display BMW M3 1998 E36 Owner's Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 1998, Model line: M3, Model: BMW M3 1998 E36Pages: 759

Page 452 of 759

640-6

HEATING

AND

AIRCONDITIONING

Heater

core,replacing

1.

Drain

engíne

coolant

.

See170

Radiator

and

Cooling

System

.

WARNING

-

Allow

the

cooling

system

to

cool

before

opening

or

drainíng

the

cooling

system

.

2

.

Remove

center

console

.

See

513

Interior

Trim

.

3

.

Remove

Multi-Information

Display

(MID)

module

.

See

620

Instruments

.

4

.

Remove

lower

dash

panel

and

knee

bolster

on

driver

side

.

See

513

Interior

Trim

.

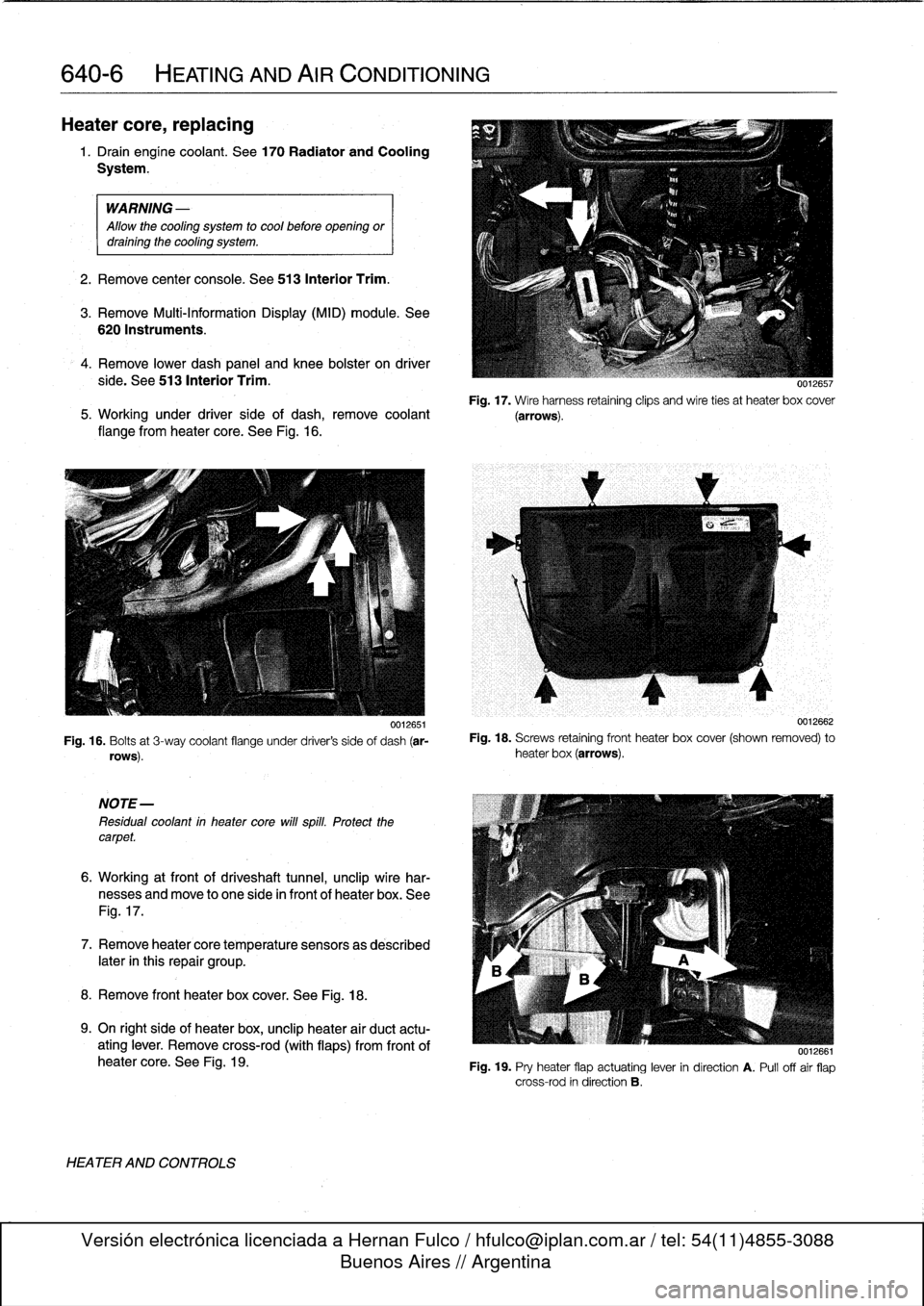

Fig

.

17

.

Wire

harness

retaining

clips

and

wire

ties

at

heater

box

cover

5

.

Working

under

driver

side

of

dash,

remove

coolant

(arrows)

.

flange

from

heater

core

.

See

Fig

.

16

.

0012651

Fig

.

16

.

Bolts

at

3-way

coolant

flange

under

driver's

side

of

dash

(ar-

rows)

.

NOTE-

Residual

coolant

in

heater

core

will

spill

.

Protect

thecarpet

.

6

.

Working

at

front

of

driveshaft

tunnel,

unclip

wire

har-

nesses

and

move

to

one

side

in

front

of

heater

box

.

See

Fig

.

17

.

7

.

Remove

heatercore

temperature

sensorsas

described

later

in

this

repair

group

.

8

.

Remove

front

heater

box

cover

.

See

Fig

.

18

.

9

.

On

right

side

of

heater

box,

unclip

heater

air

duct

actu-

ating

lever

.

Remove

cross-rod

(with

flaps)

from

frontof

heater

core

.

See

Fig

.

19

.

HEATER

AND

CONTROLS

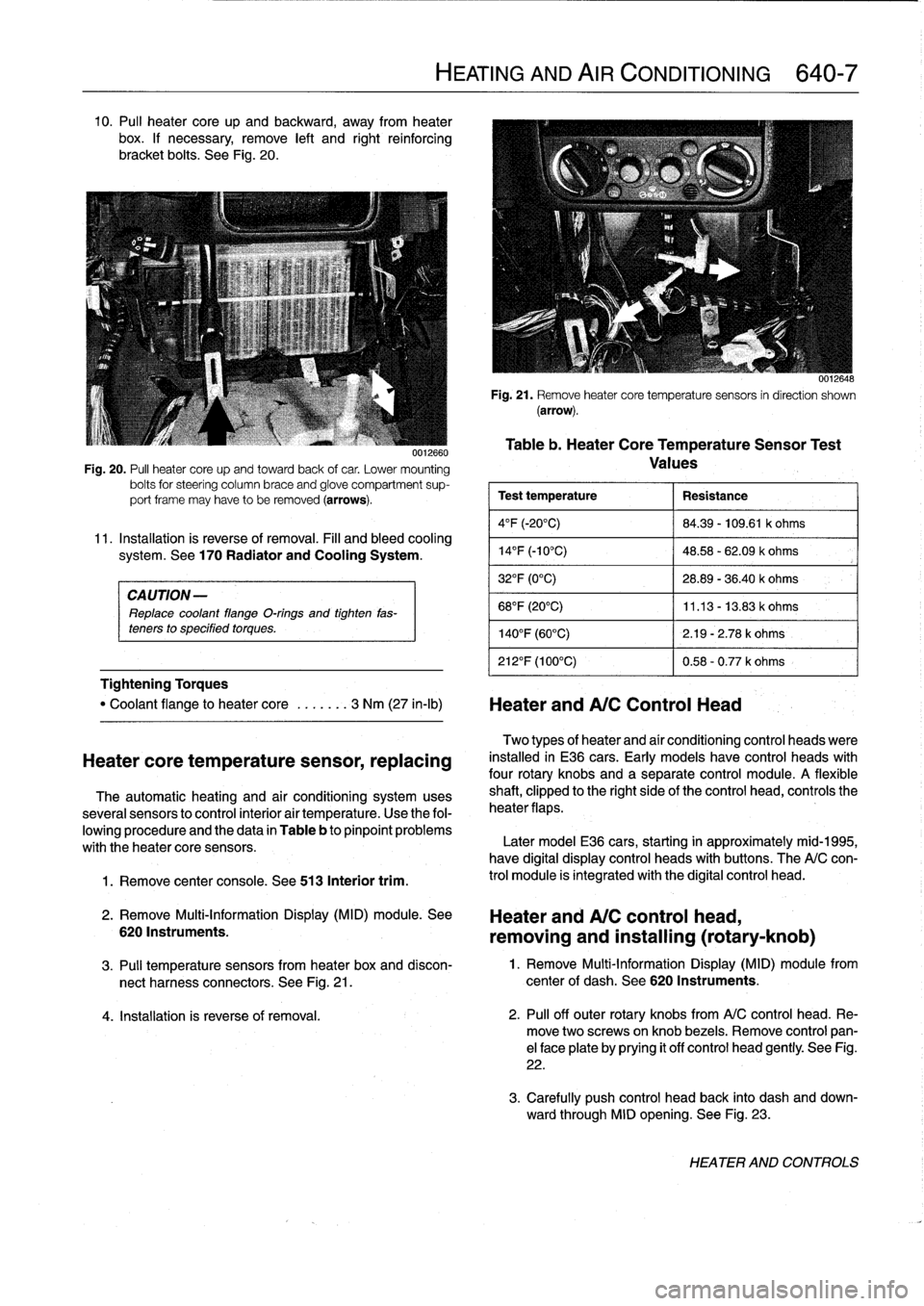

0012662

Fig

.

