fuse box diagram BMW M3 1998 E36 Workshop Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 1998, Model line: M3, Model: BMW M3 1998 E36Pages: 759

Page 155 of 759

Oxygen

Sensor

FUEL

DELIVERY

TESTS

FUEL

INJECTION

130-

9

"

Voltage

at

¡dle

..

.

..

..

....

0

.2

to

0

.8

VDC,

fluctuating

Checking

fuel

delivery

is

afundamental

part

of

trouble-

shooting

and

diagnosing

the

engine

management

system

.

Fuel

pressure

directly

influences

fuel

delivery

.

An

accurate

NOTE-

fuel

pressure

gauge

will

be

needed

to

make

the

tests

.

To

check

sensorresponse

to

lean

and

rich

mixtures,

createenairleak,

orpull

vacuumhoseofffue¡

pressure

There

are

three

significant

fuel

delivery

values

to

be

mea-

regulator

to

increase

fuel

pressure

.

sured

:

3

.

Separate

sensorharness

connector

from

sensor

.

Check

for

battery

voltage

between

terminals

3

and

4

(green

wire

and

brown

wire)

in

main

wiring

harness

side

of

con-

nector

with

engine

running

.

If

voltage

is

not

present,

check

oxygen

sensor

heater

relay

.

See610

Electrical

Component

Locations

.

4

.

Check

heater

element

resistance

between

terminals

3

and

4

in

sensor

side

of

connector

.

If

element

is

electri-

cally

open

(no

continuity),

replace

sensor

.

NOTE-

The

oxygen

sensor

heater

relay

is

mounted

in

the

main

power

distributfon

box

in

the

left

rear

of

the

engine

com-

partment

.

Refer

to

Fig

.

6

.

The

heater

relay

is

energized

wíth

positive

(+)

battery

voltage

from

the

main

relayanda

switched

ground

from

the

ECM

.

See

Electrical

Wir-

ing

Diagrams

.

"

Oxygen

sensor

to

exhaust

pipe

...

..

55

Nm

(41

ft-Ib)

"

System

pressure-created

by

the

fuel

pump

and

main-

tained

by

the

pressure

regulator

.

"

Fuel

delivery

volume-created

by

the

fuel

pump

and

af-

fected

by

restrictions,

suchasclogged

fuel

filter

.

"

Residual

pressure-the

pressure

maintained

in

the

closed

system

after

the

engine

and

fuel

pump

are

shut

off

.

Procedures

for

measuring

the

first

two

quantities

arede-

scribed

in

160

Fuel

Tank

and

Fuel

Pump

.

Residual

fuel

pres-

sure

is

checked

using

the

procedure

detailed

later

in

this

group

.

Operating

fuel

pump

fortests

To

operate

the

fuel

pump

for

testing

purposes

without

hav-

íng

to

runthe

engine,

the

fuel

pump

relay

can

be

bypassed

to

power

the

pump

directly

.

Fuel

pump

relay

location

is

shown

in

Fig

.

6

.

5

.

¡f

oxygen

sensor

doesn't

produce

a

fluctuating

voltage

To

runthe

fuel

pump,

remove

the

fuel

pump

relay

and

con-

and

preheater

circuit

is

OK,

replace

sensor

.

nect

the

socket

for

relayterminal

30

to

the

socket

for

relay

ter-

mina¡

87

with

a

fused

jumper

wire

.

After

completing

the

tests,

NOTE-

remove

the

jumper

wire

.

If

not

already

applied,

coat

the

oxygen

sensor

threads

with

an

anti-seize

compound

before

installation

.

Do

not

CAUTION-

getthe

compound

on

the

sensor

tip

.

"

Relay

locations

may

vary

.

Use

care

when

identi-

fying

relays

and

making

electrical

checks

at

the

fuselrelay

panel

.

See

610

Electrical

Compo

Tightening

Torque

nent

Locations

for

additional

relay

information

.

"

The

fuel

pump

relay

has

a

1

.5

mm2

red

wire

at

ter-

minal

30

in

the

relay

socket

.

Terminal

87

has

a

1

.5

mm

2

greenlviolet

wire

.

See

Electrical

Wiring

Di-

agrams

for

additional

wiring

information

.

NOTE-

Thejumper

wire

should

be

1.5

mm2

(14

ga

.)

and

in-

clude

an

in-line

tuse

holder

with

a15

amp

tuse

.

To

avoid

fuselrelay

panel

damage

from

repeated

connect-

ing

and

disconnecting,

also

include

a

toggle

switch

.

A

heavy-duty

jumper,

BMW

tool

no

.

61

3

050,

is

also

available

from

an

authorized

BMW

dealer

.

FUEL

DELIVERYTESTS

Page 173 of 759

0013ZIM

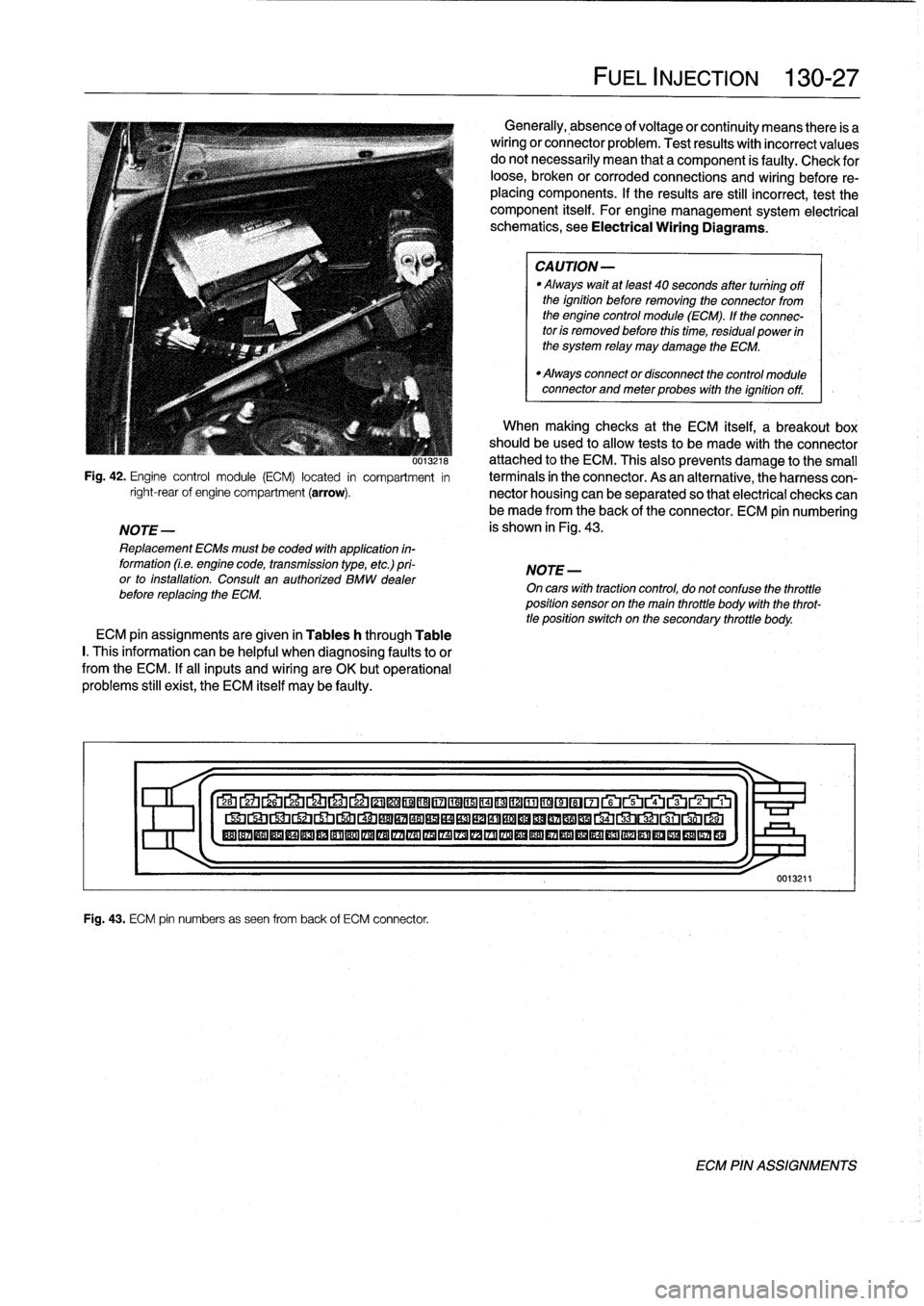

Fig

.

42

.

Engine

control

module

(ECM)

located

in

compartment

in

right-rearof

engine

compartment

(arrow)

.

NOTE-

Replacement

ECMs

must

be

coded

with

application

in-

formation

(Le

.

engine

code,

transmission

type,

etc

.)

pri-

or

to

installation

.

