torque BMW MOTORRAD K 1200 S 2004 Rider's Manual (in English)

[x] Cancel search | Manufacturer: BMW MOTORRAD, Model Year: 2004, Model line: K 1200 S, Model: BMW MOTORRAD K 1200 S 2004Pages: 162, PDF Size: 2.99 MB

Page 86 of 162

Maintenance684

The "Maintenance" chapter

describes work involving the

replacement of wear parts that

can be performed with mini-

mum effort.

The types of screws used for

the components concerned

are listed on (

b 124-125). You

can use this chart to set aside

the required tools.

If special tightening torques

are to be taken into account

for assembly, these are also

listed. Screw connections for

which there is a suitable tool

in the toolkit are marked

additionally.If you are interested in informa-

tion on more extensive work,

we recommend the repair

manual on CD-ROM which

applies to your particular

motorcycle. You can obtain a

copy of this from your author-

ised BMW motorcycle dealer.

Page 99 of 162

697Maintenance

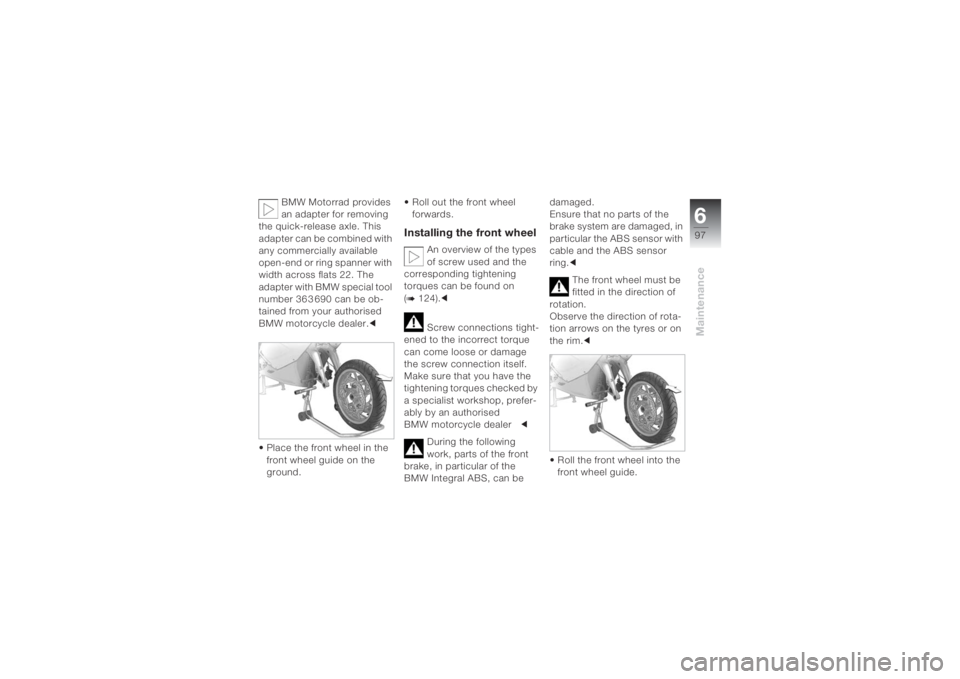

BMW Motorrad provides

an adapter for removing

the quick-release axle. This

adapter can be combined with

any commercially available

open-end or ring spanner with

width across flats 22. The

adapter with BMW special tool

number 36 3 690 can be ob-

tained from your authorised

BMW motorcycle dealer.c

• Place the front wheel in the

front wheel guide on the

ground.• Roll out the front wheel

forwards.

Installing the front wheel

An overview of the types

of screw used and the

corresponding tightening

torques can be found on

(

b 124).c

Screw connections tight-

ened to the incorrect torque

can come loose or damage

the screw connection itself.

Make sure that you have the

tightening torques checked by

a specialist workshop, prefer-

ably by an authorised

BMW motorcycle dealerc

During the following

work, parts of the front

brake, in particular of the

BMW Integral ABS, can be damaged.

Ensure that no parts of the

brake system are damaged, in

particular the ABS sensor with

cable and the ABS sensor

ring.c

The front wheel must be

fitted in the direction of

rotation.

Observe the direction of rota-

tion arrows on the tyres or on

the rim.c

• Roll the front wheel into the

front wheel guide.

