automatic BMW M3 1998 E36 Manual PDF

[x] Cancel search | Manufacturer: BMW, Model Year: 1998, Model line: M3, Model: BMW M3 1998 E36Pages: 759

Page 447 of 759

GENERAL

E36

cars

are

equipped

with

integrated

automatic

heating

and

air

conditioning

systems

.

Many

of

the

procedures

given

in

this

repair

group

require

that

the

A/C

refrigerant

charge

be

evacuated

using

specialized

equipment

.

See

A/C

System

Warningsand

Cautions

later

in

this

repair

group

.

HEATER

AND

CONTROLS

Blower

motor,

removing

and

installing

NOTE-

On

6-cylinder

cars,

the

plastic

top

enginecover

and

fuel

rail

covermustbe

removed

.

The

fuel

injectorhamess

re-

taining

screws

must

be

removed

and

the

harness

set

aside

.

The

engine

control

module

(ECM)

cover

must

be

removed,

the

control

unit

connectors

unplugged

and

the

harness

pulled

out

of

the

way

.

See

130

Fuel

Injection

.

1

.

Disconnect

negative

(-)

cable

from

battery

.

2

.

Open

hood

.

Unclip

engine

bulkhead

plenum

grille

at

base

of

windshíeld

and

remove

grille

.

See

Fig

.

1

.

HEATING

AND

AIR

CONDITIONING

640-1

640

Heating

and

Air

Conditioning

GENERAL

.

...

.

....

.

.

.

.

.

.

.

.

.

.......

.

.

.

640-1

Heater

andA/C

air

distribution

motor,

replacing(rotary-knob)

.

.

...

.

.

.

.......

.

640-10

HEATER

AND

CONTROLS

.

.....

.

.

.

.

.

.

.640-1

Rear

Window

Defogger

.

.

.

.

.

.

.

.

.

.

...

.

.

.

640-10

Blower

motor,

removing

and

installing

.

.

.

.

.

.

640-1

Rear

Window

Blower

(convertible

models)

.

.640-10

Blowermotor

resistor

pack,

replacing

.

.

.

.

.

.

640-3

AIR

CONDITIONING

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

640-11

Heater

valve,

replacing

...........

.

.

.

.

.

.

.

640-3

Heater

box,

removing

and

installing

.

.

.

.

.

.

.

.

640-4

A/CSystem

Warnings

and

Cautions

.

.

.

.

.

.

:640-11

Heater

core,

replacing

.....

.

.

:

....

.

.

.

.

.

.

.

640-6

A/C

compressor,

replacing

.

.

::.

:

:

.

.

.

.

.

.

.

.640-12

Heater

core

temperature

sensor,

replacing

.

.

640-7

A/C

Compressor

Clutch

.

.

.

.

.

.

.

:

.

.

.

.

.

.

.

.

.

640-13

Heater

andA/C

Control

Head

.

.

....

.

.....

.

640-7

A/C

condenser,

replacing

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

640-14

Heater

andA/C

control

head,

removing

A/C

receiver/drier,

replacing

.

.

.

.

.

.

.

.

.

.

.

.

.

640-15

and

installing

(rotary-knob)

.

.

....

.

......

640-7

A/C

expansion

valve,

Heater

andA/C

control

head,

removing

removing

and

installing

...

.

.....

.

.

.

.

.

.

.

640-16

and

installing

(digital-display)

.

.....

.

.....

640-8

A/C

evaporator,

removing

and

installing

.

.

..

640-17

Heater

andA/C

control

module,removing

A/C

evaporator

temperature

sensor,

and

installing

(rotary-knob)

.

.

...

.

.

.

.

.

.

.

.

640-8

replacing

.

.

.

.

.

.

..............

.

.

.

.

.

..

640-17

Heater

andA/C

control

module,removing

A/C

microfilter,

replacing

......

.

....

.

.

.

..

640-18

and

installing

(digital-display)

.

...

.

.

.

.

.

...

640-8

Sensor

fan

for

interior

temperature,

TABLES

replacing

.

.

.

....

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

640-9

a

.

Blower

Motor

Test

Values

.........

...

.

.

......

640-3

Heater

andA/C

AirDistribution

Motors

.

.

.

.

.

.

640-9

b

.

Heater

Core

Temperature

Sensor

Test

Values

...

.640-7

c

.

Evaporative

Temperature

Sensor

Test

Values

...

640-17

d

.

A/C

System

Fluid

Capacities

(total)

..

..........

640-18

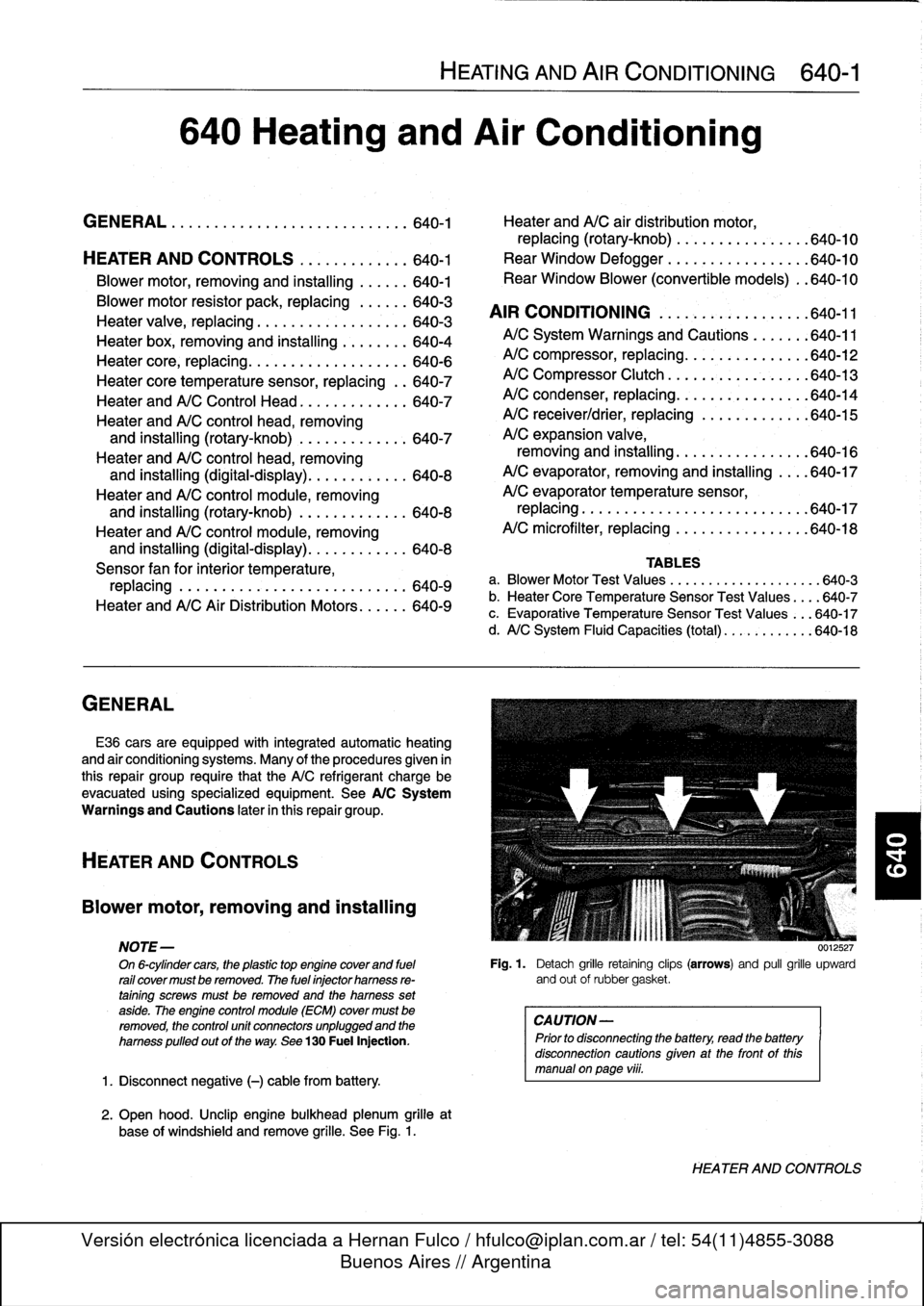

0012527

Fig

.

1

.

Detach

grille

retaining

clips

(arrows)

and

pull

grille

upward

and

out

of

rubbergasket

.

