BMW M6 CONVERTIBLE 2007 E64 Owner's Manual

Manufacturer: BMW, Model Year: 2007, Model line: M6 CONVERTIBLE, Model: BMW M6 CONVERTIBLE 2007 E64Pages: 256, PDF Size: 8.11 MB

Page 211 of 256

Mobility

209Reference

At a glance

Controls

Driving tips

Communications

Navigation

Entertainment

Replacing components

Onboard tool kit

The onboard tool kit is located in the luggage

compartment under the floor mat.

Replacing wiper blades

1.Fold the wiper arm out and grasp it firmly.

2.Press the locking tabs together while slid-

ing the wiper blade toward the front to dis-

engage it.

3.Insert the new wiper blade and slide it in

until it audibly clicks into place.

Lamps and bulbs

Lamps and bulbs make an essential contribu-

tion to driving safety. You must be duly diligent

in replacing them. If you are not familiar with the

specified procedures, have the corresponding

work carried out at your BMW center.Never touch the glass on new bulbs with

your bare fingers, as even minute

amounts of contamination will burn into the

bulb's surface and reduce its service life. Use a

clean cloth, napkin, etc., or hold the bulb by its

metal socket.<

A selection of replacement bulbs is available at

your BMW center.

Whenever you perform any work on the

electrical system, turn off the electrical

devices involved to prevent short circuits from

occurring. To avoid possible injury or equip-

ment damage when replacing bulbs, follow any

instructions provided by the bulb manufac-

turer.<

When performing maintenance on the head-

lamps, follow the instructions in the separate

Caring for your vehicle brochure.

For bulbs for which changing is not

described, and for checking and adjusting

headlamp aim, please contact your BMW cen-

ter.<

Light-emitting diodes LEDs

Light-emitting diodes installed behind translu-

cent lenses serve as the light source for many of

the controls and displays in your vehicle. These

light-emitting diodes, which operate using a

concept similar to that applied in conventional

lasers, are officially designated as Class 1 light-

emitting diodes.

Do not remove the covers, and never

stare into the unfiltered light for several

hours, as irritation of the retina could result.<

Xenon lamps

The service life of these lamps is very long and

the probability of a failure is very low, provided

that they are not switched on and off an unusual

number of times.

Page 212 of 256

Replacing components

210 Have work on the xenon lighting system

performed only by your BMW center or a

workshop that works according to BMW repair

procedures with correspondingly trained per-

sonnel. Due to the high voltage involved, there

is a danger to life and limb when work is carried

out improperly.<

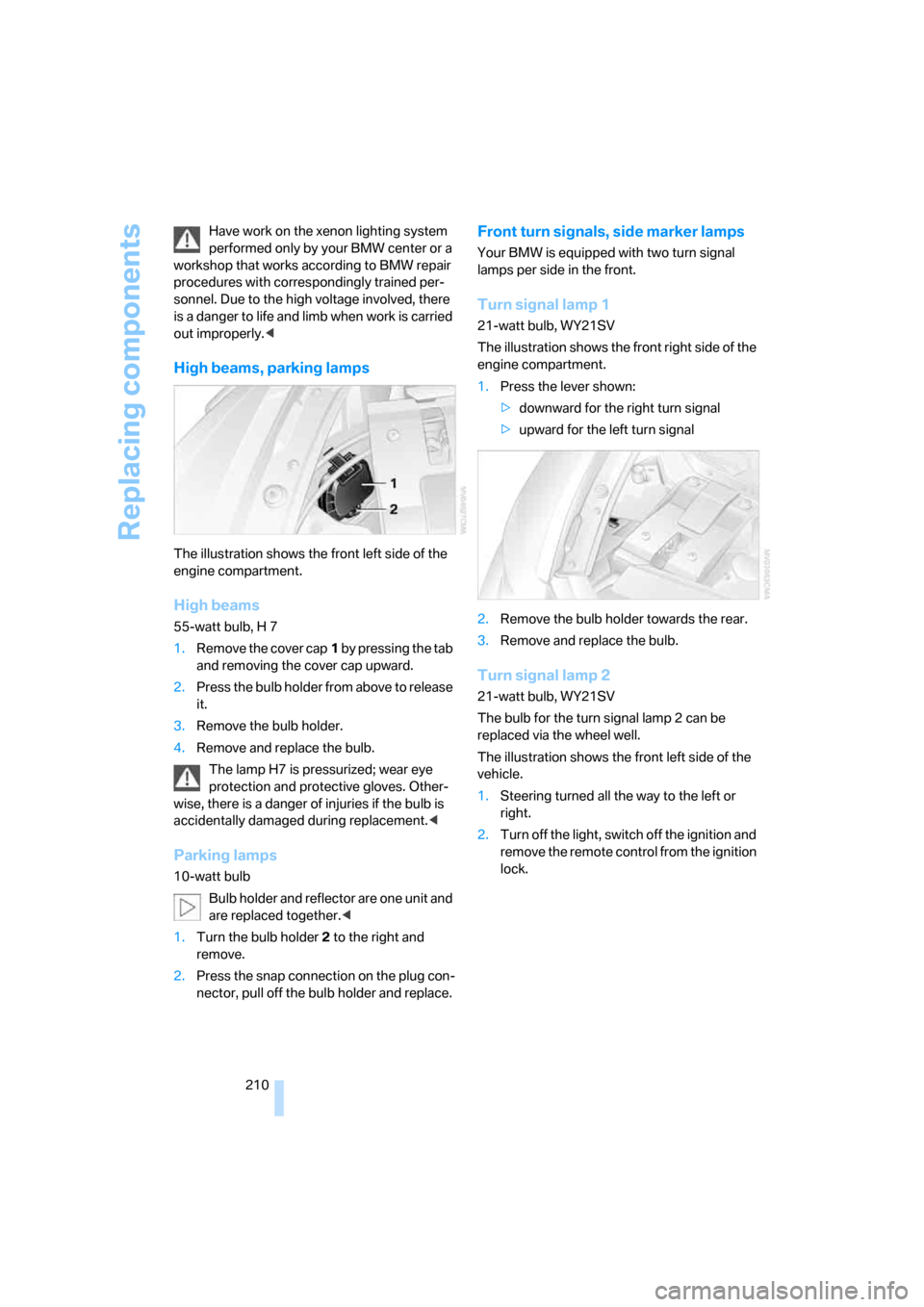

High beams, parking lamps

The illustration shows the front left side of the

engine compartment.

High beams

55-watt bulb, H 7

1.Remove the cover cap1 by pressing the tab

and removing the cover cap upward.

2.Press the bulb holder from above to release

it.

3.Remove the bulb holder.

