ECO mode BMW M3 1998 E36 Owner's Guide

[x] Cancel search | Manufacturer: BMW, Model Year: 1998, Model line: M3, Model: BMW M3 1998 E36Pages: 759

Page 336 of 759

512-

6

DOORWINDOWS

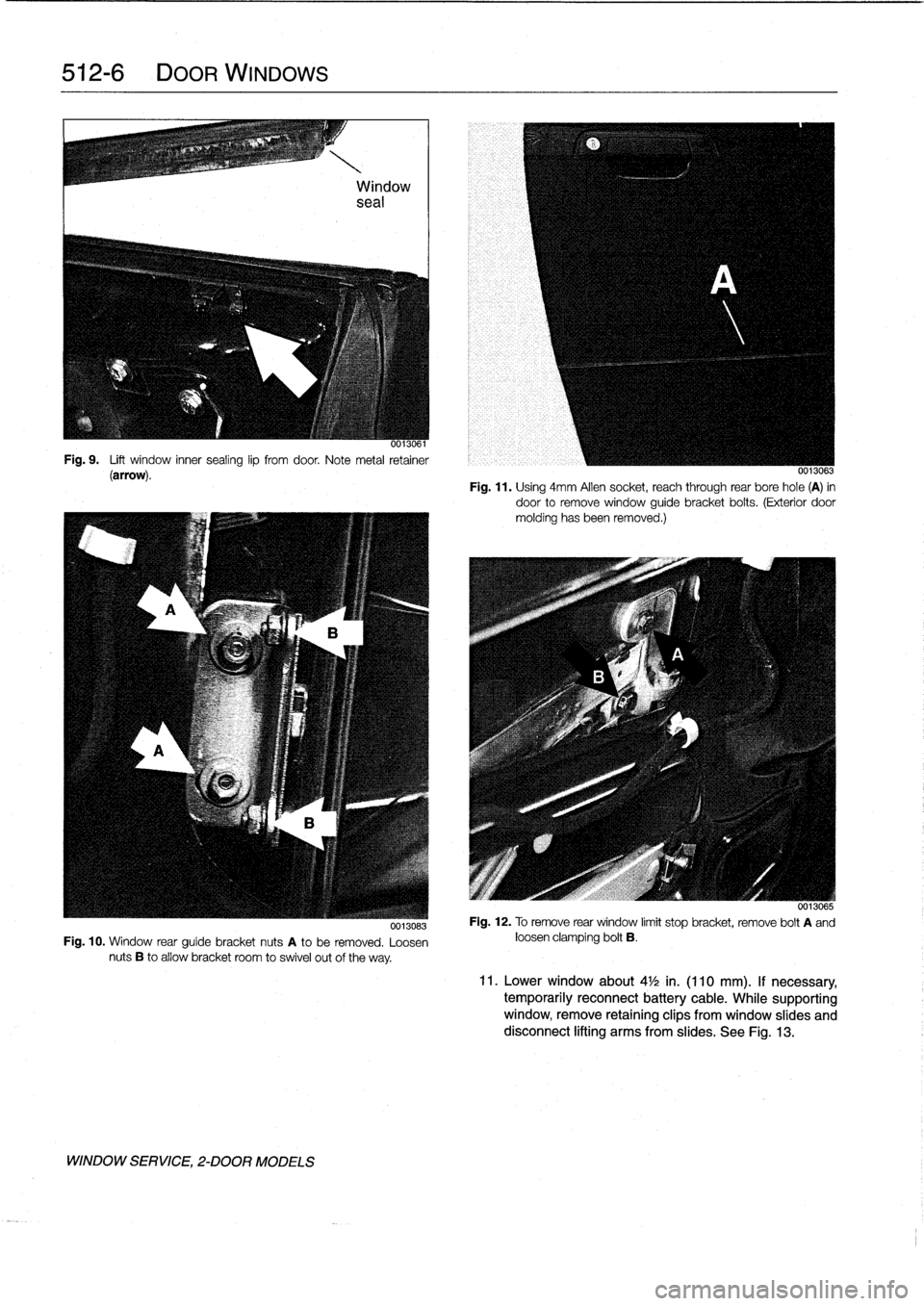

0013061

Fig

.

9

.

Lift

window

inner

sealing

lip

fromdoor

.

Note

metal

retainer

(arrow)

.

0013083

Fig

.

10

.

Window

rear

guíde

bracket

nuts

A

to

be

removed

.

Loosen

nuts

B

to

allow

bracket

room

to

swivel

out

of

the

way

.

WINDOW

SERVICE,

2-DOOR

MODELS

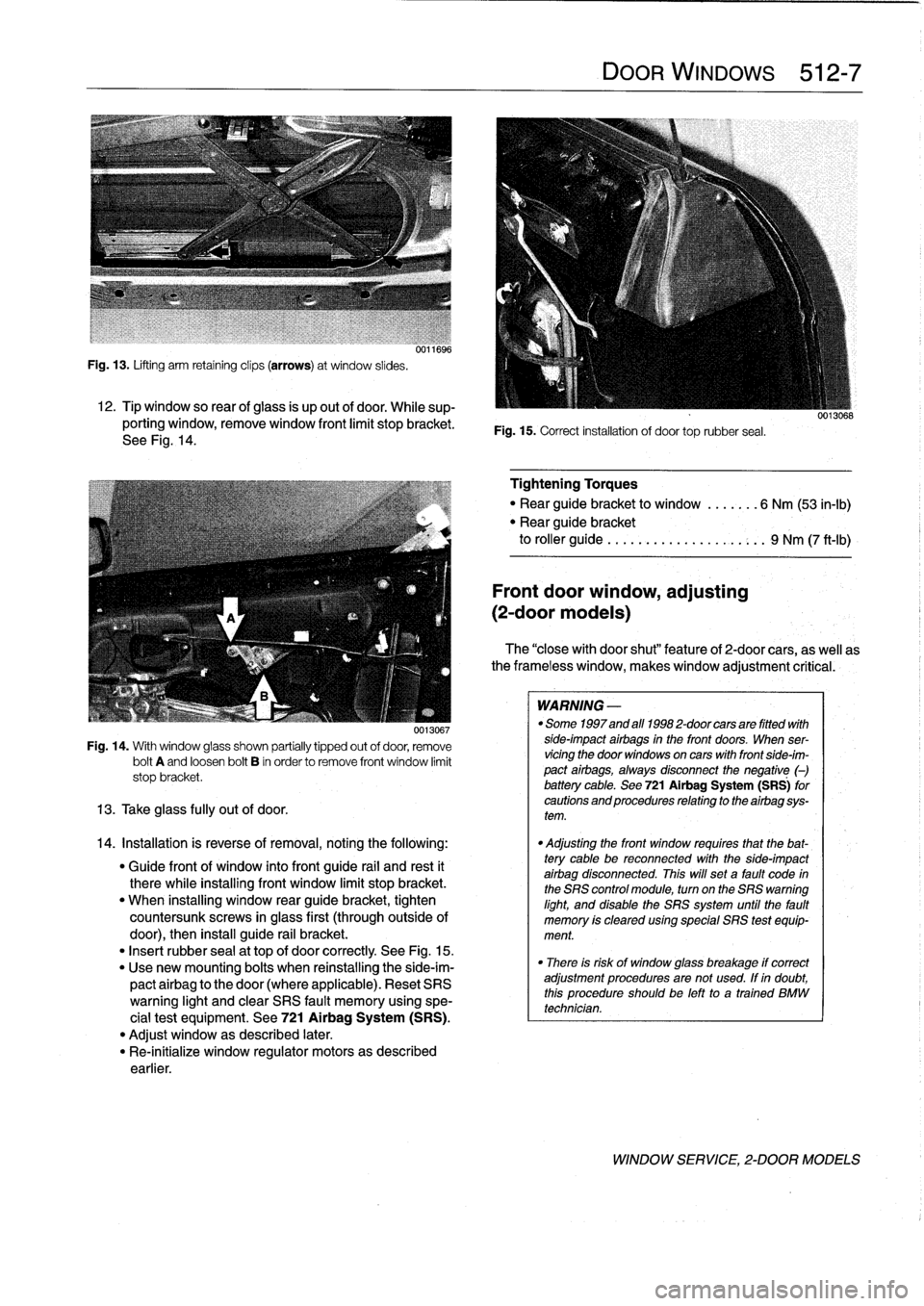

0013063

Fig

.

