tow BMW X3 2017 Owner's Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 2017, Model line: X3, Model: BMW X3 2017Pages: 265, PDF Size: 5.37 MB

Page 187 of 265

Load

The maximum load is the sum of the weight of

the occupants and the cargo.

The greater the weight of the occupants, the

less cargo that can be transported.

Stowing cargo

▷Cover sharp edges and corners on the

cargo.▷Heavy cargo: stow as far forward as possi‐

ble, directly behind and at the bottom of

the rear passenger seat backrests.▷Very heavy cargo: when the rear seat is not

occupied, secure each of the outer safety

belts in the opposite buckle.▷If necessary, fold down the rear backrests

to stow cargo.▷Do not stack cargo above the top edge of

the backrests.▷Use the cargo area partition net, refer to

page 174, to protect passengers. Make

sure that objects cannot penetrate the

cargo area partition net.Securing cargo

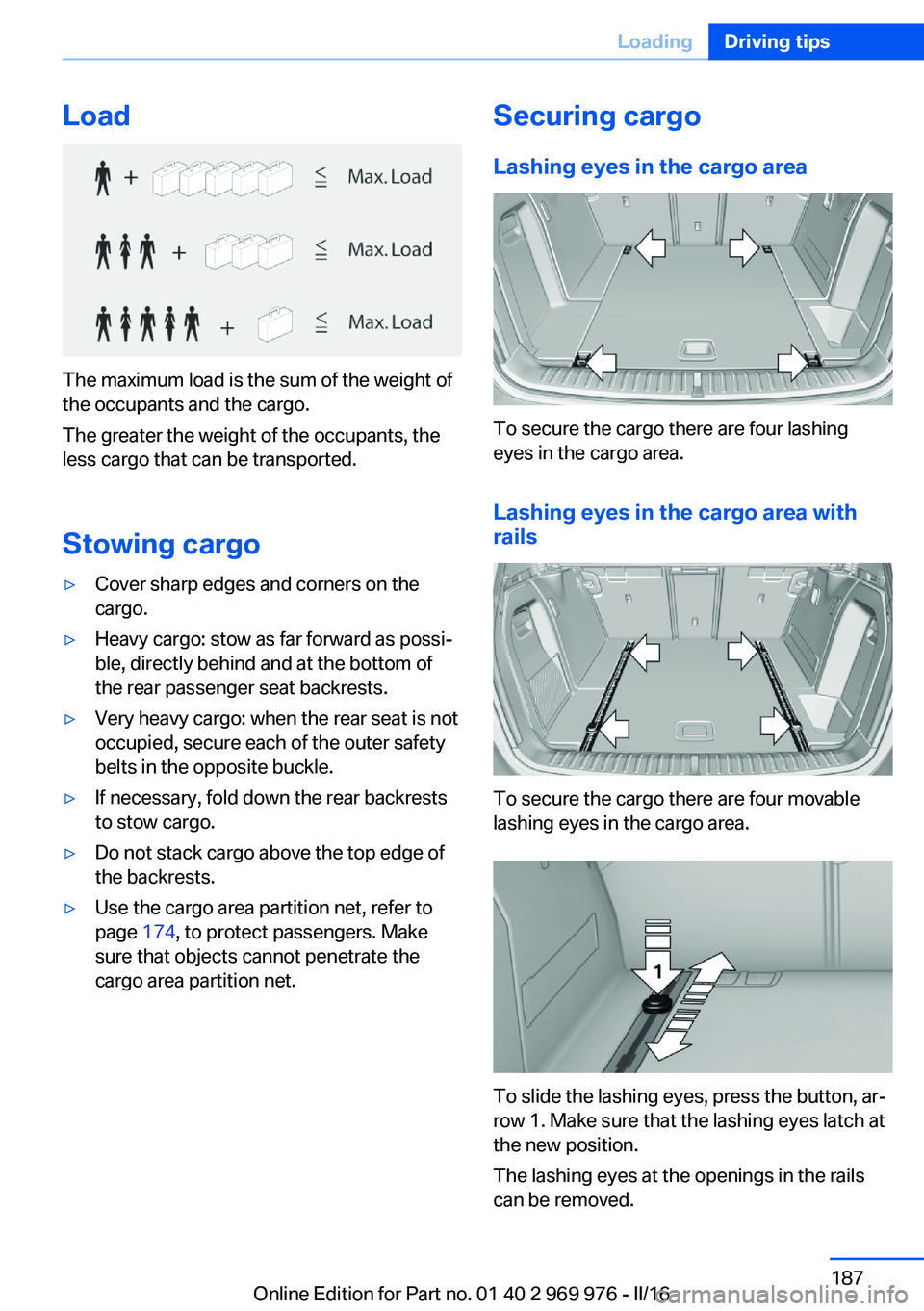

Lashing eyes in the cargo area

To secure the cargo there are four lashing

eyes in the cargo area.

