engine oil change BMW M3 1993 E36 Owner's Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 1993, Model line: M3, Model: BMW M3 1993 E36Pages: 759

Page 198 of 759

170-

4

RADIATOR

AND

COOLING

SYSTEM

A

quick

testat

the

coolant

temperature

gauge

sender

can

The

auxiliary

cooling

fan

comes

on

when

coolant

tempera

determine

if

the

gauge

is

functioning

correctly

.

ture

exceeds

a

predetermined

leve¡

or

whenever

the

air

condi-

tioning

is

on

.

A

dual-range

temperature

switch

for

cooling

fan

lf

the

gauge

needie

remains

at

the

rest

position

with

theen-

control

is

mounted

on

the

right

side

of

the

radiator

.

See

Fig

.

3

.

gine

warm,

remove

the

harness

connector

from

the

sender

and

jumper

the

correct

terminals

in

the

connector

to

simulate

a

high

engine

temperature

.

See

Table

a

.

Turn

the

ignition

on

.

If

the

gauge

needle

moves

upward,

the

sender

is

faulty

.

If

the

gauge

does

not

respond,

the

wiring

to

the

gauge

is

broken

(open

circuit)

or

the

gauge

itselfis

faulty

.

WARNING

-

1996

and

laten

models

are

OBD

11

compliant

.

Dis-

connecting

electrical

connectors

wíth

the

ignition

turned

on

may

set

fault

codes

in

the

ECM

.

It

is

rec-

ommended

that

you

leave

the

diagnosis

of

faults

in

the

coolant

temperature

sensorsystem

to

the

BMW

dealer

service

department

which

has

specialized

OBD

11

scan

tool

equipment

.

If

the

gauge

needle

reads

too

high

when

the

engine

is

cold,

remove

the

harness

connector

from

the

sender

.

Turn

the

igni-

tion

on

.

lf

the

gauge

needle

position

does

not

change,

the

wir-

ing

or

the

gauge

is

shorted

to

ground

.

If

the

gauge

needle

drops,

the

sender

is

faulty

and

should

be

replaced

.

When

re-

placing

a

faulty

coolant

temperature

sender,

the

gasket

ring

on

the

sender

should

also

be

replaced

.

Tightening

Torque

"

Temperature

gauge

sender

to

engine

18

Nm

(13

ft-Ib)

Cooling

fan,

testing

NOTE-

OnM44

engines

with

manual

transmission,

the

primary

electric

cooling

fan

is

mounted

on

the

engine

side

of

the

radiator

and

is

controlled

by

the

engine

control

module

(ECM)

.

Troubleshooting

thiscircuit

should

be

left

to

an

authorized

BMW

dealer

with

the

proper

diagnostic

equipment

An

otherwise

sound

cooling

system

may

still

overheat,

par-

ticularly

with

prolonged

idling,

due

to

a

failure

of

the

coolíng

fan(s)

.

The

belt-driven

cooling

fan

is

controlled

by

a

temperature

dependent

viscous

clutch

.

A

failed

fan

clutch

may

affect

air

flow

through

the

radiator

resulting

in

overheating

orpossibly

overcooling

.

Speed

Low

sp

High

s

With

the

engine

off,

check

thefan

clutch

by

spinning

thefan

.

eed

The

fan

should

spin

on

the

clutch

with

some

resistance

.

peed

Check

for

signs

of

leaking

fluid

from

the

clutch

.

If

thefan

free-

wheels

with

no

resistance,

cannot

be

tu

rned

by

hand,

or

there

are

signs

of

oil

leakage,

the

clutch

should

be

replaced

.

TROUBLESHOOTING

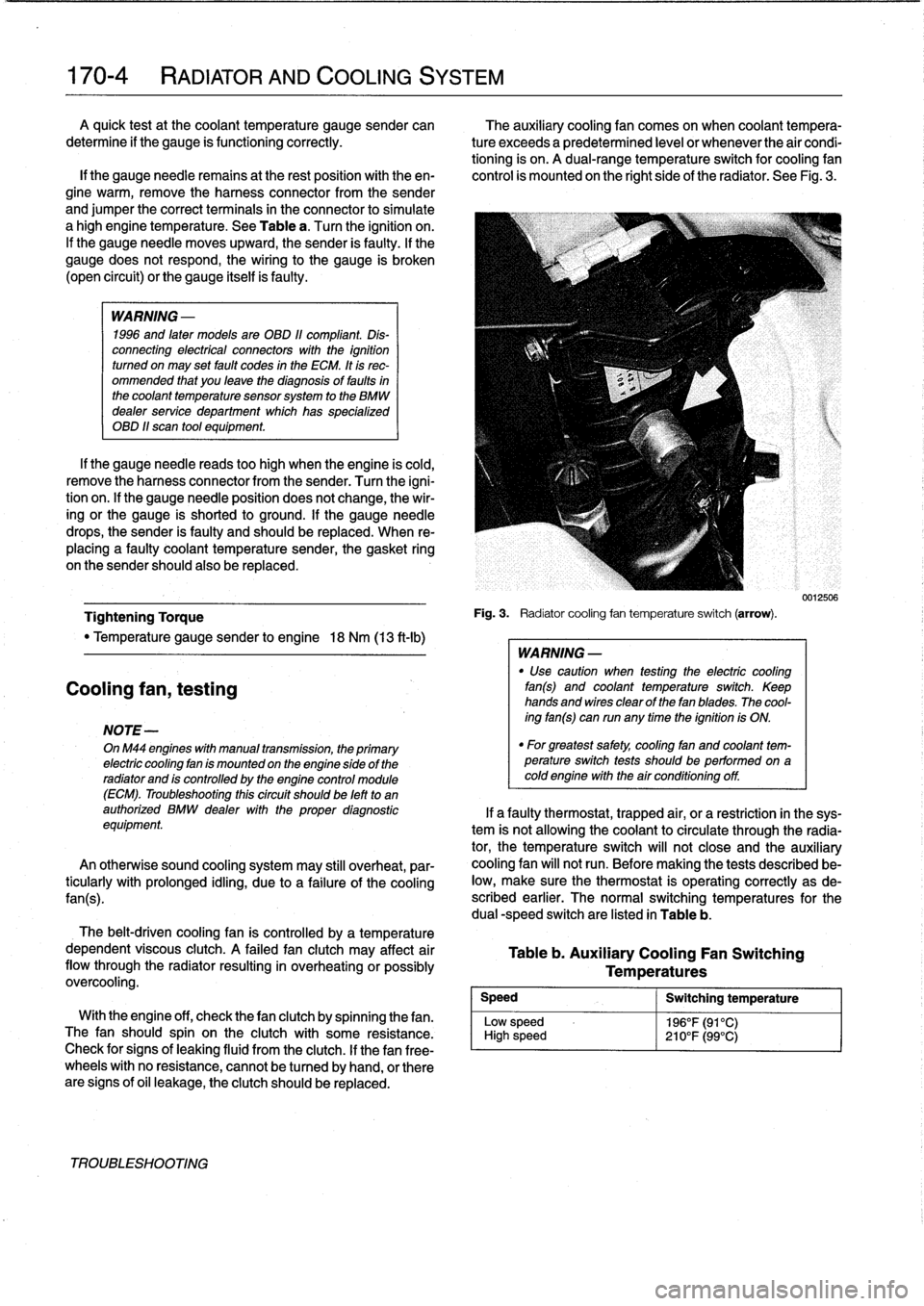

Fig

.

3

.

Radiatorcooling

fan

temperature

switch

(arrow)

.

WARNING

-

"

Use

caution

when

testing

the

electric

cooling

fan(s)

and

coolant

temperature

switch

.

Keep

hands

and

wires

clear

of

thefan

blades

.

The

cool-

ing

fan(s)

can

run

any

time

the

ignition

is

ON

.

"

For

greatest

safety,

coolíng

fan

and

coolant

tem-perature

switch

tests

shouldbe

performed

on

acoldengine

with

the

air

conditioning

off

.

Table

b

.

Auxiliary

Cooling

Fan

Switching

Temperatures

Switching

temperature

196°F(91°C)

210°F(99°C)

0012506

If

a

faulty

thermostat,

trapped

air,

or

a

restriction

in

the

sys-

tem

is

not

allowing

the

coolant

to

circulate

through

the

radia-

tor,

the

temperature

switch

will

not

close

and

the

auxiliary

cooling

fan

will

not

run

.

Before

making

the

tests

described

be-

low,

make

sure

the

thermostat

is

operating

correctly

as

de-

scribed

earlier

.

The

normal

switching

temperatures

for

the

dual

-speed

switch

are

listed

in

Table

b

.

Page 207 of 759

GENERAL

.