Consult

an

authorized

BMW

dealer

before

replacing

the

ECM

.

ECM

pin

assignments

are

given

in

Tables

h

through

Table

I.

This

information

can

be

helpful

when

diagnosing

faultsto

or

from

the

ECM

.

If

al¡

inputs

and

wiring

are

OK

butoperational

problems

still

exist,

the

ECM

itself

may

be

faulty

.

Fig

.

43

.

ECM

pin

numbers

as

seen

from

back

of

ECM

connector

.

FUEL

INJECTION

130-

2

7

Generally,

absence

of

voltage

or

continuity

means

there

is

a

wiring

or

connector

problem

.

Test

results

with

incorrect

values

do

notnecessarily

mean

that

a

component

is

faulty

:

Check

for

loose,

broken

or

corroded

connections

and

wiring

before

re-

placing

components

.

If

the

results

are

still

incorrect,

test

the

component

itself

.

For

engine

management

system

electrical

schematics,

see

Electrical

Wiring

Diagrams

.

CAUTION-

Always

waitat

least

40

seconds

after

tuniing

off

the

ignition

before

removing

the

connector

from

the

engine

control

module

(ECM)

.

If

the

connec-

tor

is

removed

before

this

time,

residual

power

in

the

system

relay

may

damage

the

ECM

.

"

Always

connector

disconnect

the

control

module

connector

and

meter

probes

with

the

ignitionoff

.

When

making

checks

at

the

ECM

itself,

a

breakout

box

should

be

used

to

allow

tests

to

be

made

with

the

connector

attached

to

the

ECM

.

This

also

prevents

damage

tothe

small

termínals

in

the

connector

.

As

an

alternative,

theharness

con-

nector

housing

can

be

separated

so

that

electrical

checks

can

be

made

from

the

back

of

the

connector

.

ECM

pin

numbering

is

shown

in

Fig

.

43

.

NOTE

-

On

cars

with

tractioncontrol,

do

not

confuse

the

throttle

position

sensor

on

the

main

throttle

body

with

the

throt-

tle

position

switch

on

the

secondary

throttle

body

.

27

Lb

2L4

LJ

22

©©®®17

©©®©©~©©®©~~rui~~ru

®®®®®®®®®®®®®®®IZA®®®®®®®®®®®®®®®®®

1

>I-

0013211

ECM

PIN

ASSIGNMENTS

Page 191 of 759

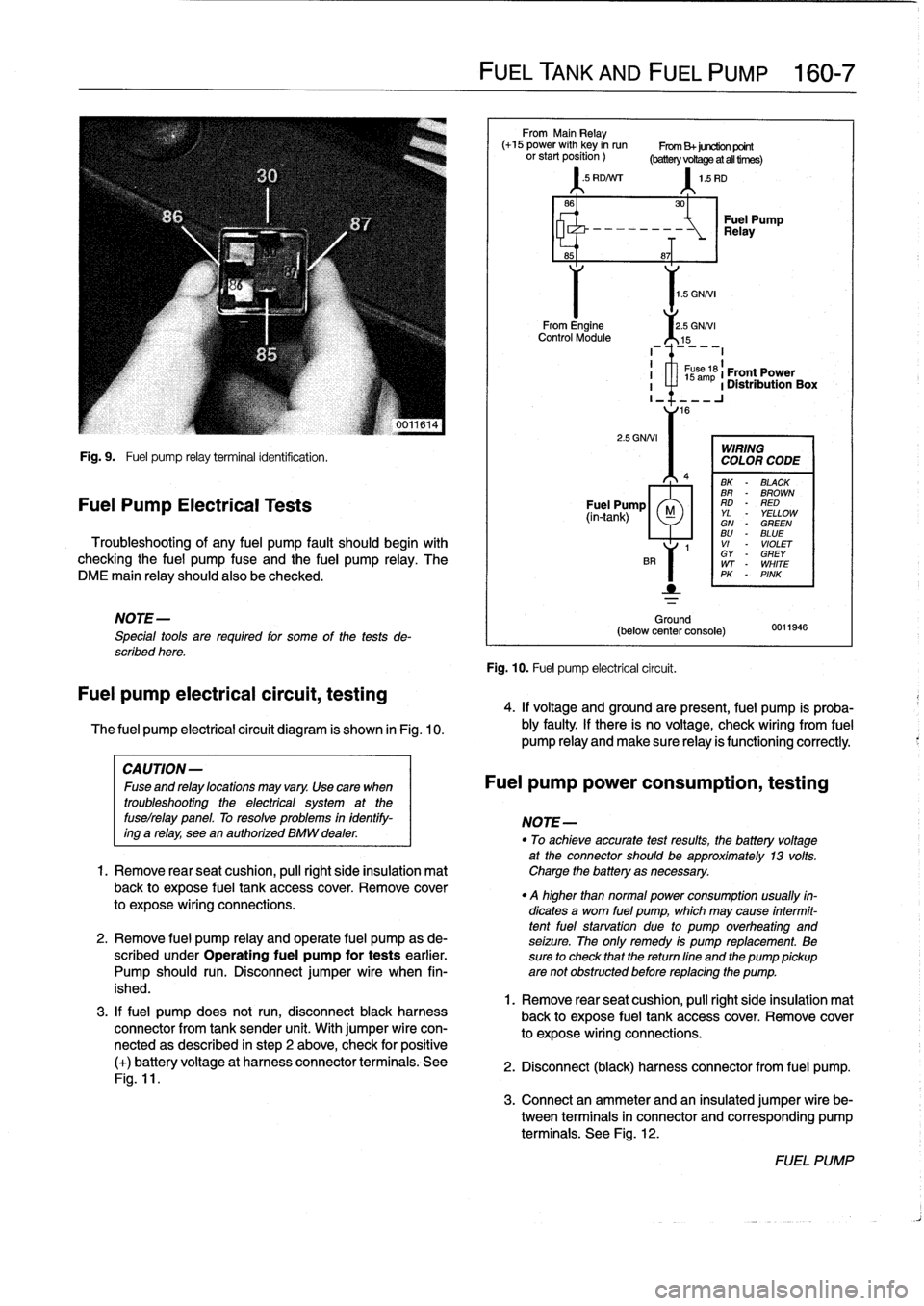

Fig

.

9

.

Fuel

pump

relay

terminal

identification

.

Fuel

Pump

Electrical

Tests

Troubleshooting

of

any

fuel

pump

fault

should

begin

with

checking

the

fuel

pump

fuse

and

the

fuel

pump

relay

.

The

DME

main

relay

should

also

be

checked

.

NOTE-

Special

tools

are

requíred

for

some

of

the

tests

de-

scribed

here

.

Fuel

pump

electrical

circuit,

testing

The

fuel

pump

electrical

circuit

diagram

is

shown

in

Fig

.

10

.

3

.

If

fuel

pump

does

not

run,

disconnect

black

harness

connector

from

tank

sender

unit

.

With

jumper

wire

con-

nectedas

described

in

step

2

above,

check

for

positive

(+)

batteryvoltage

at

harness

connector

terminals

.

See

Fig

.

11

.

FUEL

TANK

AND

FUEL

PUMP

160-

7

From

Main

Relay

(+15

power

with

key

in

run

From

B+juretion

point

orstartposition)

(batteryvoRageatalltirnes)

'

.5

RD/Nrr

1

.5

RD

1

.5

GNNI

From

Engine

2

.5

GNNI

Control

Module

15

2

.5

GNNI

Ground

(below

center

console)

Fig

.

10

.

Fuel

pump

electrical

circuit

.

30

-~

Relay

Fuel

Pump

8~T

I

1

s

ám

61

Front

Power

I

a

1

Distribution

Box

I_

16

WIRING

COLOR

CODE

BK

-

BLACK

BR

-

BROWN

Fuel

Pump

RD

-

RED

(in-tank)

M

YL

YELLOWGN

-

GREENBU

-

BLUE

1

VI

-

VIOLET

GY

-

GREY

WT

-

WHITE

PK

-

PINK

0011946

4

.

If

voltage

and

groundare

present,

fuel

pump

is

proba-

bly

faulty

.

If

there

is

no

voltage,

check

wiring

From

fuel

pump

Reay

and

make

sure

Reay

is

functioning

correctly

.

CAUTION-

Fuseandrelaylocationsmayvary

.

Usecara

when

Fuel

pump

power

consumption,

testing

troubleshooting

the

electrical

system

at

the

fuselrelay

panel

.

To

resolve

problems

in

identify-

NOTE-

ing

a

relay,

see

en

authorízed

BMW

dealer

.

"

To

achieveaccurate

testresults,

fhe

battery

voltage

at

the

connector

should

be

approximately

13

volts

.