18

.

Screws

retaining

front

heater

box

cover

(shown

removed)

to

heater

box

(arrows)

.

0012661

Fig

.

19

.

Pry

heater

flap

actuating

lever

in

direction

A

.

Pull

offair

flap

cross-rod

in

direction

B

.

Page 453 of 759

10

.

Pul¡

heater

core

up

and

backward,

away

from

heater

box

.

If

necessary,

remove

left

and

right

reinforcing

bracket

bolts

.

See

Fig

.

20

.

CAUTION-

Replace

coolant

flange

O-rings

and

tighten

fas-

teners

to

specified

torques

.

Tightening

Torques

1

.

Remove

center

console

.

See

513

Interior

trim

.

0012660

Fig

.

20

.

PA

heater

core

upand

towardback

of

car

.

Lower

mounting

bolts

for

steering

column

brace

and

glove

compartment

sup-

port

frame

may

have

to

be

removed

(arrows)

.

11

.

Installation

is

reverse

of

removal

.

Fill

and

bleed

cooling

system

.

See

170

Radiator

and

Cooling

System

.

"

Coolant

flange

to

heater

core

.

..

....

3

Nm

(27

in-lb)

Heater

andA/C

Control

Head

Heatercore

temperature

sensor,

replacing

The

automatic

heating

and

air

conditioning

systemuses

severa¡

sensors

to

control

interior

air

temperature

.

Use

the

fol-

lowing

procedure

and

the

data

in

Table

b

to

pinpoint

problems

with

theheater

core

sensors

.

2

.

Remove

Multi-Information

Display

(MID)

module

.

See

6201nstruments

.

HEATING

AND

AIR

CONDITIONING

640-7

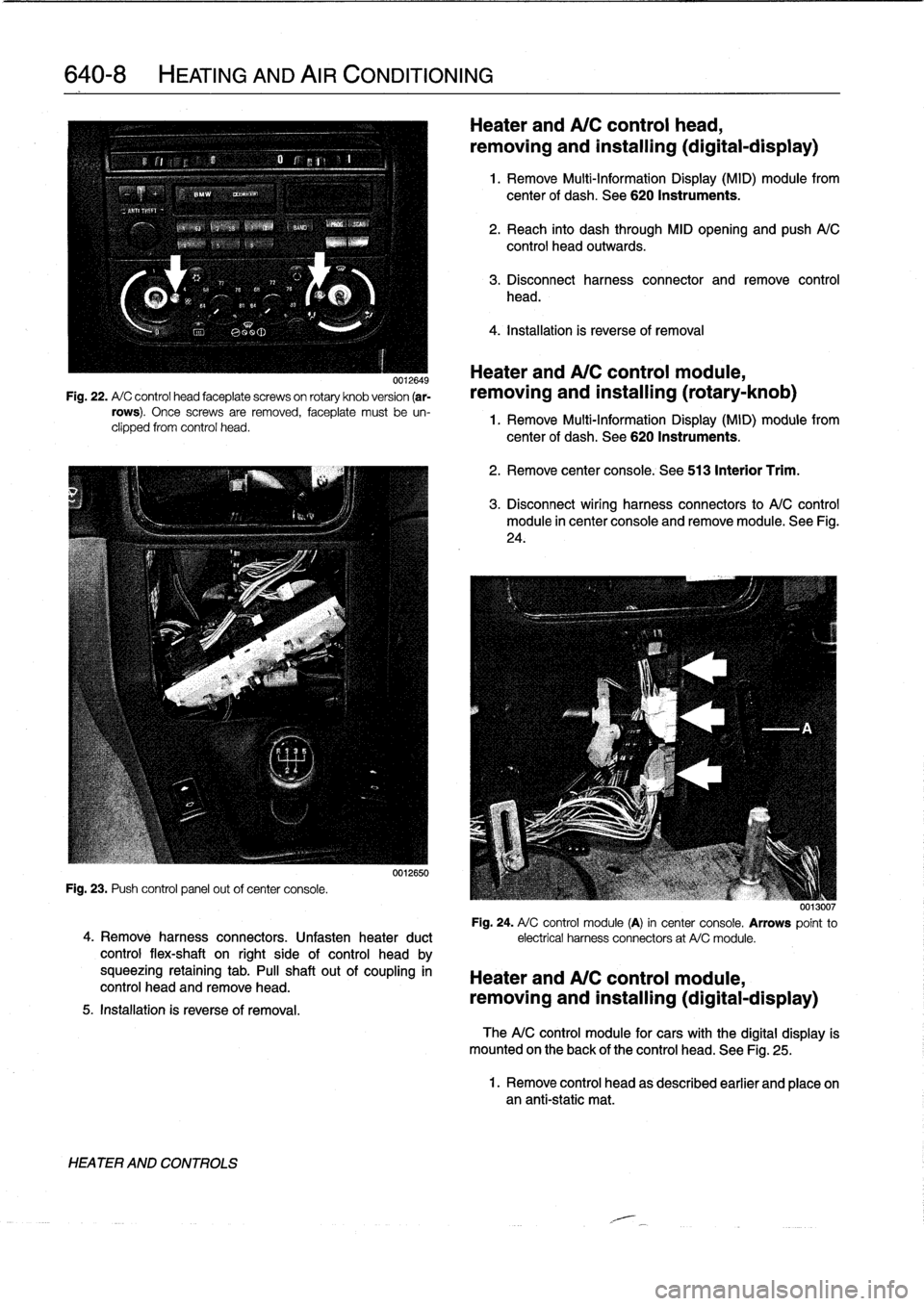

0012648

Fig

.

21

.

Remove

heatercore

temperaturesensors

in

direction

shown

(arrow)

.

Table

b

.

Heater

CoreTemperatureSensor

Test

Values

Test

temperature

Resistance

4°F

(-20°C)

84

.39

-

109

.61

k

ohms

14

°

F

(-10°C)

48

.58

-

62

.09

k

ohms

32°F

(0°C)

28

.89

-

36

.40

k

ohms

68°F

(20°C)

11

.13

-

13

.83

k

ohms

140°F

(60°C)

2

.19

-

2

.78

k

ohms

212°F

(100°C)

0

.58

-

0

.77

k

ohms

Two

types

of

heater

and

aír

conditioning

control

heads

viere

installed

in

E36

cars

.

Early

models

have

control

heads

with

four

rotary

knobs

and

a

separate

control

module

.

A

flexible

shaft,

clipped

to

the

right

sideof

the

control

head,

controls

the

heater

flaps

.

Later

model

E36

cars,

starting

in

approximately

mid-1995,

have

digital

display

control

heads

with

buttons

.

The

A/C

con-

trol

module

is

integrated

with

the

digital

control

head

.

Heater

and

A/C

control

head,

removing

and

installing

(rotary-knob)

3

.

Pul¡

temperature

sensors

from

heater

box

and

discon-

1

.

Remove

Multi-Information

Display

(MID)

module

from

nect

harness

connectors

.

See

Fig

.

21

.

center

of

dash

.

See

620

Instruments

.

4

.

Installation

is

reverse

of

removal

.

2

.

Pul¡

off

outer

rotary

knobs

from

A/C

control

head

.

Re-

move

two

screwsonknob

bezels

.

Remove

control

pan-

el

face

plate

by

prying

it

off

control

head

gently

.

See

Fig

.

22

.

3

.

Carefully

push

control

head

back

into

dash

and

down-

ward

through

MID

opening

.

See

Fig

.

23

.