.

.......

.

......

.

...

.

.

.

.

.

...

180-1

Exhaust

system,

removing

and

installing

.

...

.180-3

EXHAUST

SYSTEM

REPLACEMENT

.

...

180-1

Exhaust

manifolds,

removing

and

installing

.

.

.180-5

GENERAL

The

exhaust

system

is

designed

to

be

maintenance

free,

al-

though

regular

inspection

is

warranted

due

to

the

harsh

oper-

atingconditions

.

Under

normal

conditions,

the

catalytic

converter

does

not

require

replacement

unless

it

is

damaged

.

On

1996

and

later

cars,

a

pre-

and

post-catalytic

converter

oxygen

sensor

is

used

at

each

catalytic

converter

.

Be

sure

to

take

care

when

removingthe

system

not

to

damage

the

sen-

EXHAUST

SYSTEMREPLACEMENT

sors

.

See

130

Fuel

Injection

for

information

on

testing

oxygen

sensors

.

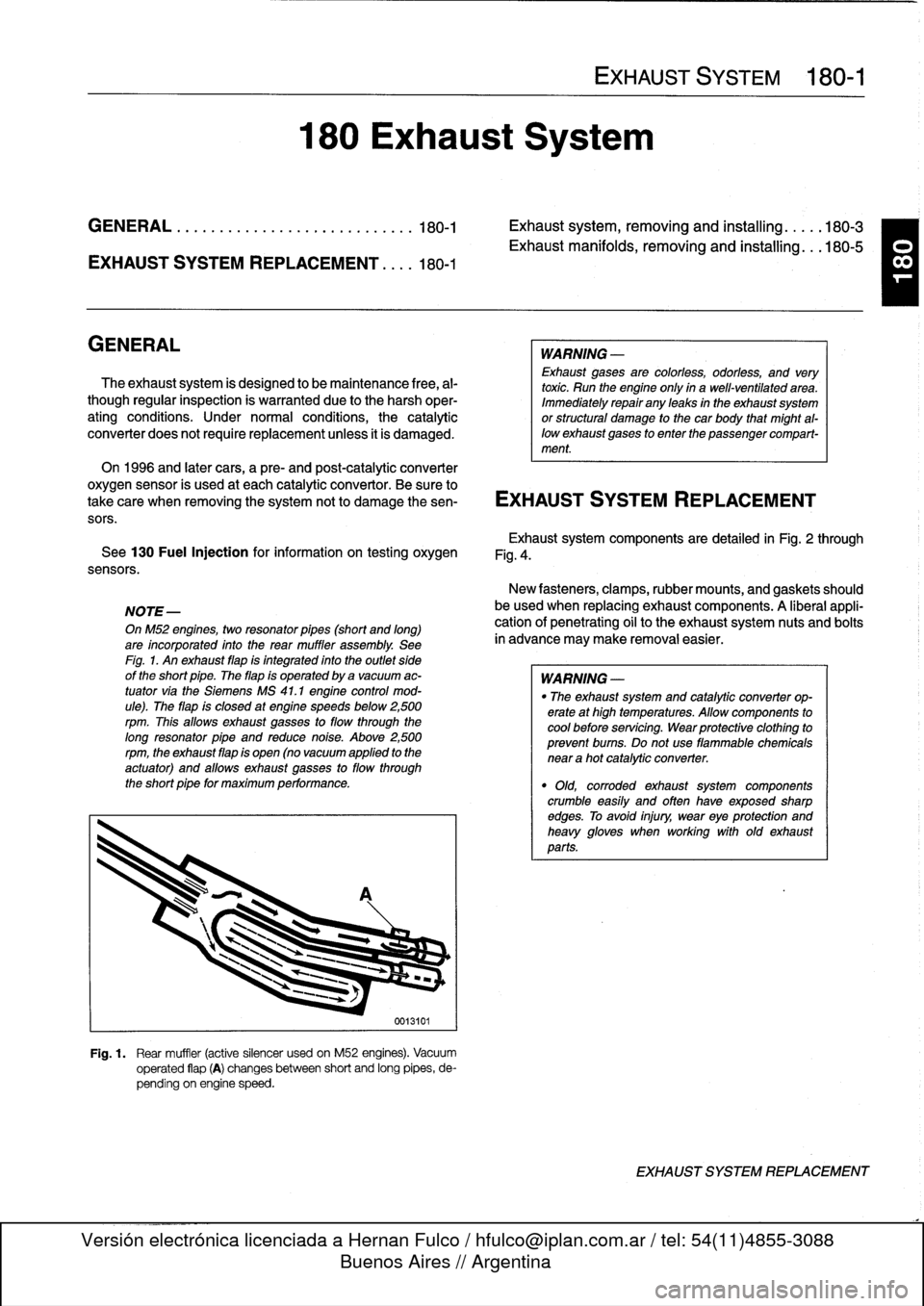

NOTE-

OnM52

engines,

two

resonator

pípes

(short

and

long)

are

incorporated

into

the

rear

muffler

assembly

.

See

Fíg

.

1

.

An

exhaust

flap

is

integrated

into

the

outlet

side

of

the

short

pipe

.

The

flap

is

operated

by

a

vacuum

ac-

tuator

via

the

Siemens

MS

41

.1

engine

control

mod-

ule)

.

The

flap

is

closed

at

engine

speeds

below

2,500

rpm

.

This

allows

exhaust

gasses

to

flow

through

the

long

resonator

pipe

and

reduce

noise

.

Above

2,500rpm,

the

exhaust

flap

is

open

(no

vacuum

applied

to

the

actuator)

and

allows

exhaust

gasses

to

flow

through

the

short

pipe

for

maximum

performance

.

180

Exhaust

System

0013101

Fig

.

1

.

Rear

muffler

(active

silencer

usedon

M52

engines)

.

Vacuum

operated

flap

(A)

changesbetween

short

and

long

pipes,

de-

pending

on

engine

speed

.

EXHAUST

SYSTEM

180-1

WARNING

-

Exhaust

gases

are

colorless,

odorless,

and

very

toxic

.

Run

the

engine

only

ín

a

well-ventilated

area

.

Immediately

repair

any

leaks

in

the

exhaust

system

or

structural

damage

to

the

car

body

that

might

al-

lowexhaust

gases

to

enter

the

passenger

compart-

ment

.

Exhaustsystem

components

are

detailed

in

Fig

.

2

through

Fig

.

4

.

New

fasteners,

clamps,rubber

mounts,

and

gaskets

should

be

used

when

replacing

exhaust

components

.

A

liberal

appli-

cationof

penetrating

oil

to

the

exhaustsystem

nuts

and

bolts

in

advance

may

make

removal

easier

.

WARNING

-

"

The

exhaust

system

and

catalytic

converter

op-

erate

at

high

temperatures

.

Allow

components

to

cool

before

servicing

.

Wear

protectíve

clothíng

to

prevent

bums

.

Do

not

use

flammable

chemicals

near

a

hot

catalytic

converter

.

"

Old,

corroded

exhaust

system

components

crumble

easíly

and

often

have

exposed

sharp

edges

.

To

avoid

injury,

wear

eye

protection

and

heavy

gloves

when

working

with

old

exhaust

parts

.