CAUTION-

Prior

to

disconnectiog

the

battery,

read

the

battery

disconnection

cautionsgiven

at

the

front

of

this

manual

onpage

viii

.

HEATER

AND

CONTROLS

Page 453 of 759

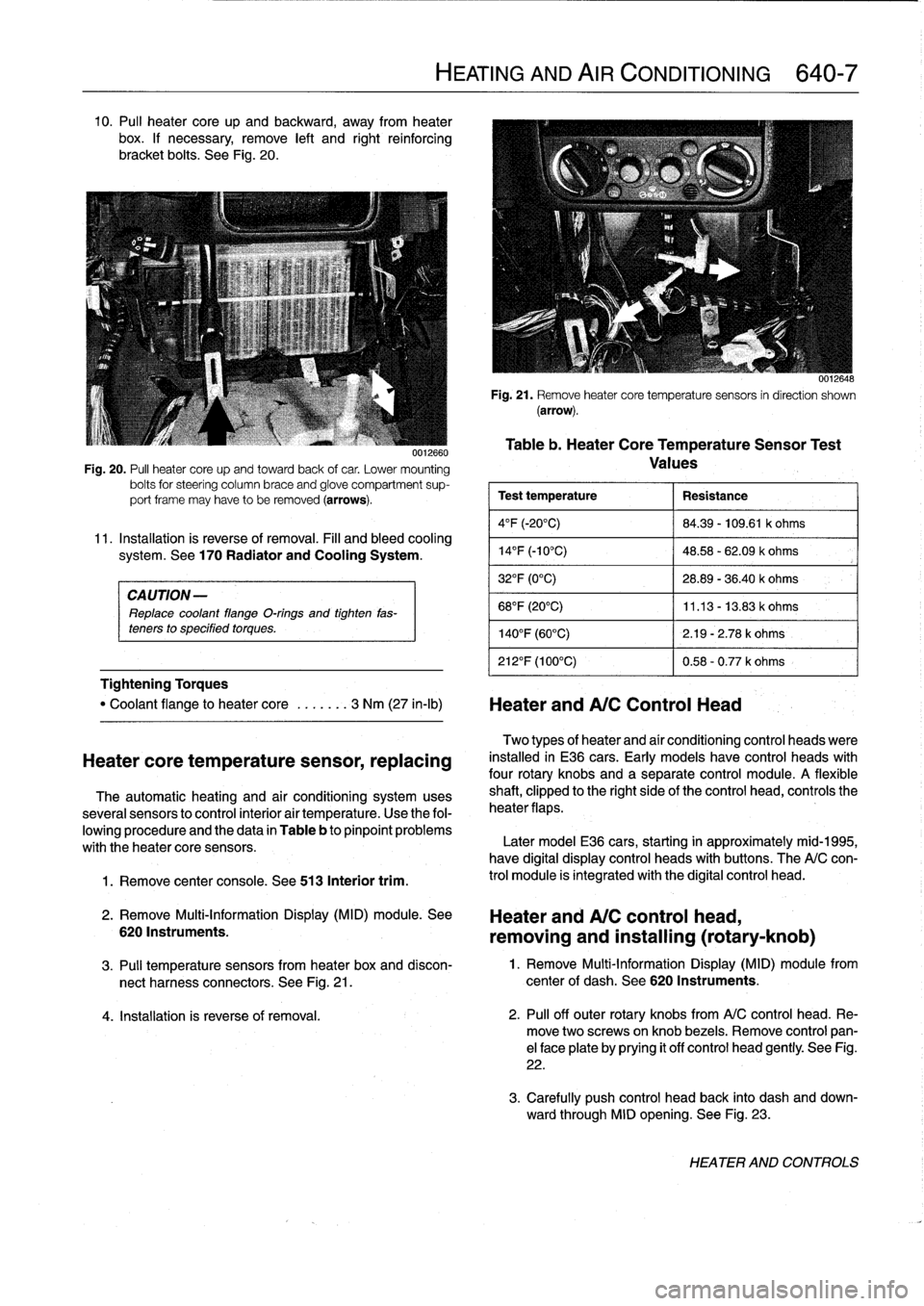

10

.

Pul¡

heater

core

up

and

backward,

away

from

heater

box

.

If

necessary,

remove

left

and

right

reinforcing

bracket

bolts

.

See

Fig

.

20

.

CAUTION-

Replace

coolant

flange

O-rings

and

tighten

fas-

teners

to

specified

torques

.

Tightening

Torques

1

.

Remove

center

console

.

See

513

Interior

trim

.

0012660

Fig

.

20

.

PA

heater

core

upand

towardback

of

car

.

Lower

mounting

bolts

for

steering

column

brace

and

glove

compartment

sup-

port

frame

may

have

to

be

removed

(arrows)

.

11

.

Installation

is

reverse

of

removal

.

Fill

and

bleed

cooling

system

.

See

170

Radiator

and

Cooling

System

.

"

Coolant

flange

to

heater

core

.

..

....

3

Nm

(27

in-lb)

Heater

andA/C

Control

Head

Heatercore

temperature

sensor,

replacing

The

automatic

heating

and

air

conditioning

systemuses

severa¡

sensors

to

control

interior

air

temperature

.

Use

the

fol-

lowing

procedure

and

the

data

in

Table

b

to

pinpoint

problems

with

theheater

core

sensors

.

2

.

Remove

Multi-Information

Display

(MID)

module

.

See

6201nstruments

.

HEATING

AND

AIR

CONDITIONING

640-7

0012648

Fig

.

21

.

Remove

heatercore

temperaturesensors

in

direction

shown

(arrow)

.

Table

b

.

Heater

CoreTemperatureSensor

Test

Values

Test

temperature

Resistance

4°F

(-20°C)

84

.39

-

109

.61

k

ohms

14

°

F

(-10°C)

48

.58

-

62

.09

k

ohms

32°F

(0°C)

28

.89

-

36

.40

k

ohms

68°F

(20°C)

11

.13

-

13

.83

k

ohms

140°F

(60°C)

2

.19

-

2

.78

k

ohms

212°F

(100°C)

0

.58

-

0

.77

k

ohms

Two

types

of

heater

and

aír

conditioning

control

heads

viere

installed

in

E36

cars

.

Early

models

have

control

heads

with

four

rotary

knobs

and

a

separate

control

module

.

A

flexible

shaft,

clipped

to

the

right

sideof

the

control

head,

controls

the

heater

flaps

.

Later

model

E36

cars,

starting

in

approximately

mid-1995,

have

digital

display

control

heads

with

buttons

.

The

A/C

con-

trol

module

is

integrated

with

the

digital

control

head

.

Heater

and

A/C

control

head,

removing

and

installing

(rotary-knob)

3

.

Pul¡

temperature

sensors

from

heater

box

and

discon-

1

.

Remove

Multi-Information

Display

(MID)

module

from

nect

harness

connectors

.

See

Fig

.

21

.

center

of

dash

.

See

620

Instruments

.

4

.

Installation

is

reverse

of

removal

.

2

.

Pul¡

off

outer

rotary

knobs

from

A/C

control

head

.

Re-

move

two

screwsonknob

bezels

.

Remove

control

pan-

el

face

plate

by

prying

it

off

control

head

gently

.

See

Fig

.

22

.

3

.

Carefully

push

control

head

back

into

dash

and

down-

ward

through

MID

opening

.

See

Fig

.

23

.