Page 100 of 162

Maintenance698

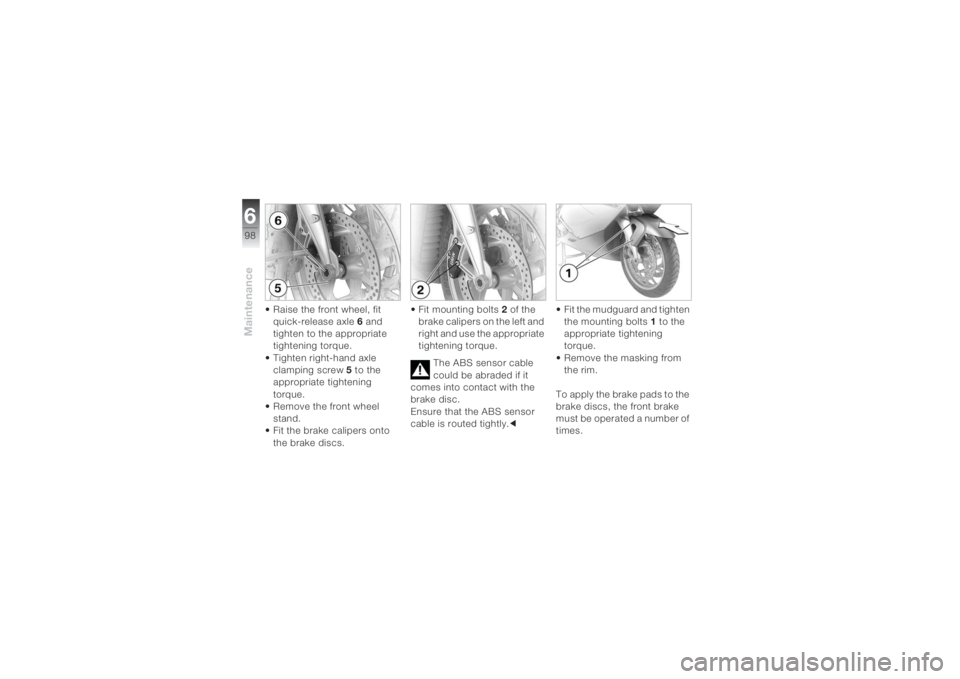

• Raise the front wheel, fit

quick-release axle 6 and

tighten to the appropriate

tightening torque.

• Tighten right-hand axle

clamping screw 5 to the

appropriate tightening

torque.

• Remove the front wheel

stand.

• Fit the brake calipers onto

the brake discs.• Fit mounting bolts 2 of the

brake calipers on the left and

right and use the appropriate

tightening torque.

The ABS sensor cable

could be abraded if it

comes into contact with the

brake disc.

Ensure that the ABS sensor

cable is routed tightly.c• Fit the mudguard and tighten

the mounting bolts1 to the

appropriate tightening

torque.

• Remove the masking from

the rim.

To apply the brake pads to the

brake discs, the front brake

must be operated a number of

times.