11

.

Using

4mm

Allen

socket,

reach

through

rear

bore

hole

(A)

in

door

to

remove

window

guide

bracket

boits

.

(Exterior

door

molding

hasbeen

removed

.)

0013065

Fig

.

12

.

Toremove

rear

window

limit

stop

bracket,

remove

bolt

A

and

loosen

clamping

bolt

B

.

11

.

Lower

window

about

4

1

/2

in

.

(110

mm)

.

If

necessary,

temporarily

reconnect

battery

cable

.

While

supporting

window,

remove

retaining

clips

from

window

slides

and

disconnect

lifting

arms

from

slides

.

See

Fig

.

13

.

Page 337 of 759

Fig

.

13

.

Lifting

arm

retaining

clips

(arrows)

at

window

slides

.

12

.

Tip

window

so

rear

ofglass

is

up

out

of

door

.

While

sup-

porting

window,

remove

window

front

limit

stopbracket

.

See

Fig

.

14

.

0013067

Fig

.

14

.

With

window

glass

shown

partially

tipped

out

of

door,

remove

bolt

A

and

loosen

bolt

B

in

order

to

remove

front

window

limit

stop

bracket

.

13

.

Take

glass

fully

out

of

door

.

14

.

Installation

is

reverse

of

removal,notingthe

following

:

"

Guide

front

of

window

into

front

guide

rail

and

rest

it

therewhile

installing

front

window

limit

stop

bracket

.

"

When

installing

window

rear

guide

bracket,

tighten

countersunk

screws

in

glass

first

(throughoutside

of

door),

then

install

guide

rail

bracket

.

"

Insert

rubber

sea¡

at

top

of

door

correctly

See

Fig

.

15

.

"

Use

new

mounting

bolts

when

reinstalling

the

side-im-

pactairbag

to

the

door

(where

applicable)

.

Reset

SRS

warning

light

and

clear

SRS

fault

memory

using

spe-

cial

test

equipment

.

See

721

Airbag

System

(SRS)

.

"

Adjust

window

as

described

later

.

"

Re-inítialize

window

regulator

motors

as

described

earlier

.

DOOR

WINDOWS

512-

7

Fig

.

15

.

Correct

installation

of

door

toprubber

seal

.

Tightening

Torques

"

Rear

guide

bracket

to

window

.......

6

Nm

(53

in-lb)

"

Rear

guide

bracket

to

roller

guide

..

.

...

...............

9

Nm

(7

ft-Ib)

Front

door

window,

adjusting

(2-door

modeis)

The

"closewith

door

shut"

feature

of

2-door

cars,

as

well

as

the

frameless

window,

makeswindow

adjustment

critical

:

WARNING

-

"

Some

1997

and

afl

1998

2-door

cars

are

fitted

with

side-impact

airbags

in

the

front

doors

.

When

ser-

vicingthe

door

windows

on

cars

with

front

side-im-

pact

airbags,

always

disconnect

the

negative

(-)

battery

cable

.

See

721Airbag

System

(SRS)

for

cautions

and

procedures

relating

to

the

airbag

sys-

tem

.

"

Adjusting

the

front

window

requires

that

the

bat-

tery

cable

be

reconnected

with

the

side-impact

airbag

disconnected

.

This

will

set

a

fault

code

in

the

SRS

control

module,

turn

on

the

SRS

warning

light,

and

disable

the

SRS

system

until

the

fault

memory

is

cleared

using

special

SRS

test

equip-

ment

.

"

There

is

risk

of

window

glass

breakage

if

correct

adjustment

proceduresare

not

used

.

If

in

doubt,

this

procedureshouldbe

left

to

a

trained

BMW

technician

.

WINDOW

SERVICE,

2-DOOR

MODELS

Page 338 of 759

512-

8

DOOR

WINDOWS

NOTE-

To

achieve

an

accurate

window

adjustment

in

2-door

models

with

"close

with

door

shut"

feature,

simulate

a

closed

dooras

follows

:

On

early

cars,

manually

turn

the

latch

on

the

door

to

the

closed

position

.

See

Fig

.

16

.

On

latercars,

insert

a

wedge

of

wood

into

the

striker

on

the

body

to

close

the

striker

switch

.

Be

sure

to

open

thero-

tary

latch

(by

pulling

upon

the

door

handle)

or

remove

the

wedge

before

closing

the

door

.

0013066

Fig

.

16

.

To

manually

close

door

latch,

push

rotary

latch

in

direction

of

arrow

.

CAUTION-

Do

not

close

the

door

with

therotary

latch

in

closed

position,

orwith

a

wedge

in

the

striker

.

WINDOW

SERVICE,

2-DOOR

MODELS

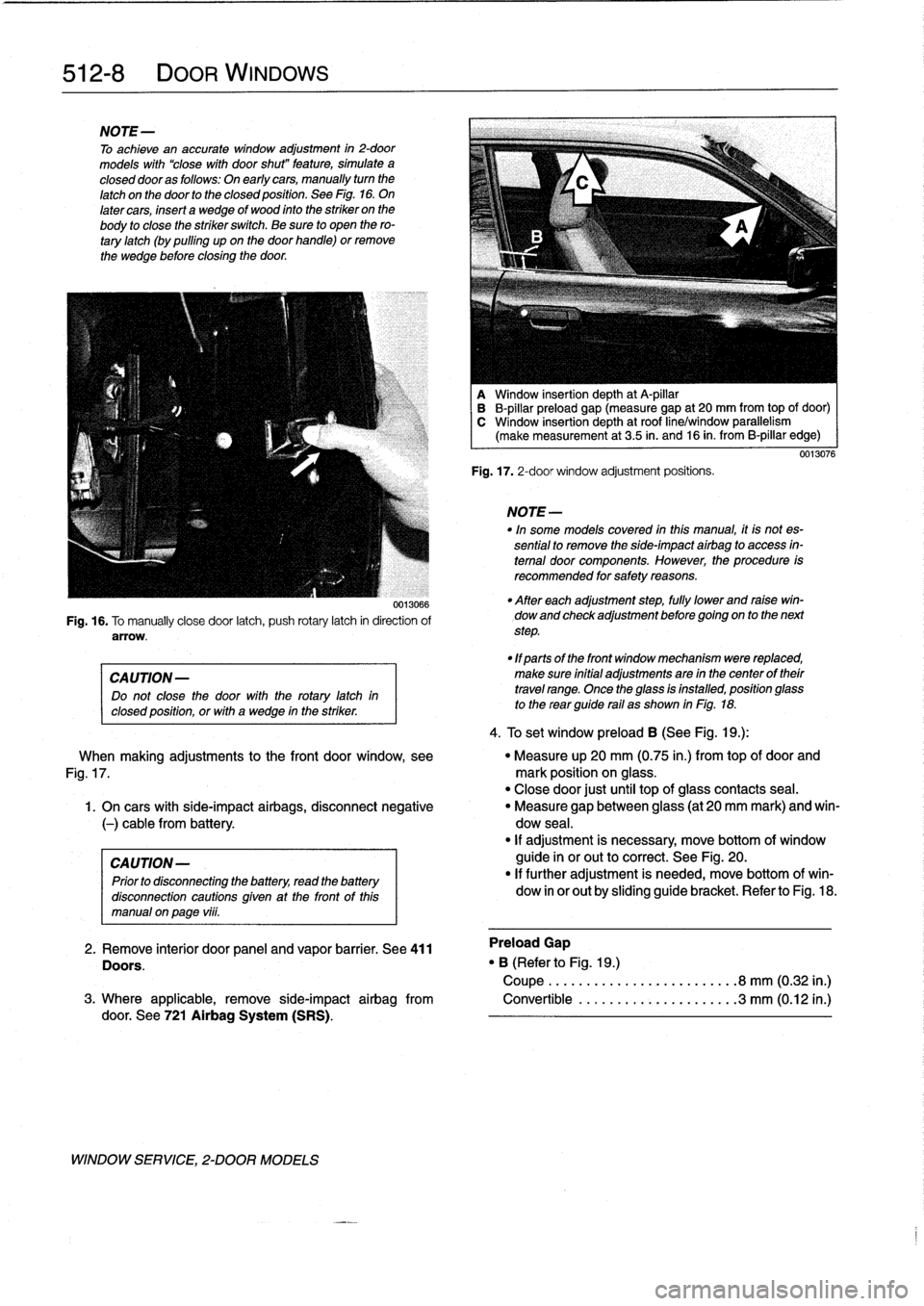

A

Window

insertion

depth

at

A-pillar

B

B-pillar

preload

gap

(measure

gap

at

20

mm

from

top

of

door)

C

Window

insertion

depth

at

roof

line/window

parallelism

(make

measurement

at

3

.5

in

.

and

16

in

.

from

B-pillar

edge)

Fig

.