HEATER

AND

CONTROLS

Page 466 of 759

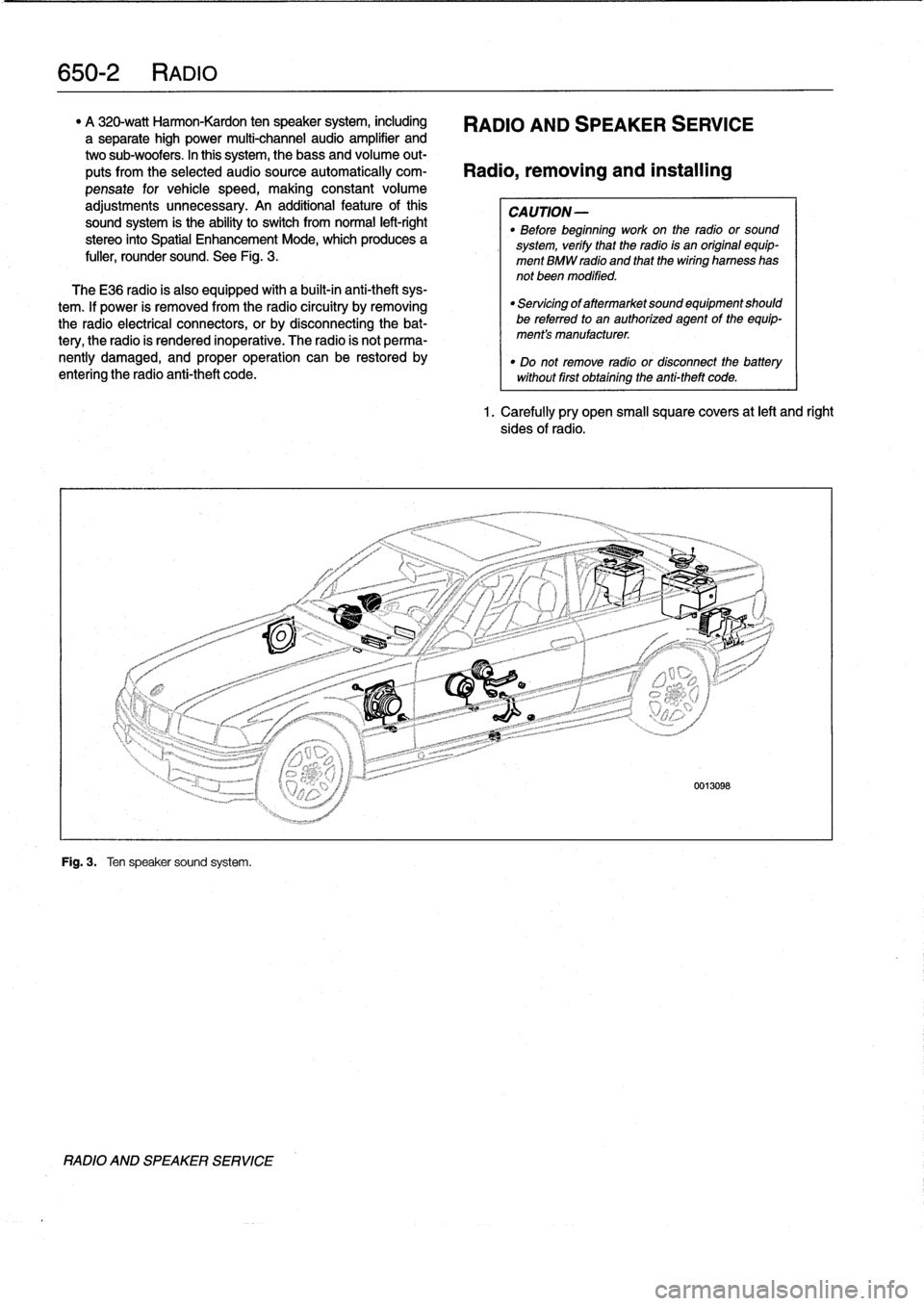

650-2

RADIO

"

A

320-watt

Harmon-Kardon

ten

speaker

system,

including

RADIO

AND

SPEAKER

SERVICE

a

separate

high

power

multi-channel

audio

amplifier

and

two

sub-woofers

.

In

this

system,

thebass

and

volume

out-

puts

from

the

selected

audiosource

automatically

com-

Radio,

removing

and

installing

pensate

for

vehicle

speed,

making

constant

volume

adjustments

unnecessary

.

An

additional

feature

ofthis

CAUTION-

sound

system

is

the

ability

to

switch

from

normal

left-right

"

Before

beginning

work

on

the

radio

or

sound

stereo

into

Spatial

Enhancement

Mode,

which

produces

a

system,

verify

that

the

radio

is

an

original

equip-

fuller,

rounder

sound

.

See

Fig

.

3

.

ment

BMW

radio

and

that

thewiring

harness

has

not

been

modified

.

TheE36

radio

is

also

equipped

with

a

built-in

anti-theft

sys-

tem

.

lf

power

is

removed

from

the

radio

circuitry

by

removing

the

radio

electrical

connectors,

or

by

disconnecting

the

bat-

tery,

the

radio

is

rendered

inoperative

.

The

radio

is

not

perma-

nently

damaged,

and

proper

operation

can

be

restored

by

entering

the

radio

anti-theft

code

.

Fig

.

3

.

Ten

speaker

sound

system

.

RADIO

AND

SPEAKER

SERVICE

"

Servicing

of

aftermarket

sound

equipment

should

be

referredto

an

authorized

agent

of

the

equip-

ment's

manufacturer

.

"

Do

not

remove

radio

or

disconnect

the

batterywithout

first

obtaining

the

anti-theft

code

.

1.

Carefully

pry

open

small

square

covers

at

left

and

right

sides

of

radio

.

Page 470 of 759

650-

6

RADIO

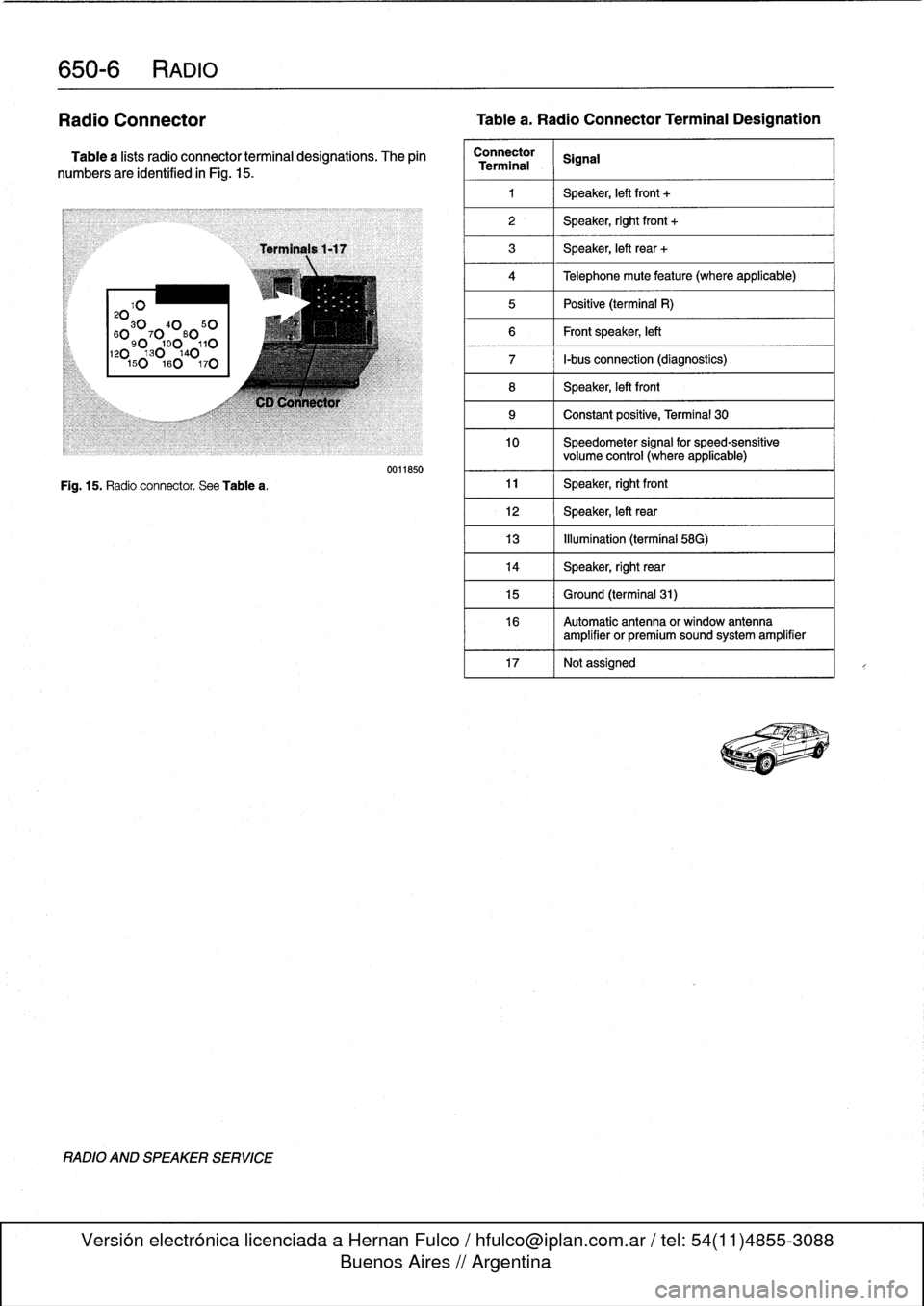

Radio

Connector

Tablea

.