4.Remove and replace the bulb.

The lamp H7 is pressurized; wear eye

protection and protective gloves. Other-

wise, there is a danger of injuries if the bulb is

accidentally damaged during replacement.<

Parking lamps

10-watt bulb

Bulb holder and reflector are one unit and

are replaced together.<

1.Turn the bulb holder2 to the right and

remove.

2.Press the snap connection on the plug con-

nector, pull off the bulb holder and replace.

Front turn signals, side marker lamps

Your BMW is equipped with two turn signal

lamps per side in the front.

Turn signal lamp 1

21-watt bulb, WY21SV

The illustration shows the front right side of the

engine compartment.

1.Press the lever shown:

>downward for the right turn signal

>upward for the left turn signal

2.Remove the bulb holder towards the rear.

3.Remove and replace the bulb.

Turn signal lamp 2

21-watt bulb, WY21SV

The bulb for the turn signal lamp 2 can be

replaced via the wheel well.

The illustration shows the front left side of the

vehicle.

1.Steering turned all the way to the left or

right.

2.Turn off the light, switch off the ignition and

remove the remote control from the ignition

lock.

Page 213 of 256

Mobility

211Reference

At a glance

Controls

Driving tips

Communications

Navigation

Entertainment

3.Unscrew the bolt 1 with an open-ended

wrench.

4.Turn the cover around the rear securing

point2 upward while simultaneously pulling

it out of the trim panel at the bottom.

5.Turn the bulb holder to the left and remove,

refer to arrow.

6.Remove and replace the bulb.

Side marker lamps

5-watt bulb, WY5WST

The bulb can be replaced via a cover at the front

of the wheel well, refer to the description for

turn signal lamp 2.

1.The bulb holder of the side marker lamp is

located toward the outside of the vehicle

next to the bulb holder of turn signal lamp 2.

2.Turn the bulb holder to the left and remove.

3.Remove and replace the bulb.

Side turn signals

5-watt bulb, WY5W

1.Press against the front edge of the lamp

with the tip of your finger, then push it to the

rear, release the snap connection at the

front and take it off the trim strip.

2.Turn the bulb holder to the left by 905 and

remove.

3.Remove and replace the bulb.

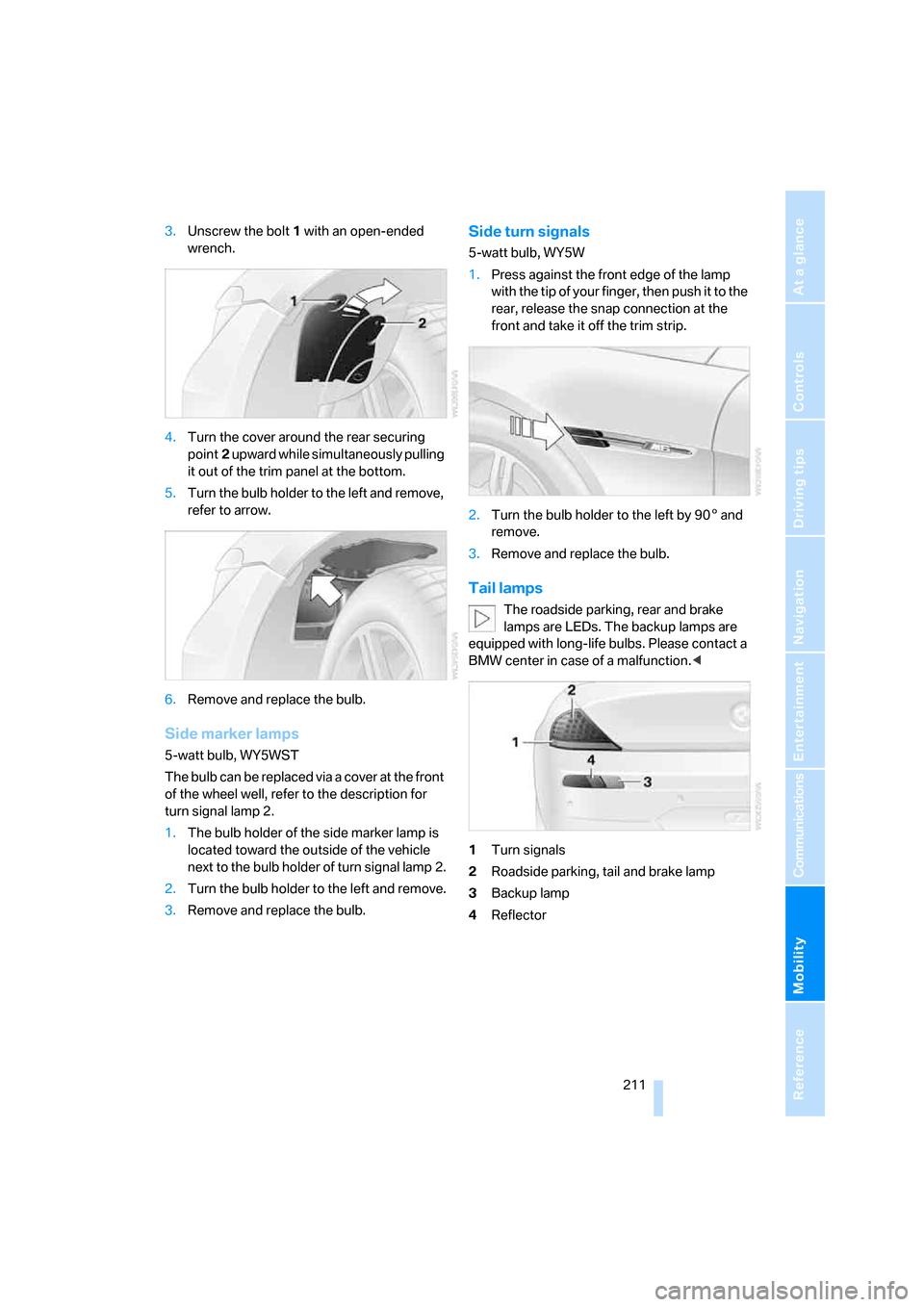

Tail lamps

The roadside parking, rear and brake

lamps are LEDs. The backup lamps are

equipped with long-life bulbs. Please contact a

BMW center in case of a malfunction.<

1Turn signals

2Roadside parking, tail and brake lamp

3Backup lamp

4Reflector

Page 214 of 256

Replacing components

212

Rear turn signals

21-watt bulb, PY21W

The illustrations shows the left section of the

luggage compartment.

1.Remove the cover.

2.Unclip the bulb holder and remove.

3.Apply gentle pressure to the bulb while

turning it to the left for removal and replace-

ment.