Page 102 of 162

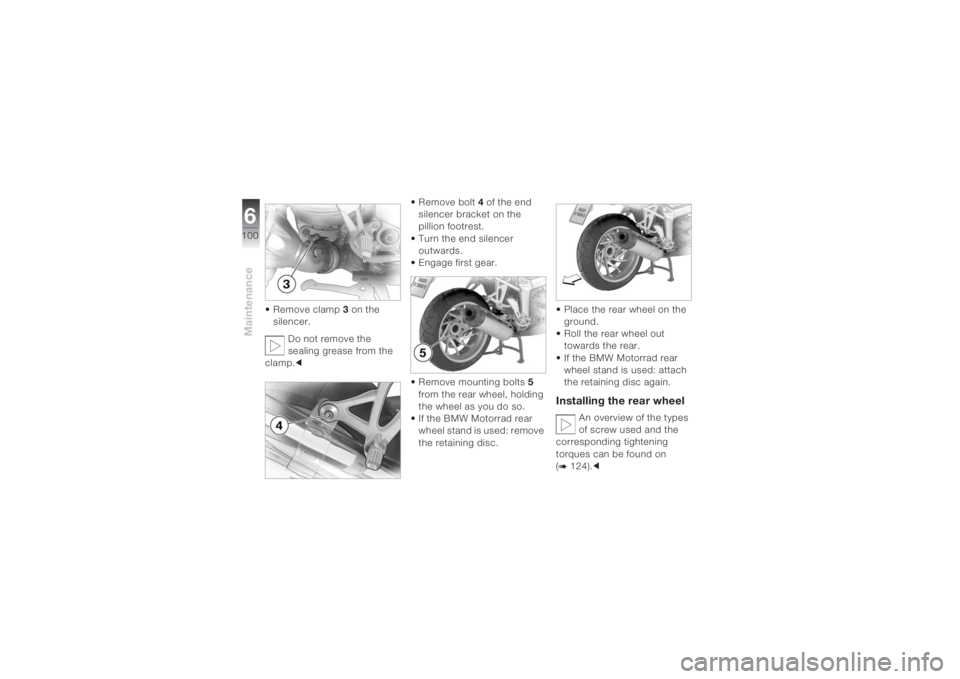

Maintenance6100

• Remove clamp3 on the

silencer.

Do not remove the

sealing grease from the

clamp.c• Remove bolt4 of the end

silencer bracket on the

pillion footrest.

• Turn the end silencer

outwards.

• Engage first gear.

• Remove mounting bolts5

from the rear wheel, holding

the wheel as you do so.

• If the BMW Motorrad rear

wheel stand is used: remove

the retaining disc.• Place the rear wheel on the

ground.

• Roll the rear wheel out

towards the rear.

• If the BMW Motorrad rear

wheel stand is used: attach

the retaining disc again.

Installing the rear wheel

An overview of the types

of screw used and the

corresponding tightening

torques can be found on

(

b 124).c

Page 103 of 162

6101

Maintenance

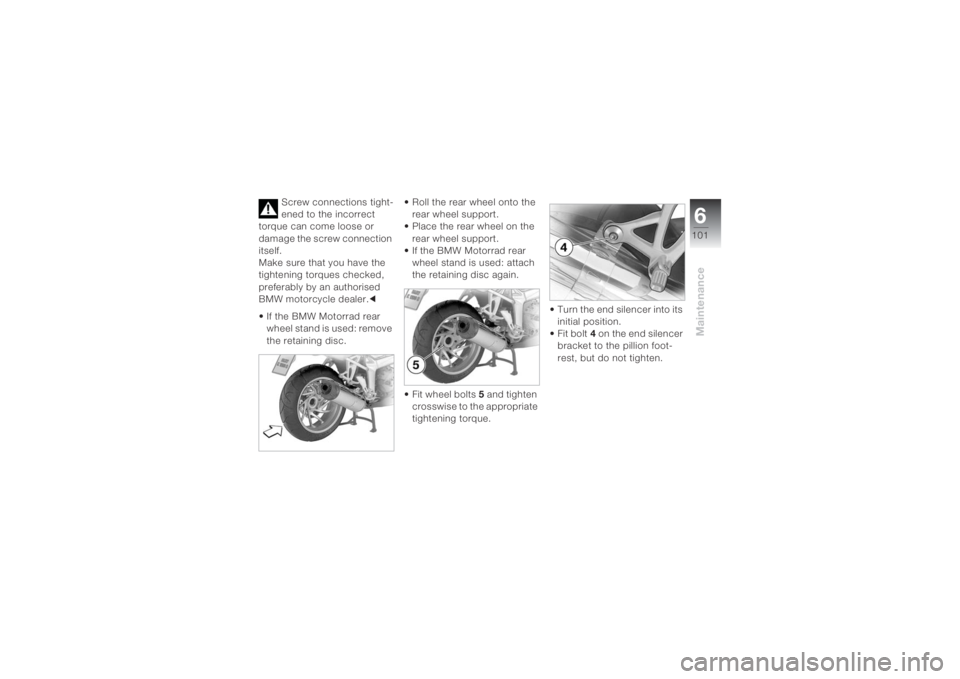

Screw connections tight-

ened to the incorrect

torque can come loose or

damage the screw connection

itself.

Make sure that you have the

tightening torques checked,

preferably by an authorised

BMW motorcycle dealer.c

• If the BMW Motorrad rear

wheel stand is used: remove

the retaining disc.• Roll the rear wheel onto the

rear wheel support.

• Place the rear wheel on the

rear wheel support.

• If the BMW Motorrad rear

wheel stand is used: attach

the retaining disc again.