Radio

Connector

Terminal

Designation

Table

a

lists

radio

connector

terminal

designations

.

The

pin

numbers

are

identified

in

Fig

.

15

.

20103040

50

60

90

7

0

0

80

110120130140150160

170

Fig

.

15

.

Radio

connector

.

See

Tablea

.

RADIO

AND

SPEAKER

SERVICE

Terminals

1-17

C1)

Connector

0011850

Connector

SignalTerminal

1

1

Speaker,

left

front

+

2

1

Speaker,

right

front

+

3

1

Speaker,

left

rear

+

4

1

Telephone

mute

feature

(where

applicable)

5

1

Positive

(terminal

R)

6

1

Frontspeaker,

left

7

1

I-bus

connection

(diagnostics)

8

Speaker,

left

front

9

1

Constant

positive,

Terminal

30

10

Speedometer

signal

for

speed-sensitive

volume

control

(where

applicable)

11

1

Speaker,

rightfront

12

1

Speaker,

left

rear

13

1

Illumination

(terminal

58G)

14

Speaker,

right

rear

15

1

Ground

(terminal

31)

16

Automatic

antenna

or

window

antenna

amplifier

or

premiumsound

system

amplifier

17

Notassigned

!'~_T-

Page 471 of 759

GENERAL

.

.

.....

.

.

.

.

.

.

.

.

.

............

720-1

REAR

SEATBELT

ASSEMBLY

...

.

....

.

.

720-4

Rear

seat

belt,

removing

and

installing

FRONT

SEATBELT

ASSEMBLY

.

.

.

.

.

.

.

.

720-2

(fixed

seat

back

models)

..

.

......

.

....

.

.720-4

Automatic

Front

Seat

Belt

Lock

Tensioners

.

.

720-2

Rear

seat

belt,

removing

and

installing

Mechanical

spring

tensioner,

disarming

.

...

.

720-2

(fold-downseat

back

models)

.

...

.

...

.

.

.

.

720-5

Front

seat

belt

reel,

removing

and

installing

.

.

720-3

Center

rear

lap-belt,

removing

and

installing

.

.720-5

GENERAL

All

E36

models

are

equipped

with

3-point

shoulder

belts

at

tract

and

tension

the

seat

belt

by

55

mm

(approximately

2

four

seating

positions

.

On

4-doormodels,

there

is

an

addition-

inches)

in

the

event

of

an

accident

.

a

l

lap

belt

in

thecenter

of

the

rear

seat

.

The

seat

beltreel

should

lock

when

driving

quickly

through

Automatic

seat

belt

tensioners

are

integrated

into

the

front

curves,

during

severe

braking

or

in

case

of

a

collision

.

The

au-

seat

belt

locks

.

Through

the

1996

model

year

cars,

a

mechan-

tomatic

reel

does

not

require

any

servicing

and

should

never

¡cal

spring

tensioner

is

used

.

See

Fig

.

1.

On

1997

and

later

be

opened

.

Belts

that

do

not

retract

and/or

lockproperly

cars,

a

pyrotechnic

(explosive

charge)

tensioner

is

used

.

Au-

should

be

replaced

promptly

.

tomatic

seat

belt

tensioners

aredesigned

to

automatically

re-

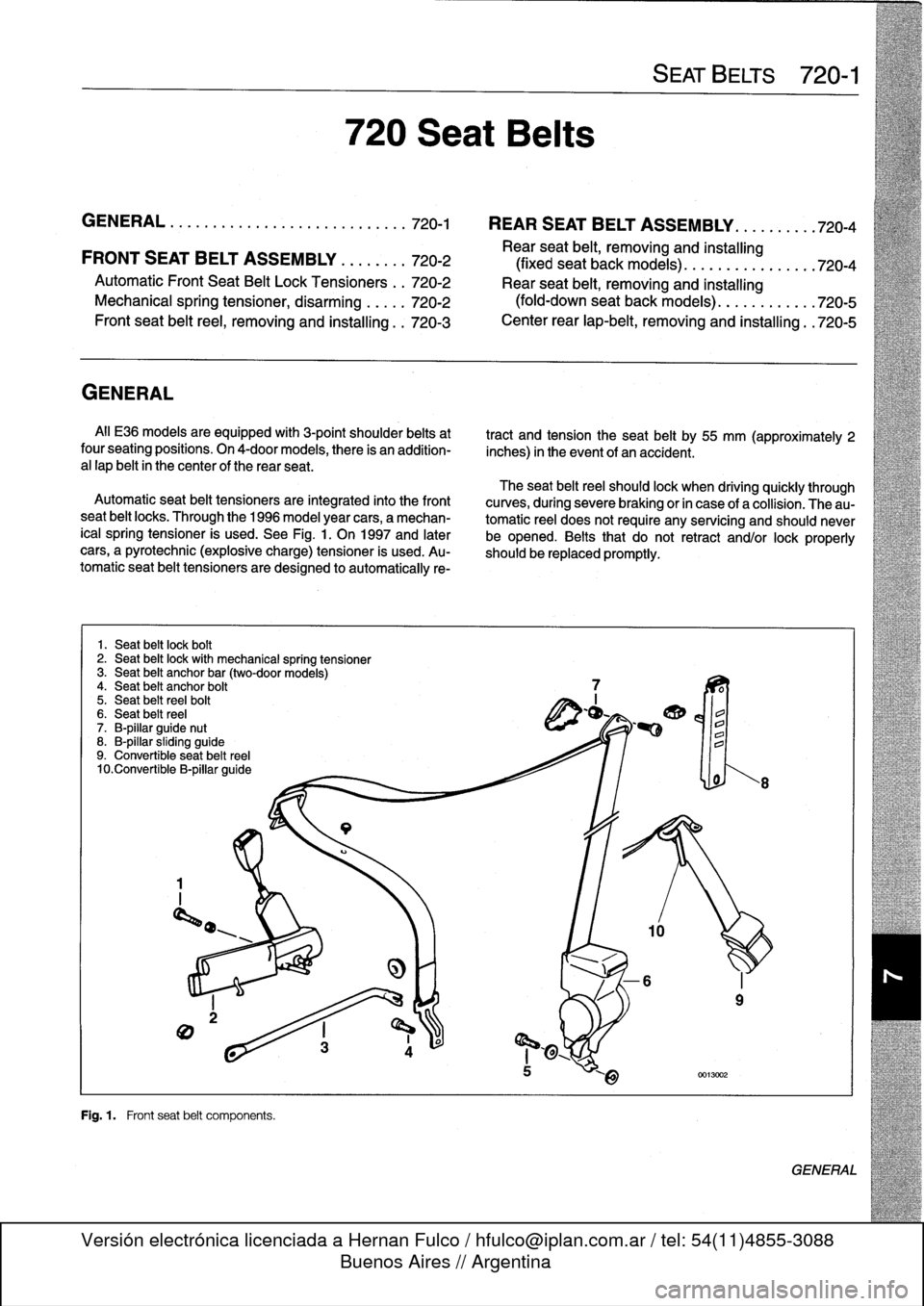

1

.

Seat

belt

lock

boft

2

.

Seat

belt

lockwith

mechanical

spring

tensioner

3

.

Seat

belt

anchor

bar

(two-door

models)

4

.

Seat

belt

anchor

bolt

5

.

Seat

belt

reelbolt

6

.

Seat

belt

reel

7

.

B-pillar

guide

nut

8

.

B-pillar

sliding

guide

9

.

Convertible

seat

beltreel

10

.Convertible

B-pillar

guide

Fig

.

1

.

Front

seat

belt

components

.

720

Seat

Belts

SEAT

BELTS

720-1

GENERAL

Page 472 of 759

720-2

SEAT

BELTS

WARNING

-

"

For

maximum

protection

from

injury,

seat

belts

should

be

replaced

as

a

set

(including

all

hard-

ware),

if

they

are

subject

to

occupant

loading

in

a

collision

.

"

Seat

belts

should

not

be

modified

or

repaired

.

The

seat

belt

anchorage

points

should

not

be

changed

or

modified

.

"

Do

notbleach

or

dye

seat

belt

webbing

.

Webbing

that

is

severely

fadedor

re-dyed

will

not

meet

the

strength

requirements

of

a

collision

and

must

be

replaced

.

"

Seat

belts

shouldbe

periodically

inspected

for

webbing

defects

suchas

cuts

or

pulled

threads

.