HEATER

AND

CONTROLS

Page 454 of 759

640-8

HEATING

AND

AIR

CONDITIONING

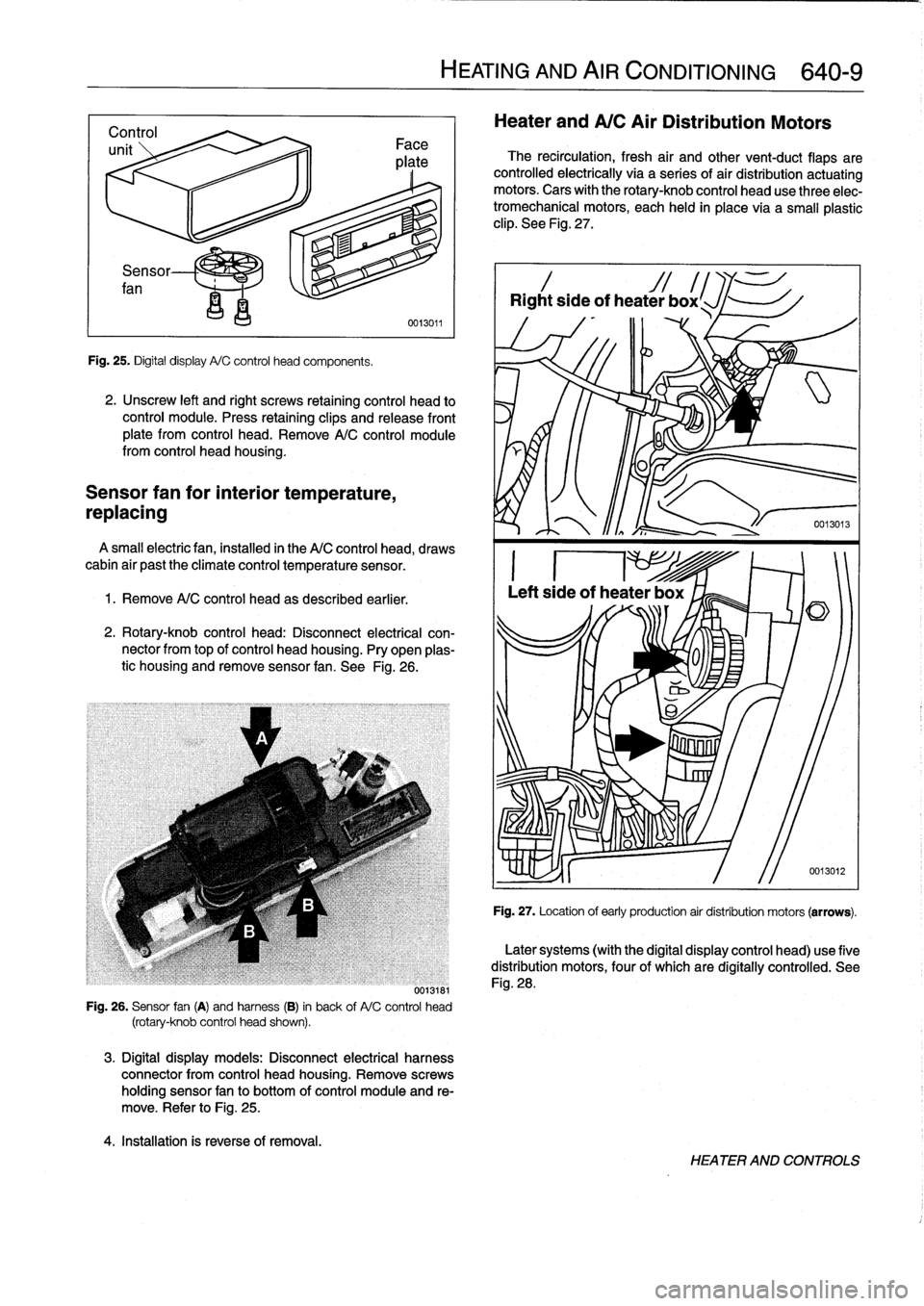

0012649

Fig

.

22

.

A/

C

control

head

faceplate

screwson

rotary

knob

version

(ar-

rows)

.

Once

screws

are

removed,

faceplate

must

be

un-

clipped

from

control

head

.

Fig

.

23

.

Push

control

panel

out

ofcenter

console

.

4

.

Remove

harness

connectors

.

Unfasten

heater

duct

control

flex-shaft

on

right

side

of

control

head

by

squeezing

retaining

tab

.

PA

shaftout

of

coupling

in

control

head

and

remove

head

.

5

.

Installation

is

reverseof

removal

.

HEATER

AND

CONTROLS

0012650

Heater

and

A/C

control

head,

removing

and

installing(digital-display)

1

.

Remove

Multi-Information

Display

(MID)

module

from

center

of

dash

.

See

620

Instruments

.

2

.

Reach

into

dash

through

MID

opening

and

push

A/C

control

head

outwards

.

3

.

Disconnect

harness

connector

and

remove

control

head

.

4

.

Installation

is

reverse

of

removal

Heater

andA/C

control

module,

removing

and

installing

(rotary-knob)

1

.

Remove

Multi-Information

Display

(MID)

module

from

center

of

dash

.

See

620

Instruments

.

2

.

Remove

center

console

.

See

513

Interior

Trim

.

3

.

Disconnect

wiring

harness

connectors

to

A/C

control

module

in

center

console

and

removemodule

.

See

Fig

.

24

.

0013007

Fig

.

24

.

A/

C

control

module

(A)

in

center

console

.

Arrows

point

to

electrical

harness

connectors

at

A/Cmodule

.

Heater

and

A/C

control

module,

removing

and

installing(digital-display)

TheA/C

control

module

for

cars

with

the

digital

display

is

mounted

on

the

back

of

the

control

head

.

See

Fig

.

25

.

1

.

Remove

control

head

as

described

earlier

and

place

onan

anti-static

mat

.

Page 455 of 759

Sensor

fan

Fig

.

25

.

Digital

display

A/C

control

head

components

.

2

.

Unscrew

left

and

right

screws

retaining

control

head

to

control

module

.

Press

retaining

clips

and

release

front

plate

from

control

head

.

Remove

A/C

control

module

from

control

head

housing

.

Sensor

fan

for

interior

temperature,

repiacing

A

small

electricfan,installed

in

the

A/C

control

head,

draws

cabin

air

past

the

climate

control

temperature

sensor

.

1.

Remove

A/C

control

head

as

described

earlier

.

2

.

Rotary-knob

control

head

:

Disconnect

electrical

con-

nector

from

top

of

control

head

housing

.

Pry

open

plas-

tic

housing

and

remove

sensor

fan

.

See

Fig

.

26

.

0013181

Fig

.

26

.

Sensor

fan

(A)

and

harness

(B)

in

back

of

A/C

control

head

(rotary-knob

control

head

shown)

.

3

.

Digital

display

models

:

Disconnect

electrical

harness

connector

from

control

head

housing

.

Remove

screws

holding

sensor

fan

to

bottom

of

control

moduleand

re-

move

.

Refer

to

Fig

.

25

.

4

.

Installation

is

reverse

of

removal

.

HEATING

AND

AIR

CONDITIONING

640-

9

Heater

and

A/C

Air

Distribution

Motors

The

recirculation,

fresh

air

and

othervent-duct

flaps

are

controlled

electrically

via

a

series

of

air

distribution

actuating

motors

.

Cars

with

the

rotary-knob

control

head

use

three

elec-

tromechanical

motors,

each

held

in

place

via

a

small

plastic

clip

.

See

Fig

.

27

.

Rightside

of

heater

box

l

Fig

.

27

.

Location

of

early

production

air

distribution

motors

(arrows)

.

Later

systems

(with

the

digital

display

control

head)

use

five

distribution

motors,

four

of

which

are

digítally

controlled

.

See

Fig

.

28

.

HEATER

AND

CONTROLS

Page 472 of 759

720-2

SEAT

BELTS

WARNING

-

"

For

maximum

protection

from

injury,

seat

belts

should

be

replaced

as

a

set

(including

all

hard-

ware),

if

they

are

subject

to

occupant

loading

in

a

collision

.

"

Seat

belts

should

not

be

modified

or

repaired

.

The

seat

belt

anchorage

points

should

not

be

changed

or

modified

.

"

Do

notbleach

or

dye

seat

belt

webbing

.

Webbing

that

is

severely

fadedor

re-dyed

will

not

meet

the

strength

requirements

of

a

collision

and

must

be

replaced

.

"

Seat

belts

shouldbe

periodically

inspected

for

webbing

defects

suchas

cuts

or

pulled

threads

.

FRONT

SEATBELT

ASSEMBLY

Automatic

Front

Seat

Belt

Lock

Tensioners

The

procedure

for

disabling

the

mechanical

spring

tension-

er

used

on

early

cars

is

covered

below

.

On

cars

with

thepyro-

technic(explosive

device)

tensioners,

the

orange

harness

connectorshould

be

removed

from

the

tensioner

any

time

the

seat

is

removed

.

WARNING

-

Both

the

mechanical

and

the

pyrotechnictensioners

are

powerful

devíces

and

shouldbehandled

with

extreme

care

.

Mechanical

spring

tensioner,

disarming

1

.

Remove

front

seat

.

See

520

Seats

.

2

.