17

.

2-door

window

adjustment

positions

.

NOTE-

In"

some

models

covered

inthis

manual,

it

is

not

es-

sential

to

remove

the

side-impact

airbag

to

access

in-

terna¡

door

components

.

However,

the

procedure

is

recommended

for

safety

reasons

.

"

After

each

adjustment

step,

fully

lower

and

raise

win-

dow

and

check

adjustment

before

goingon

to

the

next

step

.

"

1f

parts

of

the

front

window

mechanism

were

replaced,

make

sure

initial

adjustments

are

in

the

center

of

their

travel

range

.

Once

the

glass

isinstalled,

position

glass

to

the

rear

guide

rail

as

shown

in

Fig

.

18

.

4

.

To

set

window

preload

B

(See

Fig

.

1

g

.):

0013076

When

making

adjustments

to

the

front

door

window,

see

"

Measure

up

20

mm

(0

.75

in

.)

from

topof

door

and

Fig

.

17

.

mark

position

on

glass

.

"

Close

door

just

until

top

of

glass

contacts

seal

.

1

.

On

cars

with

side-impact

airbags,

disconnect

negative

"

Measure

gap

between

glass

(at

20

mm

mark)

and

win-

(-)

cable

from

battery

.

dow

seal

.

"

If

adjustment

is

necessary,

move

bottom

of

window

CAUTION-

guide

inor

out

to

correct

.

See

Fig

.

20

.

Prior

to

disconnecting

the

battery,

read

the

battery

"

If

further

adjustment

is

needed,

move

bottom

ofwin-

disconnection

cautionsgiven

at

the

front

of

this

dow

in

or

out

by

sliding

guide

bracket

.

Refer

to

Fig

.

18

.

manual

on

page

viii

.

2

.

Remove

interior

door

panel

and

vapor

barrier

.

See

411

Preload

Gap

Doors

.

"

B

(Referto

Fig

.

1

g

.)

Coupe

......................

.

.

.8

mm

(0

.32

in

.)

3

.

Where

applicable,

remove

side-impact

airbag

from

Convertible

..................

.

..

3

mm

(0

.12

in

.)

door

.

See

721

Airbag

System

(SRS)

.

Page 339 of 759

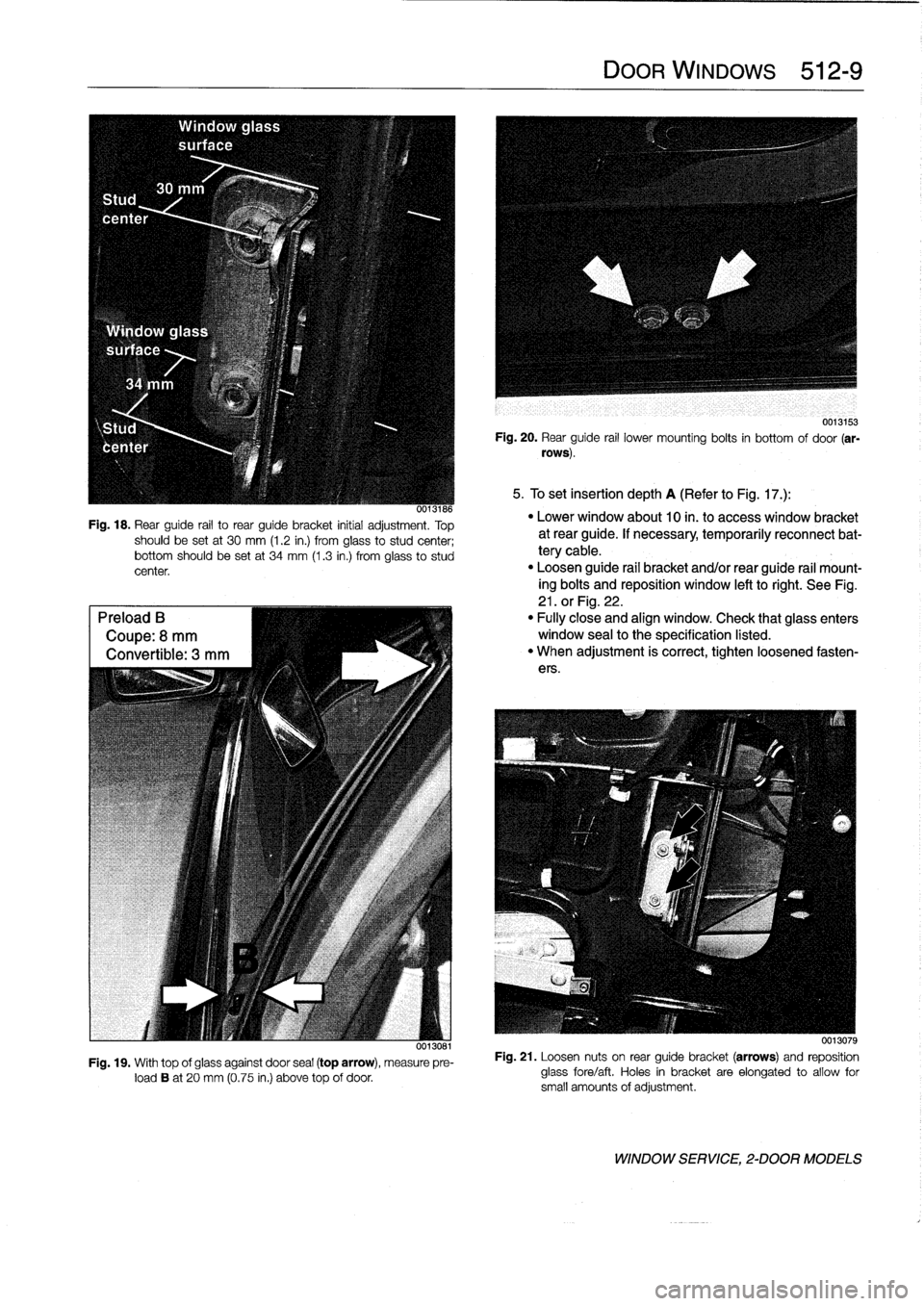

5tud

center

Window

glass

surface

Fig

.

18

.

Rear

guide

rail

to

rear

guide

bracket

initial

adjustment

.

Top

should

be

setat

30

mm

(1

.2

in

.)

from

glass

to

studcenter

;

bottom

should

be

set

at

34

mm

(1

.3

in

.)

from

glass

to

stud

center

.

Preload

B

Coupe

:

8

mm

Convertible

:

3

mm

0013081

Fig

.

19

.

With

top

of

glassagainst

door

sea¡(top

arrow),

measure

pre-load

B

at

20

mm

(0

.75

in

.)

above

top

of

door

.

DOOR

WINDOWS

512-

9

0013153

Fig

.

20

.

Rear

guide

rail

lower

mounting

bolts

in

bottom

of

door

(ar-

rows)

.

5

.

To

set

insertion

depth

A

(Referto

Fig

.