1.

Remove

rearseat

cushion,

pull

right

side

insulation

mat

Charge

the

battery

asnecessary

.

back

to

expose

fuel

tank

accesscover

.

Remove

cover

.

q

higher

than

normal

power

consumption

usually

fin-

to

expose

wiring

connections

.

dicates

a

worn

fuel

pump,

which

may

cause

intermit-

tentfuel

starvation

due

lo

pump

overheating

and

2

.

Remove

fuel

pump

relay

and

opérate

fuel

pump

as

de-

seizure

.

The

only

remedy

is

pump

replacement

.

Be

scribed

under

Operating

fuel

pump

for

tests

earlier

.

sure

to

check

that

thereturn

fine

and

the

pump

pickup

Pump

should

run

.

Disconnect

jumper

wire

when

fin-

are

not

obstructed

before

replacing

the

pump

.

ished

.

1

.

Remove

rear

seat

cushion,

pull

right

side

insulation

mal

back

to

expose

fuel

tank

accesscover

.

Remove

cover

to

expose

wiring

connections

.

2

.

Disconnect

(black)

harness

connector

from

fuel

pump

.

3

.

Connect

an

ammeter

and

an

insulated

jumper

wire

be-

tween

terminals

in

connector

and

corresponding

pump

terminals

.

See

Fig

.

12

.

FUEL

PUMP

Page 199 of 759

NOTE-

Some

cars

covered

by

this

manual

may

have

an

alter-

nate

cooling

fan

switchwith

switching

temperatures

of

176%190W

(80%88°C)

.

When

replacing

the

switch

check

theswitching

specifications,

whichshouldbe

stamped

on

the

switch

body

.

1

.

If

coolant

is

circulating

at

normal

operating

tempera-

ture,

but

auxiliary

cooling

fan

does

not

run,

disconnect

connector

from

radiator

temperature

switch

and

make

tests

listed

in

Table

c

.

Table

c

.

Auxiliary

Cooling

Fan

Temperature

Switch

Tests

Wires

jumpered

Test

Test

resuits

conditions

Black/green

(terminal2)

and

Ignition

ON

Fan

runs

on

brown

(terminal

1)

low

speed

Black/gray

(terminal

3)

and

Ignition

ON

Fan

runson

brown

(terminal

I

1)

high

speed

2

.

If

fan

runs

only

when

powered

directly

by

jumpered

connector

and

hot

coolant

is

circulating

through

radia-

tor,

radiator

temperature

switch

is

most

likelyfaulty

.

Use

a

new

sealing

ring

when

replacing

switch

Tightening

Torque

"

Temperature

switch

to

radiator

......

15

Nm

(11

ft-Ib)

3

.

If

auxiliary

fan

does

notrun

when

powered

directly,

check

for

battery

voltage

at

temperature

switch

connec-

tor

(black/green

wire)

with

ignition

on

.

If

battery

voltage

is

not

present,

check

fuses

.

See

610

Electrical

Com-

ponent

Locations

.

RADIATOR

AND

COOLING

SYSTEM

170-

5

~r~nmm

a

00

0

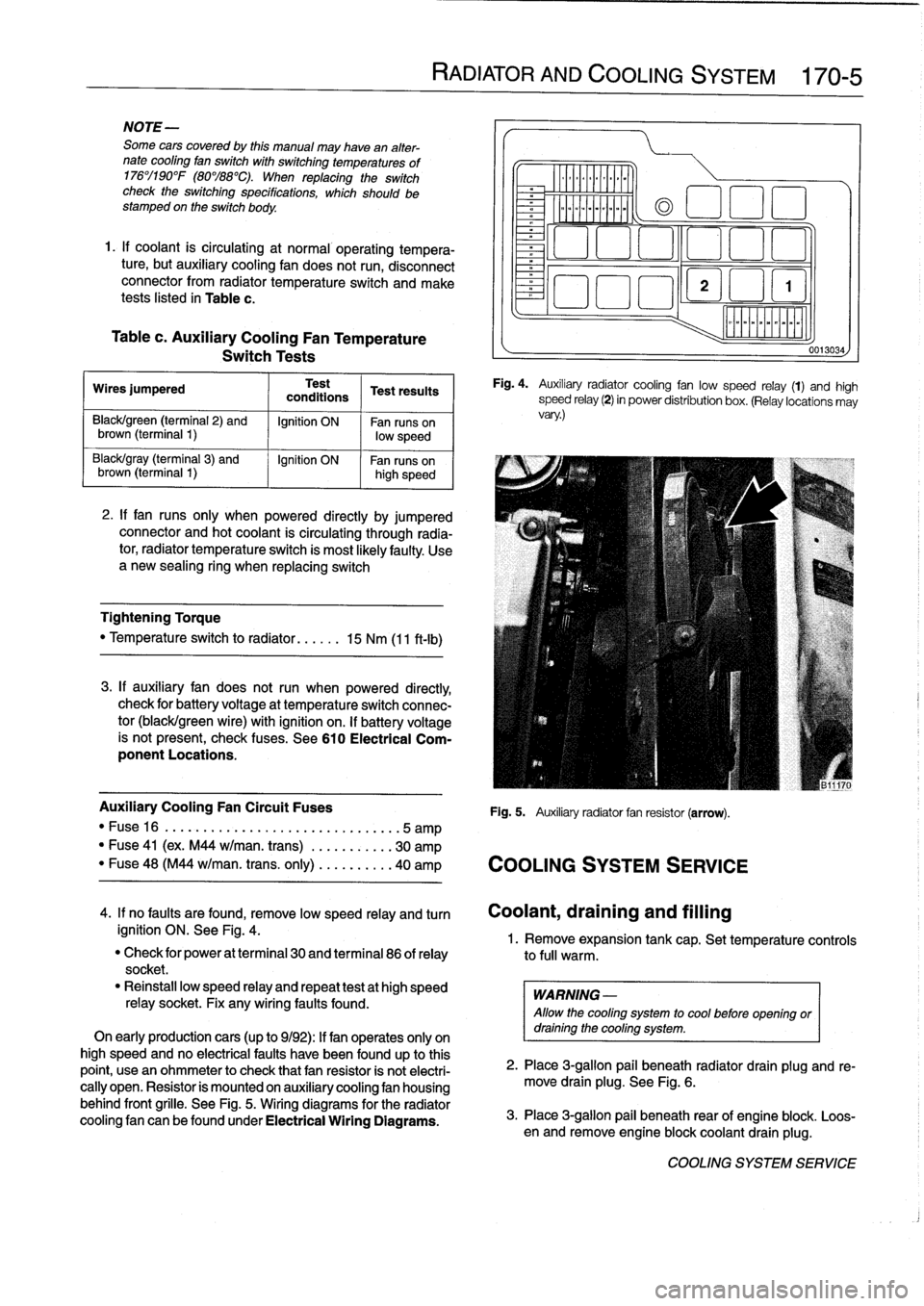

Fig

.

4

.

Auxiliary

radiator

cooling

fan

low

speed

relay

(1)

and

high

speed

relay

(2)

in

power

distribution

box

.

(Relay

locations

may

vary

.)

Auxiliary

Cooling

Fan

Circuit

Fuses

Fig

.

5

.

Auxiliary

radiator

fan

resistor

(arrow)

.

"

Fuse16

.

...................

..

..

...

...

.5

amp

"

Fuse

41

(ex

.

M44

w/man

.

trans)

.

..

.

..

.....

30

amp

"

Fuse

48

(M44

w/man

.

trans

.

only)

..

.

..

.....

40

amp

COOLING

SYSTEM

SERVICE

0013034

4

.

If

no

faults

are

found,

remove

low

speed

relay

and

turn

Coolant,draining

and

filling

ignition

ON

.

See

Fig

.

4

.

1

.

Remove

expansion

tank

cap

.

Set

temperature

controls

"

Check

for

power

at

terminal

30

and

terminal

86

of

relay

to

full

warm

.

socket

.

"

Reinstall

low

speed

relay

and

repeat

testat

high

speed

WARNING

-

relay

socket

.

Fix

any

wiring

faults

found

.

Allow

the

cooling

system

to

cool

before

openlng

or

On

early

productioncars

(up

to

9/92)

:

If

fan

operates

only

on

draining

the

cooling

system

.

high

speed

and

no

electrical

faults

have

been

foundup

to

this

point,

usean

ohmmeter

to

check

that

fan

resistor

is

not

electri-

2

.

Place

3

ra

allo

ug

.

beneath

radiator

drain

plug

and

re-

cally

open

.

Resistor

is

mounted

on

auxiliary

cooling

fan

housing

move

drain

plg

.

See

Fig

.

6

.

behind

front

grille

.

See

Fig

.

5

.