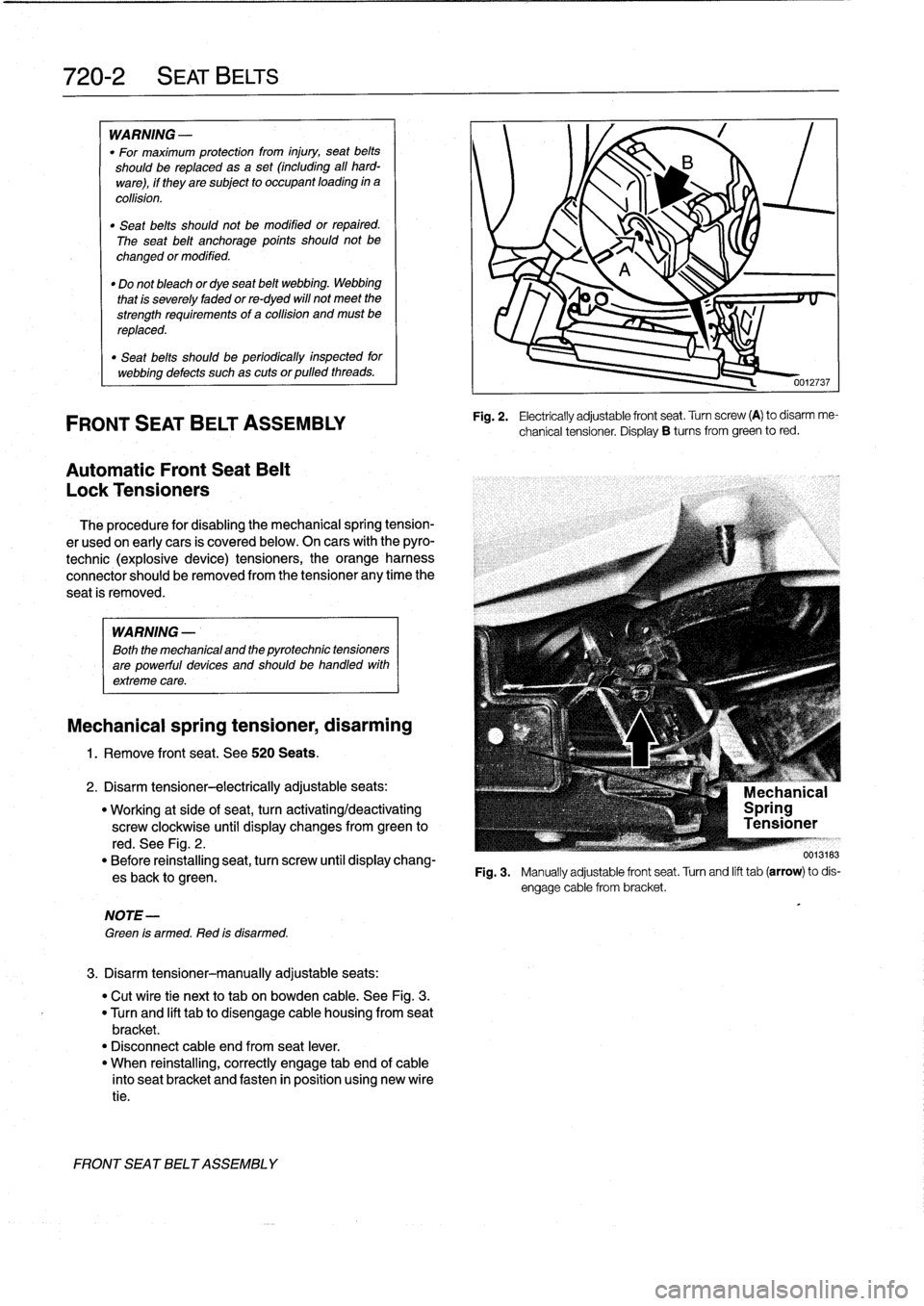

Disarm

tensioner-electrically

adjustableseats

:

"

Working

at

side

of

seat,

turn

activating/deactivating

screw

clockwise

until

display

changes

from

green

to

red

.

See

Fig

.

2

.

"

Before

reinstalling

seat,

turn

screw

until

display

chang-

esback

to

green

.

NOTE-

Green

is

armed

.

Red

is

disarmed

.

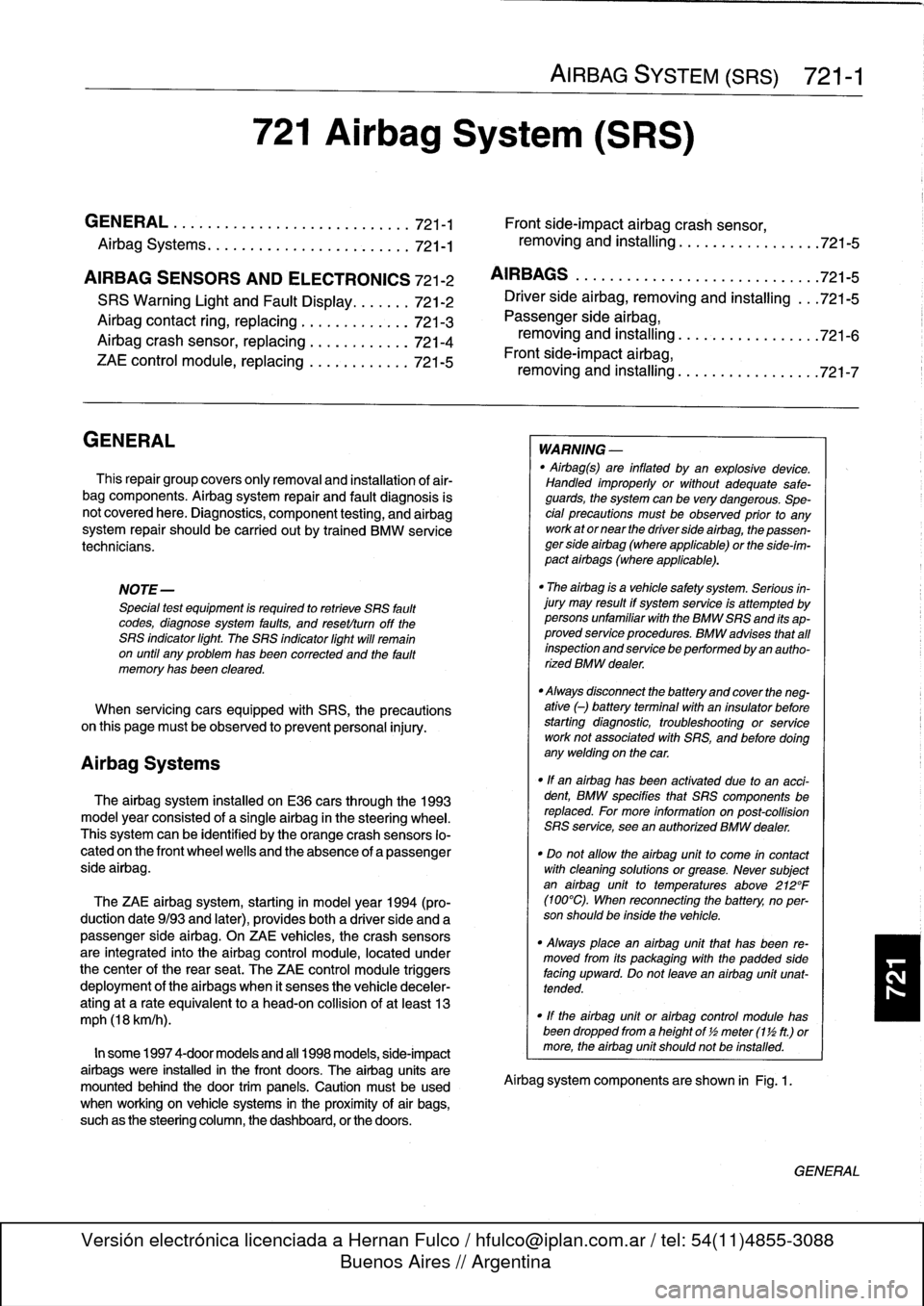

3

.

Disarm

tensioner-manually

adjustable

seats

:

"

Cut

wíre

tie

next

to

tab

on

bowden

cable

.

See

Fig

.

3

.

"

Turn

and

lift

tabto

disengage

cable

housing

from

seat

bracket

.

"

Disconnect

cable

end

from

seat

lever

.

"

When

reinstalling,

correctly

engage

tab

end

of

cable

into

seat

bracket

and

fasten

in

position

using

new

wíre

tie

.

FRONT

SEATBELT

ASSEMBLY

0012737

Fig

.

2

.

Electrically

adjustable

front

seat

.

Turn

screw

(A)

to

disarm

me-

chanical

tensioner

.