17

.)

:

"

Lowerwindow

about

10

in

.

t

o

access

window

bracket

at

rear

guide

.

If

necessary,

temporarily

reconnect

bat-

tery

cable

.

"

Loosen

guide

rail

bracket

and/or

rear

guide

rail

mount-

ing

bolts

and

reposition

window

left

to

right

.

See

Fig

.

21

.

orFig

.

22

.

"

Fully

close

and

align

window

.

Check

that

glass

enters

window

sea¡

to

the

specification

listed

.

"

When

adjustment

is

correct,

tighten

loosened

fasten-

ers

.

0013079

Fig

.

21

.

Loosen

nuts

on

rear

guide

bracket

(arrows)

and

reposition

glass

fore/aft

.

Holes

in

bracket

areelongated

to

allow

for

small

amounts

of

adjustment

.

WINDOW

SERVICE,

2-DOOR

MODELS

Page 340 of 759

512-

1

0

DOOR

WINDOWS

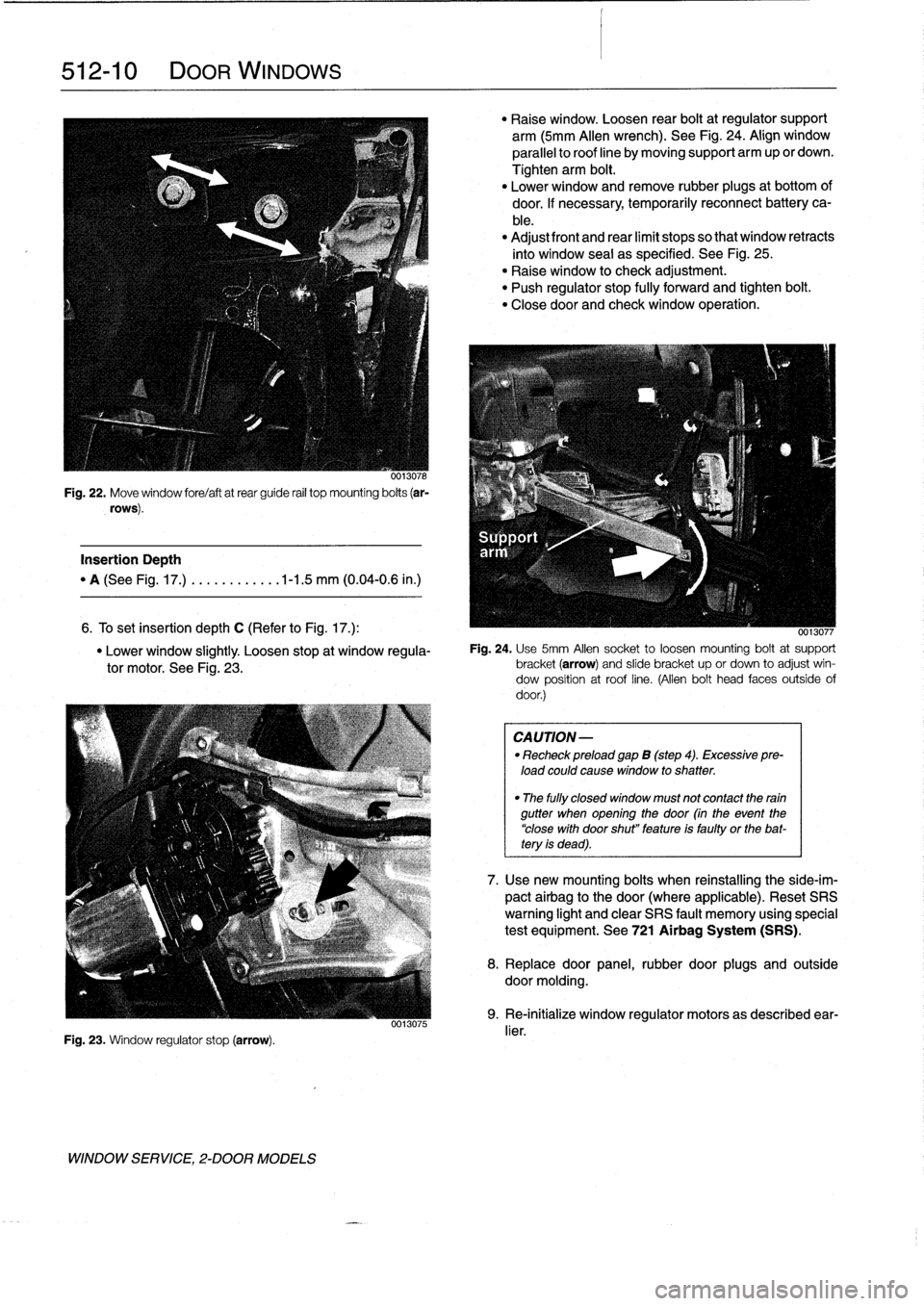

0013078

Fig

.

22

.

Move

window

fore/aftatrear

guide

rail

top

mounting

bolts

(ar-

rows)

.

Insertion

Depth

"

A

(See

Fig

.

17

.)

.

..........

.1-1

.5

mm

(0

.04-0

.6

in

.)

6

.

To

set

Insertion

depth

C

(Refer

to

Fig

.

17

.)

:

"

Lower

window

slightly

.

Loosen

stop

at

window

regula-

tor

motor

.

See

Fig

.

23

.

Fig

.

23

.

Window

regulator

stop

(arrow)

.

WINDOW

SERVICE,

2-DOOR

MODELS

0013075

"

Raise

window

.

Loosen

rear

boltat

regulator

support

arm

(5mm

Allen

wrench)

.

See

Fig

.

24

.

Align

window

parallelto

roof

line

by

moving

support

arm

up

or

clown

.

Tighten

arm

bolt

.

"

Lower

window

and

remove

rubber

plugs

at

bottom

of

door

.

If

necessary,temporarily

reconnect

battery

ca-

ble

.

"

Adjust

front

and

rear

limit

stops

so

that

window

retracts

into

window

seal

as

specified

.

See

Fig

.

25

.

"

Raise

window

to

check

adjustment

.

"

Push

regulator

stop

fully

forward

and

tighten

bolt

.

"

Closedoor

and

check

window

operation

.

0013077

Fig

.

24

.

Use

5mm

Afen

socket

to

loosen

mounting

boltat

support

bracket(arrow)

and

slide

bracket

up

or

clown

to

adjust

win-

dow

position

at

roof

line

.

(Allen

bolt

head

faces

outside

of

door

.)

CAUTION

-

"

Recheck

preload

gap

B

(step

4)

.

Excessive

pre-

load

could

cause

window

to

shatter

.

"

The

fully

closed

window

must

not

contact

the

rain

gutter

when

opening

the

door

(in

the

event

the

"close

with

door

shut"

feature

is

faulty

or

the

bat-tery

is

dead)

.

7

.

Usenew

mounting

bolts

when

reinstalling

the

side-im-

pact

airbag

to

the

door

(where

applicable)

.

Reset

SRS

warning

light

and

clear

SRS

fault

memory

using

special

test

equipment

.

See

721

Airbag

System

(SRS)

.

8

.

Replace

door

panel,

rubber

door

plugs

and

outside

doormolding

.

9

.

Re-initialize

window

regulator

motors

as

described

ear-

lier

.

Page 349 of 759

515

Central

Locking

and

Anti-Theft

GENERAL

.....

.

.

.

.

.

.

.

..:

.

.

.

......

.

.

.

.

515-1

Luggage

compartment

locking

actuator,

removing

and

installing

.

.

.

.

.

...........

.

515-6

DOOR

HANDLES

AND

LOCKS

.........

515-1

LOCKING

SYSTEM

AND

Front

door

lock,

removing

and

installing

....

.515-1

ELECTRONIC

IMMOBILIZATION

......

.515-7

Front

door

handle,

removing

and

installing

...

515-3

Rear

door

lock,

removing

and

installing

.....

515-4

Central

Locking

System(ZVM)

.

.

.

.

.......

.