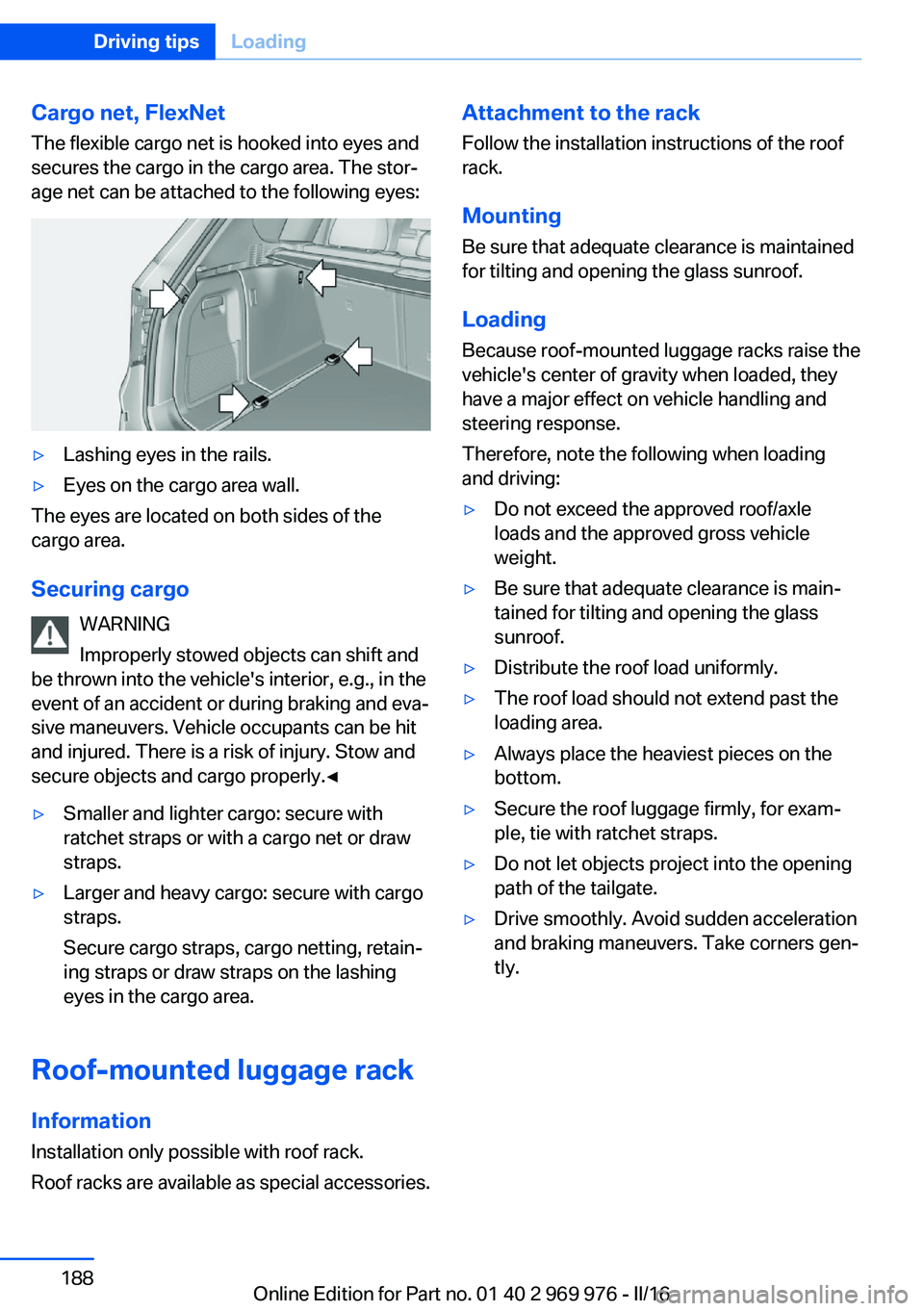

Lashing eyes in the cargo area with

rails

To secure the cargo there are four movable

lashing eyes in the cargo area.

To slide the lashing eyes, press the button, ar‐

row 1. Make sure that the lashing eyes latch at

the new position.

The lashing eyes at the openings in the rails

can be removed.

Seite 187LoadingDriving tips187

Online Edition for Part no. 01 40 2 969 976 - II/16

Page 188 of 265

Cargo net, FlexNetThe flexible cargo net is hooked into eyes and

secures the cargo in the cargo area. The stor‐

age net can be attached to the following eyes:▷Lashing eyes in the rails.▷Eyes on the cargo area wall.

The eyes are located on both sides of the

cargo area.

Securing cargo WARNING

Improperly stowed objects can shift and

be thrown into the vehicle's interior, e.g., in the

event of an accident or during braking and eva‐

sive maneuvers. Vehicle occupants can be hit

and injured. There is a risk of injury. Stow and

secure objects and cargo properly.◀

▷Smaller and lighter cargo: secure with

ratchet straps or with a cargo net or draw

straps.▷Larger and heavy cargo: secure with cargo

straps.

Secure cargo straps, cargo netting, retain‐

ing straps or draw straps on the lashing

eyes in the cargo area.

Roof-mounted luggage rack

Information

Installation only possible with roof rack.

Roof racks are available as special accessories.

Attachment to the rack Follow the installation instructions of the roof

rack.

Mounting

Be sure that adequate clearance is maintained

for tilting and opening the glass sunroof.

LoadingBecause roof-mounted luggage racks raise thevehicle's center of gravity when loaded, they

have a major effect on vehicle handling and

steering response.

Therefore, note the following when loading

and driving:▷Do not exceed the approved roof/axle

loads and the approved gross vehicle

weight.▷Be sure that adequate clearance is main‐

tained for tilting and opening the glass

sunroof.▷Distribute the roof load uniformly.▷The roof load should not extend past the

loading area.▷Always place the heaviest pieces on the

bottom.▷Secure the roof luggage firmly, for exam‐

ple, tie with ratchet straps.▷Do not let objects project into the opening

path of the tailgate.▷Drive smoothly. Avoid sudden acceleration

and braking maneuvers. Take corners gen‐

tly.Seite 188Driving tipsLoading188

Online Edition for Part no. 01 40 2 969 976 - II/16

Page 210 of 265

Tire treadSummer tires

Do not drive with a tire tread depth of less than

0.12 inches/3 mm.

There is an increased danger of hydroplaning if

the tire tread depth is less than 0.12 in‐

ches/3 mm.

Winter tires

Do not drive with a tire tread depth of less than

0.16 inches/4 mm.

Below a tread depth of 0.16 inches/4 mm, tires

are less suitable for winter operation.

