light BMW M3 CONVERTIBLE 2002 E46 Owner's Guide

[x] Cancel search | Manufacturer: BMW, Model Year: 2002, Model line: M3 CONVERTIBLE, Model: BMW M3 CONVERTIBLE 2002 E46Pages: 159, PDF Size: 2.19 MB

Page 108 of 159

108n

Hardtop

*

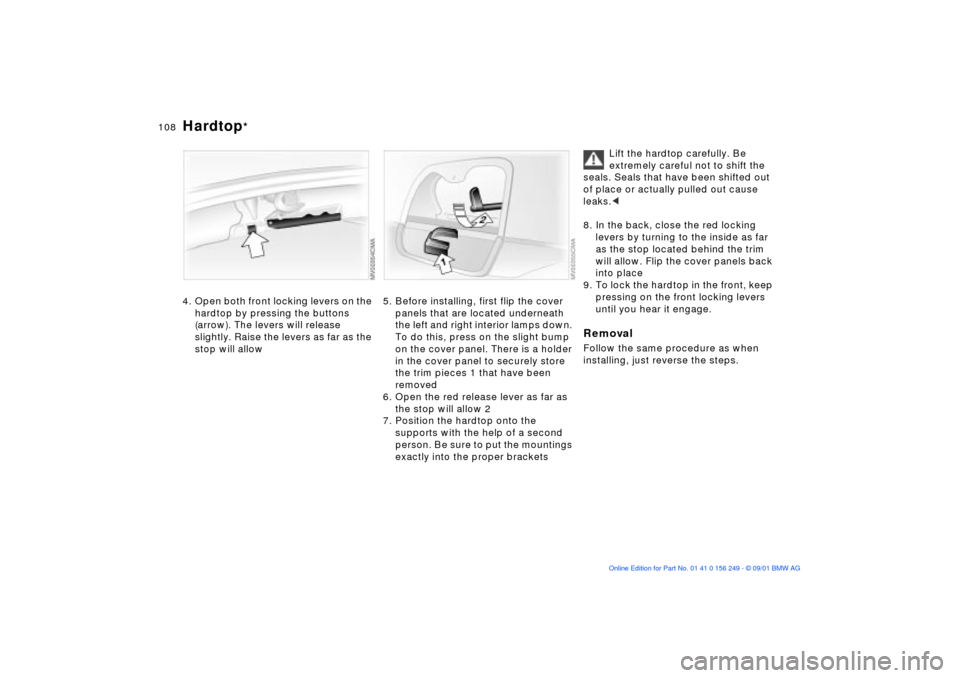

4. Open both front locking levers on the

hardtop by pressing the buttons

(arrow). The levers will release

slightly. Raise the levers as far as the

stop will allow

5. Before installing, first flip the cover

panels that are located underneath

the left and right interior lamps down.

To do this, press on the slight bump

on the cover panel. There is a holder

in the cover panel to securely store

the trim pieces 1 that have been

removed

6. Open the red release lever as far as

the stop will allow 2

7. Position the hardtop onto the

supports with the help of a second

person. Be sure to put the mountings

exactly into the proper brackets

Lift the hardtop carefully. Be

extremely careful not to shift the

seals. Seals that have been shifted out

of place or actually pulled out cause

leaks.<

8. In the back, close the red locking

levers by turning to the inside as far

as the stop located behind the trim

will allow. Flip the cover panels back

into place

9. To lock the hardtop in the front, keep

pressing on the front locking levers

until you hear it engage.

RemovalFollow the same procedure as when

installing, just reverse the steps.

Page 111 of 159

111n

OverviewControlsMaintenanceRepairsDataIndex

Tire replacement Wheel and tire combinations Tire ageBMW recommends the replacing of all

tires after 6 years at the latest, even if a

tire life of 10 years is possible.

The date on which the tire was manu-

factured is indicated by the code on the

sidewall:

DOT ... 3501 indicates that the tire was

manufactured in week 35 of the year

2001.Following wheel/tire changesFollowing wheel and/or tire changes

you will need to reinitialize both the Flat

Tire Monitor and the sequential M

gearbox

* SMG II, refer to pages 70, 83.

