Vanos BMW X5 2002 E53 M54 Engine Workshop Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 2002, Model line: X5, Model: BMW X5 2002 E53Pages: 48, PDF Size: 2.52 MB

Page 1 of 48

Initial Print Date: 02/2000Revision Date: 6/2000

Subject Page

M54 Engine

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Mechanical changes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Performance Charts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Review Questions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Siemen’s MS 43.0 System

• Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

• I - P - O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

MS 43.0 New functions

• Electronic throttle Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

• Accelerator Pedal Sensor (PWG) . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

• Electronic Throttle Valve (EDK) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

• Main Relay Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

• Engine Optimized Ignition Key OFF . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

• Diagnosis Module Tank Leakage (DM-TL) . . . . . . . . . . . . . . . . . . . . . . .17

• DM-TL Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

• DM-TL Test Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Carry Over Functions

Inputs

• Oxygen Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

• Camshaft Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

• Crankshaft Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

• Misfire Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

• OBD Fault Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

• Mass Air Meter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Outputs

• VANOS Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

• Electric Fan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

• Secondary Air Injection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

• Engine Speed Limit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

• RZV Ignition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

• Resonance - Turbulence Manifold . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

• Idle Speed control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

• Cruise Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

• Purge Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

Table of Contents

Page 26 of 48

26

M54engMS43/ST036/6/2000

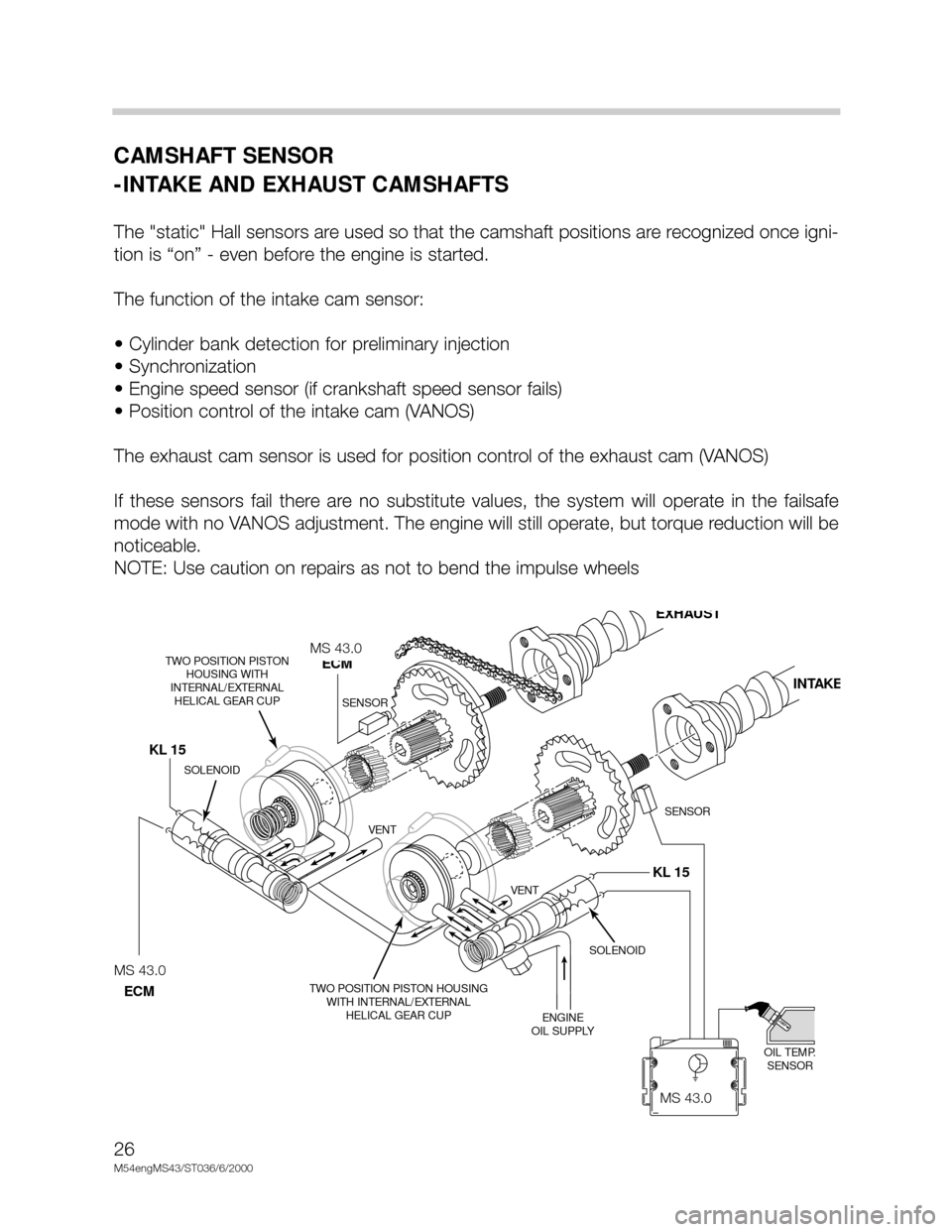

CAMSHAFT SENSOR

-INTAKE AND EXHAUST CAMSHAFTS

The "static" Hall sensors are used so that the camshaft positions are recognized once igni-