EXHAUST

SYSTEM

REPLACEMENT

T

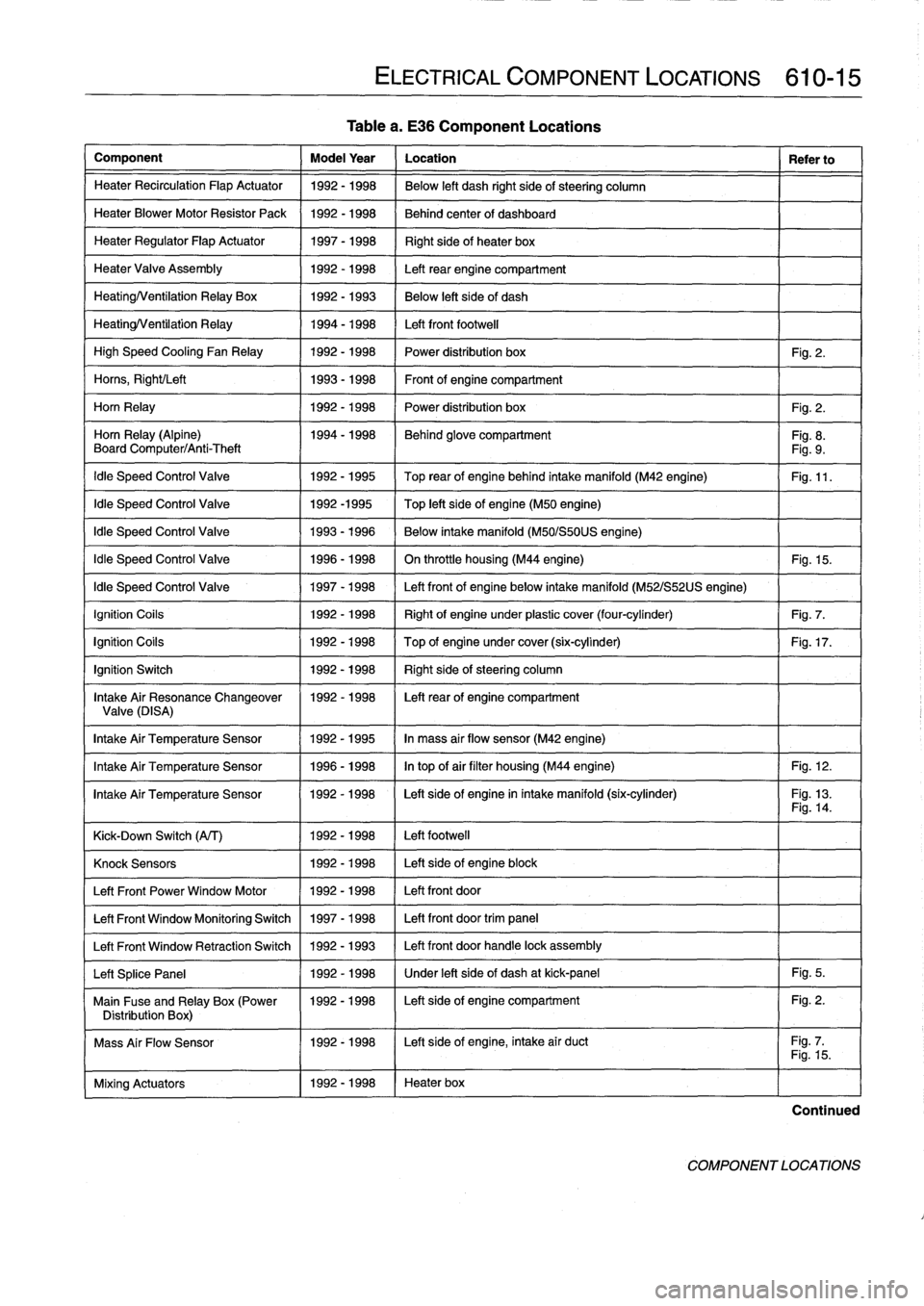

Page 401 of 759

Component

Model

Year

Location

Refer

to

Heater

Recirculation

Flap

Actuator

1992-1998

Below

left

dash

right

side

of

steering

column

HeaterBlowerMotor

Resistor

Pack

1992-1998

Behind

center

of

dashboard

Heater

Regulator

FlapActuator

1997-1998

Right

side

of

heater

box

HeaterValve

Assembly

1992-1998

Left

rear

engine

compartment

HeatingNentilation

Relay

Box

1992-1993

Below

left

side

of

dash

HeatingNentilation

Relay

1994-1998

Left

front

footwell

High

Speed

Cooling

Fan

Relay

1992-1998

Power

distribution

box

Fig

.

2

.

Homs,

Right/Left

1993-1998

Front

of

engine

compartment

Horn

Relay

1992-1998

Power

distribution

box

Fig

.

2

.

Horn

Relay

(Alpine)

1994-1998

Behind

glove

compartment

Fig

.

8

.

Board

Computer/Anti-Theft

Fig

.

9

.

Idle

Speed

Control

Valve

1992-1995

Top

rearof

enginebehind

intake

manifold

(M42

engine)

Fig

.

11

.

Idle

Speed

Control

Valve

1992-1995

Top

left

side

of

engine

(M50

engine)

Idle

Speed

Control

Valve

1993-1996

Below

intake

manifold

(M50/S50US

engine)

Idle

Speed

Control

Valve

1996-1998

On

throttle

housing

(M44

engine)

Fig

.

15

.

Idle

Speed

Control

Valve

1997-1998

Left

front

of

engine

below

intake

manifold

(M52/S52US

engine)

Ignition

Coils

1992-1998

Right

of

engineunder

plastic

cover

(four-cylinder)

Fig

.

7

.

Ignition

Cofs

1992-1998

Top

of

engine

undercover

(six-cylinder)

Fig

.

17

.

Ignition

Switch

1992-1998

Right

sídeofsteering

column

Intake

Air

Resonance

Changeover

1992-1998

Leftrear

of

engine

compartment

Valve(DISA)

Intake

Air

Temperature

Sensor

1992-1995

In

mass

air

flow

sensor

(M42

engine)

Intake

Air

TemperatureSensor

1996-1998

In

top

ofair

filter

housing

(M44

engine)

Fig

.

12

.

Intake

Air

Temperature

Sensor

1992-1998

I

Left

sídeof

engine

in

intake

manifold

(six-cylinder)

-

-

I

Fig

.

13

.

Fig

.

14

.

Kick-Down

Switch

(A/T)

1

1992-1998

1

Left

footwell

Mixing

Actuators

1

1992-1998

1

Heater

box

ELECTRICAL

COMPONENT

LOCATIONS

610-15

Table

a

.

E36

Component

Locations

Knock

Sensors

1

1992-1998

1

Left

side

of

engine

block

Left

Front

Power

Window

Motor

11992-1998

/

Left

front

door

Left

Front

Window

Monitoring

Switch

1

1997-1998

1

Left

front

door

trim

panel

Left

Front

Window

Retraction

Switch

1

1992

-

1993

1

Left

front

door

handle

lock

assembly

Left

Splice

Panel

1

1992-1998

1

Under

left

side

of

dash

at

kick-panel

1

Fig

.

5

.

Main

Fuse

and

Relay

Box

(Power

1992-1998

I

Left

sideof

engine

compartment

Fig

.

2

.

Distribution

Box)

1

I

Mass

Air

Flow

Sensor

1992-1998

I

Left

side

of

engine,

intake

air

duct

Fig

.

7

.1

I

Fig

.

15

.