License plate lamps

5-watt bulb, W5W

1.Push a screwdriver from the left under the

lamp and pry out the lamp toward the right.

2.Turn the bulb holder to the left by 905 and

remove.

3.Remove and replace the bulb.

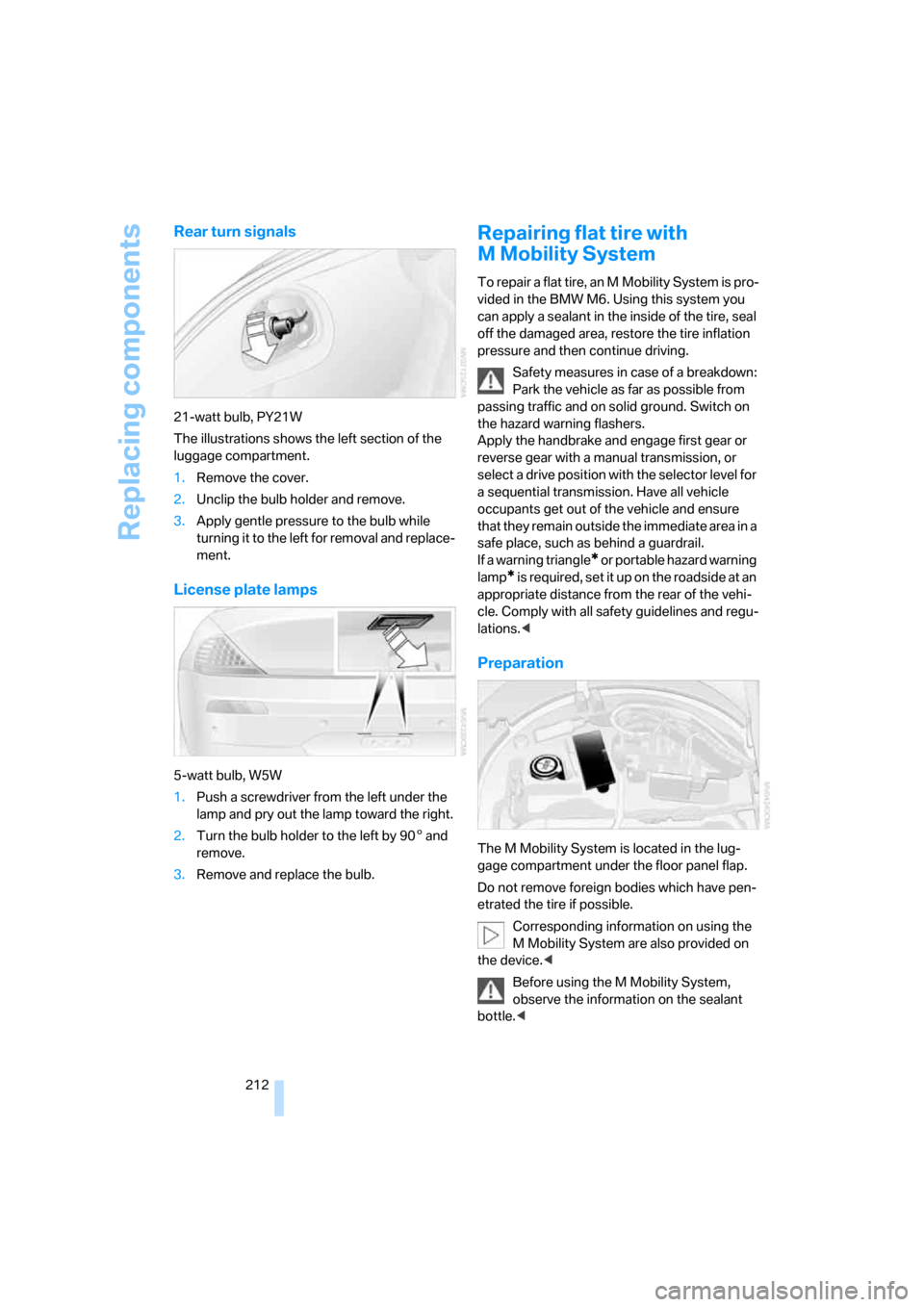

Repairing flat tire with

M Mobility System

To repair a flat tire, an M Mobility System is pro-

vided in the BMW M6. Using this system you

can apply a sealant in the inside of the tire, seal

off the damaged area, restore the tire inflation

pressure and then continue driving.

Safety measures in case of a breakdown:

Park the vehicle as far as possible from

passing traffic and on solid ground. Switch on

the hazard warning flashers.

Apply the handbrake and engage first gear or

reverse gear with a manual transmission, or

select a drive position with the selector level for

a sequential transmission. Have all vehicle

occupants get out of the vehicle and ensure

that they remain outside the immediate area in a

safe place, such as behind a guardrail.

If a warning triangle

* or portable hazard warning

lamp

* is required, set it up on the roadside at an

appropriate distance from the rear of the vehi-

cle. Comply with all safety guidelines and regu-

lations.<

Preparation

The M Mobility System is located in the lug-

gage compartment under the floor panel flap.

Do not remove foreign bodies which have pen-

etrated the tire if possible.

Corresponding information on using the

M Mobility System are also provided on

the device.<

Before using the M Mobility System,

observe the information on the sealant

bottle.<

Page 215 of 256

Mobility

213Reference

At a glance

Controls

Driving tips

Communications

Navigation

Entertainment

Pull the sticker for the speed limit off the sealant

bottle and apply it to the steering wheel.