• Fit wheel bolts 5 and tighten

crosswise to the appropriate

tightening torque.• Turn the end silencer into its

initial position.

• Fit bolt4 on the end silencer

bracket to the pillion foot-

rest, but do not tighten.

Page 104 of 162

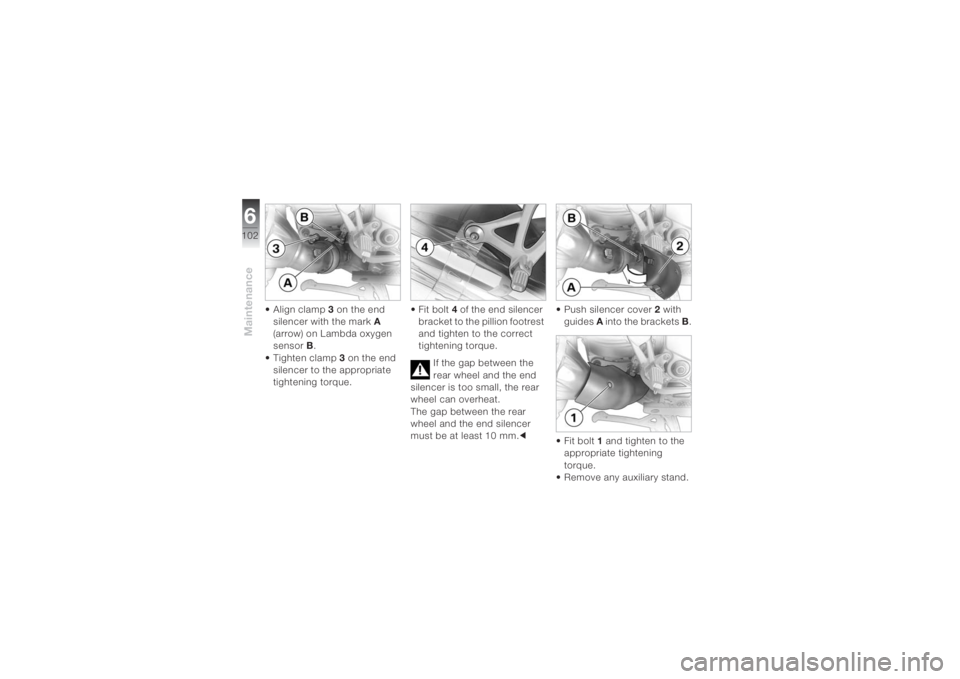

Maintenance6102

• Align clamp3 on the end

silencer with the markA

(arrow) on Lambda oxygen

sensor B.

• Tighten clamp3 on the end

silencer to the appropriate

tightening torque.• Fit bolt 4 of the end silencer

bracket to the pillion footrest

and tighten to the correct

tightening torque.

If the gap between the

rear wheel and the end

silencer is too small, the rear

wheel can overheat.

The gap between the rear

wheel and the end silencer

must be at least 10 mm.c• Push silencer cover 2 with

guides A into the brackets B.

• Fit bolt1 and tighten to the

appropriate tightening

torque.

• Remove any auxiliary stand.

Page 117 of 162

6115

Maintenance

• Remove negative battery

lead 2 first.

•Then remove the positive

battery lead 3.

•Undo screws 4 and pull the

retaining bracket backwards.• Lift the battery upwards; if it is

difficult to move, moving it

back and forth will help.

Installing the battery

An overview of the types of

screw used and the corre-

sponding tightening torques can

be found on (

b 125).c

During the work described

below, a motorcycle that

has been parked unsafely can

fall over.

Make sure that the motorcycle is

parked securely.c

• If necessary, ignition key in the

"ignition off" position.

• Place the battery in the battery

compartment, positive termi-

nal on the right in the direction

of travel.• Push the retaining bracket

over the battery; tighten the

screws to the appropriate

tightening torque.

• Fit the positive battery lead first

of all; tighten to the appropri-

ate tightening torque.

• Then fit the negative battery

lead; tighten to the appropriate

tightening torque.

• Fit the battery compartment

lid; tighten the screws to the

appropriate tightening torque.

• Switch on the ignition.

• Fully open the throttle once or

twice.

» The engine management

system records the throttle-

valve position.