515-7

Rear

door

handle,

removing

and

installing

...

515-5

Central

Body

Electronics

(ZKE

IV)

.

.

.......

.515-8

Electronic

Immobilization

System

(EWS)

.

.

.

.

.515-8

Door

striker,

rep

lacing

.

.

.

.

.

.

.

.

.

..........

515-6

EWS

II

control

module,

re

lacin

515-10

LOCKING

ACTUATORS

.

.

.

.

.

.

..........

515-6

Ring

antenna,

replacing

.

.

.

.

.

.

.

.

.

.

...

.

.

.

.

515-10

Door

Locking

Actuator

.

.

.

.

.

.

.

.

..........

515-6

EWS

II

transmitter/receiver

module,

replacing

...........

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

515-11

GENERAL

This

section

covers

repair

information

for

the

central

locking

and

the

anti-theft

systems

.

Keep

in

mind

that

E36

cars

are

CA

UTION-

equipped

with

sophisticated

and

self-diagnostic

electrical

sys-

Prior

to

disconnecting

the

battery,

read

the

battery

tems

.

When

experiencing

malfunctions

relatinglo

the

central

disconnection

cautions

given

at

the

front

of

this

locking

or

the

anti-theft

system,

it

is

recommended

that

the

manual

onpage

vi¡¡

.

systembe

diagnosed

using

the

BMW

service

tester

(DIS)

.

This

advanced

diagnostic

tool

can

usually

pinpoint

electrical

NOTE-

faults

quickly

and

safely

.

Consult

an

authorized

BMW

dealer

.

In

some

models

covered

inthis

manual,

it

is

not

essen-

tial

to

remove

the

side-impact

airbag

to

access

intemal

NOTE-

door

components

.

However,

the

procedure

is

recom-

Additional

general

electrical

information

can

be

found

mended

for

safely

reasons

.

i

n

610

Electrical

Component

Locations

and

Electri-

cal

Wiring

Diagrams

.

4

.

Disconnect

harnessconnector

from

window

motor

to

DOOR

HANDLES

AND

LOCKS

Front

door

lock,

removing

and

installing

1

.

Remove

front

door

panel

and

vapor

barrier

asde-

scribed

in

411

Doors

.

WARNING

-

Some

1997

and

all

1998

cars

are

fitted

with

side-im-

pact

airbags

in

the

front

doors

.

When

servicing

the

door

locks

on

cars

with

front

side-impact

airbags,

al-

ways

disconnect

the

negative

(-)

battery

terminal

.

See721

Airbag

System

(SRS)

forcautions

andpro-

cedures

relating

to

the

airbag

system

.

2

.

Raise

door

window

completely

CENTRAL

LOCKING

AND

ANTI-THEFT

515-1

3

.

On

cars

with

side-impact

airbags,

disconnect

negative

(-)

cable

from

battery,

then

remove

airbag

module

.

prevent

accidental

operation

.

5

.

On

4-door

cars

:

Peel

back

rubber

window

guide

from

reas

guide

rail

:

Remove

guide

rail

mounting

boltat

bot-

tom

.

Unclip

any

wiring

from

guide

rail

and

pull

guide

rail

downward

and

remove

from

door

.

See

Fig

.

1

.

NOTE

-

The

top

of

the

guide

rail

is

"hooked"

to

the

doorsheet

metal

.

6

.

Remove

inside

door

handle

retaining

screw

.

Discon-

nect

inside

handle

from

linkage

and

remove

.

See

Fig

.

2

.

7

.

Cut

wire

ties

and

remove

door

lock

electrical

harness

con-

nector

.

Remove

door

lock

mounting

screws

.

See

Fig

.

3

.

8

.

Working

inside

door,

disconnect

outside

door

handle

and

lockcylinder

linkage

from

door

lock

.

Remove

lock

from

inside

door

.

See

Fig

.

4

.

DOOR

HANDLES

AND

LOCKS

Page 351 of 759

![BMW M3 1998 E36 Owners Guide

Front

door

handle,

removing

and

installing

1

.

Closedoor

window

completely

.

2

.

Remove

front

door

panel

and

vapor

barrier

asde-

scribed

in

411

Doors

.

WARNING

-

Some

1997

and

al]

1998

cars

are

f BMW M3 1998 E36 Owners Guide

Front

door

handle,

removing

and

installing

1

.

Closedoor

window

completely

.

2

.

Remove

front

door

panel

and

vapor

barrier

asde-

scribed

in

411

Doors

.

WARNING

-

Some

1997

and

al]

1998

cars

are

f](/img/1/2800/w960_2800-350.png)

Front

door

handle,

removing

and

installing

1

.

Closedoor

window

completely

.

2

.

Remove

front

door

panel

and

vapor

barrier

asde-

scribed

in

411

Doors

.

WARNING

-

Some

1997

and

al]

1998

cars

are

fitted

with

side-im-

pact

airbags

in

the

front

doors

.

When

servicing

the

door

handles

on

cars

with

front

side-impact

airbags,

always

disconnect

the

negative

(-)

battery

terminal

.

See

721

Airbag

System

(SRS)

for

cautions

and

pro-

cedures

relatíng

to

the

airbag

system

.

3

.

On

carswíth

side-impact

airbags,

disconnect

negative

(-)

cable

from

battery,

then

remove

airbag

module

.

CAUTION-

Prior

to

disconnecting

the

battery,

read

the

battery

disconnection

cautions

given

at

the

front

of

thís

manual

onpage

vi¡¡

.

NOTE-

In

some

models

covered

inthis

manual,

it

is

not

essen-

tial

to

remove

the

side-impact

airbag

to

access

internal

door

components

.

However,

the

procedure

is

recom-

mended

for

safety

reasons

.

4

.

Remove

door

lock

as

described

earlier

.

5

.

Remove

window

as

described

in

512

Door

Windows

.

CA

UTION-

On

models

with

side-impact

airbags,

removinglin-

stalling

the

front

window

requires

that

the

battery

cable

bereconnected

wíth

the

side-impact

airbag

disconnected

.

This

will

seta

fault

code

in

the

SRS

control

module,

turn

on

the

SRS

warning

light,

and

disable

the

SRS

system

until

the

fault

memo-

ry

is

cleared

usíng

special

SRS

test

equipment

.

6

.

Pry

out

access

plug

in

end

of

door

.

Use

screwdriver

through

access

hole

to

slide

exteriortrim

locking

plate

into

released

position

.

See

Fig

.

5

.

Remove

doorhandle

exterior

trim

piece

.

7

.

Working

inside

door,

remove

locking

clip

for

doorhan-

dle

retaining

pin

and

push

pin

out

.

8

.

Working

inside

door,

disconnect

electrical

harness

con-

nector

at

door

handle

.

Twist

plastic

connector

bracket

to

remove

from

door

handle

.

CENTRAL

LOCKING

AND

ANTI-THEFT

515-

3

0011681

Fig

.

5

.

Insert

screwdriver

into

access

hole

and

push

lockingplate

forward

(arrow)

to

release

exterior

handle

trim

.

uu11682

Fig

.

6

.

Door

handle

retaining

pin(A)

and

lock

collar

nut

(B)

.

Door

handle

trim

shown

removed

.

10

.

Remove

door

handle

fromdoor

by

angling

out

of

door

cavity

.

Removed

door

handle

assembly

is

shown

in

Fig

.

7

.

0012684

Fig

.

7

.

Door

handle

harnessconnector

(A)

;

retaining

pin

Iocking

clip

9

.

Working

at

door

exterior,

remove

handle

collar

nut

(B)

;

exterior

trim

Iocking

plate

(C)

.

Handleassembly

shown

re-

while

supporting

handle

.

See

Fig

.

6

.

moved

from

door

.

DOOR

HANDLES

AND

LOCKS

Page 356 of 759

515-8

CENTRAL

LOCKING

AND

ANTI-THEFT

Central

Body

Electronics

(ZKE

IV)

Electronic

Immobilization

System

(EWS)

Beginning

withvehicles

produced

9193

(model

year

1994),

The

electronic

anti-theft

system

known

as

EWS

was

first

in-

the

centrallocking

system

was

integrated

with

sunroof

and

troduced

in

January

1994

.