Please observe the best-by date on the

sealant bottle.<

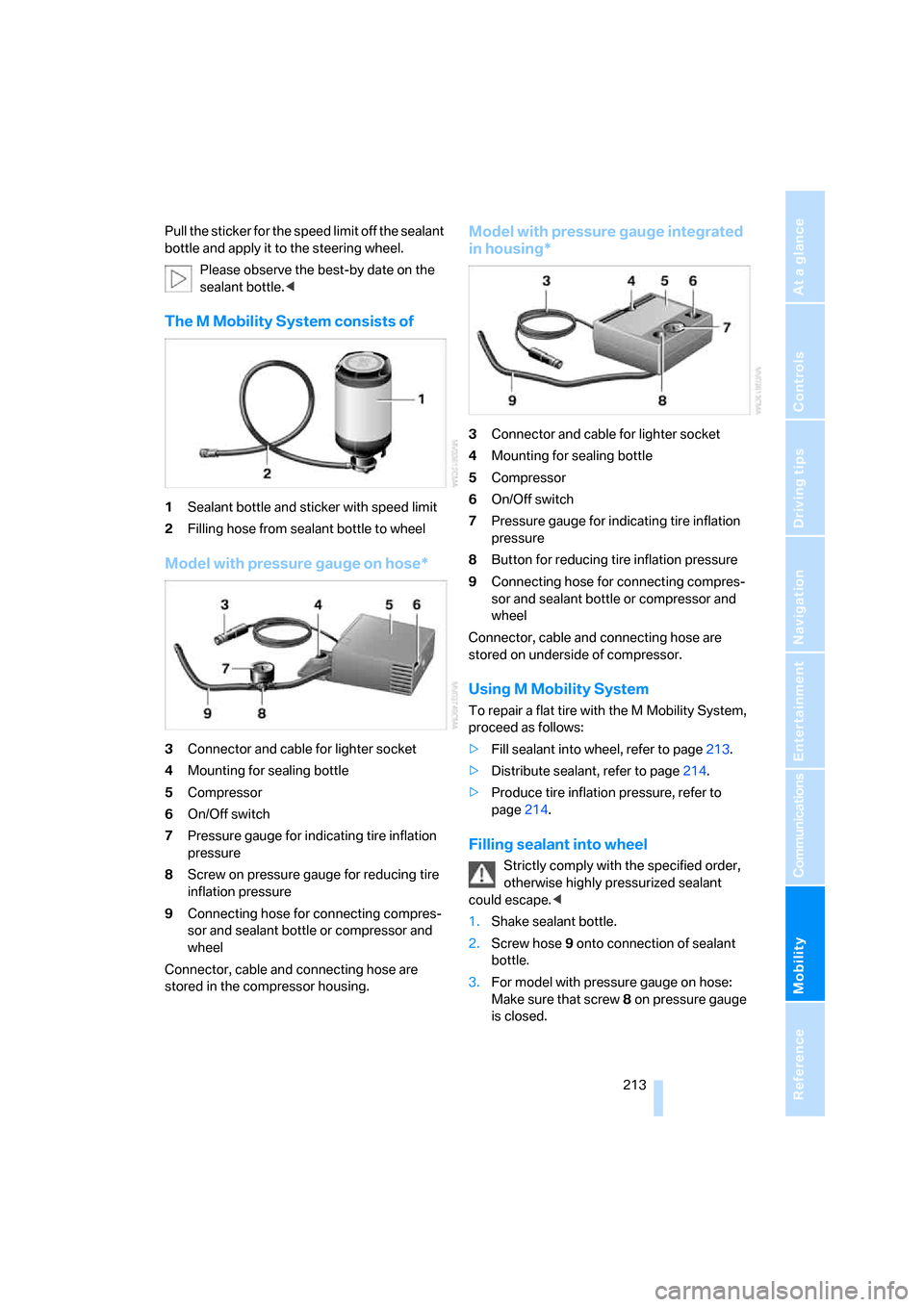

The M Mobility System consists of

1Sealant bottle and sticker with speed limit

2Filling hose from sealant bottle to wheel

Model with pressure gauge on hose*

3Connector and cable for lighter socket

4Mounting for sealing bottle

5Compressor

6On/Off switch

7Pressure gauge for indicating tire inflation

pressure

8Screw on pressure gauge for reducing tire

inflation pressure

9Connecting hose for connecting compres-

sor and sealant bottle or compressor and

wheel

Connector, cable and connecting hose are

stored in the compressor housing.

Model with pressure gauge integrated

in housing*

3Connector and cable for lighter socket

4Mounting for sealing bottle

5Compressor

6On/Off switch

7Pressure gauge for indicating tire inflation

pressure

8Button for reducing tire inflation pressure

9Connecting hose for connecting compres-

sor and sealant bottle or compressor and

wheel

Connector, cable and connecting hose are

stored on underside of compressor.

Using M Mobility System

To repair a flat tire with the M Mobility System,

proceed as follows:

>Fill sealant into wheel, refer to page213.

>Distribute sealant, refer to page214.

>Produce tire inflation pressure, refer to

page214.

Filling sealant into wheel

Strictly comply with the specified order,

otherwise highly pressurized sealant

could escape.<

1.Shake sealant bottle.

2.Screw hose9 onto connection of sealant

bottle.

3.For model with pressure gauge on hose:

Make sure that screw8 on pressure gauge

is closed.