Continued

COMPONENT

LOCATIONS

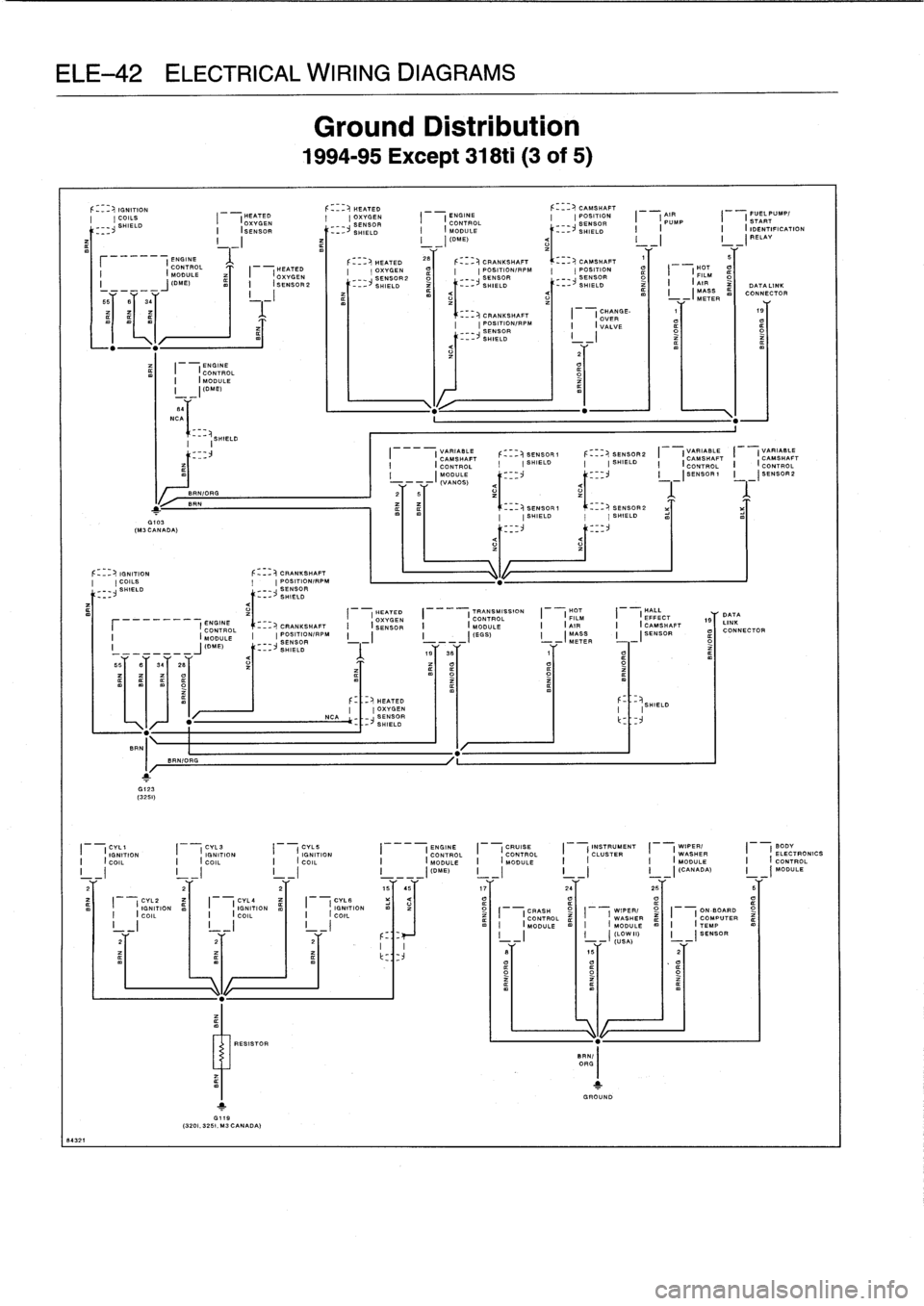

Page 526 of 759

ELE-42

ELECTRICAL

WIRING

DIAGRAMS

BC321

IGNITION

HEATED

__

COILS

HEATED

OXYGEN

ENGINE

(

SHIELD

I

IOXVGEN

II

SENBOR

I

(

CONTROL

I

(SENSOR

-~

SHIELD

I

(

MODULE

I

¢~

I

_I

(DME)

CONTROL

HEATED

I

(MODULE

I

(OXYGEN

I

_-J(OME)

ISENSOR2

0-0

G103

(M3CANADA)

IGNITION

CRANKSHAFT

I

COILS

I

I

POSITIONIRPM

SHIELD

k=__SENSOR

-

SHIELD

I

ENGINE

I-

CONTROL

I

I

MODULE

SRN

IL

1

G123

(3251)

ENGINE

I

(CONTROL

I

(MODULE

I

_

I

(DME)

BRNIORG

BRN/ORG

BRN

3

G119

(3201

.

3251

.

M3

CANADA)

Ground

Distribution

1994-95

Except

318ti

(3

of

5)

HEATED

(OXYGENSENSOR,--

SHIELD

F

_~

HEATED

(OXYGEN

NCA~

_

_~

SENSOR

--

SHIELD

---

I

VARIABLE

CAMSHAFT(CONTROL

I

I

MODULE

----

(VANOS)

CRANKSHAFT

CRANKSHAFT

POSITION/RPM

SENSOR

---~

SHIELD

CAMSHAFT

POSITION

I

I

AIR

PUMP

CAMSHAFT

POSITION/RPM

I

POSITION_

_

I

I

HOT

__

SENSOR

_

SENSOR

FILM

-~SHIELD

-~

SHIELD_

I

I

AIR

M<

I

I

MASS

z

-

--

ETER

m

SENSOR

1

SHIELD

SENSOR

1

SHIELD

-

SENSOR

METER

I

(DME)

_~

SHIELD

19

3y

1Y

__

I

-

I

I

BT

_

I

_

<

557

By

347

287

T

oI

RESISTOR

BRN/I

ORG

_

SENSOR

---~

SHIELD

I

II

v

I

I

(CHANGE-

I

I

19

OVER

I

I

VALVE

_I

m

F---D,SENSOR2

I

(VARIABLE

I

(VARIABLESHIELD

CAMSHAFT

CAMSHAFTS

I

I

(CONTROL

I

(CONTROL

I

-

ISENSORI

I

-

I3ENSOR2

SENSOR2

I

SHIELD

1

GROUND

HEATED

TRANSMISSION

HOT

HALL

I

(

OXYGEN

I

(CONTROL_

I

(

FILM

I(

EFFECT

CRANKSHAFT

I;

SENSOR

I

(MODULE

I

(AIR

I

(CAMSHAFT

POSITION/RPM

I

(EGS)I

MASS

I

I

SENSOR

._

II

(SHIELD

I

FUEL

PUMPf

START

I

I

IDENTIFICATION

I

v

I

RELAY

197

L

DAN

TA

K

I

oICONNECTOR

DATA

LINK

CONNECTOR

I

CYL1

(

ICYL3

I

CYL5

I

(ENGINE

I

(CRUISE

I

(INSTRUMENT

I

(

WIPER/

I

BODY

IGNITION

IGNITION

IGNITION

ONTROL

CONTROL

CLUSTER

WASHER

ELECTRONICS

I

;

COIL

I

(

COIL

I

(

COIL

I

IC

MODULE

I

(

MODULE

I

I

I

(

MODULE

I

(

CONTROL

I

_I

I

_I

I

_I

I

-

I

(DME)

I

_

I

(CANADA)

MODULE

2

2

2

1565

17

26

25

B

CYL2

CYL4

CYLS

U

o

I

(

IGNITION

m

I

(

IGNITION

z

I

(

IGNITION

I

(

COIL

I

(

COIL

I

(

COIL

CRASH

WIPER/

ON

-BOARD

I

I

I

I

I

I

CONTROL

rt

WASHER

O

COMPUTER

I

I

I

I

I

I

I

(MODULE

I

(

MODULE

I

(TEMP

2T2Y

.

.

F_

_

I

-I

I

_

I

(

I)

I

-

I

SENSOR

2

Y

USA)

-

,

Page 531 of 759

8907

1

I

(ENGINE

CONTROL

I

(MODULE

I

-

I

(ONE)

84

NCA

I

F-_

_

)1

I

IGNITIONCOIL

SHIELD

u

CONTROL

HEATED

I

(MODULE

I

(OXYGEN

I

-

I(DME)_

ISENSOR2

55

fi

34

I

~BR~N

BR=

m

I

B~

RN/OPG

G103

(1996)

(M3

CANADA)

I

OXYGEN

(HEATED

ENGINE

I

(CONTROL_

HEATED

I

(SENSOR

I

(MODULE

I

(OXYGEN

I

IGNITION

I

I

IGNITION

¢

I

I

IGNITION

COIL

I

i

COD

.

I

I

COIL

I

_~

I

_I

I

_I

1

G,19

(328,

M3)