The right choice

Never mount wheels and tires that

have not been specifically

approved by BMW for use on your

particular model. Although other wheels

and tires may theoretically have the

same dimensions, variations in factors

such as manufacturing tolerances can

result in contact between tire and body-

work, ultimately leading to serious acci-

dents. If non-approved wheels and tires

are used, BMW cannot evaluate their

suitability, and therefore cannot be held

liable for driving safety.<

BMW tests certain tire brands for each

tire size, classifies them as road-safe

and approves them. Consult your BMW

center for more information. Observe

any country-specific regulations, e.g.

on making a corresponding entry in the

vehicle documents.

The correct wheel and tire combi-

nation affects different systems

such as ABS, DSC, Flat Tire Monitor.

The function of these systems is

impaired if improper wheel and tire

combinations are used.

Therefore, only use tires of the same

brand and same tread configuration on

the vehicle and, for example following a

tire failure, restore the approved wheel

and tire combination as soon as

possible.<

The use of rims and lug bolts that

do not meet the specifications of

the original factory-installed equipment

will affect the safe operation of your

vehicle and may cause an accident and

personal injury.

Never mix tires of different design, such

as steel-belted radials with radial bias-

belted or bias-ply tires, etc. Mixing tire

types will adversely affect roadholding

and can lead to loss of vehicle

control.< Storage Store wheels and tires in a cool, dry

place, protecting them against light

whenever possible. Protect the tires

against contact with oil, grease and

fuel.

Page 118 of 159

118n

Coolant

Do not add coolant to the cooling

system when the engine is hot. If

you attempt to do so, escaping coolant

can cause burns.

To avoid the possibility of damage later

on, never use anything other than

factory-approved, nitrite and amino-

free extended-duty antifreeze with

corrosion inhibitor. Your BMW center is

familiar with the official specifications.

Antifreeze and anti-corrosion agents

are hazardous to health. You should

always store them in their original

containers and in a location inacces-

sible to children. Extended-duty anti-

freeze with corrosion inhibitor contains

ethylene glycol, a flammable

substance. For this reason, do not spill

extended-duty antifreeze with corrosion

inhibitor on hot engine parts. It could

catch fire and cause burns.<

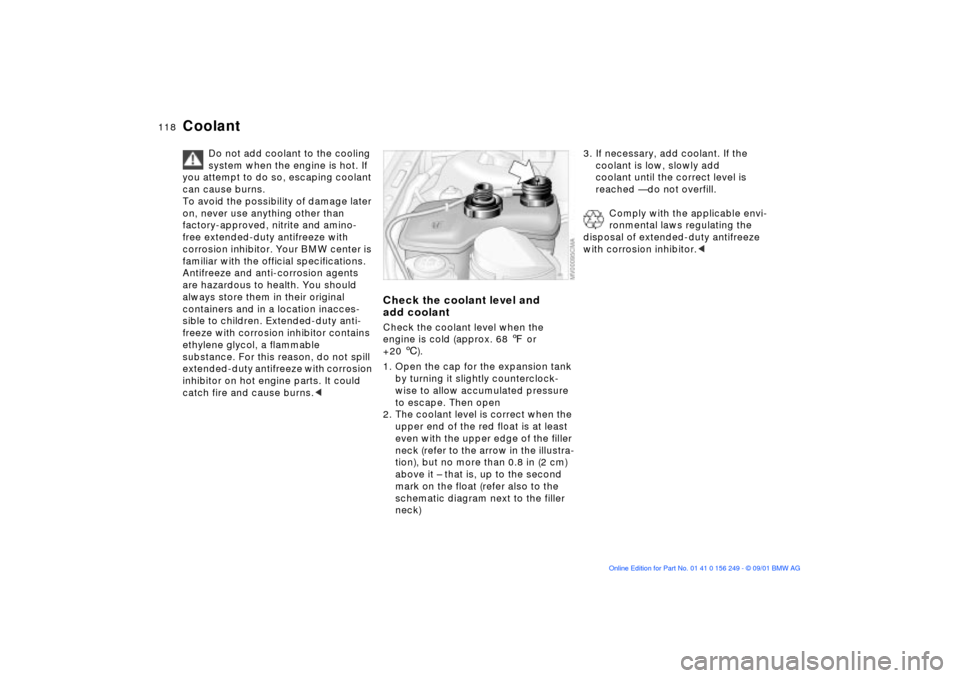

Check the coolant level and

add coolant

Check the coolant level when the

engine is cold (approx. 68 7 or

+20 6).