Page 216 of 256

Replacing components

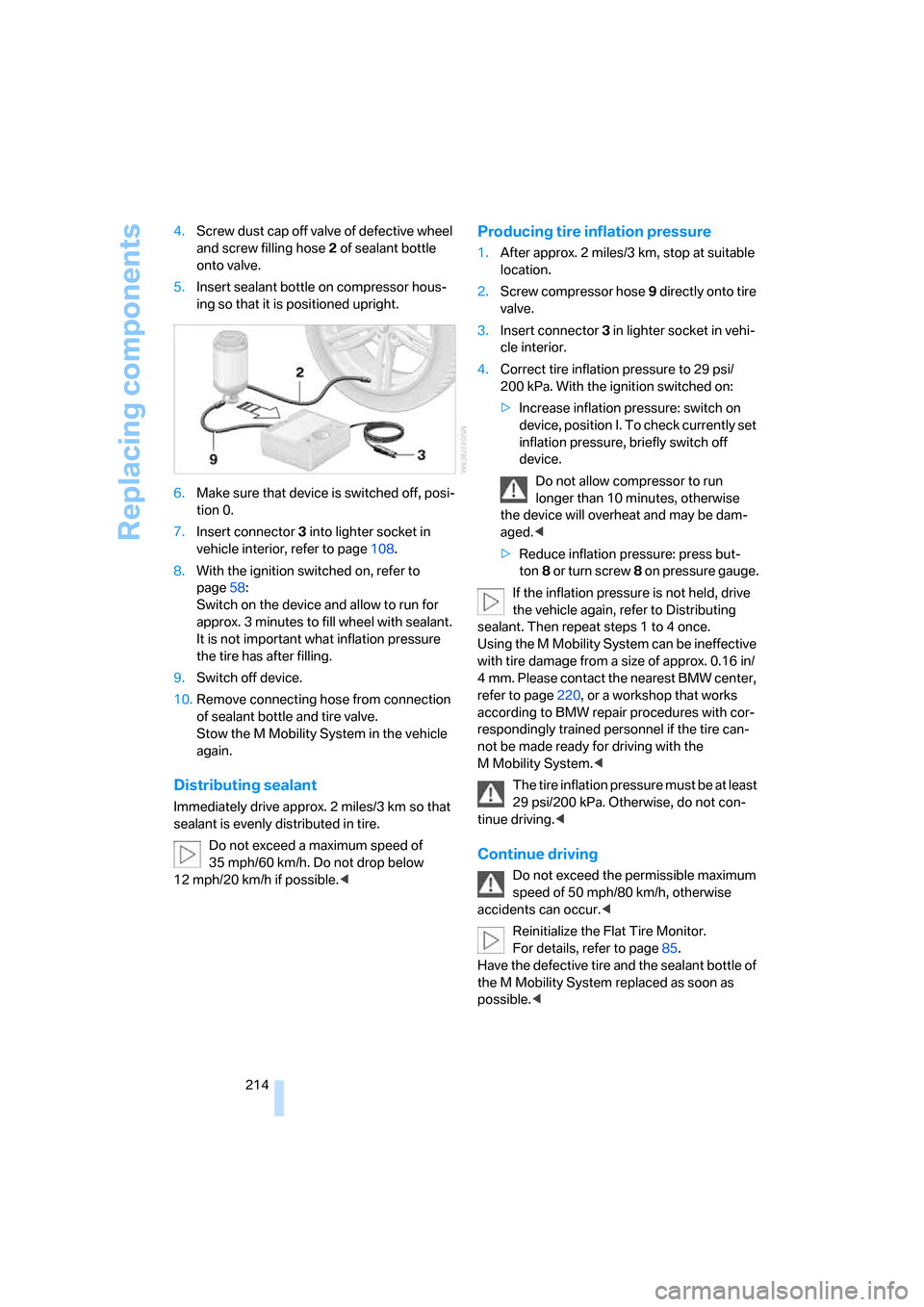

214 4.Screw dust cap off valve of defective wheel

and screw filling hose2 of sealant bottle

onto valve.

5.Insert sealant bottle on compressor hous-

ing so that it is positioned upright.

6.Make sure that device is switched off, posi-

tion 0.

7.Insert connector3 into lighter socket in

vehicle interior, refer to page108.

8.With the ignition switched on, refer to

page58:

Switch on the device and allow to run for

approx. 3 minutes to fill wheel with sealant.

It is not important what inflation pressure

the tire has after filling.

9.Switch off device.

10.Remove connecting hose from connection

of sealant bottle and tire valve.

Stow the M Mobility System in the vehicle

again.

Distributing sealant

Immediately drive approx. 2 miles/3 km so that

sealant is evenly distributed in tire.

Do not exceed a maximum speed of

35 mph/60 km/h. Do not drop below

12 mph/20 km/h if possible.<

Producing tire inflation pressure

1.After approx. 2 miles/3 km, stop at suitable

location.

2.Screw compressor hose9 directly onto tire

valve.

3.Insert connector 3 in lighter socket in vehi-

cle interior.

4.Correct tire inflation pressure to 29 psi/

200 kPa. With the ignition switched on:

>Increase inflation pressure: switch on

device, position I. To check currently set

inflation pressure, briefly switch off

device.

Do not allow compressor to run

longer than 10 minutes, otherwise

the device will overheat and may be dam-

aged.<

>Reduce inflation pressure: press but-

ton8 or turn s crew8 on pressure gauge.

If the inflation pressure is not held, drive

the vehicle again, refer to Distributing

sealant. Then repeat steps 1 to 4 once.

Using the M Mobility System can be ineffective

with tire damage from a size of approx. 0.16 in/

4 mm. Please contact the nearest BMW center,

refer to page220, or a workshop that works

according to BMW repair procedures with cor-

respondingly trained personnel if the tire can-

not be made ready for driving with the

M Mobility System.<

The tire inflation pressure must be at least

29 psi/200 kPa. Otherwise, do not con-

tinue driving.<

Continue driving

Do not exceed the permissible maximum

speed of 50 mph/80 km/h, otherwise

accidents can occur.<

Reinitialize the Flat Tire Monitor.

For details, refer to page85.

Have the defective tire and the sealant bottle of

the M Mobility System replaced as soon as

possible.<

Page 217 of 256

Mobility

215Reference

At a glance

Controls

Driving tips

Communications

Navigation

Entertainment

Changing wheels*

Safety precautions in the event of a flat

tire or wheel change: Park the vehicle as

far as possible from passing traffic and on solid

ground. Switch on the hazard warning flashers.

Apply the handbrake and engage first gear or

reverse gear with a manual transmission, or

select a drive position with the selector level for

a sequential transmission.

Have all vehicle occupants get out of the vehicle

and ensure that they remain outside the imme-

diate area in a safe place, such as behind a

guardrail.

If a warning triangle

* or portable hazard warning

lamp

* is r e q u ir e d , s e t i t up o n t h e ro a d s id e a t a n

appropriate distance from the rear of the vehi-

cle. Comply with all safety guidelines and regu-

lations.

Change the wheel only on a level, firm surface

which is not slippery. The vehicle or the jack

could slip to the side if you attempt to raise the

vehicle on a soft or slippery surface such as

snow, ice, tiles, etc.

Position the jack on a firm support surface.

Do not use a wooden block or similar object as a

support base for the jack, as this would prevent

it from extending to its full support height and

reduce its load-carrying capacity.