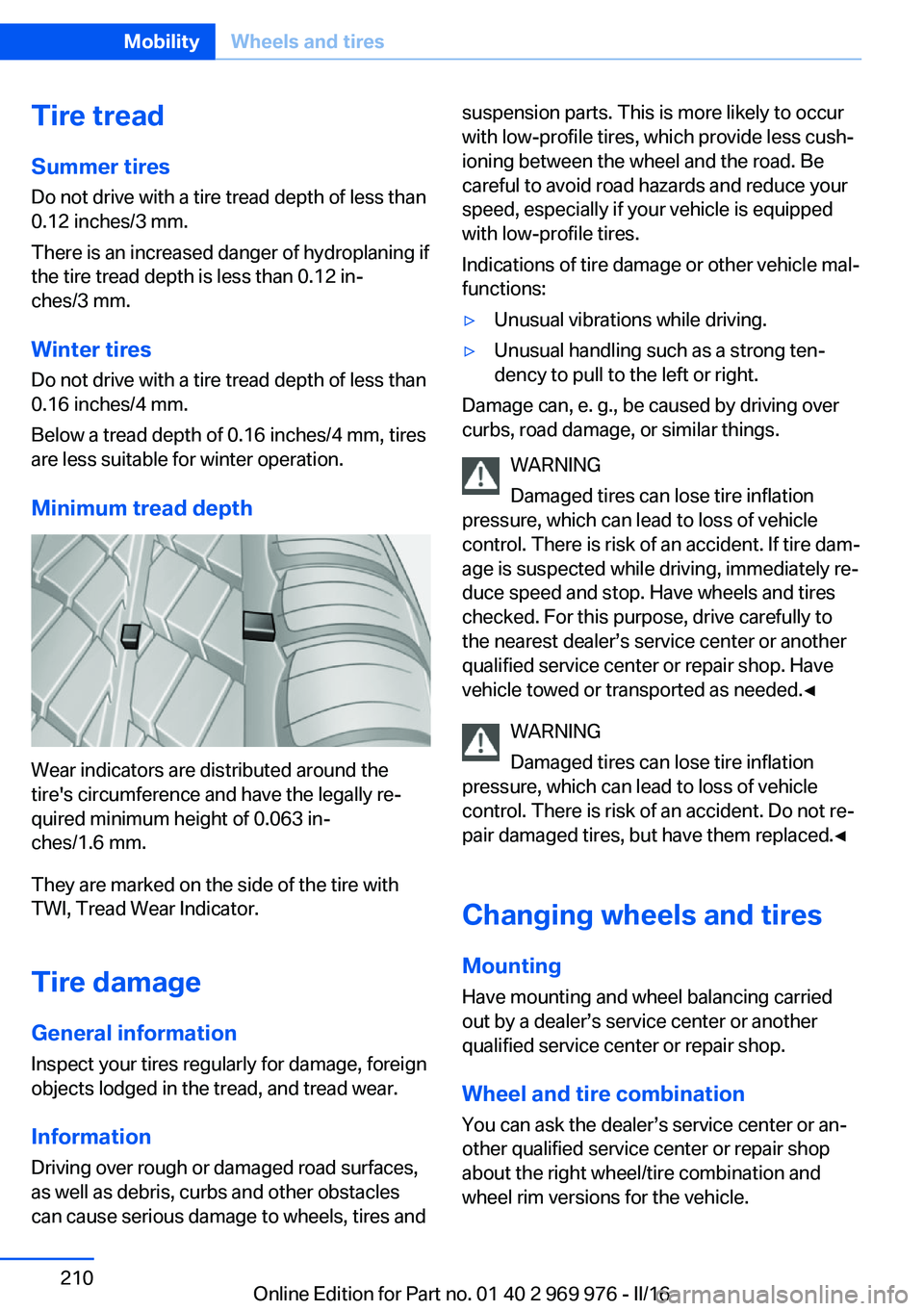

Minimum tread depth

Wear indicators are distributed around the

tire's circumference and have the legally re‐

quired minimum height of 0.063 in‐

ches/1.6 mm.

They are marked on the side of the tire with

TWI, Tread Wear Indicator.

Tire damage

General information

Inspect your tires regularly for damage, foreign

objects lodged in the tread, and tread wear.

Information Driving over rough or damaged road surfaces,

as well as debris, curbs and other obstacles

can cause serious damage to wheels, tires and

suspension parts. This is more likely to occur

with low-profile tires, which provide less cush‐

ioning between the wheel and the road. Be

careful to avoid road hazards and reduce your

speed, especially if your vehicle is equipped

with low-profile tires.

Indications of tire damage or other vehicle mal‐

functions:▷Unusual vibrations while driving.▷Unusual handling such as a strong ten‐

dency to pull to the left or right.

Damage can, e. g., be caused by driving over

curbs, road damage, or similar things.

WARNING

Damaged tires can lose tire inflation

pressure, which can lead to loss of vehicle

control. There is risk of an accident. If tire dam‐

age is suspected while driving, immediately re‐

duce speed and stop. Have wheels and tires

checked. For this purpose, drive carefully to

the nearest dealer’s service center or another

qualified service center or repair shop. Have

vehicle towed or transported as needed.◀

WARNING

Damaged tires can lose tire inflation

pressure, which can lead to loss of vehicle

control. There is risk of an accident. Do not re‐

pair damaged tires, but have them replaced.◀

Changing wheels and tires

Mounting Have mounting and wheel balancing carriedout by a dealer’s service center or another

qualified service center or repair shop.

Wheel and tire combination

You can ask the dealer’s service center or an‐

other qualified service center or repair shop

about the right wheel/tire combination and

wheel rim versions for the vehicle.

Seite 210MobilityWheels and tires210

Online Edition for Part no. 01 40 2 969 976 - II/16

Page 215 of 265

If a tire inflation pressure of 2 bar cannot be

reached, contact your dealer’s service cen‐

ter or another qualified service center or

repair shop.