Display

B

tucos

from

green

to

red

.

F19

.3

.

Manuallyadjustablefrontseat

.Turnandlifttab(arrow)todis-

Page 477 of 759

721

Airbag

System

(SRS)

Airbag

Systems

.......

.

...

.

.

.

.

.

....

.

.

.

.

721-1

AIRBAG

SENSORS

AND

ELECTRONICS

721-2

SRS

Warning

Light

and

Fault

Display

.

.

.

.

.

..

721-2

Airbagcontact

ring,

replacing

........

.

.

.

.

.

721-3

Airbag

crash

sensor,replacing

..

.

....

.

...

.

721-4

ZAE

control

module,

replacing

.

.

.

.........

721-5

GENERAL

This

repair

group

covers

only

removal

and

installation

of

air-

bag

components

.

Airbag

system

repair

and

fault

diagnosis

is

not

covered

here

.

Diagnostics,

component

testing,

and

airbag

system

repair

should

be

carried

out

by

trained

BMW

service

technicians

.

NOTE-

Special

test

equipment

is

required

to

retrieve

SRS

fault

codes,

diagnose

system

faults,

and

resetltum

off

the

SRS

indicator

light

.

The

SRS

indicator

light

will

remain

on

until

any

problem

has

been

corrected

and

the

fault

memory

has

been

cleared

.

When

servicing

cars

equipped

with

SRS,

the

precautions

on

this

page

mustbeobserved

to

prevent

personal

injury

.

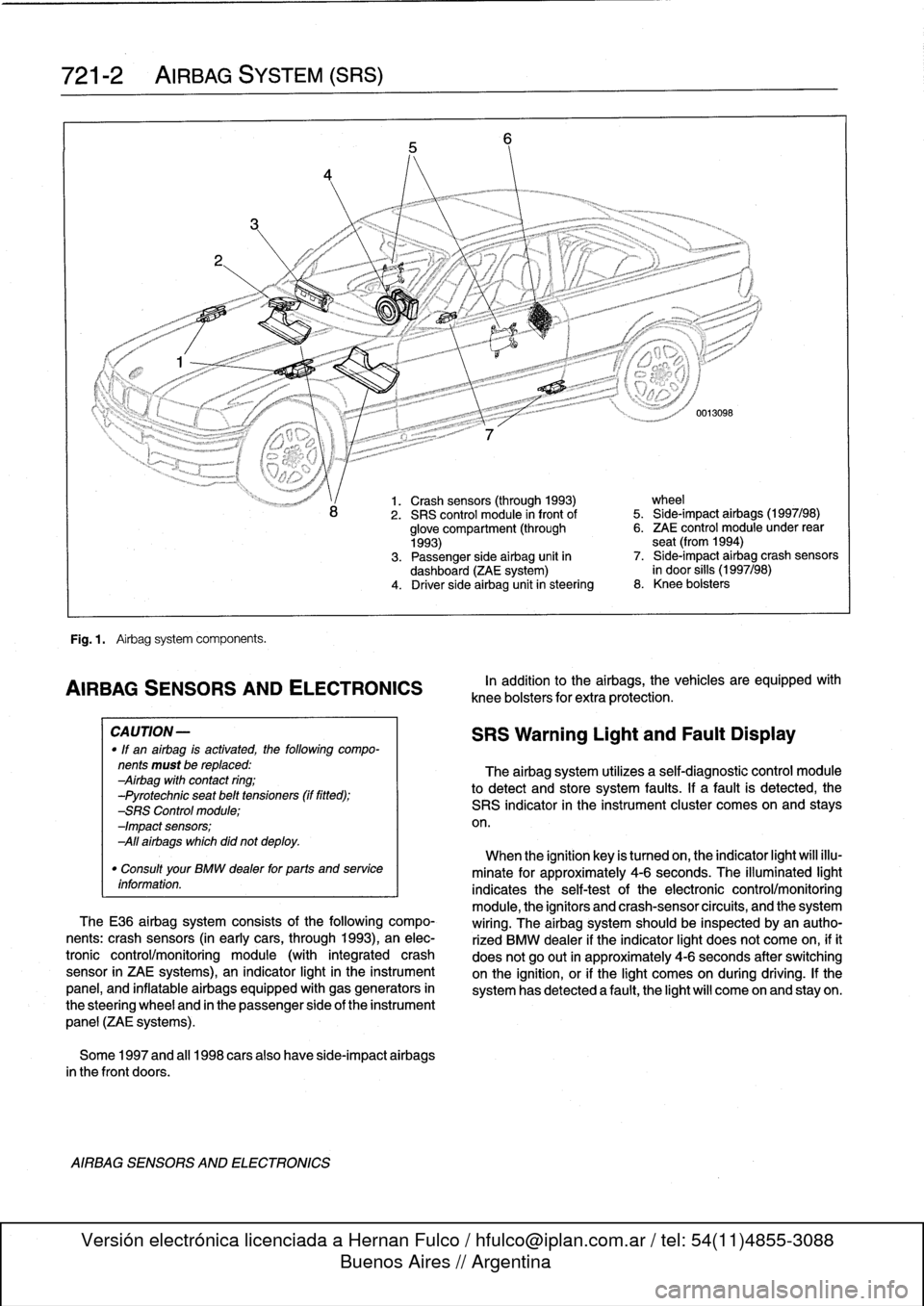

Airbag

Systems

The

airbag

system

installed

on

E36

cars

through

the

1993

model

year

consisted

of

a

single

airbag

in

the

steering

wheel

.

This

systemcan

be

identified

by

the

orange

crash

sensors

lo-

cated

on

the

front

wheel

wells

and

the

absence

of

a

passenger

side

airbag

.

The

ZAE

airbag

system,

starting

in

model

year

1994

(pro-

duction

date9/93

and

later),

provides

both

a

driver

side

and

a

passenger

sideairbag

.

On

ZAE

vehicles,

the

crash

sensorsare

integrated

into

the

airbag

control

module,

located

under

thecenter

of

the

rear

seat

.

The

ZAE

control

module

triggers

deployment

of

the

airbags

When

it

sensos

the

vehicle

deceler-

ating

at

a

rate

equivalent

to

a

head-on

collisionof

at

least

13

mph

(18

km/h)

.

In

some

1997

4-door

models

and

all

1998

models,

side-impact

airbags

were

installed

in

the

front

doors

.

The

airbag

units

are

mounted

behindthe

door

trim

panels

.

Caution

mustbeused

when

working

on

vehicle

systems

in

the

proximity

of

air

bags,

such

as

the

steering

column,

the

dashboard,

or

the

doors

.

AIRBAG

SYSTEM

(SRS)

721-1

GENERAL

.

.

.

.

.

.

.

.

.

.

.......

.

......

.

.

.

.

721-1

Front

side-impact

airbag

crash

sensor,

removing

and

installing

....

.

.....

.

.....

.

721-5

AIRBAGS

..............

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

721-5

Driver

side

airbag,

removing

and

installing

.

.

.

721-5

Passenger

side

airbag,

removing

and

installing

..............

.

.

.721-6

Front

side-impact

airbag,

removing

and

installing

.

.

.

.

.

.

.

.

.

.

......

.721-7

WARNING

-

"

Airbag(s)

are

inflated

byan

explosive

device

.

Handled

improperly

or

without

adequate

safe-

guards,

the

System

can

be

very

dangerous

.

Spe-

cial

precautions

must

be

observed

prior

to

any

work

ator

near

the

driverside

airbag,

the

passen-

ger

side

airbag

(where

applicable)

or

the

side-im-

pact

airbags

(where

applicable)

.

"

The

airbag

is

a

vehicle

safety

system

.

Serious

in-

jury

may

result

if

System

service

is

attempted

by

persons

unfamiliar

with

the

BMW

SRS

and

its

ap-

proved

service

procedures

.

BMW

advises

that

all

inspection

and

service

be

performed

by

an

autho-

rized

BMW

dealer

.

"

Always

disconnect

the

battery

and

cover

the

neg-

ative

()

battery

terminal

with

an

insulator

before

startingdiagnostic,

troubleshooting

or

service

worknot

associated

with

SRS,

and

before

doing

any

welding

on

the

car

.

"

If

an

airbag

has

been

activated

due

to

an

acci-dent,

BMW

specifies

that

SRS

components

be

replaced

.

For

more

information

on

post-collision

SRS

service,

see

an

authorized

BMW

dealer

.

"

Do

not

allow

the

airbag

unit

to

come

in

contact

with

cleaning

solutions

orgrease

.

Never

subject

an

airbag

unit

to

temperatures

aboye

212°F

(100°C)

.

When

reconnecting

the

battery,

no

per-

son

should

be

inside

the

vehicle

.

"

Always

place

an

airbag

unitthat

has

been

re-

moved

from

its

packaging

with

the

padded

sidefacing

upward

.