1. Open the cap for the expansion tank

by turning it slightly counterclock-

wise to allow accumulated pressure

to escape. Then open

2. The coolant level is correct when the

upper end of the red float is at least

even with the upper edge of the filler

neck (refer to the arrow in the illustra-

tion), but no more than 0.8 in (2 cm)

above it Ð that is, up to the second

mark on the float (refer also to the

schematic diagram next to the filler

neck)

3. If necessary, add coolant. If the

coolant is low, slowly add

coolant until the correct level is

reached Ñ do not overfill.

Comply with the applicable envi-

ronmental laws regulating the

disposal of extended-duty antifreeze

with corrosion inhibitor.<

Page 121 of 159

121n

OverviewControlsMaintenanceRepairsDataIndex

Technical modifications California Proposition 65 WarningLight-emitting diodes (LEDs)Light-emitting diodes installed behind

translucent lenses serve as the light

source for many of the controls and

displays in your vehicle. The concept

behind their operation is related to that

employed for lasers, and they are offi-

cially designated as Class 1 light-emit-

ting diodes.

Do not remove the protective lens

and avoid staring directly at the

unfiltered beam for extended periods

(several hours), as inflammation of the

iris could result.<

California laws require us to state the

following warning:

Engine exhaust, some of its

constituents, and certain vehicle

components contain or emit chemicals

known to the State of California to

cause cancer and birth defects or other

reproductive harm.<

Page 122 of 159

122n

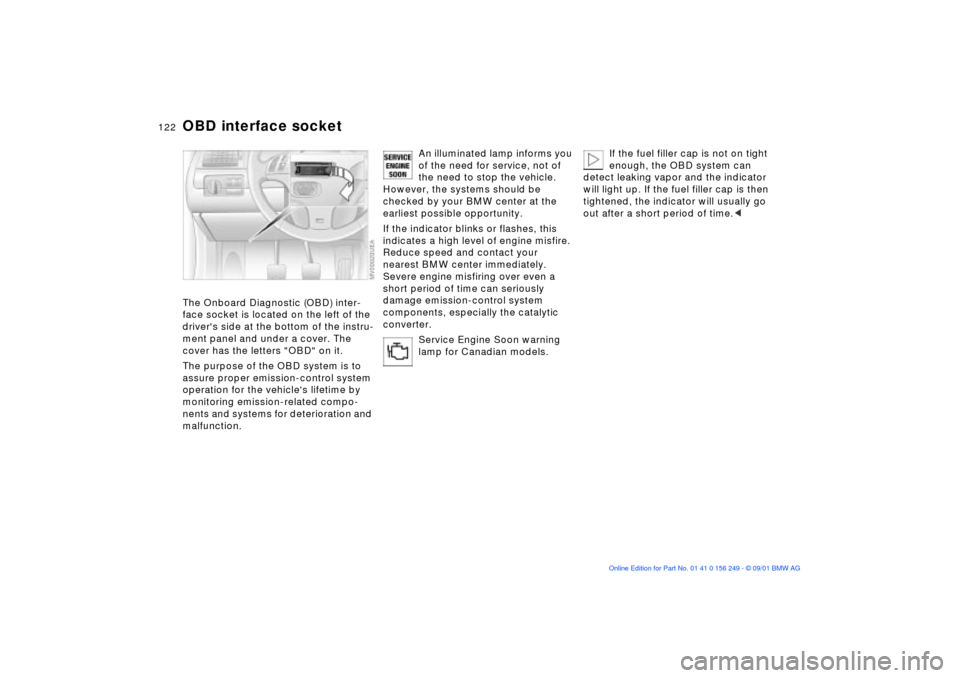

OBD interface socketThe Onboard Diagnostic (OBD) inter-

face socket is located on the left of the

driver's side at the bottom of the instru-

ment panel and under a cover. The

cover has the letters "OBD" on it.

The purpose of the OBD system is to

assure proper emission-control system

operation for the vehicle's lifetime by

monitoring emission-related compo-

nents and systems for deterioration and

malfunction.

An illuminated lamp informs you

of the need for service, not of

the need to stop the vehicle.

However, the systems should be

checked by your BMW center at the

earliest possible opportunity.

If the indicator blinks or flashes, this

indicates a high level of engine misfire.

Reduce speed and contact your

nearest BMW center immediately.

Severe engine misfiring over even a

short period of time can seriously

damage emission-control system

components, especially the catalytic

converter.

Service Engine Soon warning

lamp for Canadian models.