Stowing the Mobility System

1.Unscrew the filling hose of the sealant con‐

tainer from the wheel.2.Unscrew the connection hose of the com‐

pressor from the sealant container.3.Connect the filling hose of the sealant con‐

tainer previously connected to the tire

valve with the available connector on the

sealant container.

This prevents leftover sealant from escap‐

ing from the container.4.Wrap the empty sealant container in suita‐

ble material to avoid dirtying the cargo

area.5.Stow the Mobility System back in the vehi‐

cle.

Distributing the sealant

Immediately drive approx. 5 miles/10 km to en‐

sure that the sealant is evenly distributed in the

tire.

Do not exceed a speed of 50 mph/80 km/h.

If possible, do not drive at speeds less than

12 mph/20 km/h.

To correct the tire inflation pressure

1.Stop at a suitable location.2.Screw the connection hose of the com‐

pressor directly onto the tire valve stem.3.Insert the connector into the power socket

inside the vehicle.4.Correct the tire inflation pressure to

2.5 bar.▷Increase pressure: with the ignition

turned on or the engine running, switch

on the compressor.▷To reduce the pressure: press the but‐

ton on the compressor.

Continuing the trip

Do not exceed the maximum permissible

speed of 50 mph/80 km/h.

Reinitialize the Flat Tire Monitor.

Reinitialize the Tire Pressure Monitor.

Replace the nonworking tire and the sealant

container of the Mobility System as soon as

possible.

Snow chains

Fine-link snow chains

The manufacturer of your vehicle recommends

use of fine-link snow chains. Certain types of

fine-link snow chains have been tested by the

manufacturer of the vehicle and recommended

as road-safe and suitable.

Information regarding suitable snow chains is

available from a dealer’s service center or an‐

other qualified service center or repair shop.

Use WARNING

With the mounting of snow chains on un‐

suitable tires, the snow chains can come into

contact with vehicle parts. There is a risk of ac‐

cidents or a risk of property damage. Only

mount snow chains on tires that are desig‐

nated by their manufacturer as suitable for the

use of snow chains.◀

Use only in pairs on the rear wheels, equipped

with the tires of the following size:

▷205/65 R 17.▷225/60 R 17.▷245/50 R 18.▷245/45 R 19.

Do not mount snow chains on size 245/55 R

17 tires.

Seite 215Wheels and tiresMobility215

Online Edition for Part no. 01 40 2 969 976 - II/16

Page 225 of 265

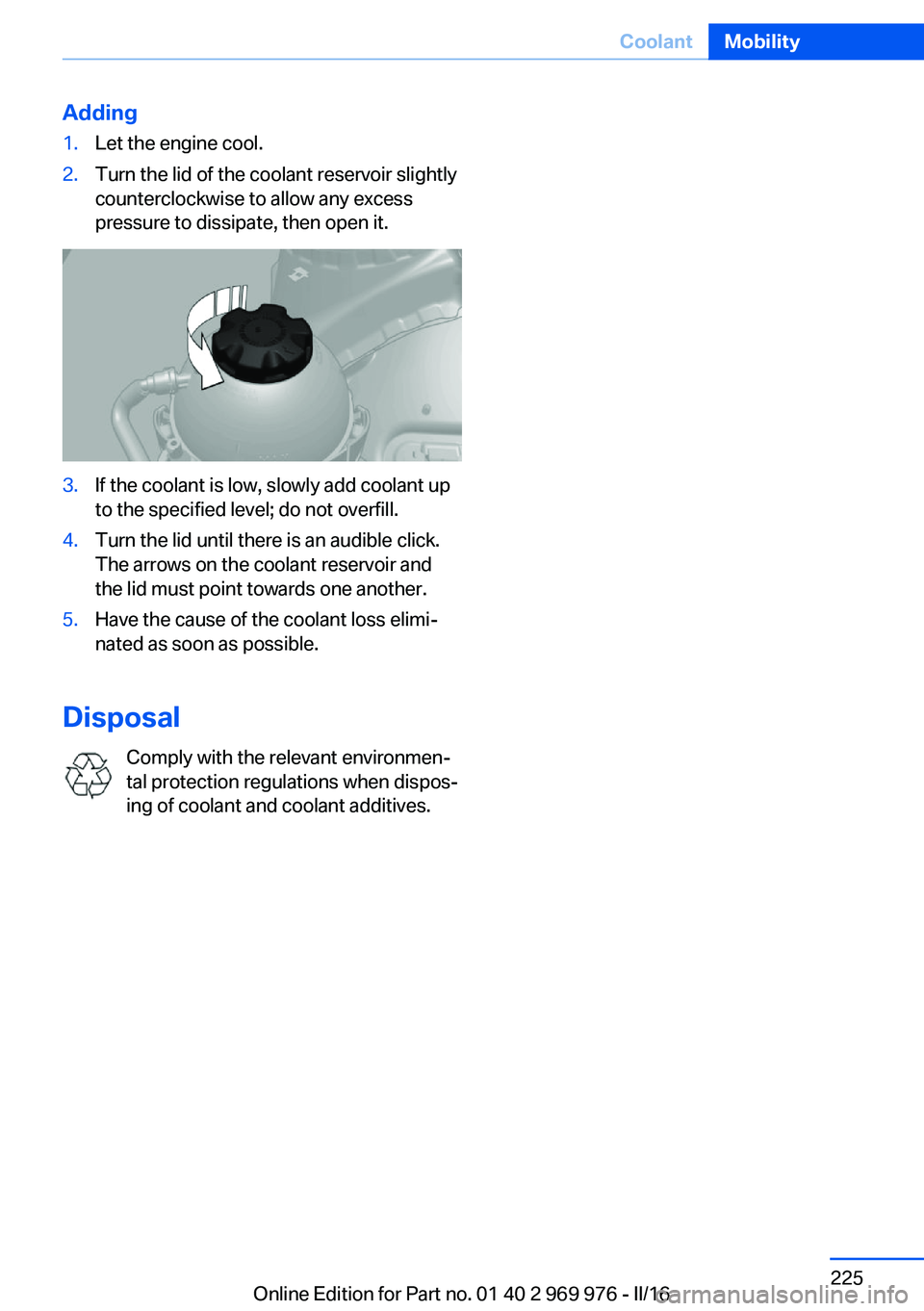

Adding1.Let the engine cool.2.Turn the lid of the coolant reservoir slightly

counterclockwise to allow any excess

pressure to dissipate, then open it.3.If the coolant is low, slowly add coolant up

to the specified level; do not overfill.4.Turn the lid until there is an audible click.