The

early

version

of

the

system

window

closure

into

the

Central

Body

Electronics

(ZKE

IV)

uses

a

starting

inhibition

module

to

interrupt

the

ignition,

the

(generation

four)

system

.

The

control

module

for

this

system

fuel

injection

and

the

starter

motor

.

This

system

is

activated

ís

mounted

in

front

of

the

glove

compartment

.

and

deactivated

by

the

centrallockíng

system

.

The

control

module

for

the

system

is

installed

under

the

left

side

of

the

Inthis

system

two

microswítches

are

operated

viathe

door

dashboard

.

lock

cylinder

at

both

front

doors

.

Turning

the

key

approximate-

ly

45°

(position

1)

operates

the

door

locking

microswitch

and

Startingwith

modeis

built

since

January

1995,

E36

cars

activates

the

alarm

system

.

Holding

the

key

in

thatposition

come

equipped

with

a

sophisticated

coded

electronic

immobi

also

closes

any

open

windows

and

the

sunroof

.

lization

system

called

EWS

II

.

Foraschematic

of

the

system,

refer

to

Fig

.

21

.

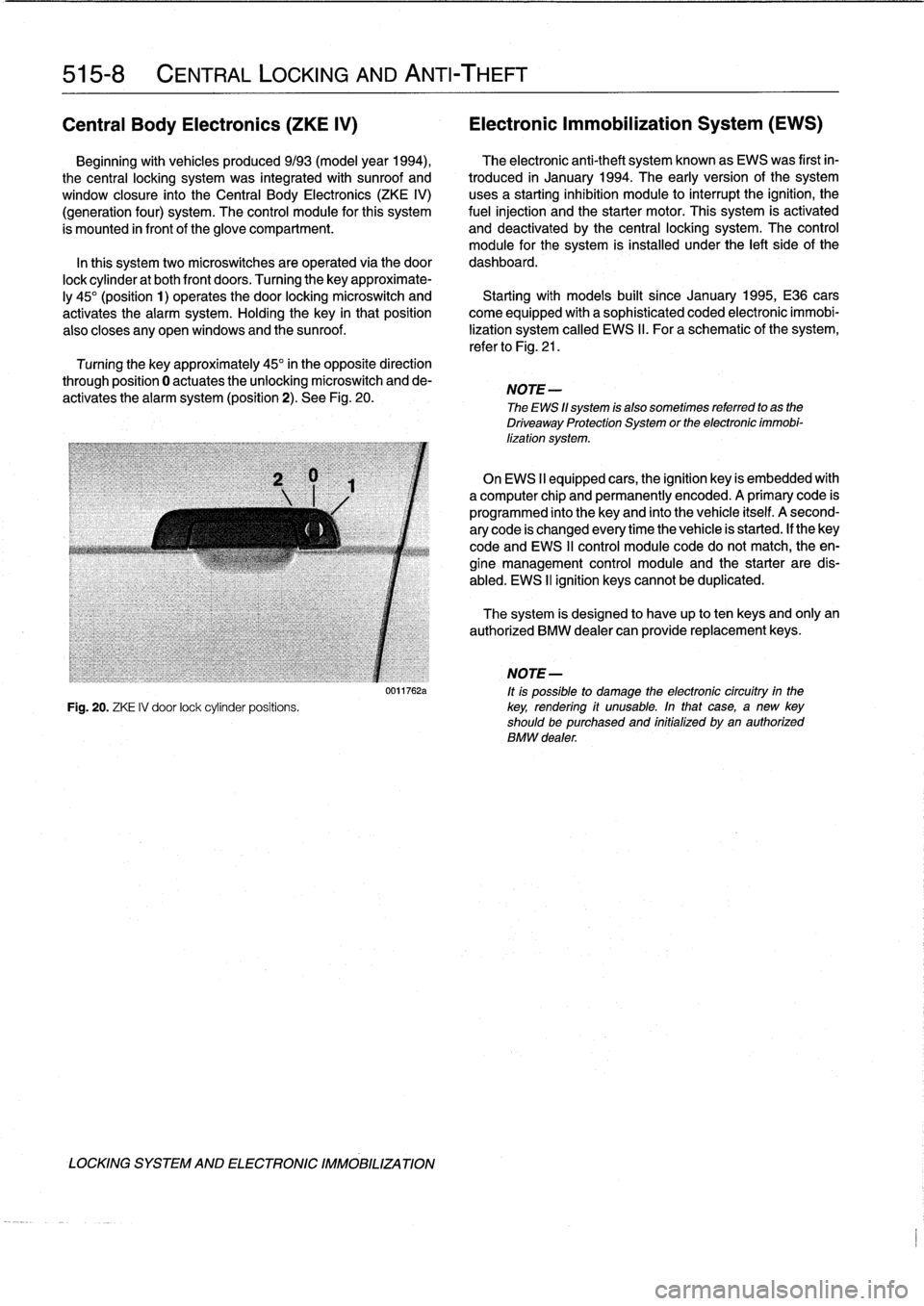

Turning

the

key

approximately

45°

in

the

opposite

direction

through

position

0

actuates

theunlocking

microswitch

and

de-

activates

the

alarm

system

(position

2)

.

See

Fig

.

20

.

NOTE

-

The

EWS

11

system

is

also

sometimes

referred

to

as

the

Driveaway

Protection

System

or

the

electronic

immobi-

lization

system

.

On

EWS

II

equipped

cars,

the

ignition

key

is

embedded

with

a

computer

chip

and

permanently

encoded

.

A

primary

code

is

programmed

into

the

keyand

finto

the

vehicle

itself

.

A

second-

ary

code

is

changed

every

time

the

vehicle

is

started

.

If

thekey

code

and

EWS

II

control

module

code

do

notmatch,

the

en-

gine

management

control

module

and

the

starter

are

dis-

abled

.

EWS

II

ignition

keyscannot

be

duplicated

.

The

system

is

designed

to

have

up

to

ten

keys

and

only

an

authorized

BMW

dealer

can

provide

replacement

keys

.

j

NOTE-

0011762a

ft

is

possible

to

damage

the

electronic

circuítry

in

the

Fig

.

20

.

ZKE

IV

door

lock

cylinder

positions

.

key,

rendering

if

unusable

.

In

that

case,

a

new

key

shouldbe

purchased

and

initialized

byan

authorized

BMW

dealer

.

LOCKING

SYSTEM

AND

ELECTRONIC

IMM081LIZATION

Page 383 of 759

NOTE

-

Sometimes

the

color

of

en

installed

wire

may

be

differ-

ent

than

the

one

on

the

wiring

diagram

.

Don't

be

con-

cerned

.

Just

be

sure

lo

confirm

that

the

wire

connects

lo

the

proper

terminals

.

Wire

color

codes

"

BLU

.........

.

..

..

...

.

.................

Blue

"

BRN

....:....

.

..

..

...

..

...............

Brown

"

YEL

.........

.

..

..

...................

.Yellow

"

GRN

.........

.

..

..

...

.

................

creen

"

G

RY

.......

.

.

.

..

..

.....................

G

ray

"

ORG

.........

.

..

..

...

.

..............

.Orange

"

RED

......

...

.

.

..

.....................

.Red

"

BLK

.........

.

..

..

...

.

................

Black

"

VIO

..........

.

..

...

..

..

.......

.

.......

Violet

"

WHT

.........

.

.

....

.

...

:..............