FRONT

SEATBELT

ASSEMBLY

Automatic

Front

Seat

Belt

Lock

Tensioners

The

procedure

for

disabling

the

mechanical

spring

tension-

er

used

on

early

cars

is

covered

below

.

On

cars

with

thepyro-

technic(explosive

device)

tensioners,

the

orange

harness

connectorshould

be

removed

from

the

tensioner

any

time

the

seat

is

removed

.

WARNING

-

Both

the

mechanical

and

the

pyrotechnictensioners

are

powerful

devíces

and

shouldbehandled

with

extreme

care

.

Mechanical

spring

tensioner,

disarming

1

.

Remove

front

seat

.

See

520

Seats

.

2

.

Disarm

tensioner-electrically

adjustableseats

:

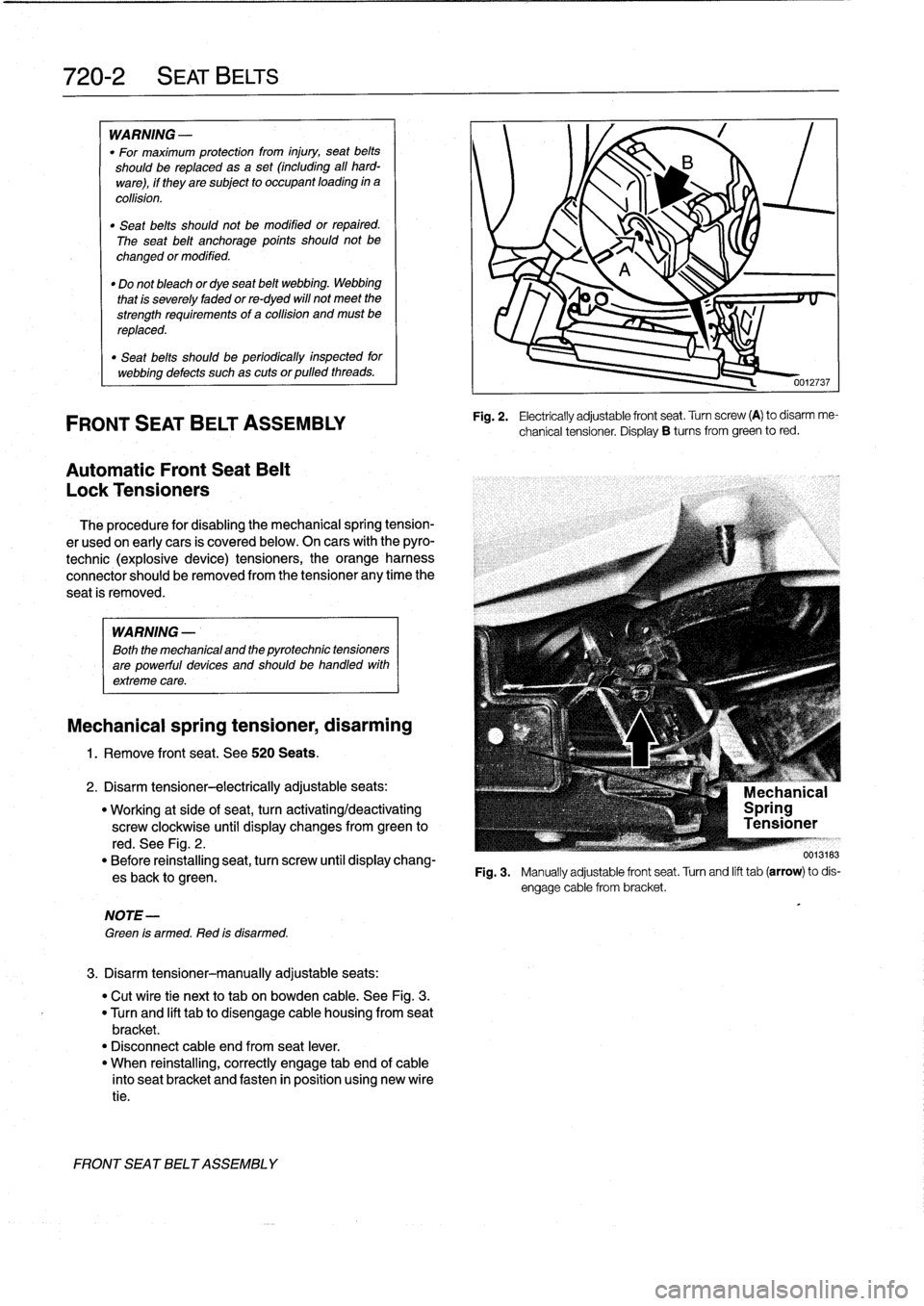

"

Working

at

side

of

seat,

turn

activating/deactivating

screw

clockwise

until

display

changes

from

green

to

red

.

See

Fig

.

2

.

"

Before

reinstalling

seat,

turn

screw

until

display

chang-

esback

to

green

.

NOTE-

Green

is

armed

.

Red

is

disarmed

.

3

.

Disarm

tensioner-manually

adjustable

seats

:

"

Cut

wíre

tie

next

to

tab

on

bowden

cable

.

See

Fig

.

3

.

"

Turn

and

lift

tabto

disengage

cable

housing

from

seat

bracket

.

"

Disconnect

cable

end

from

seat

lever

.

"

When

reinstalling,

correctly

engage

tab

end

of

cable

into

seat

bracket

and

fasten

in

position

using

new

wíre

tie

.

FRONT

SEATBELT

ASSEMBLY

0012737

Fig

.

2

.

Electrically

adjustable

front

seat

.

Turn

screw

(A)

to

disarm

me-

chanical

tensioner

.

Display

B

tucos

from

green

to

red

.

F19

.3

.

Manuallyadjustablefrontseat

.Turnandlifttab(arrow)todis-

Page 485 of 759

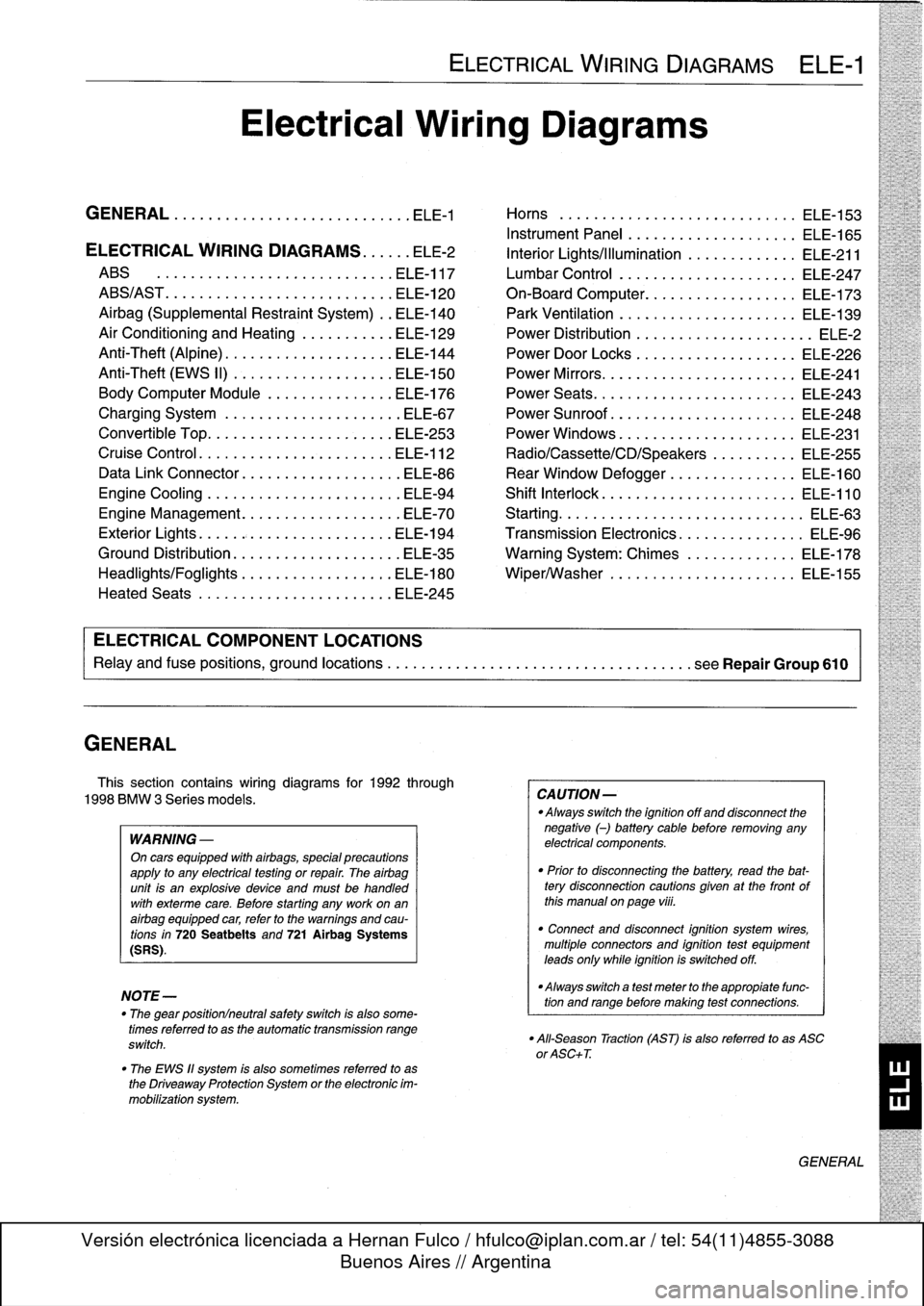

GENERAL

This

section

contains

wiring

diagrams

for

1992

through

1998

BMW

3

Series

models

.