The arrows on the coolant reservoir and

the lid must point towards one another.5.Have the cause of the coolant loss elimi‐

nated as soon as possible.

Disposal

Comply with the relevant environmen‐

tal protection regulations when dispos‐

ing of coolant and coolant additives.

Seite 225CoolantMobility225

Online Edition for Part no. 01 40 2 969 976 - II/16

Page 228 of 265

Replacing componentsVehicle features and optionsThis chapter describes all standard, country-

specific and optional features offered with the

series. It also describes features that are not

necessarily available in your car, e. g., due to

the selected options or country versions. This

also applies to safety-related functions and

systems. The respectively applicable country

provisions must be observed when using the

respective features and systems.

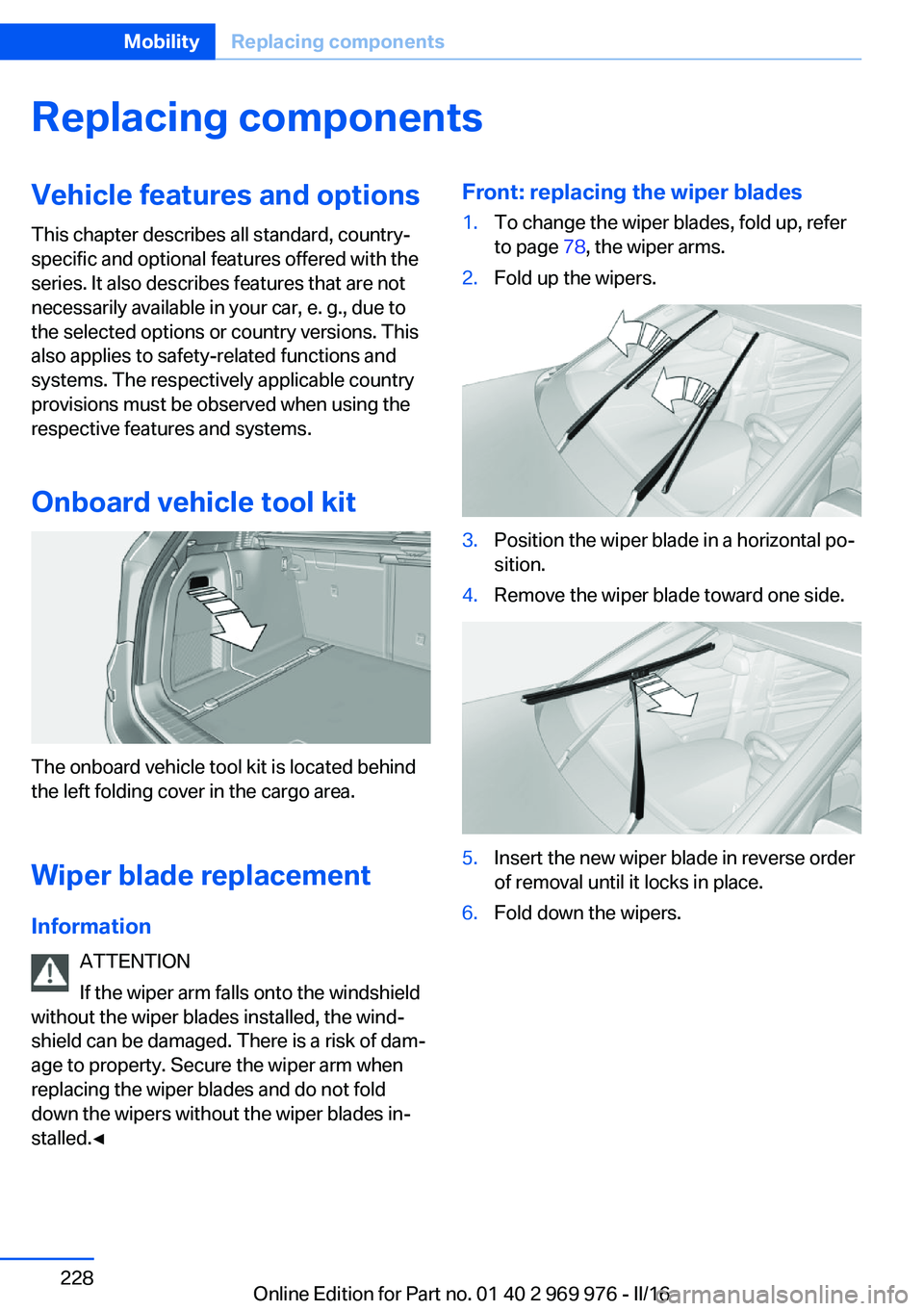

Onboard vehicle tool kit

The onboard vehicle tool kit is located behind

the left folding cover in the cargo area.

Wiper blade replacement Information ATTENTION

If the wiper arm falls onto the windshield

without the wiper blades installed, the wind‐ shield can be damaged. There is a risk of dam‐

age to property. Secure the wiper arm when

replacing the wiper blades and do not fold down the wipers without the wiper blades in‐

stalled.◀

Front: replacing the wiper blades1.To change the wiper blades, fold up, refer

to page 78, the wiper arms.2.Fold up the wipers.3.Position the wiper blade in a horizontal po‐

sition.4.Remove the wiper blade toward one side.5.Insert the new wiper blade in reverse order

of removal until it locks in place.6.Fold down the wipers.Seite 228MobilityReplacing components228

Online Edition for Part no. 01 40 2 969 976 - II/16

Page 232 of 265

In the case of a malfunction, contact a dealer’s

service center or another qualified service cen‐

ter or repair shop.