To avoid serious or fatal injury: never lie under

the vehicle, and never start the engine while it is

supported by the jack.<

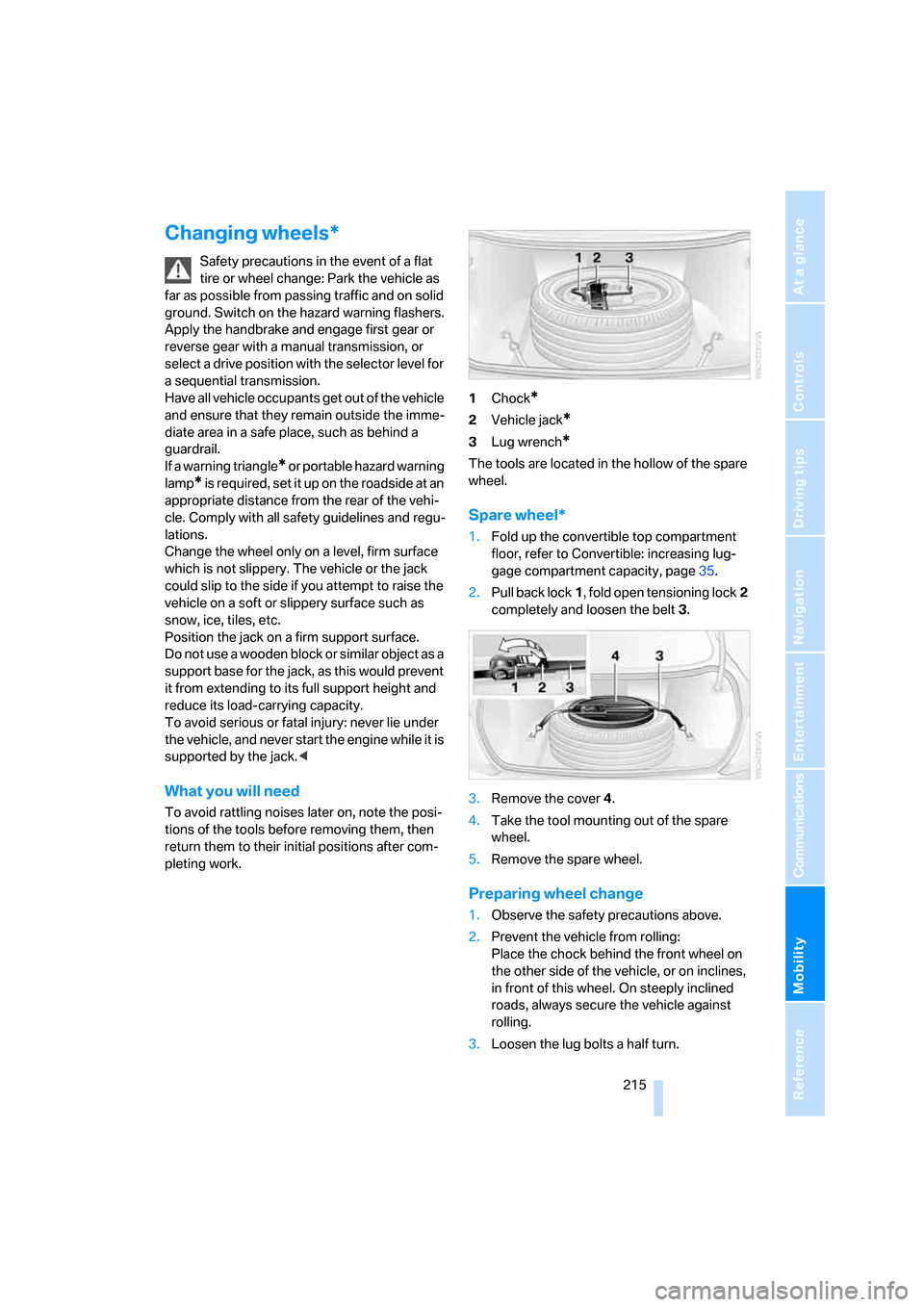

What you will need

To avoid rattling noises later on, note the posi-

tions of the tools before removing them, then

return them to their initial positions after com-

pleting work.1Chock

*

2Vehicle jack*

3Lug wrench*

The tools are located in the hollow of the spare

wheel.

Spare wheel*

1.Fold up the convertible top compartment

floor, refer to Convertible: increasing lug-

gage compartment capacity, page35.

2.Pull back lock1, fold open tensioning lock2

completely and loosen the belt3.

3.Remove the cover4.

4.Take the tool mounting out of the spare

wheel.

5.Remove the spare wheel.

Preparing wheel change

1.Observe the safety precautions above.

2.Prevent the vehicle from rolling:

Place the chock behind the front wheel on

the other side of the vehicle, or on inclines,

in front of this wheel. On steeply inclined

roads, always secure the vehicle against

rolling.

3.Loosen the lug bolts a half turn.

Page 218 of 256

Replacing components

216

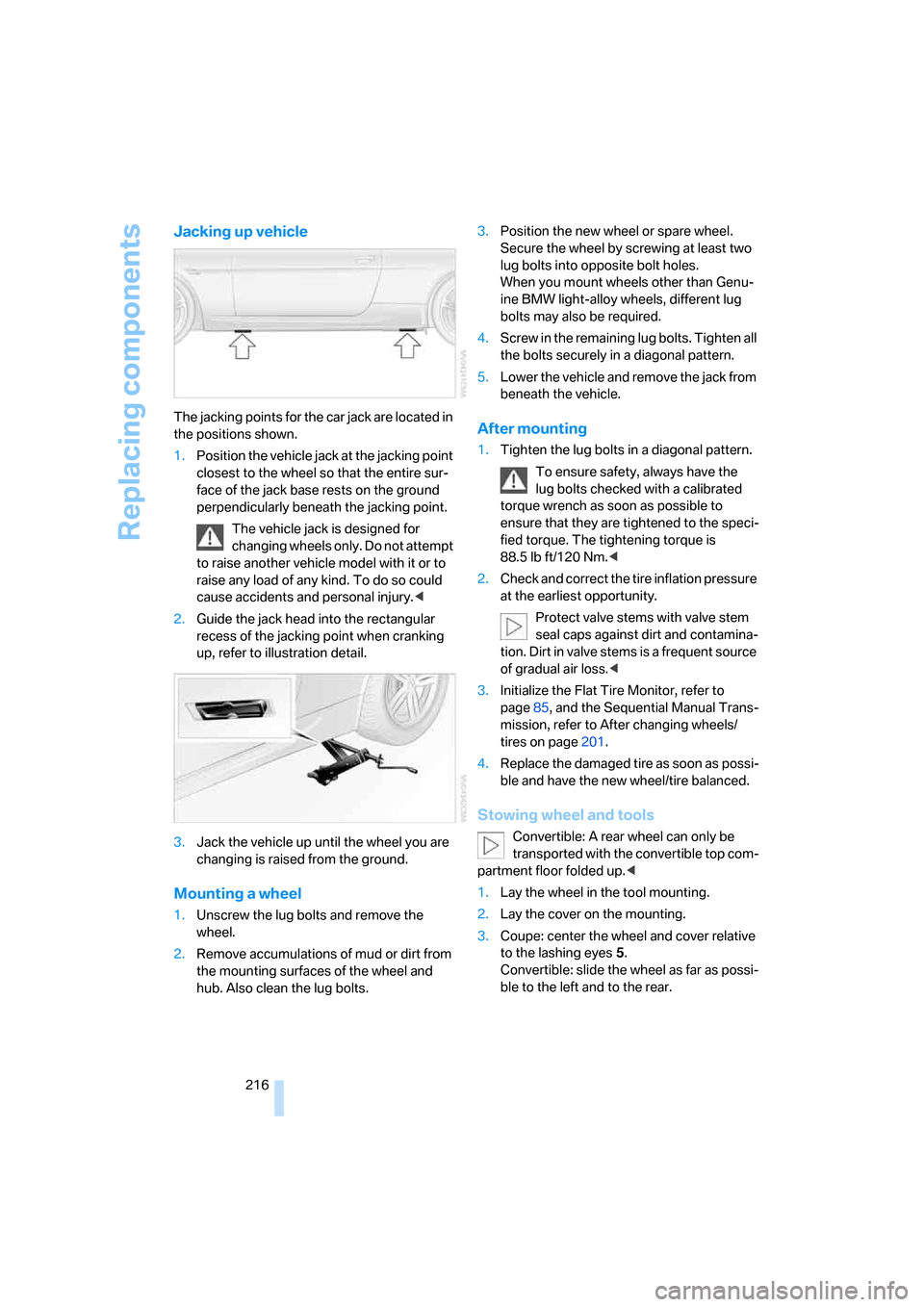

Jacking up vehicle

The jacking points for the car jack are located in

the positions shown.