WARNING

-

On

cars

equipped

with

airbags,

special

precautions

apply

to

any

electrical

testing

or

repair

.

The

airbag

unit

is

an

explosive

device

and

must

be

handled

with

exterme

care

.

Before

starting

any

work

onan

airbag

equipped

car,

refer

to

the

warnings

and

cau-

tions

in

720

Seatbelts

and

721

Airbag

Systems

(SRS)

.

NOTE-

The

"

gear

position/neutral

safetyswitch

is

also

some-

timesreferred

to

as

the

automatic

transmission

range

switch

.

"

The

EWS

11

system

is

also

sometimes

referred

to

as

the

Driveaway

Protection

System

or

the

electronic

im-

mobilization

system

.

ELECTRICAL

WIRING

DIAGRAMS

ELE-1

Electrical

Wiring

Diagrams

GENERAL

.

.

.

.

.

.

.

.

.

................

.

.

.

ELE-1

Horns

.....

.

.....

.

.

.

....

.

.

.

.

.

...

.

.

ELE-153

Instrument

Panel

.

.

.

.

.

.

..............

ELE-165

ELECTRICAL

WIRING

DIAGRAMS

...

.

.

.

ELE-2

Interior

Lights/Illumination

.............

ELE-211

ABS

..............

.

.

.

.....

.

.....

ELE-117

Lumbar

Control

.

....................

ELE-247

ABS/AST

.............

.

.

.

...

.

.

.

.....

ELE-120

On-Board

Computer

..................

ELE-173

Airbag

(Supplemental

Restraint

System)

..

ELE-140

Park

Ventilation

.

.

.

...........

.

...

.

..

ELE-139

Air

Conditioning

and

Heating

.

.

.

.

.

.

.....