LED headlightsLight-emitting diodes (LEDs)

With LED headlights, all front lights and side

indicators are designed with LED technology.

If an LED fails, switch on the front fog lamps

and continue the trip with great care. Comply

with local regulations.

In the case of a malfunction, contact a dealer’s

service center or another qualified service cen‐

ter or repair shop.

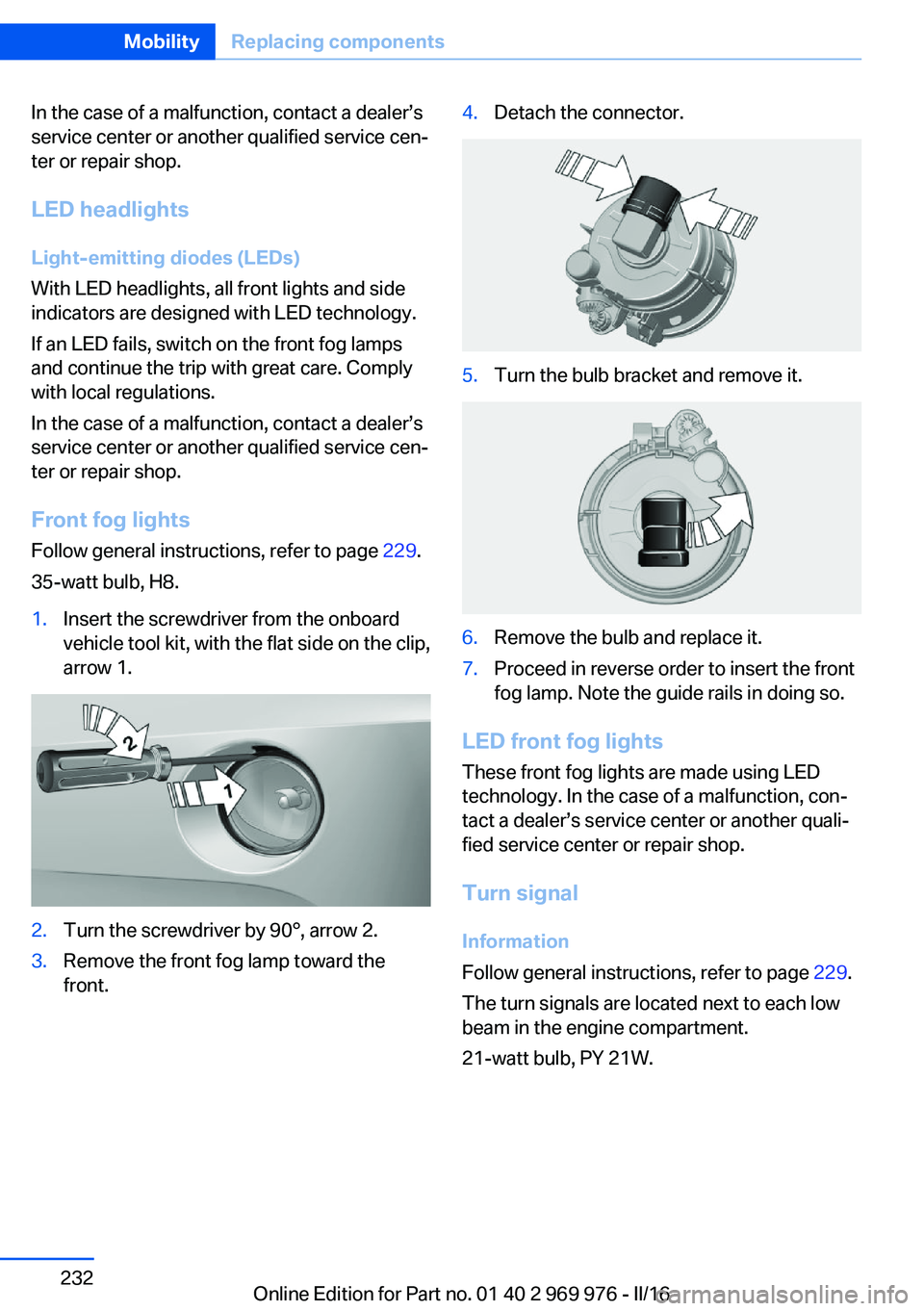

Front fog lights

Follow general instructions, refer to page 229.

35-watt bulb, H8.1.Insert the screwdriver from the onboard

vehicle tool kit, with the flat side on the clip,

arrow 1.2.Turn the screwdriver by 90°, arrow 2.3.Remove the front fog lamp toward the

front.4.Detach the connector.5.Turn the bulb bracket and remove it.6.Remove the bulb and replace it.7.Proceed in reverse order to insert the front

fog lamp. Note the guide rails in doing so.

LED front fog lights

These front fog lights are made using LED

technology. In the case of a malfunction, con‐

tact a dealer’s service center or another quali‐

fied service center or repair shop.

Turn signal

Information

Follow general instructions, refer to page 229.

The turn signals are located next to each low

beam in the engine compartment.

21-watt bulb, PY 21W.

Seite 232MobilityReplacing components232

Online Edition for Part no. 01 40 2 969 976 - II/16

Page 240 of 265

corresponding engine or body ground of

the vehicle to be started.

Starting the engine

Never use spray fluids to start the engine.

1.Start the engine of the assisting vehicle

and let it run for several minutes at an in‐

creased idle speed.

If the vehicle to be started has a diesel en‐

gine: let the engine of the assisting vehicle

run for approx. 10 minutes.2.Start the engine of the vehicle that is to be

started in the usual way.