RESISTOR

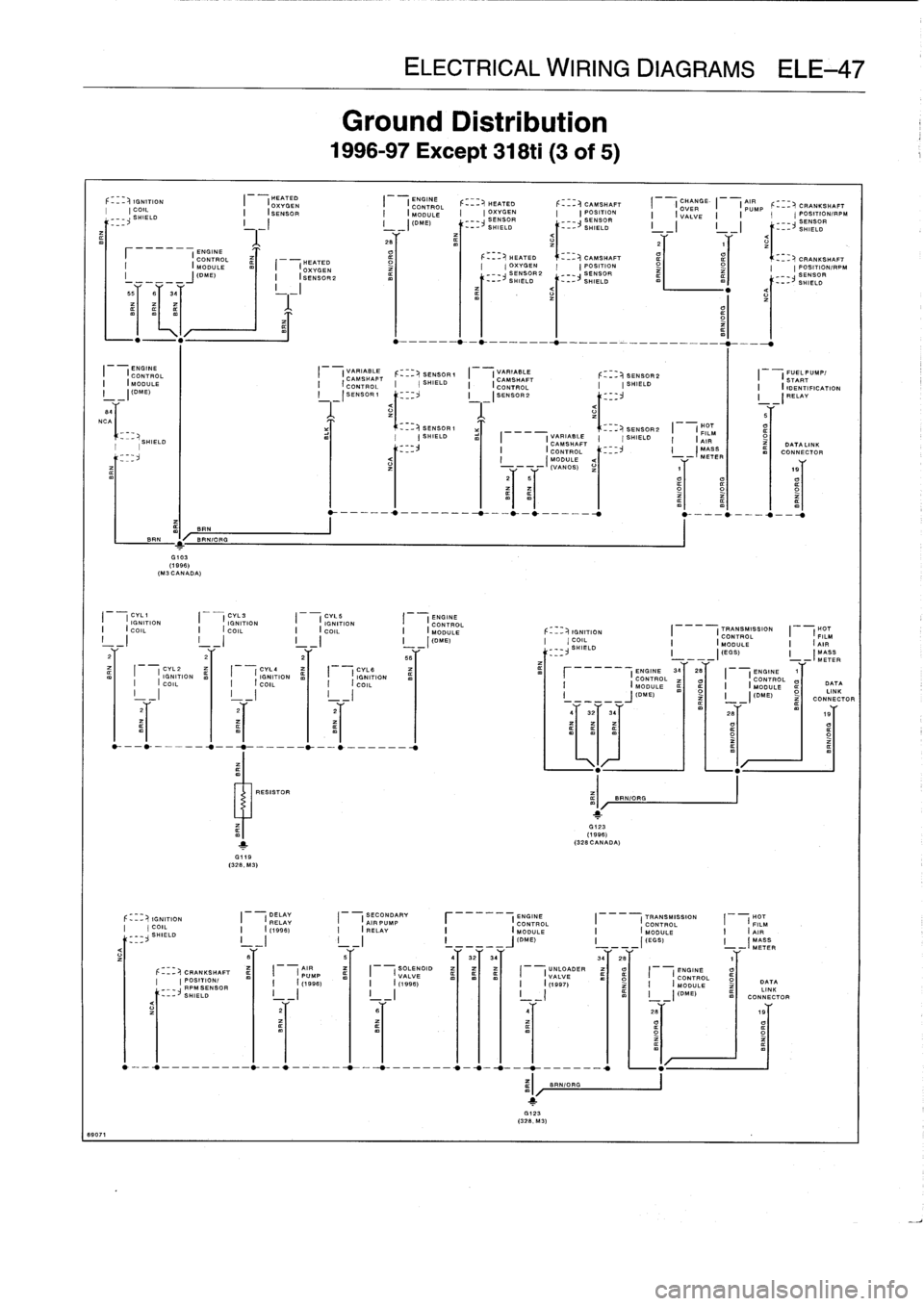

Ground

Distribution

1996-97

Except

318ti

(3

of

5)

(

-

I

(DIVE)

SENSOR

SHIELD

28

I

(VARIABLE

SENSOR(

I

(VARIABLE

SENSOR2

FUEL

PUMP/

CONTROL

(SHIELD

CAMSHAFT

I

(START

C

I

I

I

(

CONTROL

SHIELD_

I

(

IDENTIFICATION

I

_

(SENSOR(

ISENSOR2

_

(RELAY

1

II

I5

SENSOR2

I

(HOT

_-~

SENSOR1

FILMSHIELD

I

(

VARIABLE

I

-(

SHIELD

I

(

AIR

CAMSHAFT

DATA

INK

I

(CONTROL

<1-_-~

I

(MASS

I

ml

CONNECTOR

(VANCE)

19

CVL1

CVL3

CVLE

ENGINE

(

IGNITION

I

(

IGNITION

I

(

IGNITION

i

(

CONTROL

I

(

COIL

I

(

COIL

I

(

COIL

I

(

MODULE

I

_I

I

_I

I

_I

I

_I

(DME)

ELECTRICAL

WIRING

DIAGRAMS

ELE=47

F---

HEATED

CAMSHAFT

I

I

OXYGEN

I

I

POSITION

SENSOR2

SENSOR--

SHIELD

--

SHIELD

mI

I

-

-

------------

-

-

-

4/

32/34/

341

26

j

.123

(328,M3)

_-~CAMSHAFT

I

ICHANGE

I

(PUMP

F---~

CRANKSHAFT

(

POSITION_

I

(

VALVE

I

(

POSITION/PPM

_

SENSOR

__

SENSOR

--~

SHIELD

SHIELD

IGNITION

TRANSMISSION

HOT

(

COIL

I

(

CONTROL

I

(

FILM

__

SHIELD

_

I

(

MODULE

I

(

AIR

_I(EGS)

I

(MASS

---

_

METER

ENGINE

3428

M

I

I

ENGINE

r

-I

(

ECONTROL

O

CONTROL

I

(ODULE

ml

¢O

I

(ODULE

DATA

M

I

-

j

(DIVE)

I

-

I

(DIVE)

¢I

LINK

CONNECTOR

Y

YY

.

.

G123

(1996)(328

CANADA)

BRN/ORG

O

IGNITION

DELAY

SECONDARY

ENGINE

TRANSMISSION

HOT

COIL

I

(

RELAY

I

I

AIR

PUMP

F

(

CONTROL

I

(

CONTROL

I

(

FILM

SHIELD

I

(

(1996)

I

(

RELAY

I

(

MODULE

I

(

MODULE

i

(

AIR

L

_

_I

I

I

I

__

__J(OME)

I

_

I(EGSI

MASS

_

I

-(MATS

YY

Y

v

CRANKSHAFT

AIR

I

SOLENOID

UNLOADER

I

(ENGINE

O

(

PUMP

I(

VALVE

(VALVE

CONTROL

POSITION/_

m

I

(

(1998)

m)

I

(

(1996)

(

(1997)

I

(

MODULE

DATA

_

RPMSENSOR

LINK

SHIELD

I_-

I

I

-

I

I

_I

I

_I

(DM

E)

CONNECTOR

zBY

,9T

CRANKSHAFT

I

POSITION/RPM

1

(MODULE

-

_

METER

SENSOR--

SHIELD

Page 532 of 759

ELE-48

ELECTRICAL

WIRING

DIAGRAMS

TRANSMISSION

r

I

ENGINE

(HALL

CON

TROL

I

CONTROL

I_

(

I

EFFECT

I

(

MODULE

I

(

MODULE

I

(

CAMSHAFT

I

_____y

_

I

11"S)

1

--

j

(DIE)

I

(SENSOR

B'f

28

y_

1

..'r

BY

3ar

BET

26

~

3

8907

2

PASSENGERS

PASSENGERSPASSENGERS

PASSENGERS

SUPPRESSION

DRIVERS

DOOR

DRIVER

I

(DOOR

I

(

SEAT

I

(SEAT

I

I

SEATBACK

I

(

FILTER

I

(

WINDOW

I

(

LOCK

I

(

DOOR

I

(JAMB

I

(CONTROL

I

(HEATER

I

(HEATER

II

I

(MOTOR

I

(HEATER

I

(HANDLE

RIGHT

RIGHT

RIGHT

CD

I---

m

I

-

I_

i

II

REAR

REAR

REAR

CHANGER

(

INTERIOR

I

I

(

WINDOW

ml

I

(

INTERIOR

ml

I

I

1

G313

G302

(4

DOOR)

(1996)

ROLLOVER

CONVERTIBLE

CONVERTIBLECONVERTIBLE

CONVERTIBLE

WINDSCREEN

HIFI

RADIO

I

(

SENSOR

I

---

(

TOP

I

(

TOP

I

(

TOP-END

I

---

(

TOP

I

I

CoWLPANEL

I

(

AMPLIFIER

I

II

I

I

(

ACTUATING

I

I

OONTROL

I

(

POSITION

I

(

POSITION

I

(

LOCK

I

i

I

I

SWITCH

I

-(

MODULE

I

-(

SWITCH

I

,

---(

SWITCH

I

,-(

SWITCH

I

-I

1

-I

IGNITION

F---

CRANKSHAFT

I

(HOT

I

I

UNLOADER

1

'CYL1

IOYL3

COIL

POSITION

FILM

RELAY

IGNITIONIGNITION

I

I

(

AIR

I

(

(1997)

I

(

COIL

I

(

COILCOILSHIELD

_

SENSOR

SHIELD

MASS

METER

S

1

(

I

I

I

I

1

I

___

1

r

(

1996

)

.T

2T

21"

,

.-------

.

.W_-*---___--7-----__-41"

-

----___--0-f---_---7

1

.1

m

SEAT

CHECK

LEFT

ANTI-

RIGHT

DRIVERS

PASSENGERS

I

(

OCCUPANCY

I

(

CONTROL

I

(

REAR

I

(

THEFT

I

(

REAR

I

(

SEATBELT

I

(

SEAT

I

1

DETECTOR

I

(

MODULE

I

(

DOOR

I

(

CONTROL

I

(

DOOR

I

I

SWITCH

I

T

HEATER

1

_I

I

-I

L-1

CONTACT

I

-I

MODULE

I

-I

CONTACT

I

-I

I

_

I

SWITCH

I

PASSENGERS

9

I

'

DRIVERS

4

PASSENGERS

DRIVERS

1

PASSENGERS

1

4

DRIVERS

(

WINDOW

WINDOW

I

(

SIDE

I

(

SIDE

I

(

SEATBELT

I

(

SEA

2

T

I

I

MONITIORING

I

I

MONITIORING

I

(

IMPACT

I

(

IMPACT

I

(

SWITCH

I

(

HEATER

1

(

SWITCH

I-.(

SWITCH

I

V

I

SENSOR

I

v

I

SENSOR

I

5I

I

I

-(

-

(1997)

--

(1997)

--

(1997)

T

--

(1997)