1.Position the vehicle jack at the jacking point

closest to the wheel so that the entire sur-

face of the jack base rests on the ground

perpendicularly beneath the jacking point.

The vehicle jack is designed for

changing wheels only. Do not attempt

to raise another vehicle model with it or to

raise any load of any kind. To do so could

cause accidents and personal injury.<

2.Guide the jack head into the rectangular

recess of the jacking point when cranking

up, refer to illustration detail.

3.Jack the vehicle up until the wheel you are

changing is raised from the ground.

Mounting a wheel

1.Unscrew the lug bolts and remove the

wheel.

2.Remove accumulations of mud or dirt from

the mounting surfaces of the wheel and

hub. Also clean the lug bolts.3.Position the new wheel or spare wheel.

Secure the wheel by screwing at least two

lug bolts into opposite bolt holes.

When you mount wheels other than Genu-

ine BMW light-alloy wheels, different lug

bolts may also be required.

4.Screw in the remaining lug bolts. Tighten all

the bolts securely in a diagonal pattern.

5.Lower the vehicle and remove the jack from

beneath the vehicle.

After mounting

1.Tighten the lug bolts in a diagonal pattern.

To ensure safety, always have the

lug bolts checked with a calibrated

torque wrench as soon as possible to

ensure that they are tightened to the speci-

fied torque. The tightening torque is

88.5 lb ft/120 Nm.<

2.Check and correct the tire inflation pressure

at the earliest opportunity.

Protect valve stems with valve stem

seal caps against dirt and contamina-

tion. Dirt in valve stems is a frequent source

of gradual air loss.<

3.Initialize the Flat Tire Monitor, refer to

page85, and the Sequential Manual Trans-

mission, refer to After changing wheels/

tires on page201.

4.Replace the damaged tire as soon as possi-

ble and have the new wheel/tire balanced.

Stowing wheel and tools

Convertible: A rear wheel can only be

transported with the convertible top com-

partment floor folded up.<

1.Lay the wheel in the tool mounting.

2.Lay the cover on the mounting.

3.Coupe: center the wheel and cover relative

to the lashing eyes5.

Convertible: slide the wheel as far as possi-

ble to the left and to the rear.

Page 219 of 256

Mobility

217Reference

At a glance

Controls

Driving tips

Communications

Navigation

Entertainment

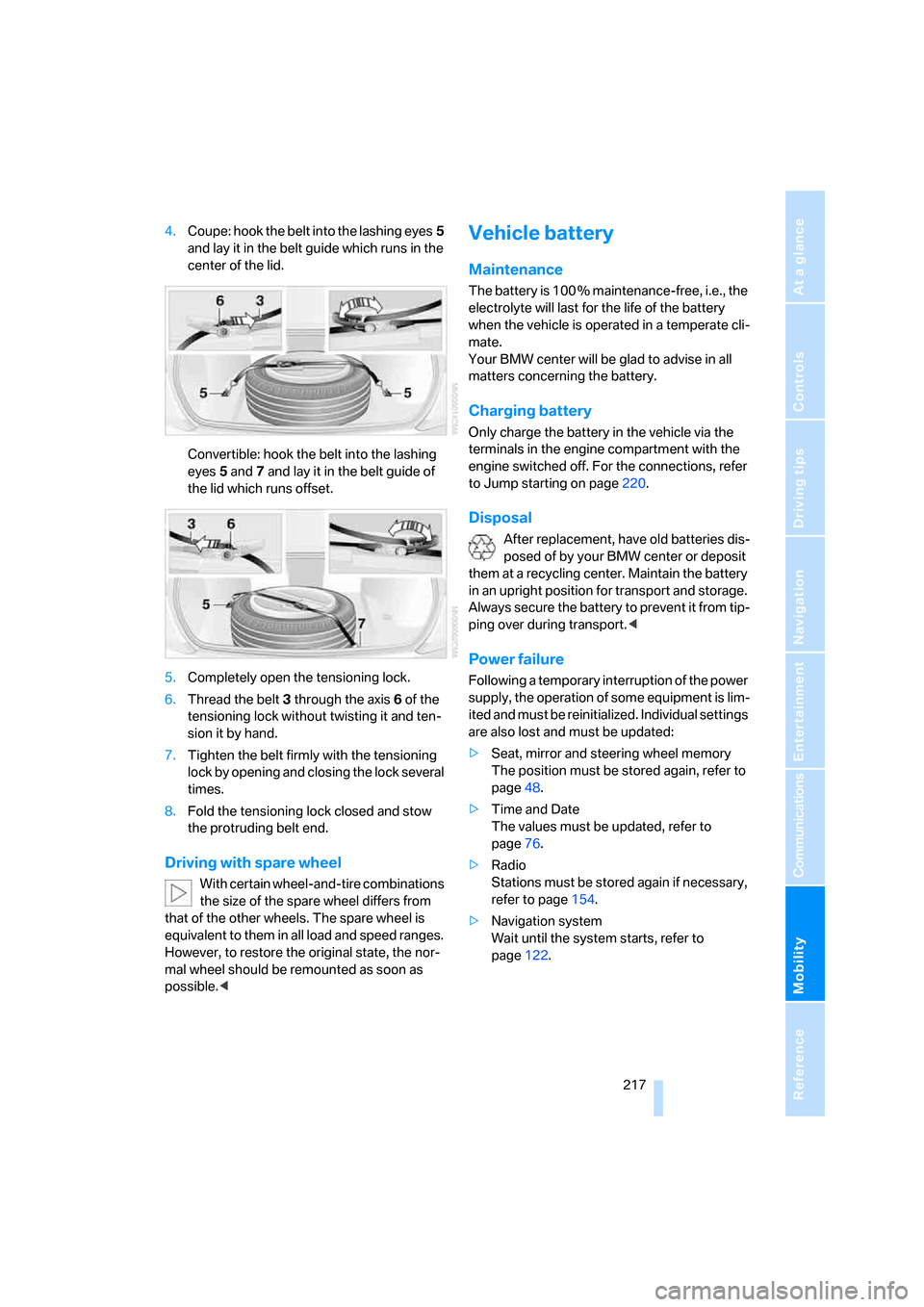

4.Coupe: hook the belt into the lashing eyes5

and lay it in the belt guide which runs in the

center of the lid.