ELE-129

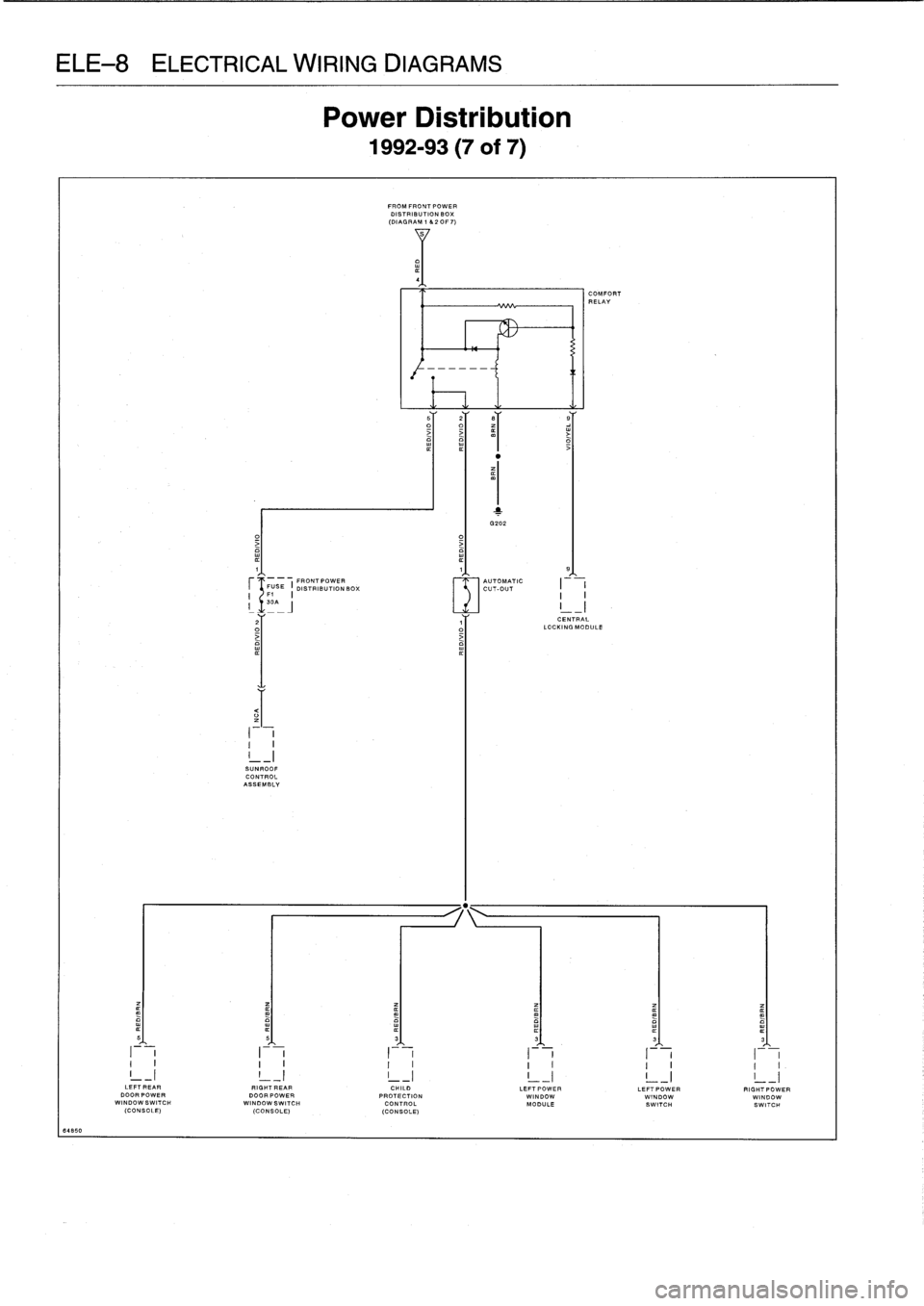

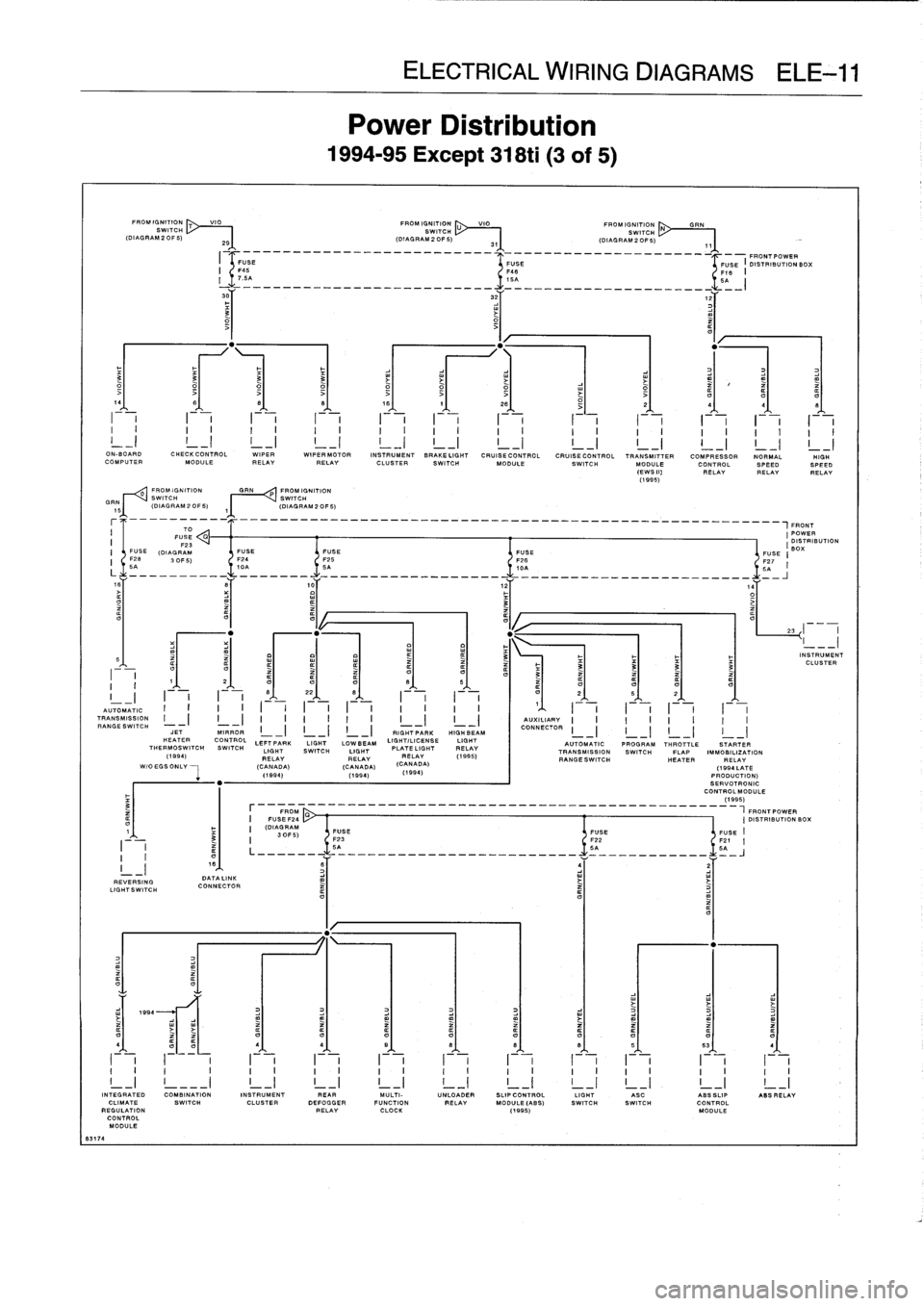

Power

Distribution

......

.

...

.

.

.

.

.

.

.

...

.

ELE-2

Anti-Theft

(Alpine)

..........

.

.

.

...

.

...

ELE-144

Power

Door

Locks

.

.

......

.

.

.

.

.

.

.

.

.

..

ELE-226

Anti-Theft

(EWS

II)

.

........

.

.

.

...

.

...

ELE-150

Power

Mirrors

...

.

.

.

......

.

.

.

.

.

.

.

.

.

..

ELE-241

Body

Computer

Module

.....

.

.....

.

...

ELE-176

Power

Seats

......

.

......

.

.

.

...

.

.

.

..

ELE-243

Charging

System

.

.

................

.

.

.

ELE-67

Power

Sunroof

.

.

.

.

.

.

.

...............

ELE-248

Convertible

Top

.

.

.

.

................

.

.

ELE-253

Power

Windows

.

.

.

.

.

.

.....

.

.........

ELE-231

Cruise

Control

..

.

.

.

...........

.

....

.

.

ELE-112

Radio/Cassette/CD/Speakers

..........

ELE-255

Data

Link

Connector

................

.

.

.

ELE-86

Rear

Window

Defogger

...............

ELE-160

Engine

Cooling

.......

.

.......

.

....

.

.

.

ELE-94

Shift

Interlock

.

.

.

.

.

.

.

.

...............

ELE-110

Engine

Management

...

.

.......

.

....

.

.

.

ELE-70

Starting

....

.

.

.

.

.

...

.

................

ELE-63

Exterior

Lights

........

.

.

.

.

.

.

.

.

.

......

ELE-194

Transmission

Electronics

.

..............

ELE-96

Ground

Distribution

....

.

.

.

.

.

.

.

.

.

.......

ELE-35

Warning

System

:

Chimes

.............

ELE-178

Headlights/Foglights

...

.

.

.

.

.

.

.

.

.

......

ELE-180

Wiper/Washer

.

.....

.

...............

ELE-155

Heated

Seats

........

.

.

.

.

.

.

.

.

.

......

ELE-245

ELECTRICAL

COMPONENT

LOCATIONS

Relayand

fuse

positions,

ground

locations

...........

.

.

.

.

.

.

.

.

.

................

seeRepair

Group

610

CAUTION-

Always

switchthe

ignition

off

and

disconnect

the

negative

(-)

battery

cablebefore

removing

any

electrical

components

.

"

Prior

to

disconnecting

the

battery,

read

the

bat-tery

disconnection

cautions

given

at

the

front

of

this

manual

on

page

viii

.

"

Connect

and

disconnect

ignition

system

wires,

multiple

connectors

and

ignition

test

equipment

leads

only

while

ignition

is

switched

off

.

-Always

switch

a

test

meter

to

the

appropiate

func-

tion

and

range

before

making

test

connections

.

"

All-Season

Traction

(AST)

is

also

referred

to

as

ASC

or

ASC+T

.

GENERAL

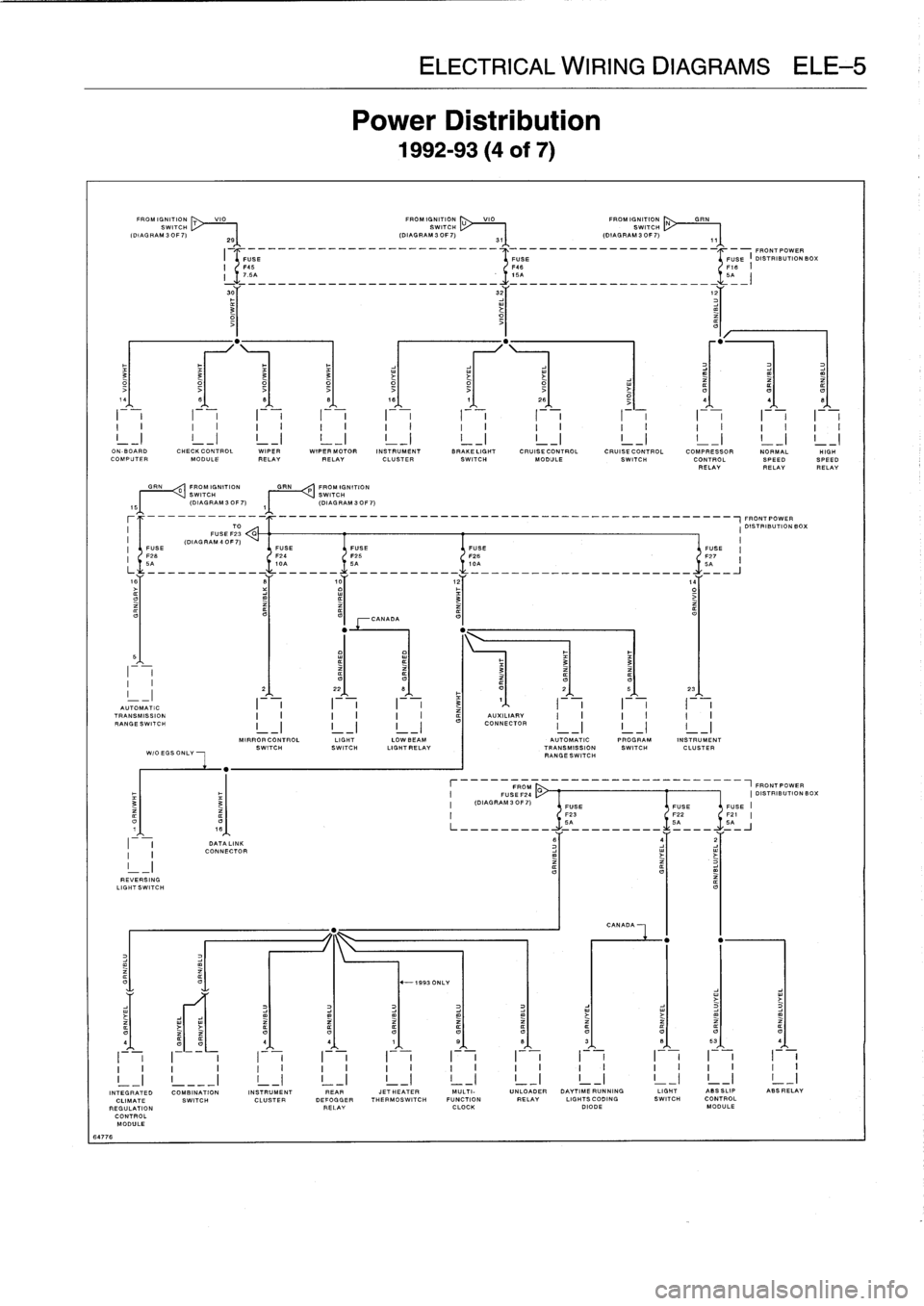

Page 489 of 759

EKE

Power

1992-

VIO

FROMIGNITION

U

VIO

FROM

IGNITI

ON

SWITCH

SWITCH

2S

(DIAGRAM3OF7)