Do

not

leave

an

airbag

unlt

unat-

tended

.

"

!f

the

airbag

unit

or

airbag

control

modulehas

been

dropped

froma

height

of

!

1

2

meter

(1

Y2

ft.)

ormore,

theairbag

unit

should

not

be

installed

.

Aírbag

system

components

are

shown

in

Fig

.

1.

GENERAL

Page 478 of 759

721-2

AIRBAG

SYSTEM

(SRS)

Fig

.

1

.

Airbag

system

components

.

AIRBAG

SENSORSAND

ELECTRONICS

CA

UTION-

"

If

an

airbag

is

activated,

the

following

compo-

nents

must

be

replaced

:

Airbag

with

contact

ring

;

-Pyrotechnic

seat

belt

tensioners

(if

fitted)

;

-SRS

Control

module

;

-Impact

sensors

;

All

airbags

which

did

not

deploy

.

"

Consult

your

BMW

dealer

for

parts

and

service

information

.

TheE36

airbag

system

consists

of

the

following

compo-

nents

:

crash

sensors

(in

earlycars,

through

1993),

an

elec-

tronic

control/monitoring

module

(with

integrated

crash

sensor

in

ZAE

systems),

an

indicator

light

in

the

instrument

panel,

and

inflatable

airbags

equipped

with

gas

generators

in

the

steering

wheel

and

in

the

passenger

side

of

the

instrument

panel

(ZAE

systems)

.

Some

1997

and

al¡

1998

carsalso

have

side-impact

airbags

in

the

front

doors

.

AIRBAG

SENSORS

AND

ELECTRONICS

1.

Crash

sensors

(through

1993)

wheel

2

.

SRS

control

module

in

front

of

5

.

Side-impact

airbags

(1997/98)

glove

compartment

(through

6

.

ZAE

control

module

under

rear

1993)

seat

(from

1994)

3

.

Passenger

side

airbag

unit

in

7

.

Side-impact

airbag

crash

sensors

dashboard

(ZAE

system)

in

door

silis

(1997/98)

4

.

Driver

side

airbag

unitin

steering

8

.

Knee

bolsters

In

addition

to

the

airbags,

the

vehicles

are

equipped

wíth

knee

bolsters

for

extra

protection

.

SRS

Warning

Light

and

Fault

Display

The

airbag

system

utilizes

a

self-diagnostic

control

module

to

detect

and

store

system

faults

.

If

a

fault

is

detected,

the

SRS

indicator

in

the

instrument

cluster

comes

on

and

stays

on

.

When

the

ignition

key

is

tumed

on,

the

indicator

light

will

illu-

minate

for

approximately

4-6

seconds

.

The

illuminated

light

indicates

the

self-testof

the

electronic

control/monitoring

module,

the

ignítors

and

crash-sensorcircuits,

and

the

system

wiring

.

The

airbag

system

should

be

inspected

byan

autho-

rized

BMW

dealer

if

the

indicator

light

does

not

come

on,

ifit

does

not

go

out

in

approximately

4-6

seconds

after

switching

onthe

ignition,

or

if

the

light

comes

on

during

driving

.

If

the

system

has

detected

a

fault,

the

light

will

come

on

and

stay

on

.

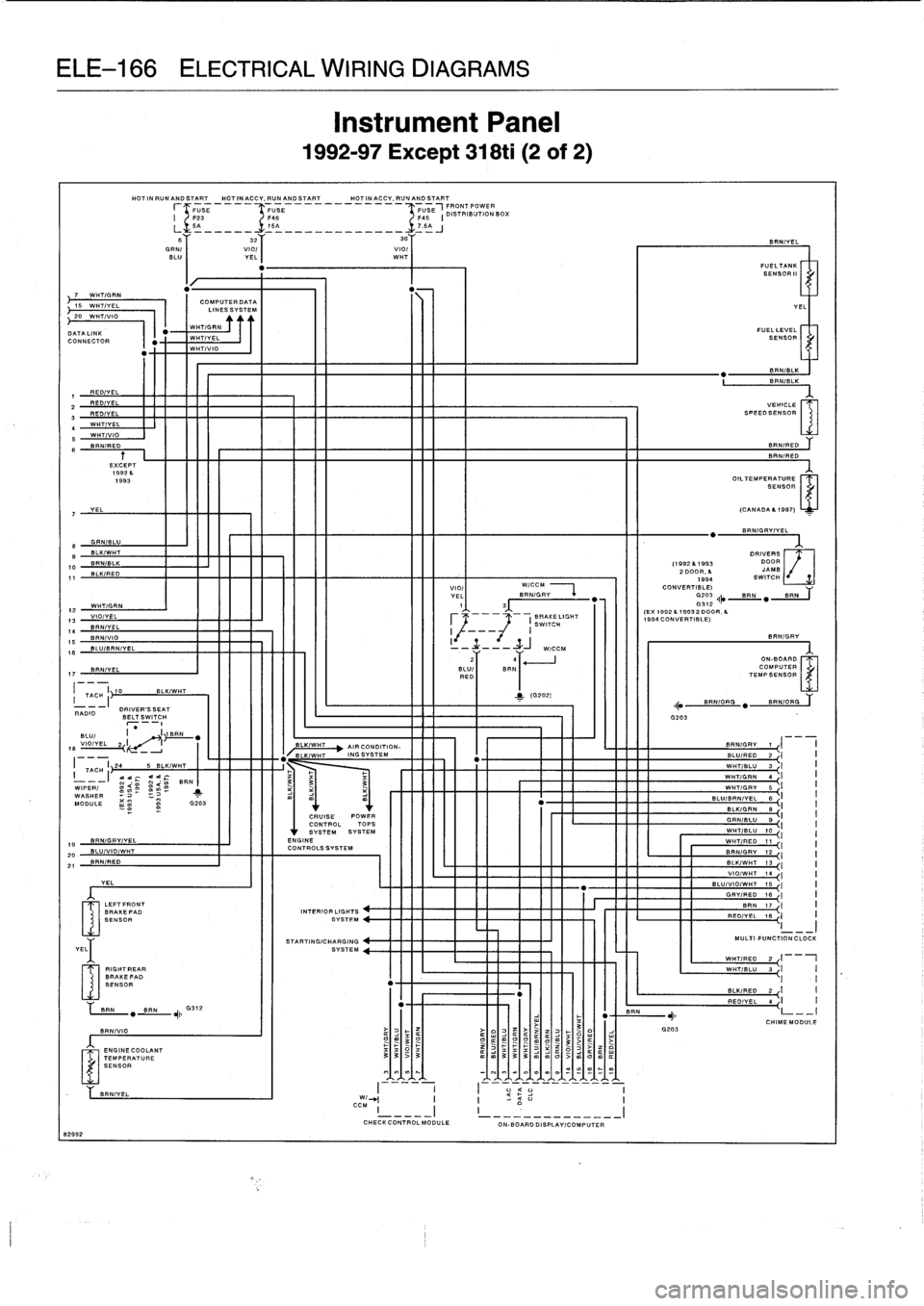

Page 649 of 759

ELE-166

ELECTRICAL

WIRING

DIAGRAMS

"

-

N15

WH7/VA

I

COLIESSSVSTEM

20

WHT/VIO

DATALINK

WHT/GRN

CONNECTOR

WHT/YEL

1

WHT/VIO

REDIVEL

FF"

2

REDIVELREDIVEL

17

BRNIYEL

170

I

TAC-I~

RADIO

DRIVER'SSEAT

BELT

SWITCH

BLUI

I

_

I1

BRN

VIO/YEL

2

I

-

18

19

BRN/GFY/YEL

20

BLU/VIOIWHT

21

BRN/RED

YEL

8299

2

YEL

LEFTFRONT

BRAKEPAD

SENSOR

RIGHT

EAR

BRAKEPAD

SENSOR

HOTINRUNANDSTART

HOTINACCY,PUNANDSTART

HOTINACCY,RUNANDSTART

r

F23

E___

USE

__________-IFFUSE

USE

IDSOTRIBUTIONBOX

BLK/WHT

BRN

"BAN

,I

G312

BRNIVIO

ENGINECOOLANT

TEMPERATURESENSOR

InstrumentPanel

1992-97

Except

318ti

(2

of

2)

5A_____-TISA

____________

.T7

.5AJ

B

32

30Y

GRN/

viol

I

viol

BLU

I

YEL

WHT

WHT/VEL

WHT/VIO

BRNIRED

EXCEPT

1992

&

1993

OIL7EMPESENSOR

7

YEL

(CANADA61997)

.