After connecting the

battery, the time must be

reset.c

Page 126 of 162

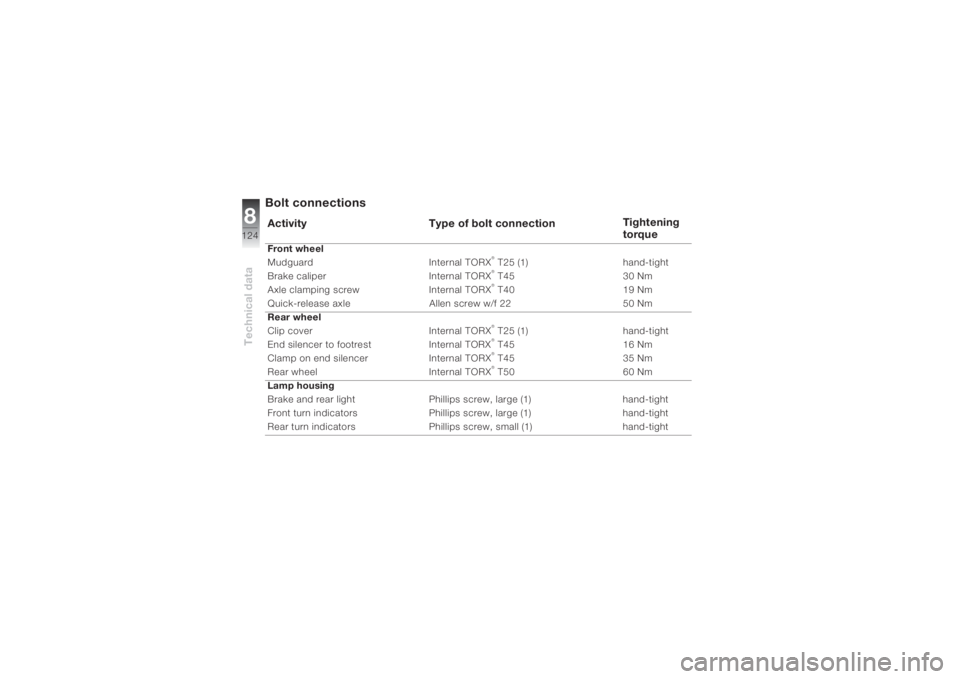

Technical data8124

Bolt connections Activity Type of bolt connectionTightening

torqueFront wheel

Mudguard Internal TORX

® T25 (1) hand-tight

Brake caliper Internal TORX® T45 30 Nm

Axle clamping screw Internal TORX® T40 19 Nm

Quick-release axle Allen screw w/f 22 50 Nm

Rear wheel

Clip cover Internal TORX® T25 (1) hand-tight

End silencer to footrest Internal TORX® T45 16 Nm

Clamp on end silencer Internal TORX® T45 35 Nm

Rear wheel Internal TORX® T50 60 Nm

Lamp housing

Brake and rear light Phillips screw, large (1) hand-tight

Front turn indicators Phillips screw, large (1) hand-tight

Rear turn indicators Phillips screw, small (1) hand-tight

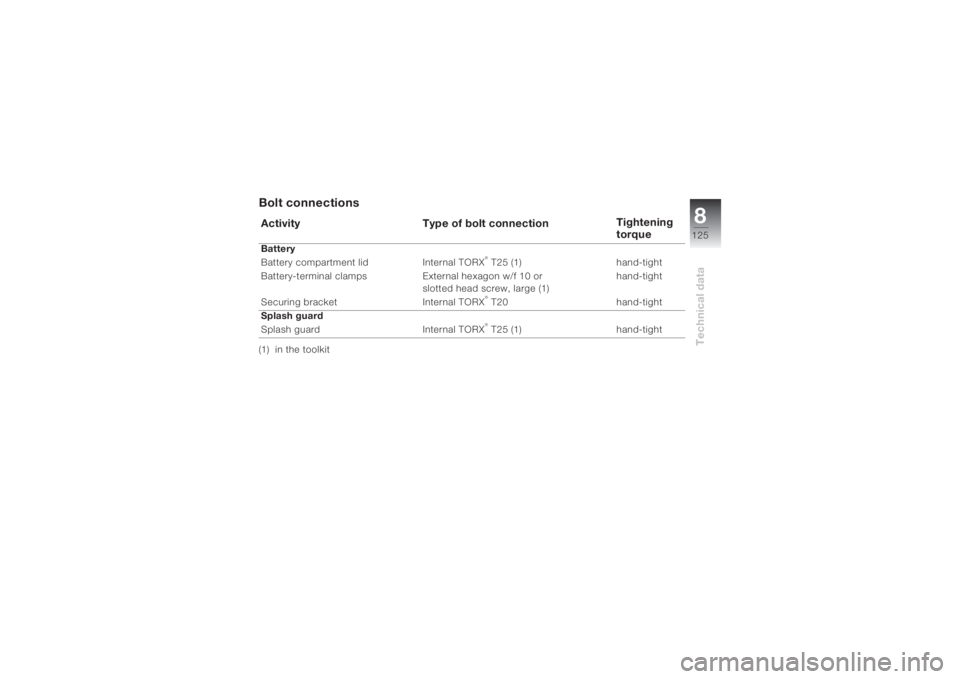

Page 127 of 162

8125

Technical data

Bolt connections(1) in the toolkitActivity Type of bolt connectionTightening

