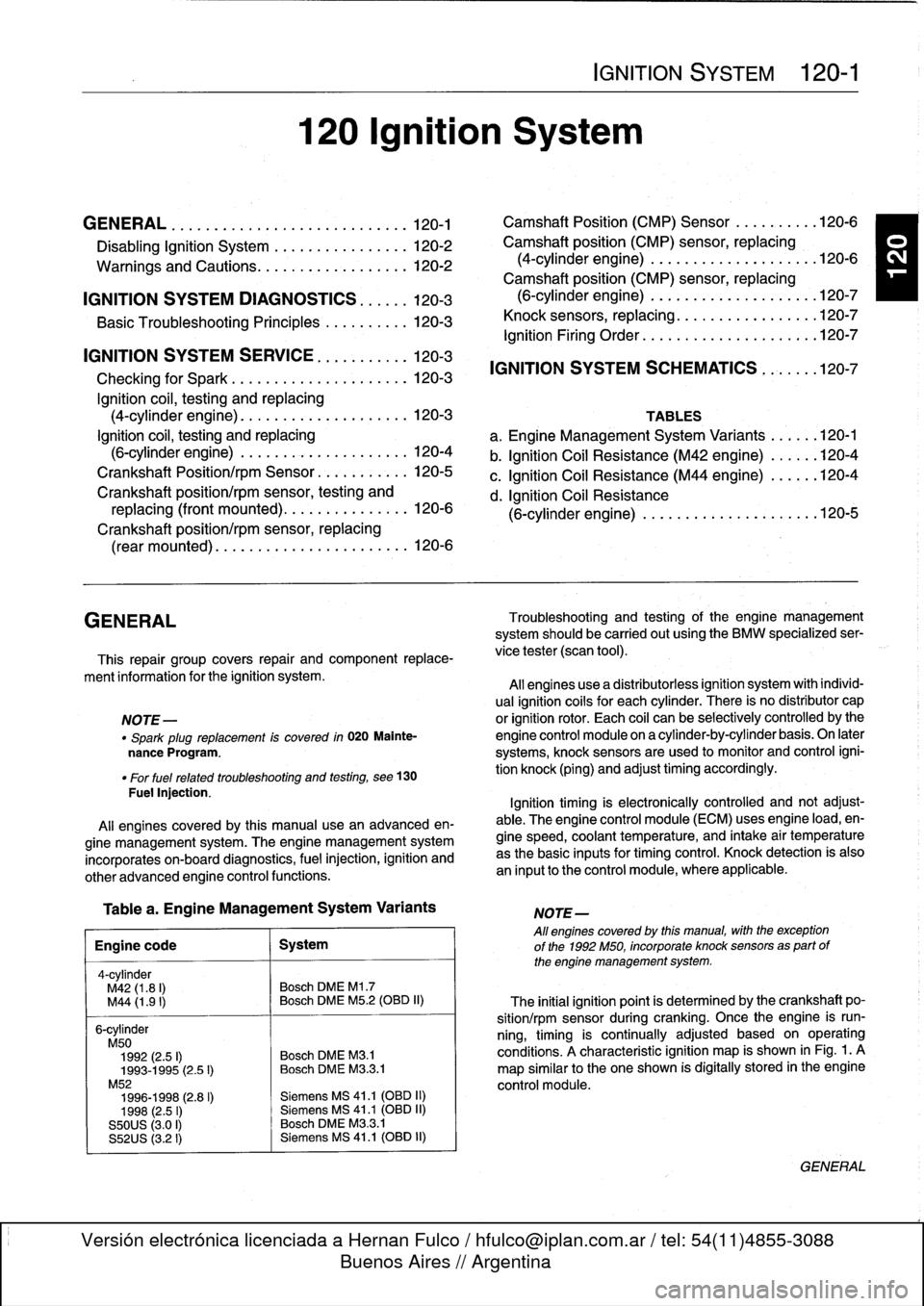

Table

a

.

Engine

Management

System

Variants

Engine

code

1

System

4-cylinder

M42

(1.8

I)

Bosch

DME

Ml

.7

M44

(1

.9

I)

Bosch

DME

M5

.2

(OBD

II)

6-cylinder

M50

1992

(2.5

I)

Bosch

DME

M8

.1

1993-1995

(2

.5

I)

Bosch

DME

M33

.1

M52

1996-1998

(2.8

I)

Siemens

MS

41

.1

(OBD

II)

1998

(2

.5

I)

Siemens

MS

41

.1

(013D

11)

S50US

(3.0

I)

Bosch

DME

M3

.3.1

S52US

(3.2

I)

Siemens

MS

41

.1

(OBD

II)

120

Ignition

System

IGNITION

SYSTEM

120-1

IGNITION

SYSTEM

SCHEMATICS

...

.

.

.

.120-7

TABLES

a

.

Engine

Management

System

Variants

......

120-1

b

.

Ignition

Coil

Resistance

(M42

engine)

......

120-4

c

.

Ignition

Coil

Resistance

(M44

engine)

......

120-4

d

.

Ignition

Coil

Resistance

(6-cylinder

engine)

..

.

.

.

.

.

.

.

.

.

.

.

.....

.

..

120-5

NOTE-

All

engines

coveredby

this

manual,

with

theexception

of

the

1992

M50,

incorporate

knocksensors

as

part

of

the

engine

management

system

.

The

initial

ignition

point

is

determined

by

the

crankshaft

po-

sition/rpm

sensor

during

cranking

.

Once

the

engine

is

run-

ning,

timing

is

continually

adjusted

based

on

operating

conditions

.

A

characteristic

ignition

map

is

shown

in

Fig

.

1

.

A

map

similar

to

the

one

shown

is

digitally

stored

in

the

engine

control

module

.

GENERAL