BRNIGRVIYEL

e

GRNIBLU

9

BLKIWHT

DRIVERS

DOOR

0

JAMB

1994

SWITCH

1

BIN/ILK

(19926

1

993

BLK/RED

2

DOOR,

6

VIOI

WICCM

CONVERT

BR

WHTIGRN

YE'

I

3

N/GRY

~

(EX

1992

6

7993

200

V"'

0R

6

VIO/YEL

I

BRAKELIGHT

.

1990

CONVERTIBLE)

BRNIYEL

SWITCH

BRN/VIO

I

I

8RN/GRV

BLUIBRN/VEL

-

----+-j

W/CCM

.LU/

COMPUTER

REDI

BRN1

~

TEMPSENSOR

MMONE

-

.

INNER

BRNIYEL

I----

I

I--

-

-----

--

W/_I

I

I

CC

M

CHECK

CONTROLMODULE

ON-BOARD

DISPLAYICOMPUTER

BRN

G203

BRNIYEL

FUELTANKI

SENSOR"

FUELLEVEL

SENSORI

8RN/BLK

BRN/BLK

VEHICLE

SPEEDSENSOR

BF

RED

an

RED

YEL

GRN/BLU

9

I

WIT/

WHT/RED

11-I

I

BRNI

.P

Y12

I

I

BLK/WHT

13

I

VIO/WHT

10

I

BLU/VIO/WHT

75

I

GRV/RED

18`

I

I

BRN

17

~I

PEDIYEL

18

I

I

MULTI

FUNCTION

CLOCK

WHTwHTRG1

-

I

WHT/BLU

3

I

II

I

BLKIRED

2

{

I

I

REOIVE

L4

I

I

CHIMEMODULE

Page 651 of 759

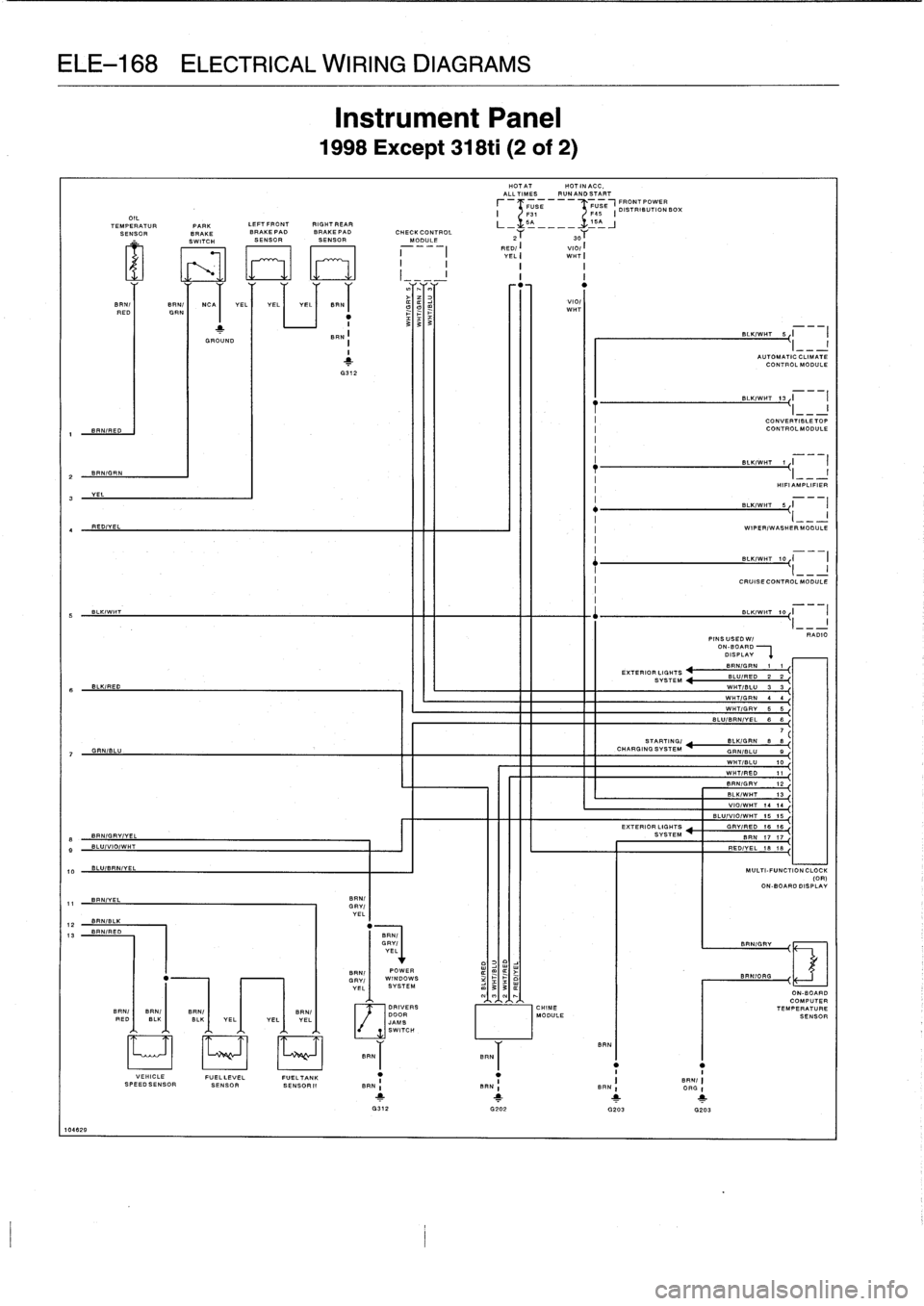

ELE-168

ELECTRICAL

WIRING

DIAGRAMS

5

6

7

0

10

10462

9

GRN/BLU

BRN/YEL

BRN/BLK

BRN/RED

DRIVERS

DOOR

JAMB

SWITCHBAN

t

YEL

SAW

ELI

YEL

Instrument

Panel

1998

Except

318ti

(2

of

2)

OIL

TEMPERATUR

PARK

LEFTFRONTRIGHTREAR

SENSOR

BRAKE

BRAKEPAD

BRAKEPAD

CHECK

CONTROL

SWITCH

SENSOR

SENSOR

MODULE

I

SREDI

BFI

GRNI

NCAI

YELIYELI

YELI

BR

.:

1

I

3I3I

3GROUND

I

BANI

III

III

I

BLK/WHT

CONVERTIBLETOP

BRN/RED

CONTROLMODULE

I

T

BLK/WHT

1

I

I

BRN/GRN

II

I

HIPI

AMPLIFIER

L

I

;

BLK/WHT

5

i_--I

REDIYEL

q

WIPERIWASHERMODULE

II

-_

BLK/WHT

10I

I

I--I

CRUISE

CONTROLMODULE

I

BLKIWHT

SLK/WHT

10

I

I

PINS

USED

W/

BRN/GRN

11

BLU/RED

22

BLK/RED

WHT/SLU

33

WHT/GRN

44

WHT/GRY

55

BLU/BRN/YEL

667

STARTING/

BLK/GRN

BB

CHARGINGSYSTEM

GRN/BLU

9

WHT/BLU

10

WHTIRED

11

BRN/GRY

12

BLK/WHT

13

V

11

/WHT

1414

BLU/VIOIWHT

1515

EXTERIOR

LIGHTS

GRY/RED

1616

H

BRN/GRY/YEL

SYSTEM

RAN

1717

BLU/VIO/WHT

RED/YEL

1515

BLUIBRN/YEL

MULTI-FUNCTION

CLOCK

ON-BOARD

DISPLAY

EXTERIOR

LIGHTS

SYSTEM

BRN/

DAY

/

YEL

GVEL

BRN/GRY

BRN/

POWER

GRY/I

WINDOWS

YEL

SYSTEM

mI

3I

3

:1

R.

t

HOT

AT

HOT

IN

ACC,

ALLTIMES

RUNAND

START

FUSE

y

FUSE

FRONTPOWER

F45

I

DISTRIBUTION

11,

5=____~-5_J

30Y

REDII

V101

I

YELI

WHTI

vIOf

WHT

ON-BOARD

COMPUTERMODULE

TEMPERATURE

BRN

"

1

I

VEHICLE

FUELLEVEL

FUELTANK

I

"