If the first starting attempt is not success‐

ful, wait a few minutes before making an‐

other attempt in order to allow the dis‐

charged battery to recharge.3.Let both engines run for several minutes.4.Disconnect the jumper cables in the re‐

verse order.

Check the battery and recharge if needed.

Tow-starting and towing Information WARNING

Due to system limits, individual functions

can malfunction during tow-starting/towing

with the Intelligent Safety systems activated,

e.g., approach control warning with light brak‐

ing function. There is risk of an accident.

Switch all Intelligent Safety systems off prior to

tow-starting/towing.◀

Steptronic transmission: transporting

the vehicle

Information

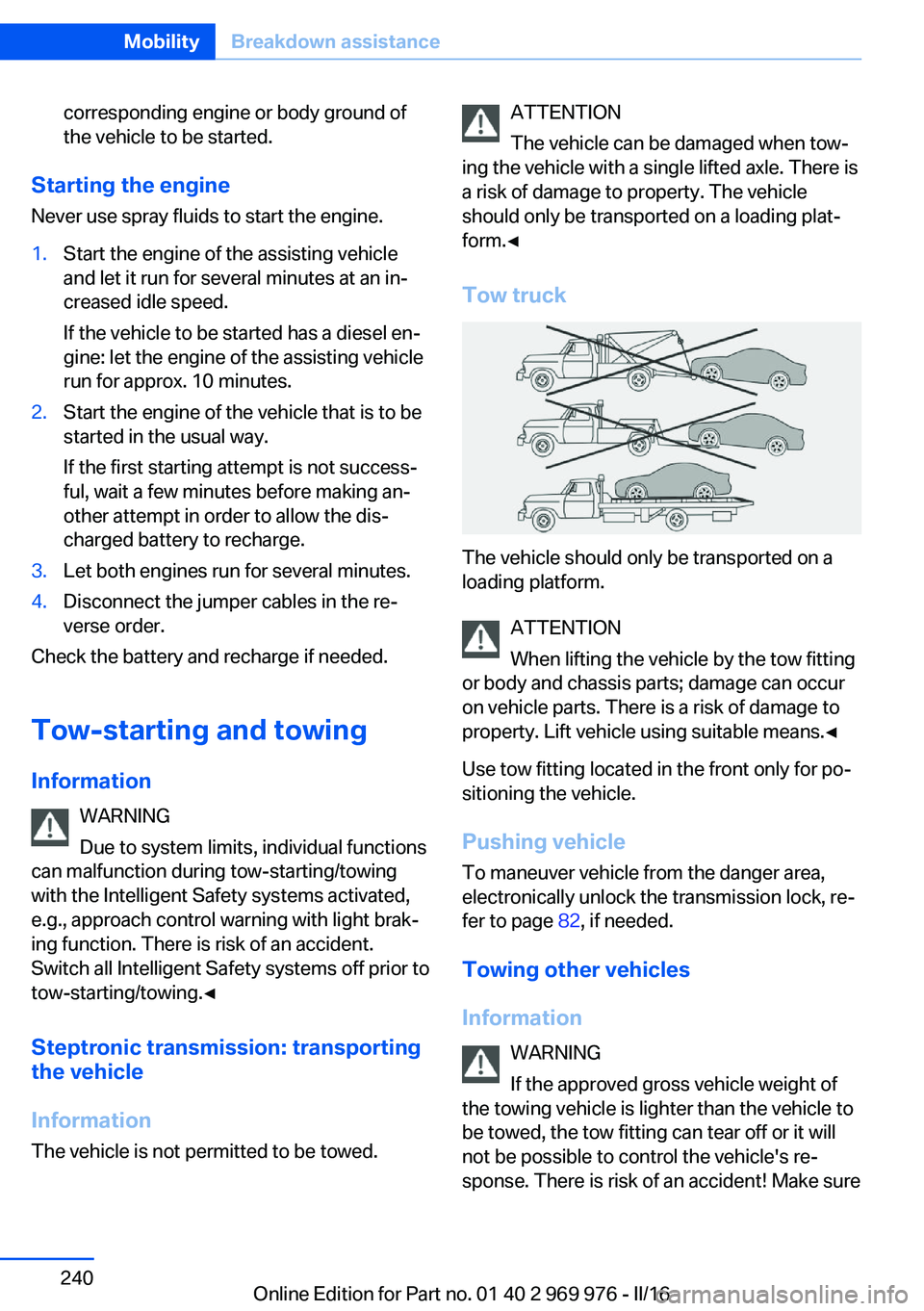

The vehicle is not permitted to be towed.

ATTENTION

The vehicle can be damaged when tow‐

ing the vehicle with a single lifted axle. There is

a risk of damage to property. The vehicle

should only be transported on a loading plat‐

form.◀

Tow truck

The vehicle should only be transported on a

loading platform.

ATTENTION

When lifting the vehicle by the tow fitting

or body and chassis parts; damage can occur

on vehicle parts. There is a risk of damage to

property. Lift vehicle using suitable means.◀

Use tow fitting located in the front only for po‐

sitioning the vehicle.

Pushing vehicle To maneuver vehicle from the danger area,

electronically unlock the transmission lock, re‐

fer to page 82, if needed.

Towing other vehicles

Information WARNING

If the approved gross vehicle weight of

the towing vehicle is lighter than the vehicle to

be towed, the tow fitting can tear off or it will

not be possible to control the vehicle's re‐

sponse. There is risk of an accident! Make sure

Seite 240MobilityBreakdown assistance240

Online Edition for Part no. 01 40 2 969 976 - II/16

Page 241 of 265

that the gross vehicle weight of the towing ve‐

hicle is heavier than the vehicle to be towed.◀

ATTENTION

If the tow bar or tow rope is attached in‐

correctly, damage to other vehicle parts can

occur. There is a risk of damage to property.