Wiring

diagrams

for

the

radiator

cooling

fan

canbefoundunder

Electrical

Wiring

Diagrams

.

3

.

Place

3-g

pail

beneath

rear

of

engine

blo

.

Loos-

en

and

re

mlon

ove

engine

blockcoolant

drain

plug

k

.

COOLING

SYSTEM

SERVICE

Page 387 of 759

610

Electrical

Component

Locations

GENERAL

...........

.

.

.

.

.

.

.

.

.

........

610-1

FOSE

POSITION

TABLES

..

.

.

.

.

.

.....

.

610-19

FUSE

AND

RELAY

POSITIONS

.

...

.

.

.

.

.

610-1

Fuse

Positions

.

.

.

................

.

.

.

.

.

610-1

Relay

Positions

.

.

.

.....

.

.

.

........

.

.

.

.

.

610-2

Auxiliary

RelayPanel

.....

.

...

.

........

.

610-2

SplicePanel,

Left

.

.

.

...

.

.

.

...

.

........

.

610-2

SplicePanel,

Right

.

.

.

.

.

.

.

.

...

.

.........

610-3

COMPONENT

LOCATIONS

.

.

.

.

.......

.

.610-3

Component

Location

Table

.

.

.

.

.

.

.........

610-9

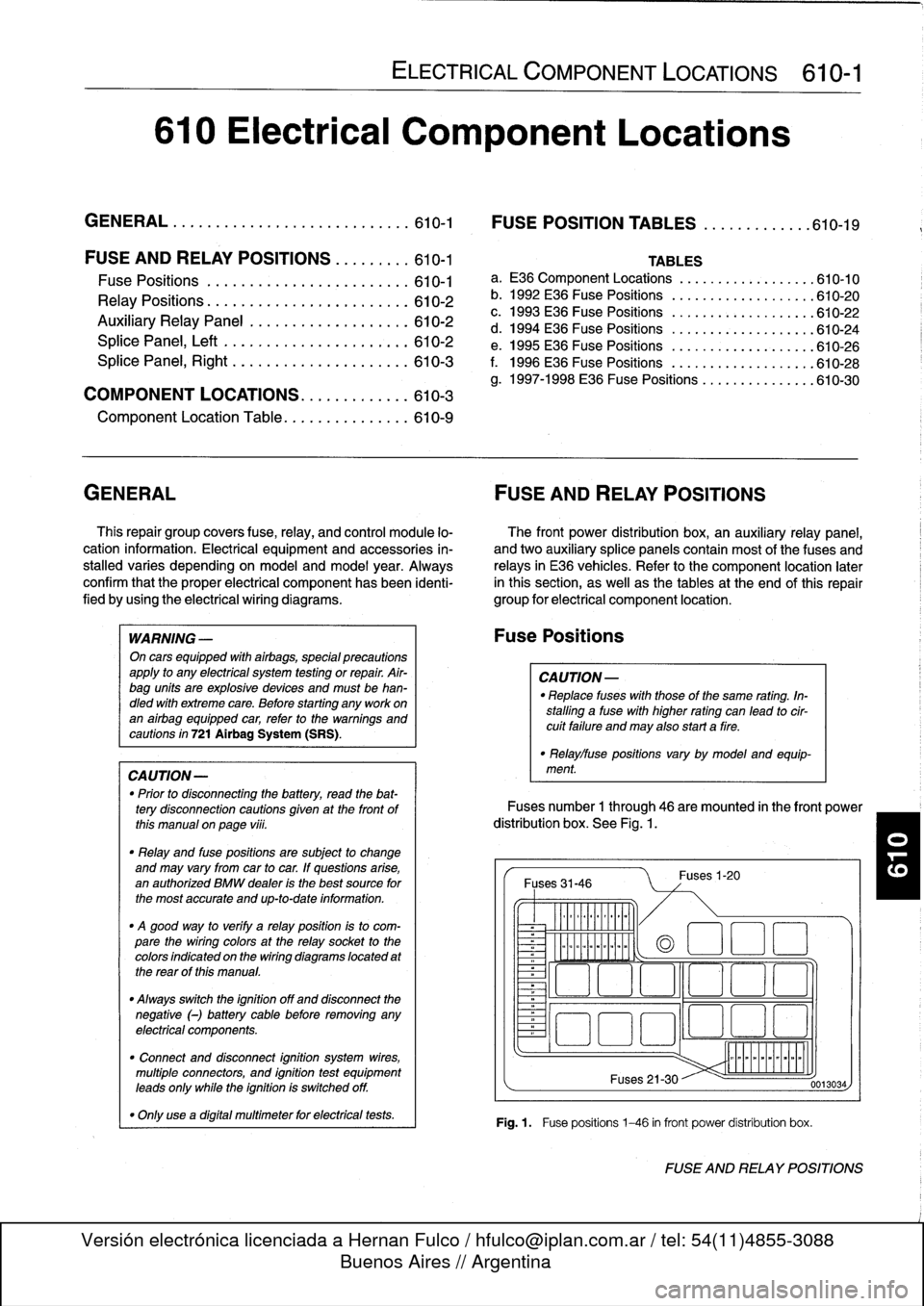

GENERAL

FUSE

AND

RELAY

POSITIONS

This

repair

group

covers

f

use,

relay,

and

control

module

lo-

The

front

power

distribution

box,

an

auxiliary

relay

panel,cation

information

.

Electrical

equipment

and

accessories

in-

and

two

auxiliary

splice

panels

contain

most

of

the

fuses

and

stalled

varies

depending

on

model

and

model

year

.

Always

relays

in

E36

vehicles

.

Refer

to

the

component

location

later

confirm

that

the

proper

electrical

component

has

been

identi-

in

this

section,

as

well

as

the

tables

at

the

end

of

this

repair

fied

by

using

the

electrical

wiring

diagrams

.

group

for

electrical

component

location

.

WARNING

-

On

cars

equipped

with

airbags,

special

precautionsapply

to

any

electrical

system

testing

orrepair

.

Air-

bag

units

areexplosive

devices

and

mustbe

han-

dled

with

extremecare

.

Before

starting

any

work

onan

airbag

equipped

car,

refer

to

the

wamings

and

cautions

in

721

Airbag

System

(SRS)

.

CAUTION

-

"

Prior

to

disconnectiog

the

battery,

read

the

bat-

tery

disconnection

cautions

given

at

the

front

of

this

manual

on

page

viii

.

"

Relay

and

fuse

positions

are

subject

to

changeand

may

varyfrom

car

to

car

.

If

questions

arise,

an

authorized

BMW

dealer

is

the

best

source

for

the

most

accurate

and

up-to-date

information

.

"

A

good

way

to

verify

a

relay

position

isto

com-

pare

the

wiring

colors

at

the

relay

socket

to

thecolors

indicated

on

the

wiring

diagrams

located

at

the

rear

of

this

manual

.

"

Always

switchthe

ignition

off

and

disconnect

the

negative

(-)

battery

cable

before

removing

any

electrical

components

.

"

Connect

and

disconnect

ignition

system

wires,

multiple

connectors,

and

ignition

test

equipment

leads

only

while

the

ignition

is

switched

off

.

"

Only

usea

digital

multimeter

for

electrical

tests

.

ELECTRICAL

COMPONENT

LOCATIONS

610-1

TABLES

a

.

E36Component

Locations

...........

.

.

..

...

610-10b

.

1992

E36

Fuse

Positions

..........

..

.

.

.....

610-20c

.

1993

E36

Fuse

Positions

..........

..

..

.

....

610-22d

.

1994

E36

Fuse

Positions

.........

...

.......

610-24e

.

1995

E36

Fuse

Positions

.........

...

.......

610-26

f

.

1996

E36

Fuse

Positions

.........

...

.......

610-28g

.

1997-1998

E36

Fuse

Positions

..

.

..

...

.......

610-30

Fuse

Positions

CAUTION

-

"

Replace

fuses

with

those

of

the

same

rating

.

In-

stalling

a

fuse

with

higher

rating

can

lead

to

cir-

cuit

failure

and

may

also

start

a

fire

.

"

Relay/fuse

positions

vary

by

model

and

equip-

ment

.

Fuses

number

1

through

46

are

mounted

in

the

front

power

distribution

box

.

See

Fig

.

1.

Fuses

31-46

~

Illlllllllll

°

-

Ilmmlmomlmoi

Fuses

1-20

(a

1

:1

E

El

~

~O!7

L~~n

4~

i

Fuses

21-30

Fig

.1.

Fuse

positions

1-46

in

front

power

distribution

box

.