I

1

BAN/

SPEEDSENSOR

SENSOR

SENSORII

BAN

I

SANI

BAN

I

GAS

I

1

1

1

1

G312

G202

G203

G203

I

AUTOMATIC

CLIMATE

CONTROL

MODULE

BLKLKIW

J

T

13

1

I

RADIO

BRN/ORG

Page 750 of 759

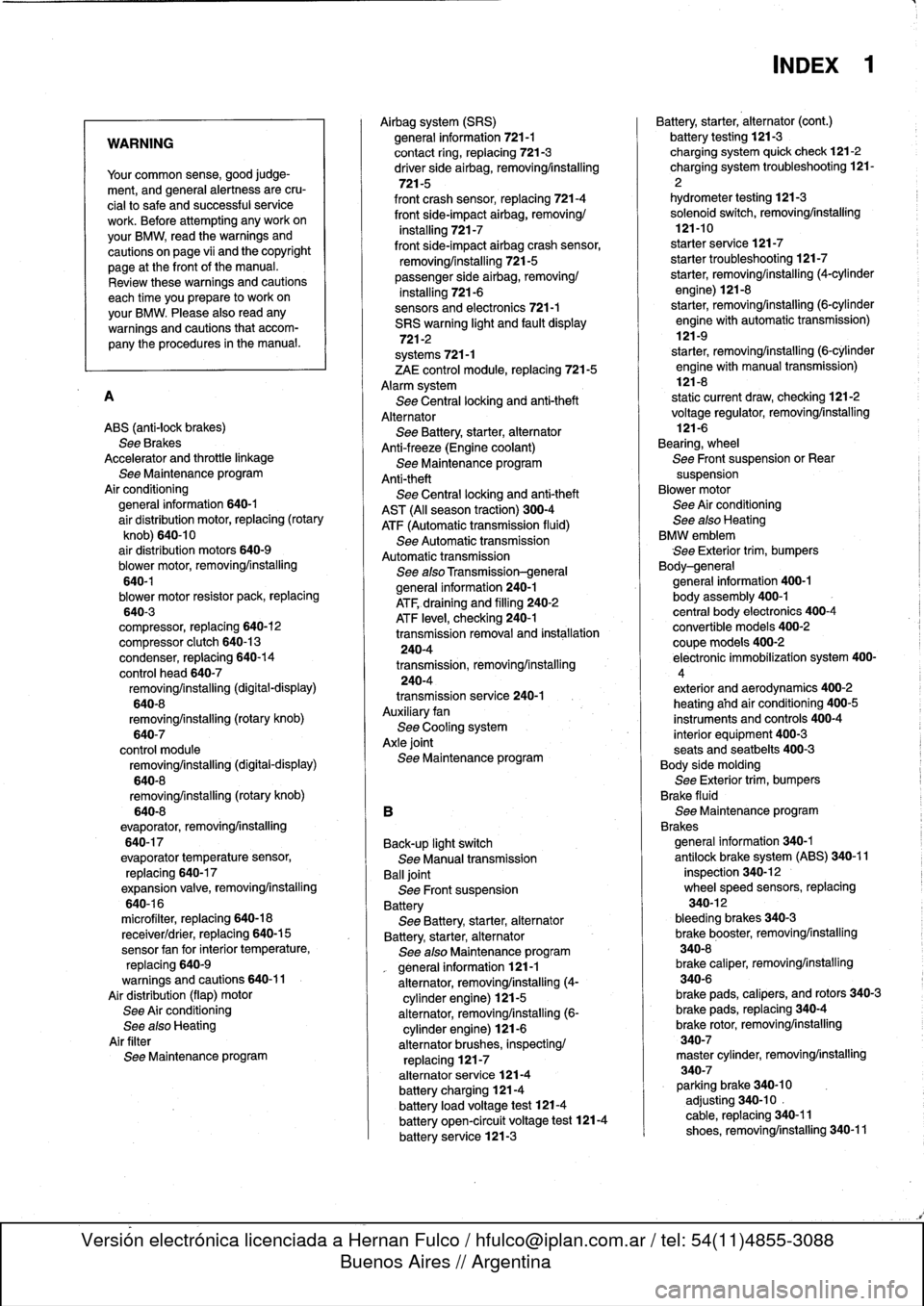

WARNING

Your

common

sense,

good

judge-

ment,

and

general

alertness

are

cru-

cial

to

safe

and

successful

service

work

.

Before

attempting

any

work

on

your

BMW,

read

the

warnings

and

cautions

on

page

vi¡

and

the

copyright

page

at

the

front

of

the

manual

.

Review

these

warnings

and

cautions

each

time

youprepare

to

work

on

your

BMW

.

Please

also

read

any

warnings

and

cautions

that

accom-

pany

the

procedures

in

the

manual

.

A

ABS

(anti-lock

brakes)

See

Brakes

Accelerator

and

throttle

linkage

See

Maintenance

program

Air

conditioning

general

information

640-1

air

distribution

motor,

replacing

(rotary

knob)

640-10

air

distribution

motors

640-9

blower

motor,

removing/installing

640-1blower

motor

resistor

pack,

replacing

640-3

compressor,

replacing

640-12

compressor

clutch

640-13

condenser,

replacing

640-14

control

head

640-7

removing/installing

(digital

-display)

640-8

removing/installing

(rotary

knob)

640-7

control

module

removing/installing

(digital-display)

640-8

removing/installing

(rotary

knob)

640-8

evaporator,

removinglinstalling

640-17

evaporator

temperature

sensor,

replacing

640-17

expansion

valve,

removing/installing

640-16

microfilter,

replacing

640-18

receiverldrier,

replacing

640-15

sensor

fan

forinterior

temperature,

replacing

640-9

warnings

and

cautions

640-11

Air

distribution

(flap)

motor

See

Air

conditioning

See

also

Heating

Air

filter

See

Maintenanceprogram

Airbag

system

(SRS)

general

information

721-1

contact

ring,

replacing

721-3

driver

side

airbag,removing/installing

721-5

front

crash

sensor,

replacing

721-4

front

side-impact

airbag,

removing/

installing

721-7

front

side-impact

airbag

crash

sensor,

removing/installing

721-5

passenger

side

airbag,

removing/

installing

721-6

sensors

and

electronics

721-1

SRS

warning

light

and

fault

display

721-2

systems

721-1

ZAE

control

module,

replacing

721-5

Alarm

system

See

Central

locking

and

anti-theft

Alternator

See

Battery,

starter,

alternator

Anti-freeze

(Engine

coolant)

See

Maintenance

program

Anti-theft

See

Central

lockíng

and

anti-theft

AST

(Al¡

season

traction)

300-4

ATF

(Automatic

transmission

fluid)

See

Automatic

transmission

Automatic

transmission

See

alsoTransmission-general

general

information

240-1

ATF,draining

and

filling

240-2

ATF

leve¡,

checking

240-1

transmission

removaland

ínstallation

240-4

transmission,

removinglinstalling

240-4

transmission

service

240-1

Auxiliary

fan

See

Cooling

system

Axle

joint

See

Maintenance

program

B

Back-up

light

switch

See

Manual

transmission

Balljoint

See

Front

suspension

Battery

See

Battery,

starter,

alternator

Battery,

starter,

alternator

See

also

Maintenance

program

general

information

121-1

alternator,

removing/installing

(4-

cylinder

engine)

121-5

alternator,

removinglinstalling

(6-

cylinder

engine)

121-6

alternator

brushes,

inspecting/

replacing

121-7

alternator

service

121-4

batterycharging

121-4

battery

load

voltage

test

121-4

batteryopen-circuit

voltage

test

121-4

battery

service

121-3

INDEX

1

Battery,

starter,

alternator

(cont

.)

battery

testing

121-3

charging

system

quick

check121-2

charging

system

troubleshooting

121-

2

hydrometer

testing

121-3

solenoid

switch,

removinglinstalling

121-10

starter

service

121-7

starter

troubleshooting

121-7

starter,

removing/installing(4-cylinder

engine)

121-8

starter,

removing/installing(6-cylinder

engine

with

automatic

transmission)

121-9

starter,

removing/installing

(6-cylinder

engine

with

manual

transmission)

121-8

static

current

draw,

checking

121-2

voltage

regulator,

removing/installing

121-6

Bearing,

wheel

See

Front

suspension

or

Rear

suspension

Blowermotor

See

Air

conditioning

See

also

Heatíng

BMW

emblem

See

Exterior

trim,

bumpers

Body-general

general

information

400-1

body

assembly

400-1

central

body

electronics

400-4

convertible

models

400-2

coupe

models

400-2

electronic

immobilizatíon

system

400-

4

exterior

and

aerodynamics

400-2

heating

afhdair

conditioning

400-5

instruments

and

controls

400-4

interior

equipment

400-3

seats

and

seatbelts

400-3

Body

side

molding

See

Exterior

trim,

bumpers

Brake

fluid

See

Maintenance

program

Brakes

general

information

340-1

antilock

brake

system

(ABS)

340-11

inspection

340-12

wheelspeed

sensors,

replacing

340-12

bleeding

brakes

340-3

brake

booster,

removinglinstalling

340-8

brake

caliper,

removing/installing

340-6

brake

pads,

calipers,

and

rotors

340-3

brake

pads,

replacing

340-4

brake

rotor,

removing/installing

340-7

master

cylinder,

removing/installing

340-7

parking

brake

340-10

adjusting

340-10

.

cable,

replacing

340-11

shoes,

removinglinstalling

340-11