White

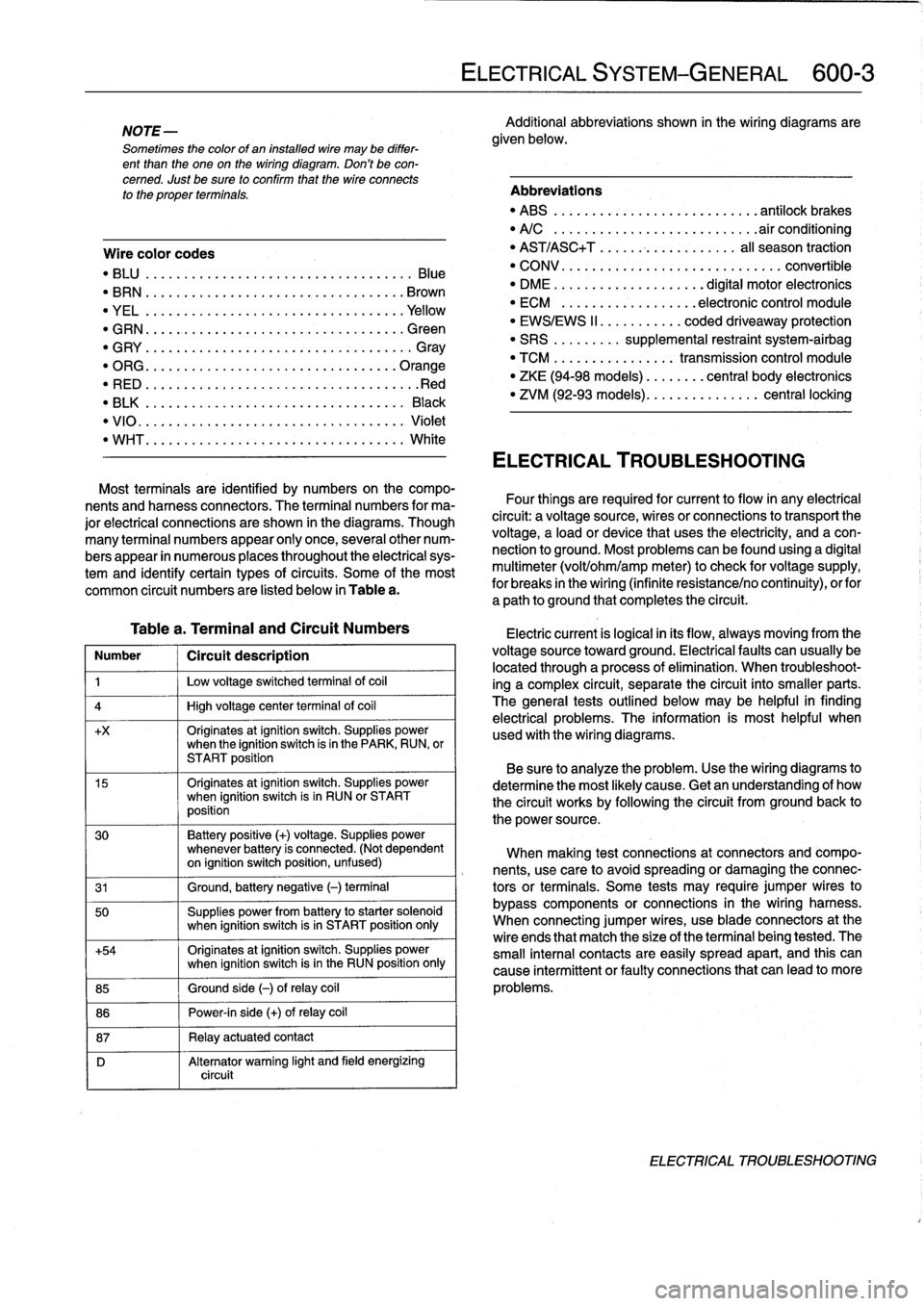

Table

a

.

Terminal

and

Circuit

Numbers

Number

1

Circuít

description

1

j

Low

voltage

switched

terminal

of

coi¡

4

1

High

voltage

center

termina¡

of

coi¡

+x

Originates

atignition

switch

.

Supplies

powerwhen

the

ignition

switch

is

in

the

PARK,

RUN,

or

START

position

15

Originates

atignition

switch

.

Supplies

powerwhen

ignition

switch

is

in

RUN

or

START

position

30

Battery

positive

(+)

voltage

.

Supplies

power

whenever

battery

is

connected

.

(Not

dependent

on

ignition

switch

position,

unfused)

31

1

Ground,

battery

negative

(-)

terminal

50

Supplies

power

from

battery

to

starter

solenoid

when

ignition

switch

isin

START

position

only

+54

Originates

atignition

switch

.

Supplies

power

when

ignition

switch

isin

the

RUN

position

only

85

1

Ground

side

(-)

ofrelay

coil

86

1

Power-in

side

(+)

ofrelay

coil

87

1

Relay

actuatedcontact

D

Alternator

warning

light

and

field

energizing

circuit

ELECTRICAL

SYSTEM-GENERAL

600-

3

Additional

abbreviations

shown

in

the

wiring

diagrams

are

given

below

.

Abbreviations

"

ABS

........

.

...

.

...

.

..........

antilock

brakes

"

A/C

........

.

...

..

..

.

.........

.airconditioning

"

AST/ASC+T

.......

...

.

.

.......

al¡

season

traction

"

CONV

.......

.

.

...

.................

convertible

"

DME

........

.

.

...

.......

digital

motor

electronics

"

ECM

.......

.

...

..

..

.

..

electronic

control

module

"

EWS/EWS

II

......

...

.

.

coded

driveaway

protection

"

SRS

........

.

supplemental

restraint

system-airbag

"

TCM

........

.

..

....

.

transmission

control

module

"

ZKE

(94-98

models)

..

..

.

...

central

body

electronics

"

ZVM

(92-93

models)

...

.

.

..

.

.......

central

locking

ELECTRICAL

TROUBLESHOOTING

Most

terminals

are

identified

by

numbers

on

the

compo-

nents

and

harness

connectors

.

The

terminal

numbers

for

ma-

Four

things

are

required

for

current

toflow

in

any

electrical

jor

electrical

connections

are

shown

in

the

diagrams

.

Though

circuit

:

a

voltagesource,

wires

or

connections

to

transport

the

many

terminal

numbers

appear

only

once,

severa¡other

num-

voltage,

a

load

or

device

that

uses

the

electricity,

and

a

con-

bers

appear

in

numerous

places

throughout

the

electrical

sys-

nection

to

ground

.

Most

problemscanbefound

using

a

digital

tem

and

identify

certain

types

ofcircuits

.

Some

of

the

most

multimeter

(volt/ohm/amp

meter)to

check

for

voltage

supply,

common

circuit

numbers

are

listed

below

in

Table

a

.

for

breaks

in

the

wiring

(infinite

resistance/no

continuity),

orfor

a

path

to

ground

that

completesthe

circuit

.

Electric

current

is

logical

in

its

flow,

always

moving

from

the

voltage

sourcetoward

ground

.

Electricalfaults

can

usually

be

located

through

a

process

of

elimination

.

When

troubleshoot-

ing

a

complex

circuit,

separate

the

circuit

into

smaller

parts

.

The

general

testsoutlined

below

may

be

helpful

in

finding

electrical

problems

.

The

information

is

most

helpful

when

used

with

the

wiring

diagrams

.

Be

sure

to

analyze

the

problem

.

Use

the

wiring

diagrams

to

determine

the

most

likely

cause

.

Getan

understanding

of

how

the

circuit

works

by

following

the

circuit

from

groundback

to

the

power

source

.

When

making

test

connections

at

connectors

andcompo-

nents,

use

care

to

avoidspreading

or

damaging

the

connec-

tors

or

terminals

.

Some

tests

may

require

jumper

wires

to

bypass

components

or

connections

in

the

wiring

harness

.

When

connecting

jumper

wires,

use

bladeconnectors

at

the

wire

ends

that

match

the

size

of

the

terminal

being

tested

.

The

small

interna¡

contacts

are

easily

spread

apart,

and

this

can

cause

intermittent

or

faultyconnections

that

can

leadto

more

problems

.

ELECTRICAL

TROUBLESHOOTING

Page 387 of 759

610

Electrical

Component

Locations

GENERAL

...........

.

.

.

.

.

.

.

.

.

........

610-1

FOSE

POSITION

TABLES

..

.

.

.

.

.

.....

.