0013034

FUSE

AND

RELAY

POSITIONS

Page 486 of 759

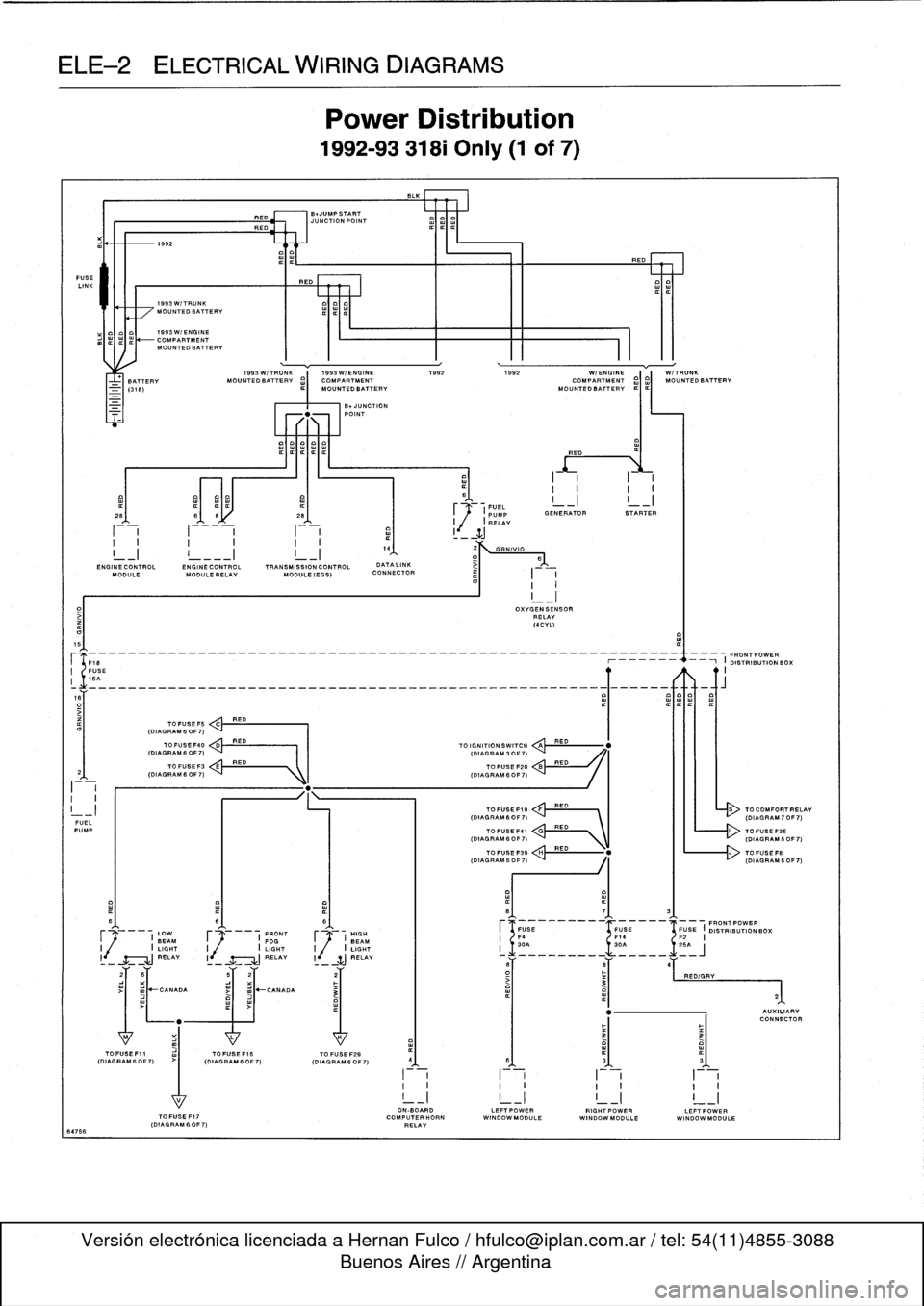

ELE--2

ELECTRICAL

WIRING

DIAGRAMS

FUSE

LINK

64766

I-i

I

-

i

a

1

I

_

ZJ

I

I

I

I

I

I.

4

2

GRN/VIO

I_I

!

___I

I_I

1

D>

6

END

INECONTROL

ENGINECONTROL

TRANSMISSION

CONTROL

DATALINK

MODULE

MODULE

RELAY

MODULE

(EGS)

CONNECTOR

I

I

I

I

5

(F18

--_______________________________________________

O19~

N

RIBUON

BOX

I

FUSE

II

15A

o~___________________________________________________Q~____-aft

TO

FUSE

F5

C

RED

(DIAGRAM

6

OF

7)

FUELPUMP

I

(DIAGRAM60F7)

C'

RED

\

L------r>

(DIAGRAM60F7)

I

LOW

F

I

FRONT

HIGH

BEAM

FOGJ

BEAM

I

I

LIGHT

I

I

LIGHT

I

j

/

I

LIGHT

RELAY

I

RELAY

li

SJ

RELAY

1992

1993W/TRUNK

MOUNTEDBATTERV

1993W/ENGINE

COMPARTMENTMOUNTEDBATTERV

1993W/TRUNK

1993W/ENGINE

1992

1992

WI

ENGINE

W/TRUNK

BATTERY

MOUNTEDBATTERV

¢)

MOUNTED

BATTERY

MOUN

O

TEDBATT

I

ERV

¢I¢I

MOUNTEDBATTERV

TOFUSEF40

<

,.k

RED

(DIAGRAM

6

OF

7)

I

I

(DIAGRAM

3

OF

7)

TO

FUSEF3

E

RED

(DIAGRAMfiOF7)

"

.

1k

I

(DIAGRAM

6OF7)

>I

mJ~CANADA

RED

BNUMPSTART

JUNCTION

POINT

REO

Power

Distribution

1992-93

318i

Only

(1

of

7)

-UNCTION

POINT

TOFUSEF15

TO

FUSE

F29

(DIAGRAM60F7)

(OIAGRAM6OF7)

I

~1

.

FUEL

_I

I

_I

~

(PUMP

GENERATOR

STARTER

I

,(

I

RELAY

TO

IGNITION

SWITCH

QA

TOFUSE

F20

TOFUSEF19

FRED

(DIAGRAM6OF7)

`

I

III

-

(DIAGRAM70F7)

OXVGENSENSOR

RELAY

(4CVL)

RED

RED

RED

ON-BOARD

LEFTPOWERRIGHTPOWERLEFTPOWER

TOFUSEF17

COMPUTERHORN

WINDOWMODULE

WINDOWMODULE

WINDOW

MODULE

(DIAGRAM

60F

7)