If the fuel filler cap is not on tight

enough, the OBD system can

detect leaking vapor and the indicator

will light up. If the fuel filler cap is then

tightened, the indicator will usually go

out after a short period of time.<

Page 127 of 159

127n

OverviewControlsMaintenanceRepairsDataIndex

Lamps and bulbsLow and high beams >Low beams: H7 bulb, 55 watts

>High beams: H7 bulb, 55 watts

The H7 bulb is pressurized. There-

fore, wear safety glasses and

protective gloves. Failure to comply

with this precaution could lead to injury

if the bulb is damaged during replace-

ment.<

Please contact a BMW center in case of

a malfunction.Parking lamps5 watt bulb

Please contact a BMW center in case of

a malfunction.

When caring for your headlamps please

observe the notes and instructions

contained in the "Care for your vehicle"

Manual.

Xenon lamps

*

The service life of these bulbs is very

long and the probability of a failure is

very low, provided that they are not

switched on and off an unusual number

of times. If one of these bulbs should

nevertheless fail, it is possible to

continue driving with great caution

using the fog lamps, provided traffic

laws in your area do not prohibit this.

Because of the extremely high

voltages involved, any work on the

lighting system should be carried out by

technically-qualified personnel only.

Otherwise, there is a risk of fatal

injury.<

Page 128 of 159

128n

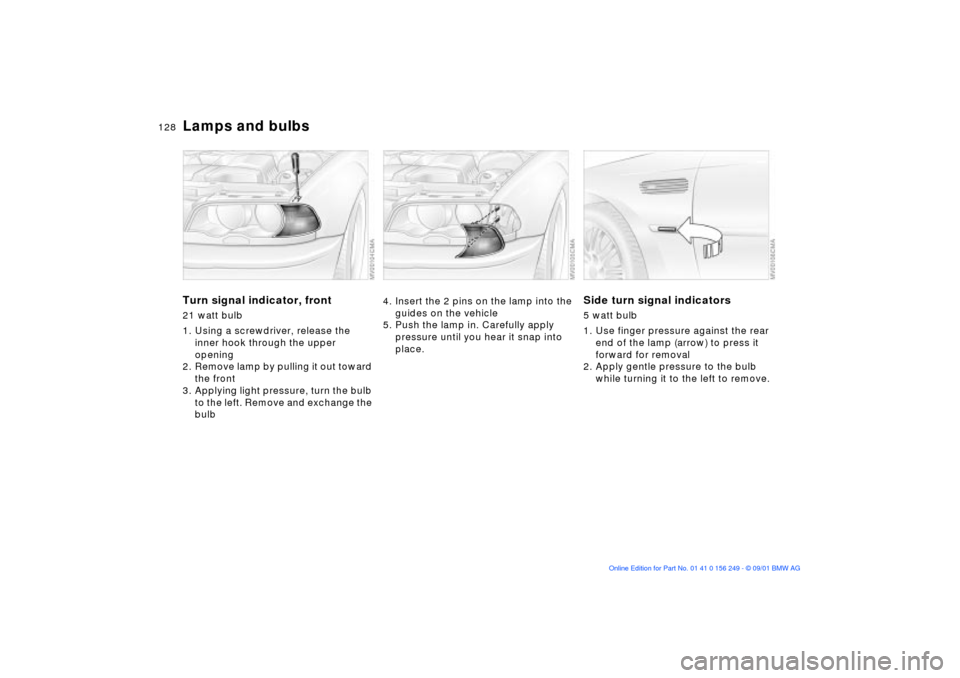

Lamps and bulbsTurn signal indicator, front 21 watt bulb

1. Using a screwdriver, release the

inner hook through the upper

opening

2. Remove lamp by pulling it out toward

the front

3. Applying light pressure, turn the bulb

to the left. Remove and exchange the

bulb

4. Insert the 2 pins on the lamp into the

guides on the vehicle

5. Push the lamp in. Carefully apply

pressure until you hear it snap into

place.

Side turn signal indicators5 watt bulb

1. Use finger pressure against the rear

end of the lamp (arrow) to press it

forward for removal

2. Apply gentle pressure to the bulb

while turning it to the left to remove.