Convertible: hook the belt into the lashing

eyes5 and7 and lay it in the belt guide of

the lid which runs offset.

5.Completely open the tensioning lock.

6.Thread the belt3 through the axis6 of the

tensioning lock without twisting it and ten-

sion it by hand.

7.Tighten the belt firmly with the tensioning

lock by opening and closing the lock several

times.

8.Fold the tensioning lock closed and stow

the protruding belt end.

Driving with spare wheel

With certain wheel-and-tire combinations

the size of the spare wheel differs from

that of the other wheels. The spare wheel is

equivalent to them in all load and speed ranges.

However, to restore the original state, the nor-

mal wheel should be remounted as soon as

possible.<

Vehicle battery

Maintenance

The battery is 100 % maintenance-free, i.e., the

electrolyte will last for the life of the battery

when the vehicle is operated in a temperate cli-

mate.

Your BMW center will be glad to advise in all

matters concerning the battery.

Charging battery

Only charge the battery in the vehicle via the

terminals in the engine compartment with the

engine switched off. For the connections, refer

to Jump starting on page220.

Disposal

After replacement, have old batteries dis-

posed of by your BMW center or deposit

them at a recycling center. Maintain the battery

in an upright position for transport and storage.

Always secure the battery to prevent it from tip-

ping over during transport.<

Power failure

Following a temporary interruption of the power

supply, the operation of some equipment is lim-

ited and must be reinitialized. Individual settings

are also lost and must be updated:

>Seat, mirror and steering wheel memory

The position must be stored again, refer to

page48.

>Time and Date

The values must be updated, refer to

page76.

>Radio

Stations must be stored again if necessary,

refer to page154.

>Navigation system

Wait until the system starts, refer to

page122.

Page 220 of 256

Replacing components

218

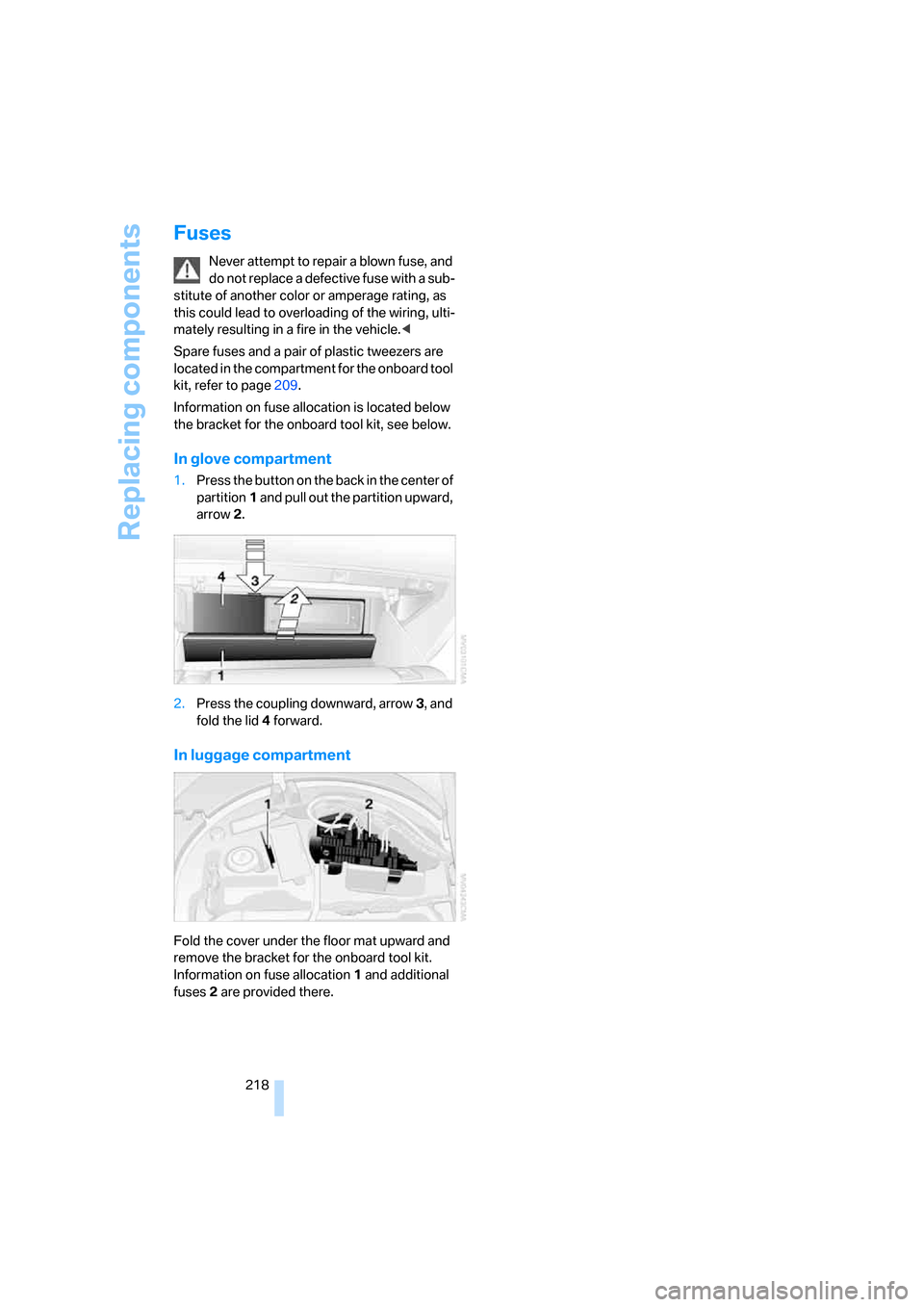

Fuses

Never attempt to repair a blown fuse, and

do not replace a defective fuse with a sub-

stitute of another color or amperage rating, as

this could lead to overloading of the wiring, ulti-

mately resulting in a fire in the vehicle.<

Spare fuses and a pair of plastic tweezers are

located in the compartment for the onboard tool

kit, refer to page209.

Information on fuse allocation is located below

the bracket for the onboard tool kit, see below.

In glove compartment

1.Press the button on the back in the center of

partition1 and pull out the partition upward,

arrow2.

2.Press the coupling downward, arrow3, and

fold the lid 4 forward.

In luggage compartment

Fold the cover under the floor mat upward and

remove the bracket for the onboard tool kit.

Information on fuse allocation1 and additional

fuses2 are provided there.