RELAY

TO

COMFORTRELAV

Page 487 of 759

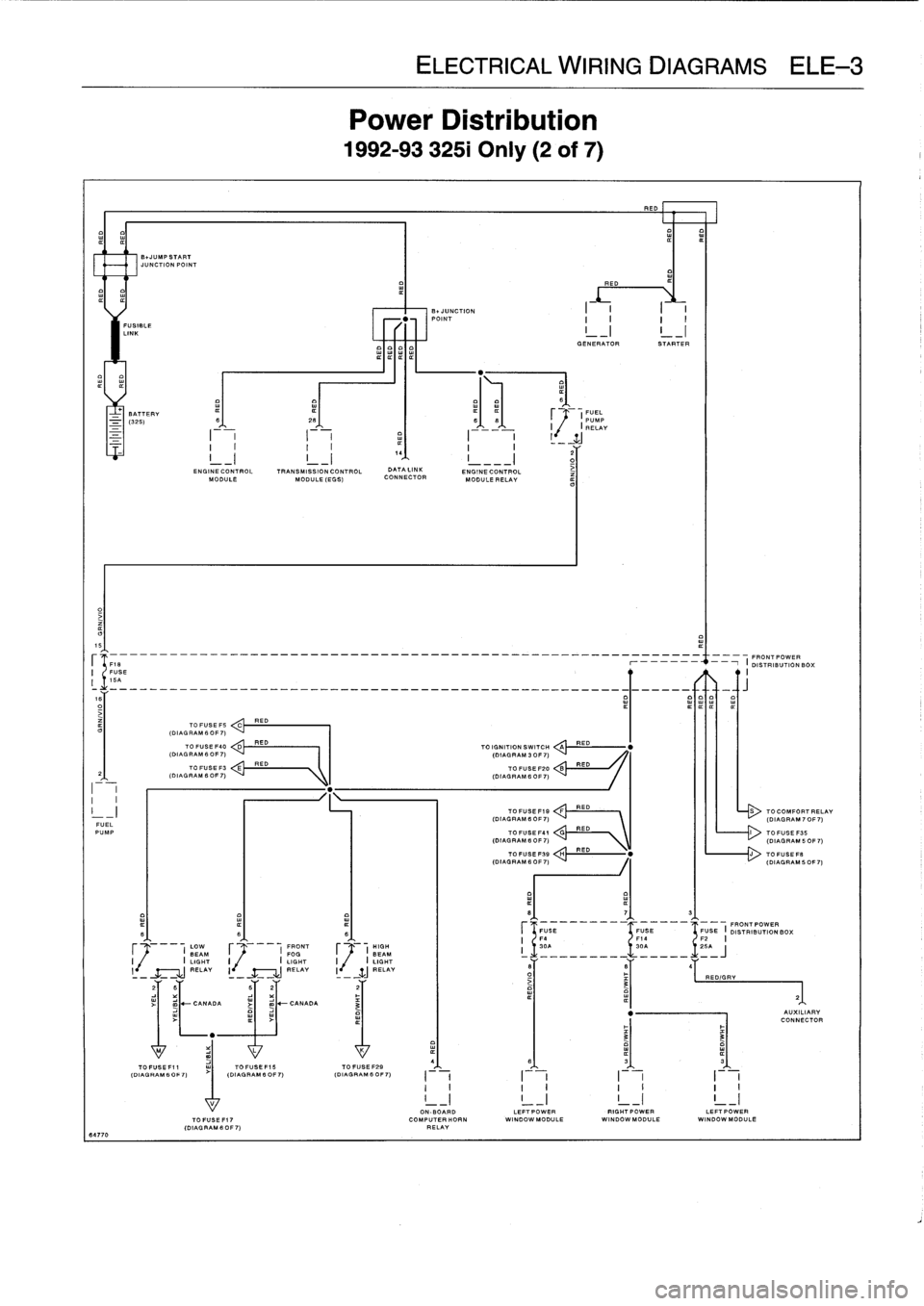

ELE

Power

L

1992-9332

RED

E01

IIIII

FUSIBLE

LINK

I

GENERATOR

STARTER

BATTERY

¢

(FUEL

-

(325)

S

26

66

PUMP

I

I

RELAY

2

G

ENGINE

CONTROL

TRANSMISSION

CONTROL

DATA

LINK

ENGINECONTROL

iMODULE

MODULE

(EGG)

CONNECTOR

MODULE

RELAY

15

--

---

-

-

----

--

FRONT

POWER

FUSE

r

-

i

DISTRIBUTIONBO

;

I

16A

R

ITIT

TO

FUSE

FS

ED

C

(DIAL

RAM

6

OF

7)

TO

FUSE

F40

D

RED

TO

IGNITION

SWITCH

A

RED

(DIAGRAM

6

OF

7)

(DIAGRAM

3

OF

7)

TO

FUSE

F3

E

RED

TO

FUSE

F20

B

RED

2

(DIAGRAM6OF7)

(DIAGRAM

6OF7)

I

I

I

I

-

I

TOFUSEF19

:

:!!RED---

RED

S

TOCOMFORTI

(DIAGRAM

6

OF

7)

(DIAGRAM

70

FUEL

PUMP

TO

FUSE

F41

V\

TOFUGEF35

(DIAGRAM

B

OF

7)

\

(DIAGRAM

50

TOFUSEFSB

H

RED

"

J

TOFUSEF

.

(DIAGRAM

6

0F

7)

(DIAGRAM

50

8

7

3

FUGE

FUSE

FUSE

I

FRONT

POWER

B

6

6

DISTRIBUTION

BOX

F4

F14

F2

I

LOW

FRONT

HIGH

I

30A

30A

~

.1

.

25A

BEAM

F

I

FOG

F

(

BEAM

i

_________

_____

J

I

I

LIGHT

I

I

LIGHT

I

.

I

LIGHT

l

RELAY

I

-

RELAY

I

-

WJ

_RELAY

6

B

4

-

-

-

O

RED/GRY

3

21

2

B

62

2

~

-

CANADA

j

m

-CANADA

3

"

AUXILIAI

CONNECT

"

3

3

M

L

K

4(D

IAGAGR

AM60

F7)

(DIAGRAM

IAGRAM

B

OFOF

7)

(DIAGRAM

6

0

6

3

3G

FO

F

~

7)

I

I

I

I

I

II

I

I

I

I

I

I

I

!

_I

!

_I

!

_I

!

_

17

I

ON-BOARD

LEFTPOWER

RIGHTPOWER

LEFT

POWERTOFUSEFI7

COMPUTERHORN

WINDOW

MODULE

WINDOWMODULE

WI

NDOWMODULE

(DIAGRAMS

OF7)

RELAY

64770

Page 488 of 759

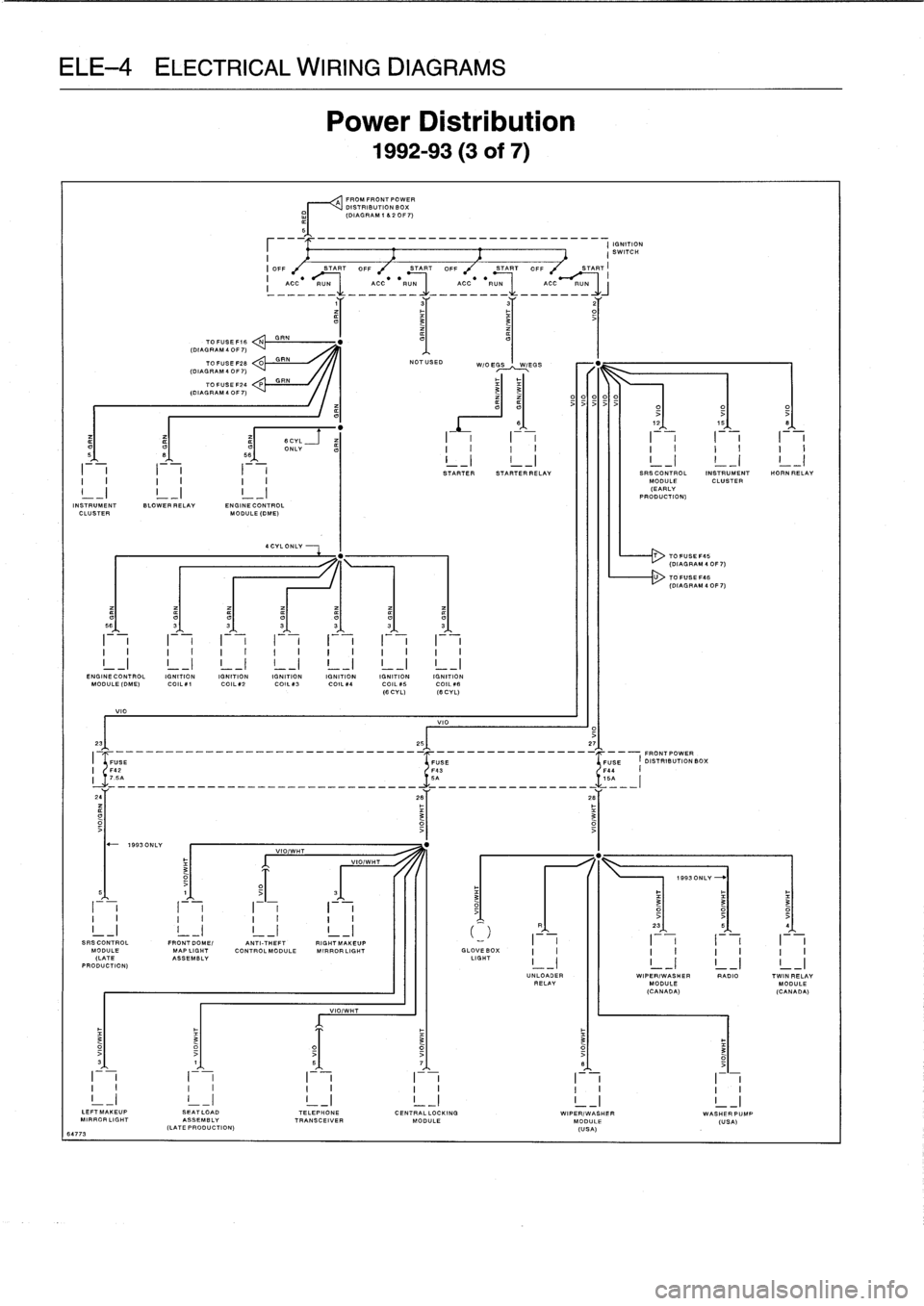

CAL

WIRING

DIAGF

Power

Di

;