SWITCH

-

Y

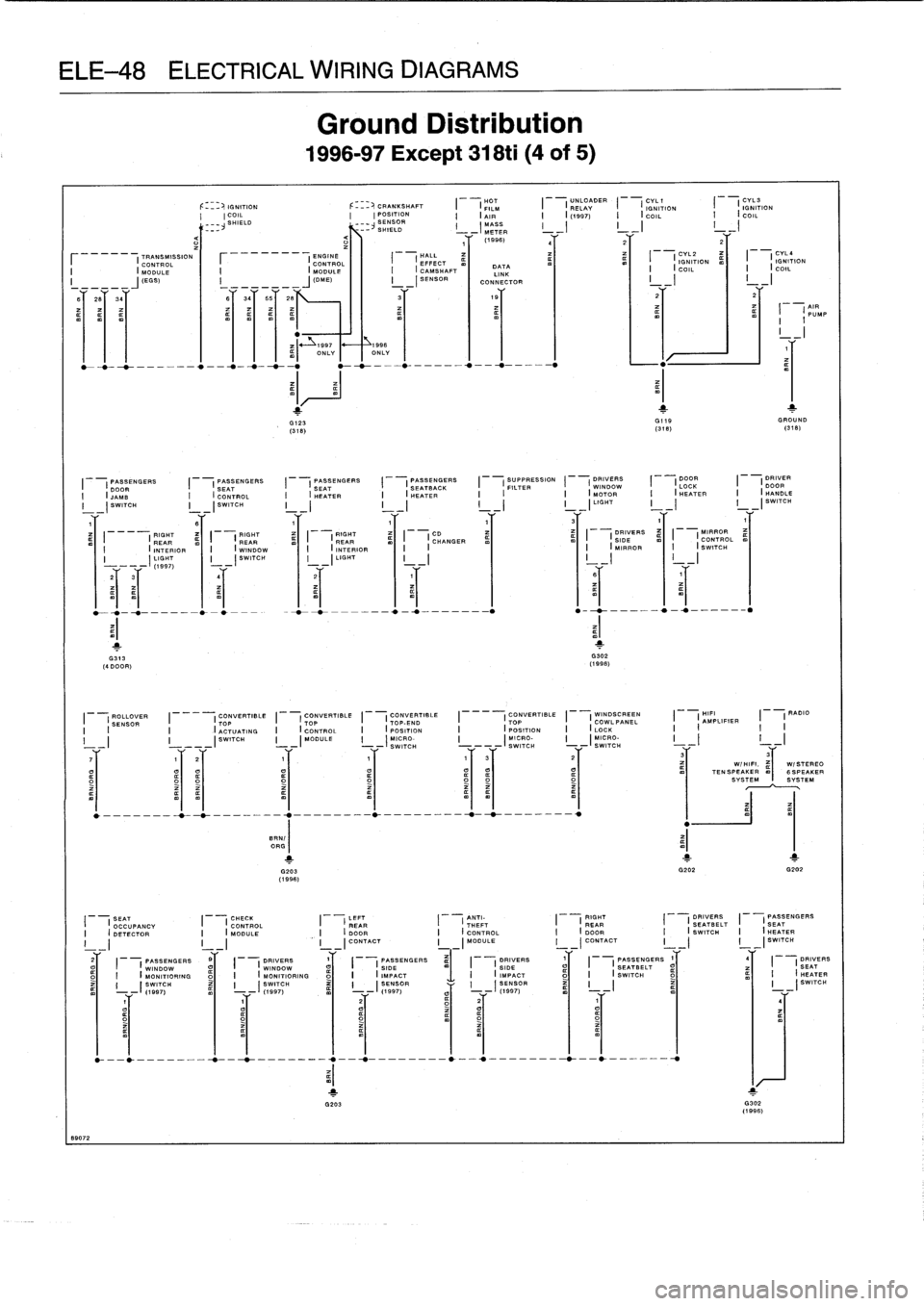

Ground

Distribution

1996-97

Except

318ti

(4

of

5)

i

997

__~

1996

m)

ONLYONLY

G123

GI9

GROUND

(318)

(318)

(318)

y

1

1

G203

G202

G202

(1996)

DATA

LINK

CONNECTOR

O

-___-___0_-t--__--_

.,---0__--_---`__

.,-_--_-_-*_--0

.-____-

CYL2

DYLa

I

I

IGNITION

I

I

IGNITION

I

I

m

COIL

l

I

I

COIL

1

'

o~

t

G302

(1996)

1

AIR

I

PUMP

31

3

aIaI¢~

W/HIFI

.

,I

W/STEREOTENSPEAKER6SPEAKER

SYSTEMSYSTEM

Page 554 of 759

ELE-70

ELECTRICAL

WIRING

DIAGRAMS

I

02

SENS

SIB

I"7

7

I

02SENSGNDI)

I

GROUNDI

2

BR

,

'IB

BRN/BLU

I

IARCVALVEI

I

IsCVALVEI}

I

ECM

RELAY

I

EEVALVEI~

I

CVL4IGNCOILI

S7~LK

I

CVL3IGNCOILI

24L

BL1(

I

CVL2IGN

COILI'

B2

~

BLK

I

CVLIIGNCOILI

2

I

GROUNDI

B'=RN

I

GF

.uNDI

),

BRN

I

GROUNOI

3~

BR"

I

RUNIST

GRN

ARTI

S~

ENGINECONTROL

MODULE

(DME)

13B

START

1

GRN

I

DN

OFF

IGNITION

S

WITCH

8727

3

HOTATALLTIMES

UELINJECTION

VALVES

NCA"

=

It,

INCA

SPIN

BRN

GRN

~GRN

OF

N

/

GRN"

\

GRN

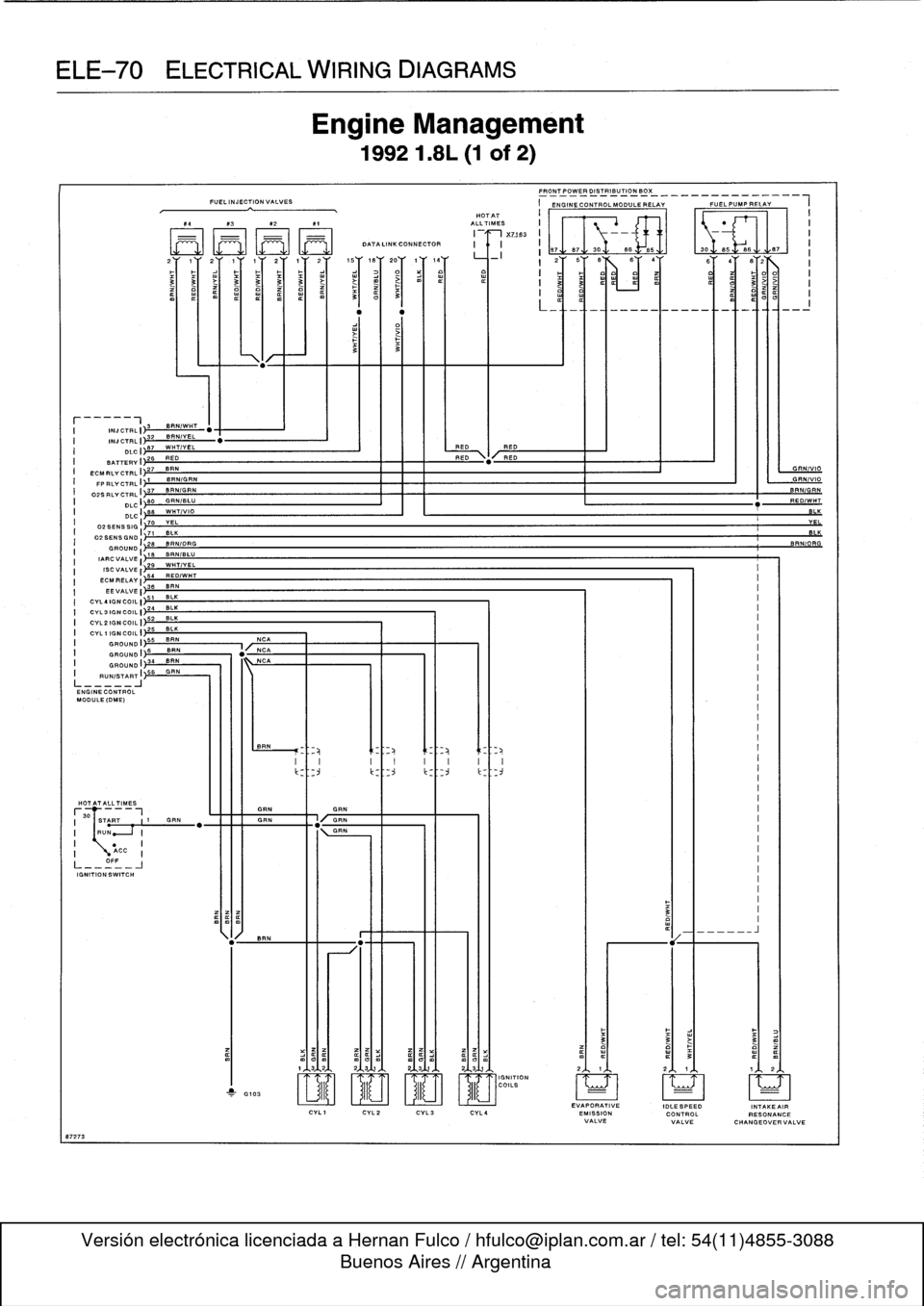

Engine

Management

19921

.8L

(1

of

2)

HOTAT

F4

X3X2

R1

ALLTIMES

I

XZ793

M

M

[]M[IM

AT

.