Correctly attach the tow bar or tow rope to the

tow fitting.◀▷Switch on the hazard warning system, de‐

pending on local regulations.▷If the electrical system has failed, clearly

identify the vehicle being towed by placing

a sign or a warning triangle in the rear win‐

dow.

Tow bar

The tow fittings used should be on the same

side on both vehicles.

Should it prove impossible to avoid mounting

the tow bar at an offset angle, please observe

the following:

▷Maneuvering capability is limited going

around corners.▷The tow bar will generate lateral forces if it

is secured with an offset.

Tow rope

When starting to tow the vehicle, make sure

that the tow rope is taut.

To avoid jerking and the associated stresses

on the vehicle components when towing, al‐

ways use nylon ropes or nylon straps.

Tow fitting

General information

The screw-in tow fitting should always be car‐

ried in the vehicle.

The tow fitting can be screwed in at the front

or rear of the vehicle.

The tow fitting and the onboard vehicle tool kit,

refer to page 228, are together in the cargo

area.

Information ATTENTION

If the tow fitting is not used as intended,

there can be damage to the vehicle or to the

tow fitting. There is a risk of damage to prop‐

erty. Observe the notes on using the tow fit‐

ting.◀

Use of the tow fitting:

▷Use only the tow fitting provided with the

vehicle and screw it all the way in.▷Use the tow fitting for towing on paved

roads only.▷Use tow fitting located in the front only for

positioning the vehicle.▷Avoid lateral loading of the tow fitting, for

example, do not lift the vehicle by the tow

fitting.Seite 241Breakdown assistanceMobility241

Online Edition for Part no. 01 40 2 969 976 - II/16

Page 242 of 265

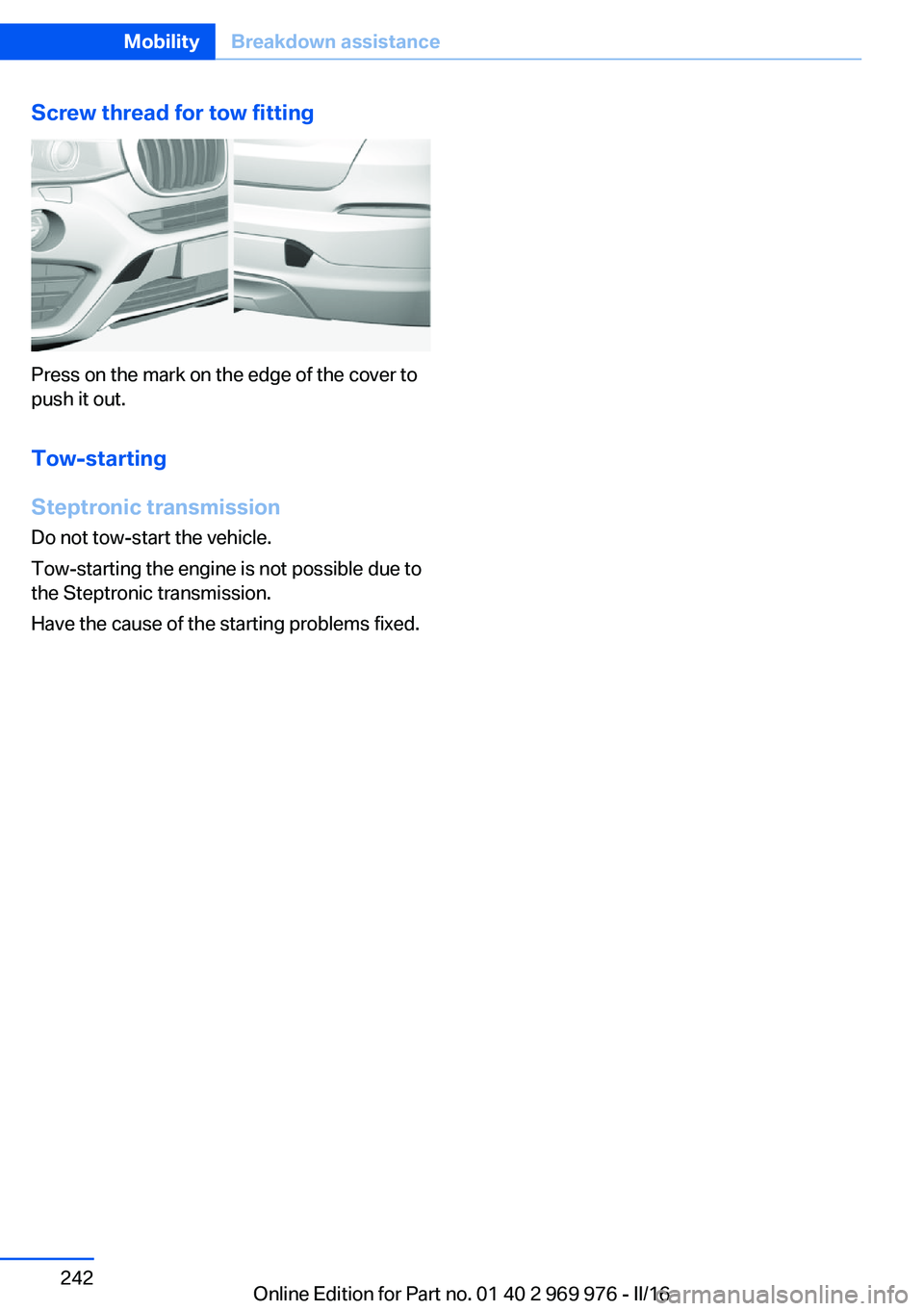

Screw thread for tow fitting

Press on the mark on the edge of the cover to

push it out.

Tow-starting

Steptronic transmission

Do not tow-start the vehicle.

Tow-starting the engine is not possible due to

the Steptronic transmission.

Have the cause of the starting problems fixed.

Seite 242MobilityBreakdown assistance242

Online Edition for Part no. 01 40 2 969 976 - II/16