1992-93

~~~A

"'0""0"'0"',

///

°°°

DISTRIBUTION

BOX

o/

(DIAGRAM1820F7)

5-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

--

-

-

-

---

-

-

-

I

IGV

NITfON

3

TOFUSEF16

NGRN

.

(DIAGRAM

4

OF

7)

TOP

.SEF28

0GRN

NOTUSED

W/OEGS

W`EGS

(CIA

40F7)

TOFU

SEF24

P

GRN

(DIAGRAM40F7)

33

>>>>>

O>

>

>

?

"

8

12

15

B

a

a

6CYL

-

f

I

I

I

I

I

I

I

I

I

I

ONLY

I

I

I

I

I

I

I

I

I

I

-

I-_I

I

I

I

I

I

STARTER

STAR

-

TER

RELAY

SRSCONTROL

INSTRUMENT

HORN

RELAY

I

I

I

I

I

J

MODULE

CLUSTER

L-I

I

_

I

I

(EARLY

PRODUCTION)

INSTRUMENT

BLOWER

RELAY

ENGINE

CONTROL

CLUSTER

GDULE

(DME)

4

CYL

ONLY

T

TO

FUSEF45

(DIAGRAM

4

OF

7)

-

U

TO

FUSEF46

(DIAGRAM

40F7)

t7

t7

t7

5fi

3

3

3

3

3

3

I

I

I

II

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

ENGINECONTROL

IGNITIONIGNITIONIGNITION

IGNITION

IGNITIONIGNITION

MOOULE(DME)

CO-1

CO

ILk2

CO

ILp3

CO

L

.1

COILkS

CO

L#6

HI

CYL)

IS

CYL)

VIO

23

VIO

26

27

FRONTPOWER

.

I

SE

FUSE

FUSE

I

DISTRIBUTIONBO%

FU

J5______________-_

.-

.__________

A________________16

24

26

2i

3

'

o

1993

ONLY

VIO/W

HT

VIO/WHT

0

1993ONLY

~

0

3

3

3

I

I

I

I

I

I

I

I

;

'

I

I

I

I

I

I

I

I

_

23

>t

5

4

SRSCONTROL

FRONTDOME/

ANTI-THEFT

RIG

!

HT

MAKE

UP

I

I

I

I

I

I

I

I

MODULE

MAP

LIGHT

Co

NTROLMODULE

MIRRORLIGHT

GLOVEBOX

I

I

I

I

I

I

I

I

(LATE

ASSEMBLY

LIGHT

I

-

I

I

-

I

I

-

I

I

-

I

PRODUCTION)

UNLOADER

WIPER/WASHER

RADIO

TWIN

RELAYRELAY

MODULE

MODULE

(CANADA)

(CANADA)

VIO/WHT

0

0

3

3>

>

>

33

1

5

7

B

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

LEFTMAKEUP

SEATLOAD

TELEPHONE

CENTRALLOCKING

WIPE

/WASHER

WASHERPUMP

MIRROR

LIGHT

ASSEMBLY

TRANSCEIVER

MODULE

MODULE

(USA)

(LATE

PRODUCTION)

64773(USA)

Page 489 of 759

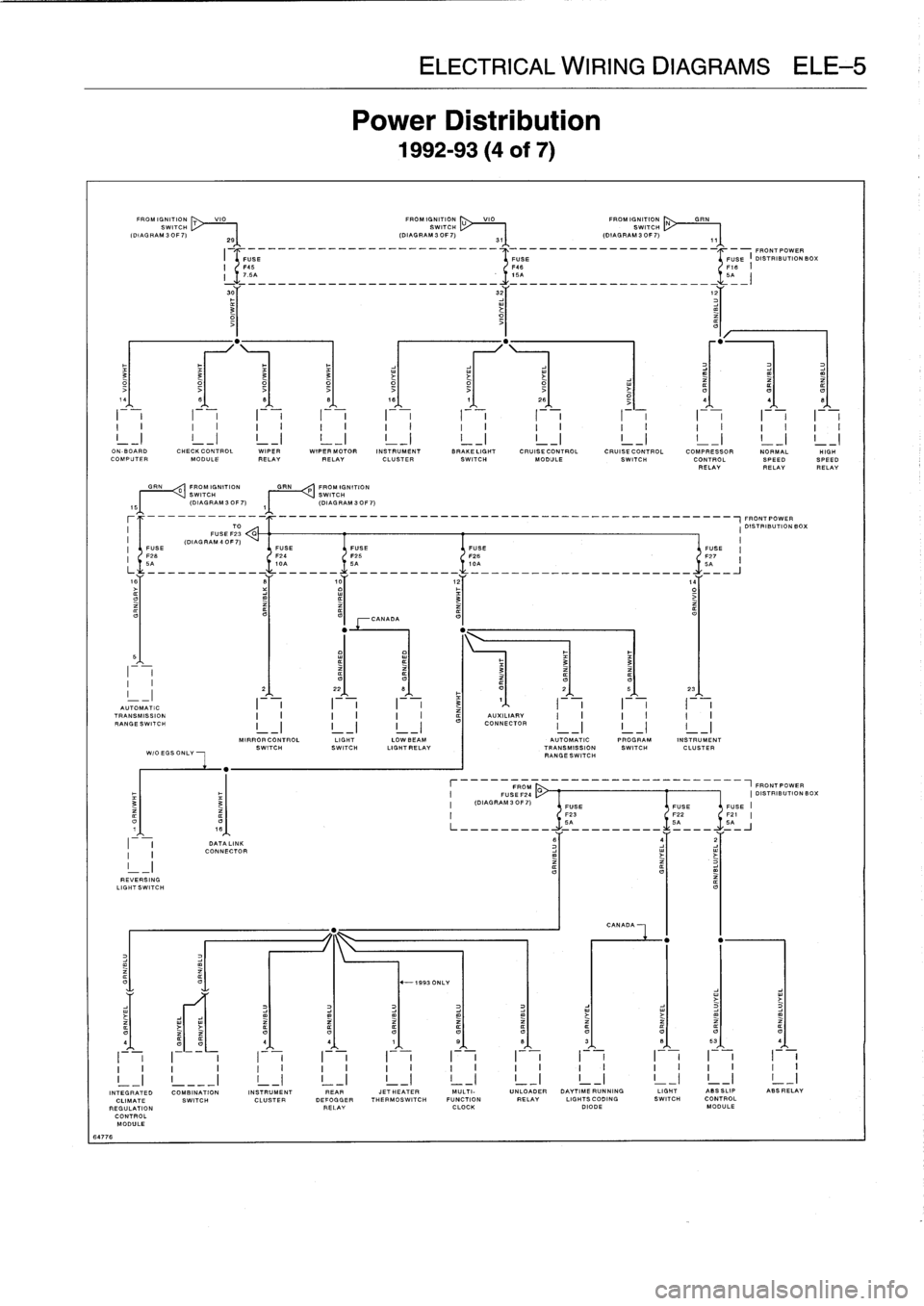

EKE

Power

1992-

VIO

FROMIGNITION

U

VIO

FROM

IGNITI

ON

SWITCH

SWITCH

2S

(DIAGRAM3OF7)

31

(DIAGRAM3OF7)

I

-

______________-__________--

4

-_____________________I_-FRONT

POWER

O

3

3

3

3

i

14

8

8

B

18

7

26

-

4

4

I

i

I

I

i

-F-

I

i

I

-

,

I

,

I

I

F-,

ON

-BOARD

CHECKCONTROL

WIPER

WIPER

MOTOR

INSTRUMENT

BRAKELIGHT

CRUISE

CONTROL

CRUISE

CONTROL

COMPRESSOR

NORMALCOMPUTER

MODULE

RELAYRELAY

CLUSTER

SWITCH

MODULE

SWITCH

CONTROL

SPEEDRELAYRELAY

GRN

0

FROM

IGNITION

GRN

P

FROM

IGNITION

~I

I

VSWITCH

SWITCH

(DIAGRAM

30F7)

,~

(DIAGRAM

3OF7)

-------_-_____________________________________________~FRONT

POWER

TO

I

DISTRIBUTIONBOX

FUSE

F23

G

(DIAG

RAM

4

0F

7)

I

FUSE

FUSE

FUSE

FUSE

FUSE

'

F26

F24

F25

F26

-

F27

6A

10A

SA

ICA

5A

is

S

,0

12

,4

o3

>

CANADA

5

I

~

~

~

3

33

-

2

22

B

F

O

2

5

23

AUTOMATIC

I

I

I

3

1

I

TRANSMISSION

AUXILIARY

RANGESWITCH

I

-

I

I

-

I

I

-

I

CONNECTOR

MIRRORCONTROL

LIGHT

LOWBEAM

AUTOMATIC

PROGRAM

INSTRUMENT

SWITCHSWITCH

LIGHTRELAY

TRANSMISSION

SWITCH

CLUSTER

WIOEGSONLY

RANGESWITCH

FROM

___________-----1FRONTPOWER

FUSEF24