LINK

CONNECTOR

8B

3Dy

eB=85

.1

.1308

I

ii

w

>

3~

3

3

BRNIWH

INJCTRLI

32

BRNIYEL

T

INJCTRLI~

DLCI

je7

L

REO

I

RED

BATTERY

I

2S

RED

RED

FRONT_POWERDISTRIBUTIONBO%

_

_

___

_

_

_

____

_

_

I

ENGINE

CONTROL

MODULE

RELAY

FUEL

PUMP

RELAY

L

ECMFLY

CTRL

1)27

BFN

FP

FLY

CTRL

I

I'

SWORN

02SFLYCTRL

I

37

BRNIGRN

BRN

GRN

DLCI

80

GRNIBLU

RE

O

DLCI

,88

WHTIVIO

1

~1~

2oY

1

Y

I4Y

_

i

2Y

SY

BX

BY

4YBY

EVAPORATIVE

IDLESPEED

INTAKE

AIR

EMISSION

CONTROL

RESONANCE

VALVE

VALVE

CHANGEOVER

VALVE

Page 566 of 759

ELE-82

ELECTRICAL

WIRING

DIAGRAMS

I

AC7IVATEVALVEII

BRNIWHT

I

ACTIVATE

VALVE

I'3

BRN/V

EL

10862

4

SIGNPLINPUTI

1T2

B

AN

ACTIVATE

VALVE

I--

GROUND

I

4B6~GRV/VIO

ENGINO1CATOR

I

~

10

BLK/VIO

DRIVE

AWAY

SIG

II

11

BLKIGRY

AC

TIVATEAIC

ACTIVATE

VALVEI

31

BRNIBLU

ACTIVATE

VALVE

I

32~BRTI/GRN

120

BLK

CRANKPOSIRPMI

Y-

CAMSHAFTPOSI

21

I

BATTERYVOLTI126

RED

ECM

RLV

CTRL

1

)21

8RN/WHT

18

BRNIRED

INTKAIRTEMPI

I

I

406

CVL3-4KSI

42

GRNIRED

FU

ELCONSUMPTI

THROTTLE

POST

44

B

RN/VIO

I

A/CCOMPCUT136

8LK/BLU

"

8LK/BLU

II

5VSUPPLVI

53

ISCVALVE

CTRLI

2

/GRN

30

BRN

02SENSH7NGI~-

19

VEL

02SENSORSIGI~

1

BRN

02

SENS

HTNG

I

SENSORGRNOI

4

23

BLU

CVL4IGNCOIL

CVL3

ON

co

ILI

2r-

INJGROUND

I

128

BRN

GROUND

GROUNDI)~pl

L_____!

ENG

ME

CONTROL

MODULE

(DME)

HOTPTALLTIMES

___

I

START

.1

1

GRN

I

RUN

~_I

I

18

I

~

ACC

I

OFF

IGNITION

SWITCH

BA7TERVVOLTI

54

RED/W~

H

IGNGROUNDI

50

READ

CYL21GN

COIL

ED

I

l

~~

CYL1IGNCOIL

49

WHT

I

IGNSWITCH

I

56

GR

"GRN

B7

REOIWHT

ACTIVATE

FAN

ACTIVATE

VALVE

I

8

tf

FUELINJECTIONVALVES

HALLEFFECT

HOTFILMAIR

CAMSHAFT

FRONT

POWER

DISTBIU710NBOX

______

.

___

CVL4CVL3

CVL2

CYLl

MASSMETERSENSOR

r

i

SYSTEM

NORMAL

SPEEDRELAY

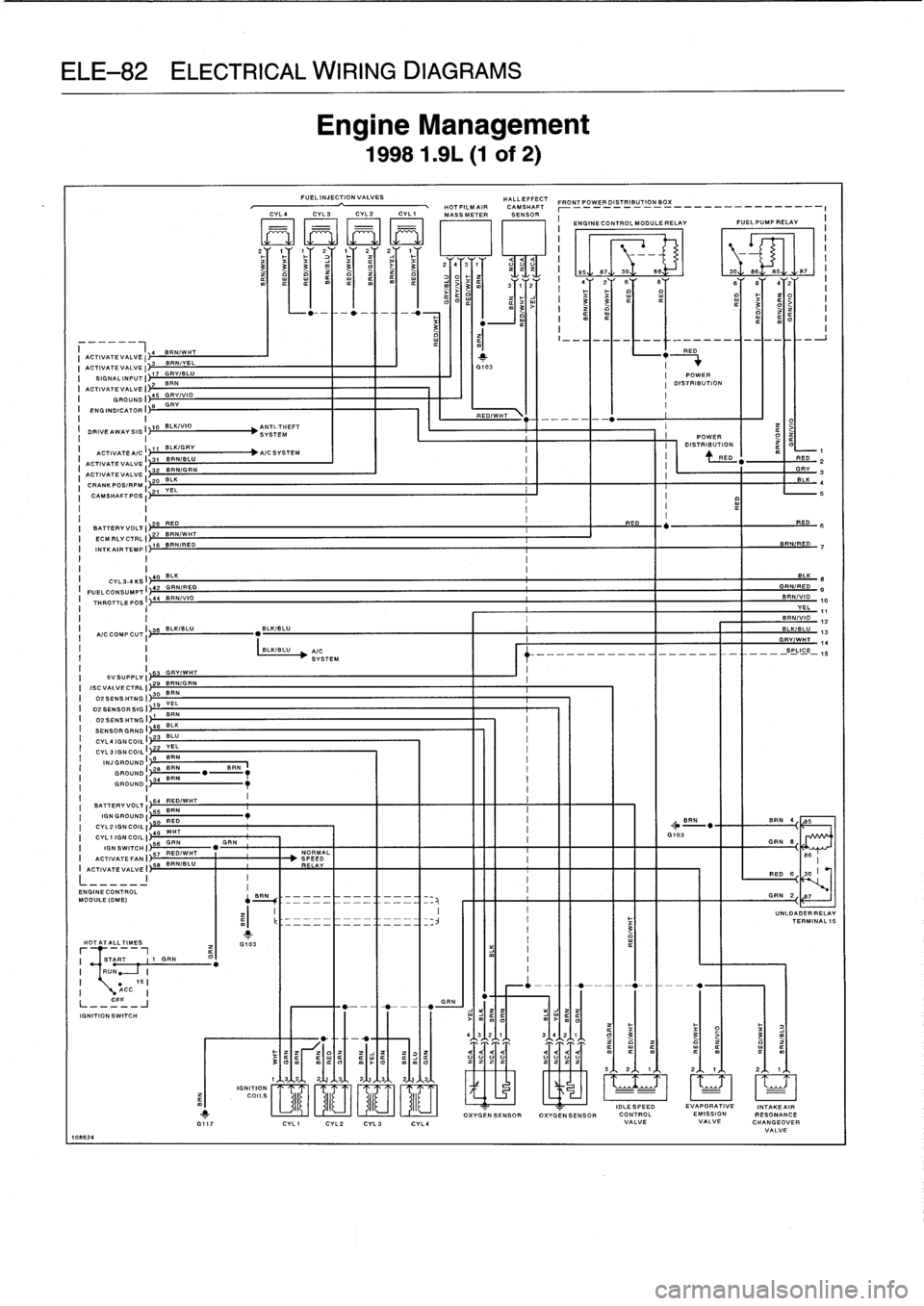

Engine

Management

19981

.9L

(1

of

2)

IGNITION

JJ

U

COILS

II

GA

.