Page 130 of 159

130n

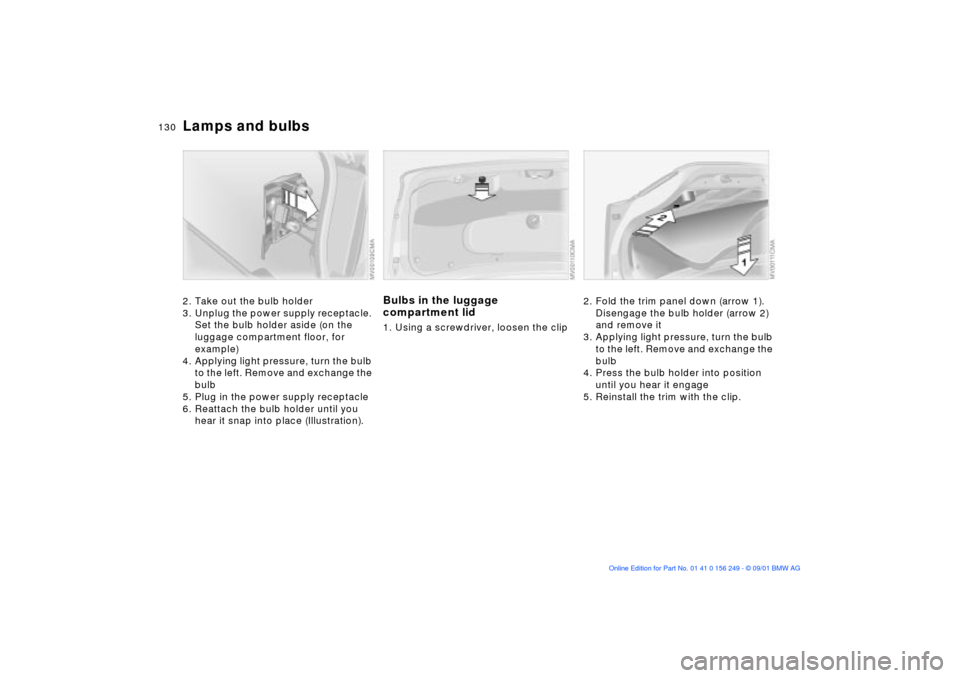

Lamps and bulbs2. Take out the bulb holder

3. Unplug the power supply receptacle.

Set the bulb holder aside (on the

luggage compartment floor, for

example)

4. Applying light pressure, turn the bulb

to the left. Remove and exchange the

bulb

5. Plug in the power supply receptacle

6. Reattach the bulb holder until you

hear it snap into place (Illustration).

Bulbs in the luggage

compartment lid1. Using a screwdriver, loosen the clip

2. Fold the trim panel down (arrow 1).

Disengage the bulb holder (arrow 2)