CI

DISTRIBUTION

BC

3

(DIAGRAM30F7)

FUSE

FUSEFUSE

F23

F22

F21

O

O

SA

SA

5A

DATA

LINK

6

j

2

I

CONNECTOR

REVERSING

LIGHTSWITCH

CANADA

O

"

-1993

ONLY

O4

4

4

1

S

B

3

B

53

4

I

v

I~

i

I

i

I

v

I

i

I

v

I

i

I

v

I

i

I

i

I

i

v

v

v

v

~

v

v

~

~

v

v

~

v

v

o

n

v

v

v

v

v

v

_I

INTEGRATED

COMBINATION

INSTRUMENT

REAR

JETHEATER

MULTI-

UNLOADER

DAYTIMERUNNING

LIGHT

ASSSLIP

ABSRELAY

CLIMATE

SWITCH

CLUSTER

DEFOGGER

THERMOSWITCH

FUNCTION

RELAY

LIGHTSCODING

SWITCH

CONTROL

REGULATION

RELAY

CLOCK

DIODE

MODULE

CONTROL

MODULE

64776

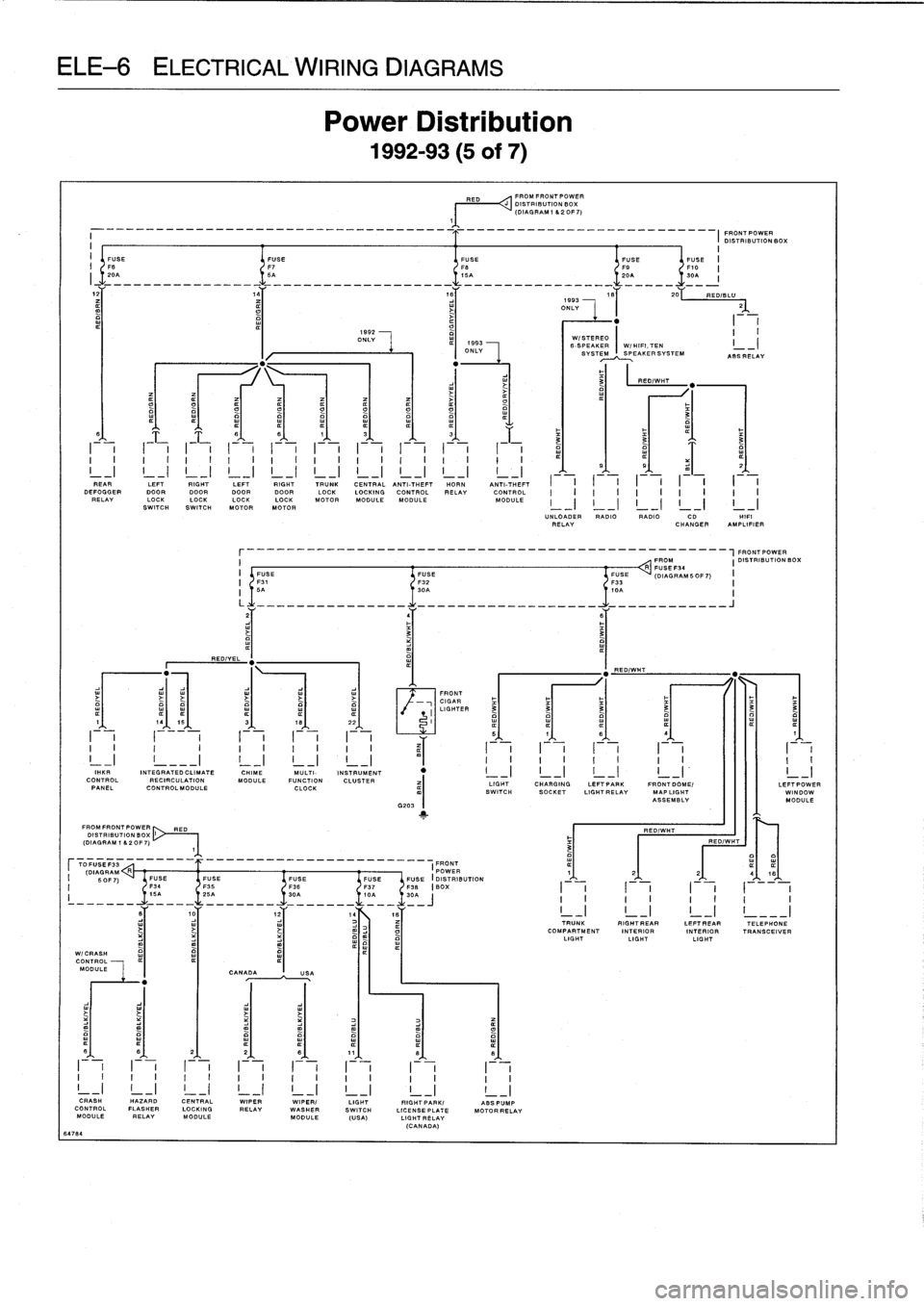

Page 490 of 759

CALWIRING

DIAGF

Power

Di

:

1992-93

RED

FROMFRONTPOWER

DISTRIBUTION

BOX

(DIAGRAM

1

620F7)

1

FRONTPOWER

DISTRIBUTION

BOX

i

I

I

1592

II

ONLY

WI

STEREO

-

I

ONLY

6-

SVS

SPEAKER

I

W/HIFI,TEN

I

TE~~PEAKERSYSTEM

ASSRELAY

3

RED/WHT

O

t7

0

t7

3

6

6

8

1

3

¢

3

F

~

~

3

a

a

o

I

I

I

II

I

I

I

I

I

I

I

I

I

I

I

I

I

i

I

¢

5

s

z

I

REAR

I

I

LEFT

I

I

RIGHT

I

I

LEFT

I

I

RIGHT

I

I

TRUNK

I

CENT

RA

I

L

ANTI-THEFT

I

HORN

I

ANTI-THEFT

I

I

I

I

I

I

I

I

I

I

DEFOGGERDOOR

DOOR

DOORDOOR

LOCK

LOCKING

CONTROL

RELAY

CONTROL

II

I

IIIIIII

RELAY

LOCK

LOCKLOCKLOCK

MOTOR

MODULEMODULE

MODULE

I

_

II

-

II

_

II

-

II

_

I

SWITCHSWITCH

MOTORMOTOR

UNLOADER

RADIO

RADIO

CD

HIF'

RELAY

CHANGER

AMPLIFIER

r________________________________________________-FRONT

POWER

I

FROM

I

DISTRIBUTION

BOXR

FUSE

I

FUSE

FUSE

FUSE

(DIAGRAMSOF7)

I

F31

F32

F33

II

5A

30A

I,0

OA

I

L

-----

______

.......

.

.

.

.

.

.

.

.

.

..

________J

z

4

6

3

3

a

"

"

REDIYEL

RED/WHT

"

FRONT

Y

CIGAR

I

LIGHTED

3

3

3

3

3

3

1

-

19

15

3

-

18

-

22

-

I

_

_I

I

I

iI

(

I

II

5

1

s

s

1

I

I

I

I

II

I

I

II

~

(-

I

I

I

I

-

I

II

IiI

_I

!

___I

!

_I

!

_I

i

-I_

I

I

I

I

I

I

I

I

I

I

I"

KIM

INTEGRATED

CLIMATE

CHIME

MULTI-

INSTRUMENT

"

I

_I

I

-

I

I

~I

I

-I

I

_I

CONTROL

RECIRCULATION

MODULE

FUNCTION

CLUSTER

LIGHT

CHARGING

LEFTPAPK

FRONT

DOME/

LEFT

POW

PANEL

CONTROLMODULE

CLOCK

SWITCH

SOCKET

LIGHTRELAV

MAP

LIGHT

WINDON

ASSEMBLY

MODULE

G203

1

FROMFRONTPOWER

RED

RED/WHT

DISTRIBUTION

BOX

(DIAGRAM

1

82OF7)

RED/WIT

3

TFUSEF33

FRONT

ODAORAM

R

______

__________________-

I

POWER

¢

1

2

2

416

I

SOFT)

FUSE

FUSE

FUSE

FUSE

FUSEFUSE

(DISTRIBUTION

F34

136

F37

F38

BOX

I

I

II

III

I

z'235

A-____

t0A

-

30=~

IIIII11I

10

1z

14Es

TRUNK

RIGHTREAR

LEFTREAR

TELEPHONE

COMPARTMENT

INTERIOR

INTERIOR

TRANSCEIVER

LIGHT

LIGHTLIGHT

P

W1

C

RASH

CONTROL

MODULE

CANADAUSA

fl

6

2

2

8

11

8

0

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

II

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

CRASH

HAZARD

CENTRAL

WIPER

WIPER/

LIGHT

RIGHTPARK/

ABSPUMP

CONTROLFLASHER

LOCKING

RELAY

WASHER

SWITCH

LICENSEPLATE

MOTORRELAV

MODULE

RELAY

MODULE

MODULE

(USA)

LIGHTRELAV

(CANADA)

64784