4

3~2

1

a

mIm

a

OXVGENSENSOROXVGENSENSOR

IDLESPEED

EVAPORATIVE

INTAKEAIR

CONTROL

EMISSION

RESONANCE

VALVEVALVE

CHANGEOVER

VALVE

I

-

"HIRED

2

Page 754 of 759

WARNING

Your

common

sense,

good

judge-

ment,

and

general

alertness

are

cru-

cial

tosafe

and

successful

service

work

.

Before

attempting

any

work

on

your

BMW,

read

the

warnings

and

cautions

on

page

vi¡

and

the

copyright

page

at

the

frontof

the

manual

.

Review

these

warnings

and

cautions

each

time

you

prepare

to

work

on

your

BMW

.

Please

also

read

any

warnings

and

cautions

that

accom-

pany

the

procedures

in

the

manual

.

Fuel

pressure

regulator

See

Fuel

injection

Fue]

pump

general

information

160-1

electrical

tests

160-7

power

consumption,

testing

160-7

delivery

tests160-8

delivery

volume,

testing

g

160-9

electrical

circuit,

checking

160-7

fuse

and

relay

160-6

level

sender

See

pump/fuel

leve¡

sender

operating

fuel

pump

for

tests

160-6

pump/fuel

level

sender

(left

side),

removing/installing

160-6

pump/fuel

leve¡

sender

(right

side),

removing/installing

160-5

relieving

fuel

pressure

and

connecting

fue¡

pressure

gauge

160-8

Fueltank

and

lines

general

information

160-1

draining

160-2

evaporative

control

system

160-4

leve¡

senders,

testing

160-5

removing/installing

160-3

Fundamentals

for

the

do-it-yourself

owner

general

information

010-1

advice

for

the

beginner

010-4

cleanliness

010-4

electrical

testing

010-6

gaskets

and

seals

010-5

non-reusable

fasteners

010-5

planning

ahead

010-4

tightening

fasteners

010-5

wire

repairs

010-6

buying

parts

010-6

genuine

BMW

parts

010-6

information

you

need

to

know

010-7

non-returnable

parts

010-7

emergencies

010-11brake

fluid

leve¡

010-13

car

will

not

start

010-11

changinga

tire

010-11

check

enginewarning

light

010-13

dim

Iights

010-13

jump

starting

car

010-12

low

o]I

pressure

010-13

overheating

010-12

Emergencies

(cont

.)

spare

parts

kit

010-14

towing

010-13

gettingstarted

010-2

lifting

thecar

010-3

raising

car

safely

010-3

safety

010-2

working

under

car

safely

010-4

how

to

use

this

manual

010-2

warnings,

cautions

and

notes

010-2

service

010-7

tools

010-7

basic

tool

requirements010-8

BMW

specialtools

010-11

feeler

gauges

010-10

jack

stands

010-9

oil

change

equipment

010-9

torque

wrench

010-10

volt-ohm

meter

(VOM)

or

Multi-

meter010-10

Fuses

See

Electrical

component

locations

G

Gaskets

See

Fundamentals

for

the

do-it-

yourself

owner

Gearshift

See

Gearshift

linkage

Gearshift

linkagegeneral

information

250-1

automatic

shiftlock,

checking

function

250-5

automatic

transmission

gearshift

250-

3

gear

position/neutral

safety

switch,

replacing

(automatic

transmission)

250-4

gearshift

lever,

installing

(manual

transmission)

250-2

gearshift

lever,

removing

(manual

transmission)

250-1

gearshift

mechanism,

adjusting

(automatictransmission)

250-3

manual

transmission

gearshift

250-1

shift

interlock,

checking

function

(automatic

transmission)

250-6Glass

See

Door

windows

Glove

compartment

See

Interior

trim

Grille

See

Exterior

trim,

bumpers

Guibo

(flex

disc)

See

Driveshaft

Handle,

door

See

Doors

Hardtop

See

Body-general

Headlight

See

Exterior

lighting

Headlight

switch

See

Switches

and

electrical

accessoriesHeater

box

See

Heating

Heater

core

See

Heating

Heater

valve

See

Heating

Heating

general

information

640-1

air

distribution

motors

640-9

air

distribution

motor,

replacing

(rotary

knob)

640-10

blower

motor,

removing/installing

640-1blower

motor

resistor

pack,

replacing

640-3

control

head

640-7

removing/installing

(digital-display)

640-8

removing/installing

(rotary

knob)

640-7

control

module

removing/installing

(digital-display)

640-8

removing/installing

(rotary

knob)

640-8

heater

box,

removing640-4

heater

core,

replacing

640-6

heater

core

temperature

sensor,

replacing

640-7

heater

valve,

replacing

640-3

rear

window

blower

(convertible

models)

640-10

reas

window

defogger

640-10sensor

fan

forinterior

temperature,

replacing

640-9warnings

and

cautions

640-11

Hood

See

Fenders,

engine

hood

Idle

speed

See

Maintenance

program

Idle

speed

control

valve

See

Fuel

injection

Ignition

switch

See

Switches

and

electrical

accessories

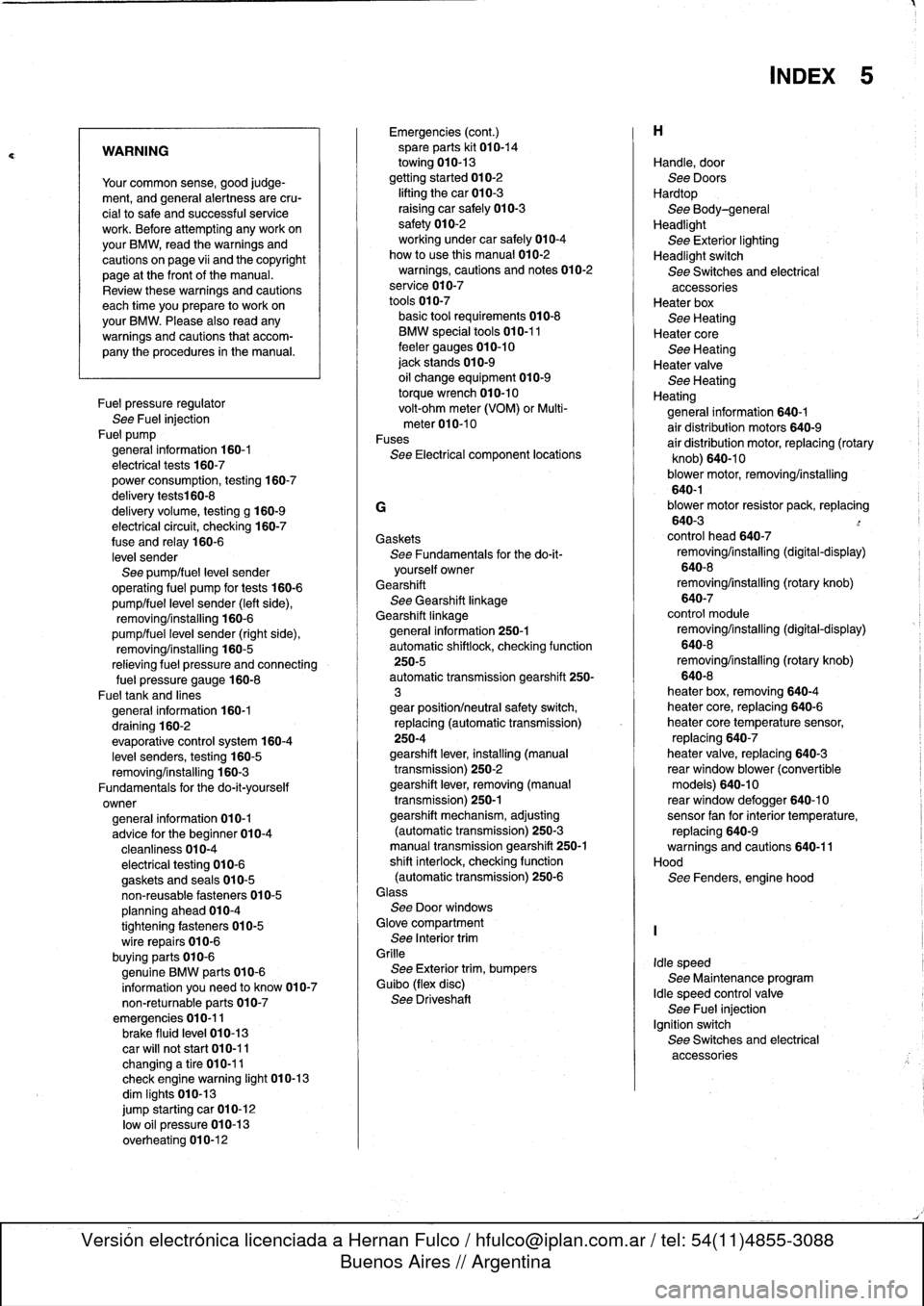

INDEX

5