and remove it

3. Applying light pressure, turn the bulb

to the left. Remove and exchange the

bulb

4. Press the bulb holder into position

until you hear it engage

5. Reinstall the trim with the clip.

Page 133 of 159

133n

OverviewControlsMaintenanceRepairsDataIndex

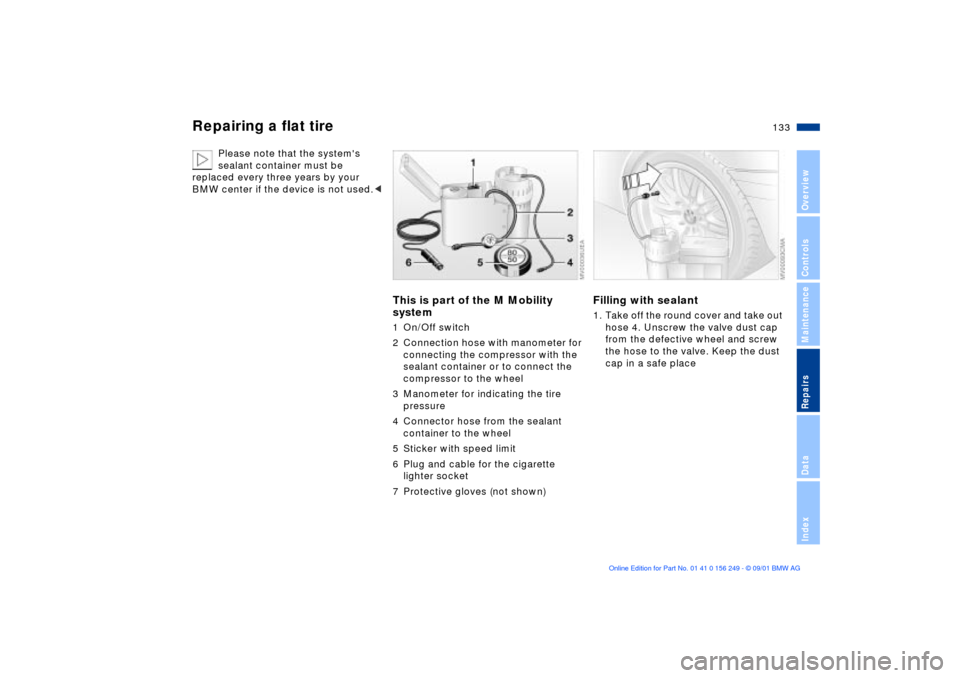

Repairing a flat tire

Please note that the system's

sealant container must be

replaced every three years by your

BMW center if the device is not used.<

This is part of the M Mobility

system1 On/Off switch

2 Connection hose with manometer for

connecting the compressor with the

sealant container or to connect the

compressor to the wheel

3 Manometer for indicating the tire

pressure

4 Connector hose from the sealant

container to the wheel

5 Sticker with speed limit

6 Plug and cable for the cigarette

lighter socket

7 Protective gloves (not shown)

Filling with sealant1. Take off the round cover and take out

hose 4. Unscrew the valve dust cap

from the defective wheel and screw

the hose to the valve. Keep the dust

cap in a safe place

Page 134 of 159

134n

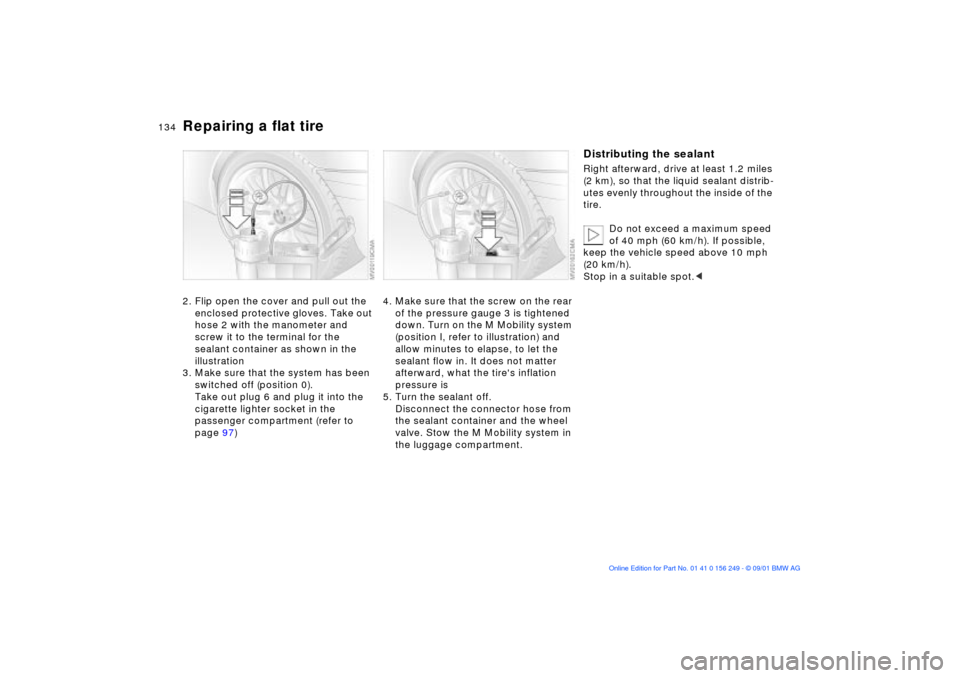

Repairing a flat tire2. Flip open the cover and pull out the

enclosed protective gloves. Take out

hose 2 with the manometer and

screw it to the terminal for the

sealant container as shown in the

illustration

3. Make sure that the system has been

switched off (position 0).

Take out plug 6 and plug it into the

cigarette lighter socket in the

passenger compartment (refer to

page 97)

4. Make sure that the screw on the rear

of the pressure gauge 3 is tightened

down. Turn on the M Mobility system

(position I, refer to illustration) and

allow minutes to elapse, to let the

sealant flow in. It does not matter

afterward, what the tire's inflation

pressure is

5. Turn the sealant off.

Disconnect the connector hose from

the sealant container and the wheel

valve. Stow the M Mobility system in

the luggage compartment.

Distributing the sealantRight afterward, drive at least 1.2 miles

(2 km), so that the liquid sealant distrib-

utes evenly throughout the inside of the

tire.

Do not exceed a maximum speed

of 40 mph (60 km/h). If possible,

keep the vehicle speed above 10 mph

(20 km/h).

Stop in a suitable spot.<