610-19

FUSE

AND

RELAY

POSITIONS

.

...

.

.

.

.

.

610-1

Fuse

Positions

.

.

.

................

.

.

.

.

.

610-1

Relay

Positions

.

.

.

.....

.

.

.

........

.

.

.

.

.

610-2

Auxiliary

RelayPanel

.....

.

...

.

........

.

610-2

SplicePanel,

Left

.

.

.

...

.

.

.

...

.

........

.

610-2

SplicePanel,

Right

.

.

.

.

.

.

.

.

...

.

.........

610-3

COMPONENT

LOCATIONS

.

.

.

.

.......

.

.610-3

Component

Location

Table

.

.

.

.

.

.

.........

610-9

GENERAL

FUSE

AND

RELAY

POSITIONS

This

repair

group

covers

f

use,

relay,

and

control

module

lo-

The

front

power

distribution

box,

an

auxiliary

relay

panel,cation

information

.

Electrical

equipment

and

accessories

in-

and

two

auxiliary

splice

panels

contain

most

of

the

fuses

and

stalled

varies

depending

on

model

and

model

year

.

Always

relays

in

E36

vehicles

.

Refer

to

the

component

location

later

confirm

that

the

proper

electrical

component

has

been

identi-

in

this

section,

as

well

as

the

tables

at

the

end

of

this

repair

fied

by

using

the

electrical

wiring

diagrams

.

group

for

electrical

component

location

.

WARNING

-

On

cars

equipped

with

airbags,

special

precautionsapply

to

any

electrical

system

testing

orrepair

.

Air-

bag

units

areexplosive

devices

and

mustbe

han-

dled

with

extremecare

.

Before

starting

any

work

onan

airbag

equipped

car,

refer

to

the

wamings

and

cautions

in

721

Airbag

System

(SRS)

.

CAUTION

-

"

Prior

to

disconnectiog

the

battery,

read

the

bat-

tery

disconnection

cautions

given

at

the

front

of

this

manual

on

page

viii

.

"

Relay

and

fuse

positions

are

subject

to

changeand

may

varyfrom

car

to

car

.

If

questions

arise,

an

authorized

BMW

dealer

is

the

best

source

for

the

most

accurate

and

up-to-date

information

.

"

A

good

way

to

verify

a

relay

position

isto

com-

pare

the

wiring

colors

at

the

relay

socket

to

thecolors

indicated

on

the

wiring

diagrams

located

at

the

rear

of

this

manual

.

"

Always

switchthe

ignition

off

and

disconnect

the

negative

(-)

battery

cable

before

removing

any

electrical

components

.

"

Connect

and

disconnect

ignition

system

wires,

multiple

connectors,

and

ignition

test

equipment

leads

only

while

the

ignition

is

switched

off

.

"

Only

usea

digital

multimeter

for

electrical

tests

.

ELECTRICAL

COMPONENT

LOCATIONS

610-1

TABLES

a

.

E36Component

Locations

...........

.

.

..

...

610-10b

.

1992

E36

Fuse

Positions

..........

..

.

.

.....

610-20c

.

1993

E36

Fuse

Positions

..........

..

..

.

....

610-22d

.

1994

E36

Fuse

Positions

.........

...

.......

610-24e

.

1995

E36

Fuse

Positions

.........

...

.......

610-26

f

.

1996

E36

Fuse

Positions

.........

...

.......

610-28g

.

1997-1998

E36

Fuse

Positions

..

.

..

...

.......

610-30

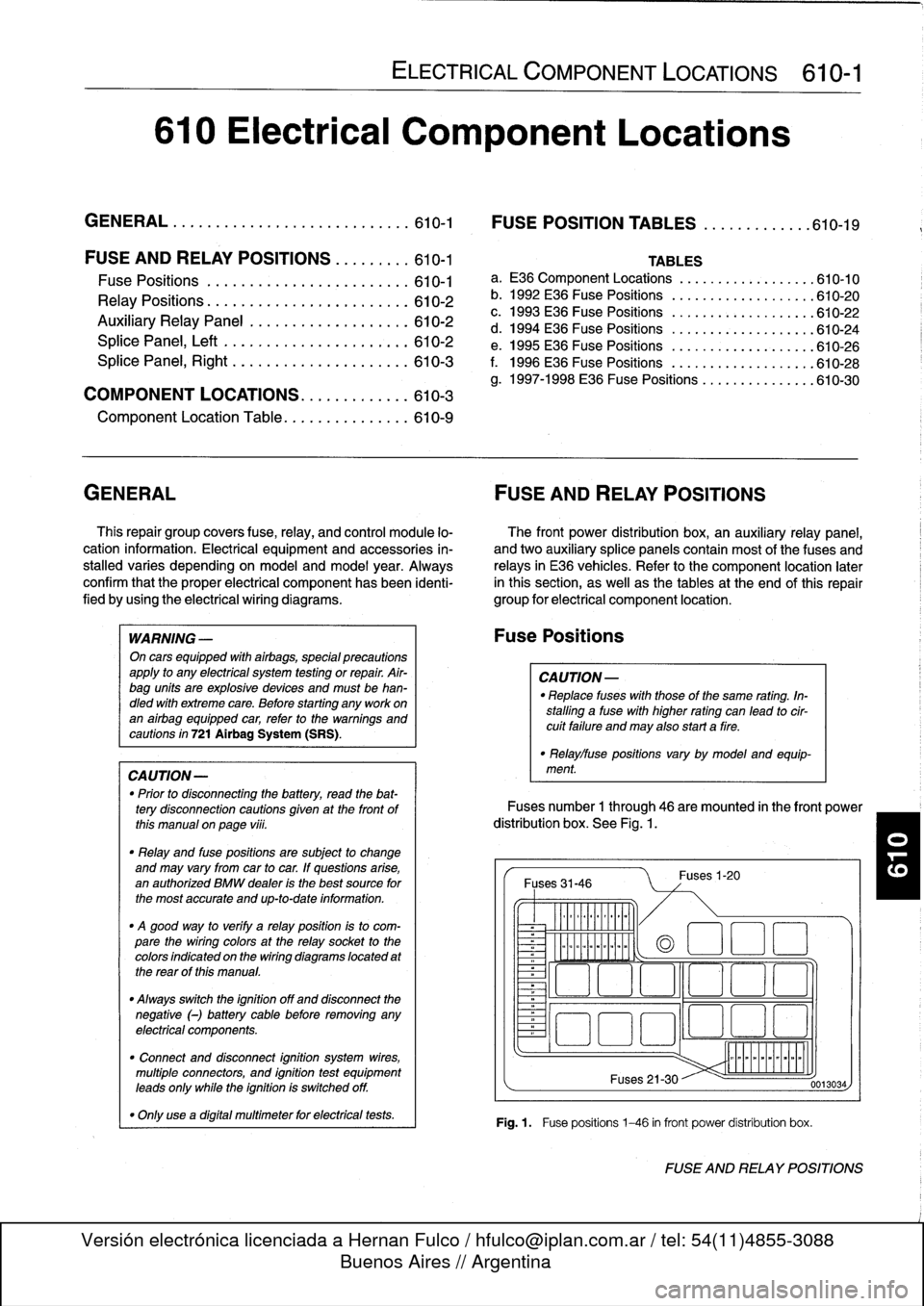

Fuse

Positions

CAUTION

-

"

Replace

fuses

with

those

of

the

same

rating

.

In-

stalling

a

fuse

with

higher

rating

can

lead

to

cir-

cuit

failure

and

may

also

start

a

fire

.

"

Relay/fuse

positions

vary

by

model

and

equip-

ment

.

Fuses

number

1

through

46

are

mounted

in

the

front

power

distribution

box

.

See

Fig

.

1.

Fuses

31-46

~

Illlllllllll

°

-

Ilmmlmomlmoi

Fuses

1-20

(a

1

:1

E

El

~

~O!7

L~~n

4~

i

Fuses

21-30

Fig

.1.

Fuse

positions

1-46

in

front

power

distribution

box

.

0013034

FUSE

AND

RELAY

POSITIONS