31

(DIAGRAM3OF7)

I

-

______________-__________--

4

-_____________________I_-FRONT

POWER

O

3

3

3

3

i

14

8

8

B

18

7

26

-

4

4

I

i

I

I

i

-F-

I

i

I

-

,

I

,

I

I

F-,

ON

-BOARD

CHECKCONTROL

WIPER

WIPER

MOTOR

INSTRUMENT

BRAKELIGHT

CRUISE

CONTROL

CRUISE

CONTROL

COMPRESSOR

NORMALCOMPUTER

MODULE

RELAYRELAY

CLUSTER

SWITCH

MODULE

SWITCH

CONTROL

SPEEDRELAYRELAY

GRN

0

FROM

IGNITION

GRN

P

FROM

IGNITION

~I

I

VSWITCH

SWITCH

(DIAGRAM

30F7)

,~

(DIAGRAM

3OF7)

-------_-_____________________________________________~FRONT

POWER

TO

I

DISTRIBUTIONBOX

FUSE

F23

G

(DIAG

RAM

4

0F

7)

I

FUSE

FUSE

FUSE

FUSE

FUSE

'

F26

F24

F25

F26

-

F27

6A

10A

SA

ICA

5A

is

S

,0

12

,4

o3

>

CANADA

5

I

~

~

~

3

33

-

2

22

B

F

O

2

5

23

AUTOMATIC

I

I

I

3

1

I

TRANSMISSION

AUXILIARY

RANGESWITCH

I

-

I

I

-

I

I

-

I

CONNECTOR

MIRRORCONTROL

LIGHT

LOWBEAM

AUTOMATIC

PROGRAM

INSTRUMENT

SWITCHSWITCH

LIGHTRELAY

TRANSMISSION

SWITCH

CLUSTER

WIOEGSONLY

RANGESWITCH

FROM

___________-----1FRONTPOWER

FUSEF24

CI

DISTRIBUTION

BC

3

(DIAGRAM30F7)

FUSE

FUSEFUSE

F23

F22

F21

O

O

SA

SA

5A

DATA

LINK

6

j

2

I

CONNECTOR

REVERSING

LIGHTSWITCH

CANADA

O

"

-1993

ONLY

O4

4

4

1

S

B

3

B

53

4

I

v

I~

i

I

i

I

v

I

i

I

v

I

i

I

v

I

i

I

i

I

i

v

v

v

v

~

v

v

~

~

v

v

~

v

v

o

n

v

v

v

v

v

v

_I

INTEGRATED

COMBINATION

INSTRUMENT

REAR

JETHEATER

MULTI-

UNLOADER

DAYTIMERUNNING

LIGHT

ASSSLIP

ABSRELAY

CLIMATE

SWITCH

CLUSTER

DEFOGGER

THERMOSWITCH

FUNCTION

RELAY

LIGHTSCODING

SWITCH

CONTROL

REGULATION

RELAY

CLOCK

DIODE

MODULE

CONTROL

MODULE

64776

Page 492 of 759

CAL

WIRING

DIAGR

Power

uis

1992-93

-

FROMFRONTPOWER

DISTRIBUTION

BOX

(DIAGRAM

1

&20F7)

1

3202

O

1

1

9

FRONTPOWER

AUTOMATIC

FUSE

I

DISTRIBUTIONBOX

CUT-OUT

I

I

I

F1

I

30

-J

2

1

CENTRAL

O

LOCKING

MODULE

II

I

-

I

I

SUNROOFCONTROL

ASSEMBLY

5

5

S

3

3

3

I

I

I

I

I

I

~

I

I

I

I

II

I

I

I

I

I

I

I

I

I

I

I.

LEFT

REAR

RIGHT

EAR

CHILD

LEFT

POWER

LEFT

POWER

RIGHTPOWER

000RPOWER

DOORPOWER

PROTECTION

WINDOW

WINDOW

WINDOWWINDOWSWITCH

WINDOWS

WITCH

CONTROL

MODULE

SWITCH

SWITCH

(CONSOLE)

(CONSOLE)

(CONSOLE)

64850

Page 495 of 759

8317

4

FROMIGNITION

T

VIO

FROM

IGNITION

U

VIO

"I"

IGNITION

SWITCH

SWITCH

SWITCH

(DIAGRAM2OF5)

29

(DIAGRAM20F5)

31

(DIAGRAM20F5)

FROMIGNITION

GRIN

PROMIGNITION

SWITCH

SWITCH

(DIAGRAM20F5)

~(DIAGRAM20F5)

REVERSING

LIGHT

SW

TO

DATA

LINK

CONNECTOR

Power

Distribution

1994-95

Except

318ti

(3

of

5)

______________________________________________

-_-

FRONTPOWER

ELECTRICAL

WIRING

DIAGRAMS

ELE-11

3

FUSE

FUSE

I

DISTRIBUTION

BOX

F46

F18

I

L

>

t

141

6'

81

81

16/

11

261

j

2

4

q

I

I

I

I

I

I

I

i

I

Jll~~~

i

I

It

i

I

JJJ

...

i

-

i

-

i

-

i

-

i

--

I

I

I

1

I

II

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

ON-BOARD

CHECKCONTROL

WIPER

WIPERMOTOR

INSTRUMENT

BRAKELIGHT

CRUISE

CONTROL

CRUISECONTROL

TRANSMITTER

COMPRESSOR

NORMAL

HIGH

COMPUTERMODULE

RELAY

RELAY

CLUSTER

SWITCH

MODULE

SWITCH

MODULE

CONTROL

SPEEDSPEED

(EWSIN

RELAYRELAYRELAY

(1995)

,FRONT

(POWER

DISTRIBUTION

FUSE

FUSE

FUSE

(BOX

FUSE

I

F24

F25

F26

F27

10A

5A

10A

5q

I

------------------

-

-------

-

I

I

I

I

I

I

I

I

I

I

I

I

I

I

'

I

I

I

I

I

I

I

I

AUTOMATIC

"1"

TRANSMISSION

I

-

I

I

_

I

I

_

I

I

I

I

I

I

-)

I

_

I

AUXILIARY

RANGESWITCH

JETMIRROR

L

II

CONNECTORCONNECTOR

RIG

H7

PARK

HIGH

BEAM

I

I

I

I

HEATER

CONTROL

LEFT

PARK

LIGHT

LOWBEAM

LIGHT/LICENSE

LIGHT

AUTOMAT

IC

PROGRAM

THROTTLE

SWITCH

LIGHT

SWITCH

LIGHT

PLATE

LIGHT

RELAY

HROTTLE

STARTER

(

(1995)

TRANSMISSIONSWITCH

FLAP

IMMOBILIZATION

994)

RELAY

RELAYRELAY

A)

RANGESWITCH

HEATER

RELAY

WIOEGSONLV

--

I

-

(CANADA)

(CANADA)

(CANAD

(1994

LATE

(1894)

(1994)

(1

994

)

PRODUCTION)

SERVOTRONIC

CONTROLMODULE

(1995)

FROM

FRONTPOWER

I

FU

SEF24

I

DISTRIBUTIONBOX

I

(DIAGRAM

30F5)

FUSE

FUSE

FUSE

II

F23

F22

F21

I

5A

5A

5A

61

_I-

=

L

41

4,

1

91

8t

el

8),

51

531

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

i

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

II

_I

!

---

I

!

_I

!

_I

23

INTEGRATED

COMBINATION

INSTRUMENT

PEAR

MULTI-

UNLOADER

SLIP

CONTROL

LIGHT

ASC

ABSSLIP

ASS

RELAY

CLIMATE

SWITCH

CLUSTER

DEFOGGER

FUNCTION

RELAY

MODULE

(AB

S)

SWITCH

SWITCH

CONTROL

REGULATION

RELAY

CLOCK

(1995)

MODULE

CONTROL

MODULE

INSTRUMENT

CLUSTER