torqueBattery

Battery compartment lid Internal TORX

® T25 (1) hand-tight

Battery-terminal clamps External hexagon w/f 10 or

slotted head screw, large (1)hand-tight

Securing bracket Internal TORX® T20 hand-tight

Splash guard

Splash guard Internal TORX® T25 (1) hand-tight

Page 129 of 162

8127

Technical data

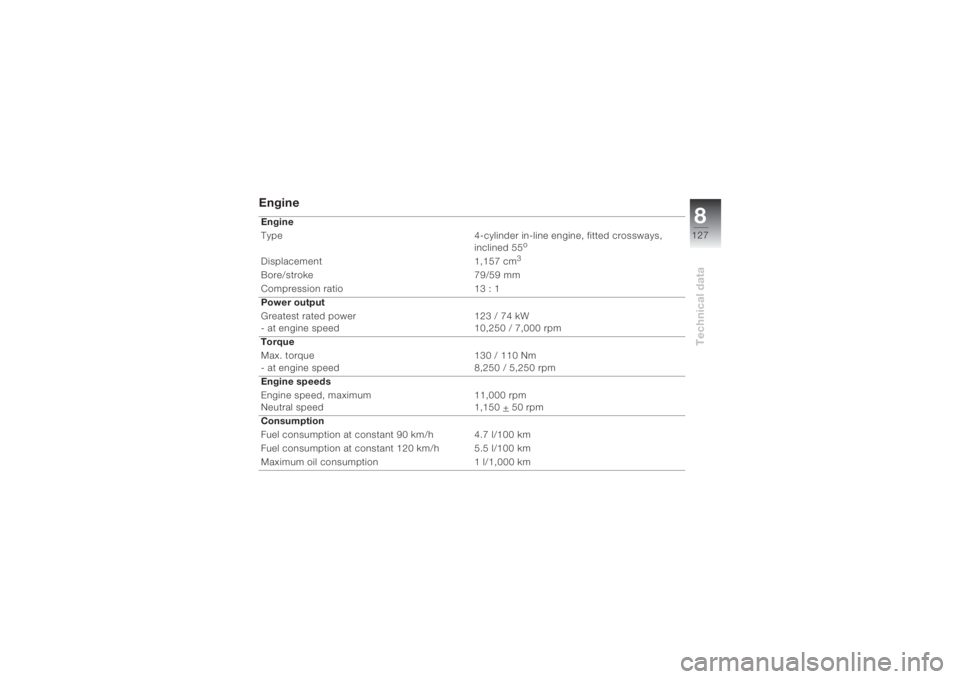

Engine Engine

Type 4-cylinder in-line engine, fitted crossways,

inclined 55

o

Displacement 1,157 cm

3

Bore/stroke 79/59 mm

Compression ratio 13 : 1

Power output

Greatest rated power

- at engine speed123 / 74 kW

10,250 / 7,000 rpm

Torque

Max. torque

- at engine speed 130 / 110 Nm

8,250 / 5,250 rpm

Engine speeds

Engine speed, maximum

Neutral speed11,000 rpm

1,150 +

50 rpm

Consumption

Fuel consumption at constant 90 km/h 4.7 l/100 km

Fuel consumption at constant 120 km/h 5.5 l/100 km

Maximum oil consumption 1 l/1,000 km