tion is “on” - even before the engine is started.

The function of the intake cam sensor:

• Cylinder bank detection for preliminary injection

• Synchronization

• Engine speed sensor (if crankshaft speed sensor fails)

• Position control of the intake cam (VANOS)

The exhaust cam sensor is used for position control of the exhaust cam (VANOS)

If these sensors fail there are no substitute values, the system will operate in the failsafe

mode with no VANOS adjustment. The engine will still operate, but torque reduction will be

noticeable.

NOTE: Use caution on repairs as not to bend the impulse wheels

KL 15 KL 15

MS42.0

SOLENOID

OIL TEMP.

SENSOR TWO POSITION PISTON HOUSING

WITH INTERNAL/EXTERNAL

HELICAL GEAR CUP TWO POSITION PISTON

HOUSING WITH

INTERNAL/EXTERNAL

HELICAL GEAR CUP

ENGINE

OIL SUPPLY VENT VENT

SOLENOID

SENSOR SENSOR

MS42

ECM

EXHAUST

INTAKE

MS42.0

ECM

MS 43.0

MS 43.0

MS 43.0

Page 32 of 48

32

M54engMS43/ST036/6/2000

MS 43 CARRY OVER FUNCTIONS

OUTPUT FUNCTIONS -VANOS CONTROL

With the double VANOS system, the valve timing is changed on both the intake and the

exhaust camshafts.

Double VANOS provides the following benefits:

• Torque increase in the low to mid (1500 - 2000 RPM) range without power loss in the

upper RPM range.

• Less incomplete combustion when idling due to less camshaft overlap (also improves

idle speed characteristics).

• Internal exhaust gas recirculation (EGR) in the part load range (reduces NOx and post-

combustion of residual gasses in the exhaust)

• Rapid catalyst warm up and lower “raw” emissions after cold start.

• Reduction in fuel consumption

Double VANOS consists of the following parts:

• Intake and exhaust camshafts with helical gear insert

• Sprockets with adjustable gears

• VANOS actuators for each camshaft

• 2 three-way solenoid switching valves

• 2 impulse wheels for detecting camshaft position

• 2 camshaft position sensors (Hall effect)

The “initial” timing is set by gear positioning (refer to the Repair Instructions for details) and

the chain tensioner. As with the previous VANOS, the hydraulically controlled actuators

move the helical geared cups to regulate camshaft timing. The angled teeth of the helical

gears cause the pushing

movement of the helical cup to be converted into a rotational

movement. This rotational movement is added to the turning of the camshafts and cause

the camshafts to “advance” or “retard”. The adjustment rate is dependent oil temperature,

oil pressure, and engine RPM.

Page 33 of 48

33

M54engMS43/ST036/6/20000

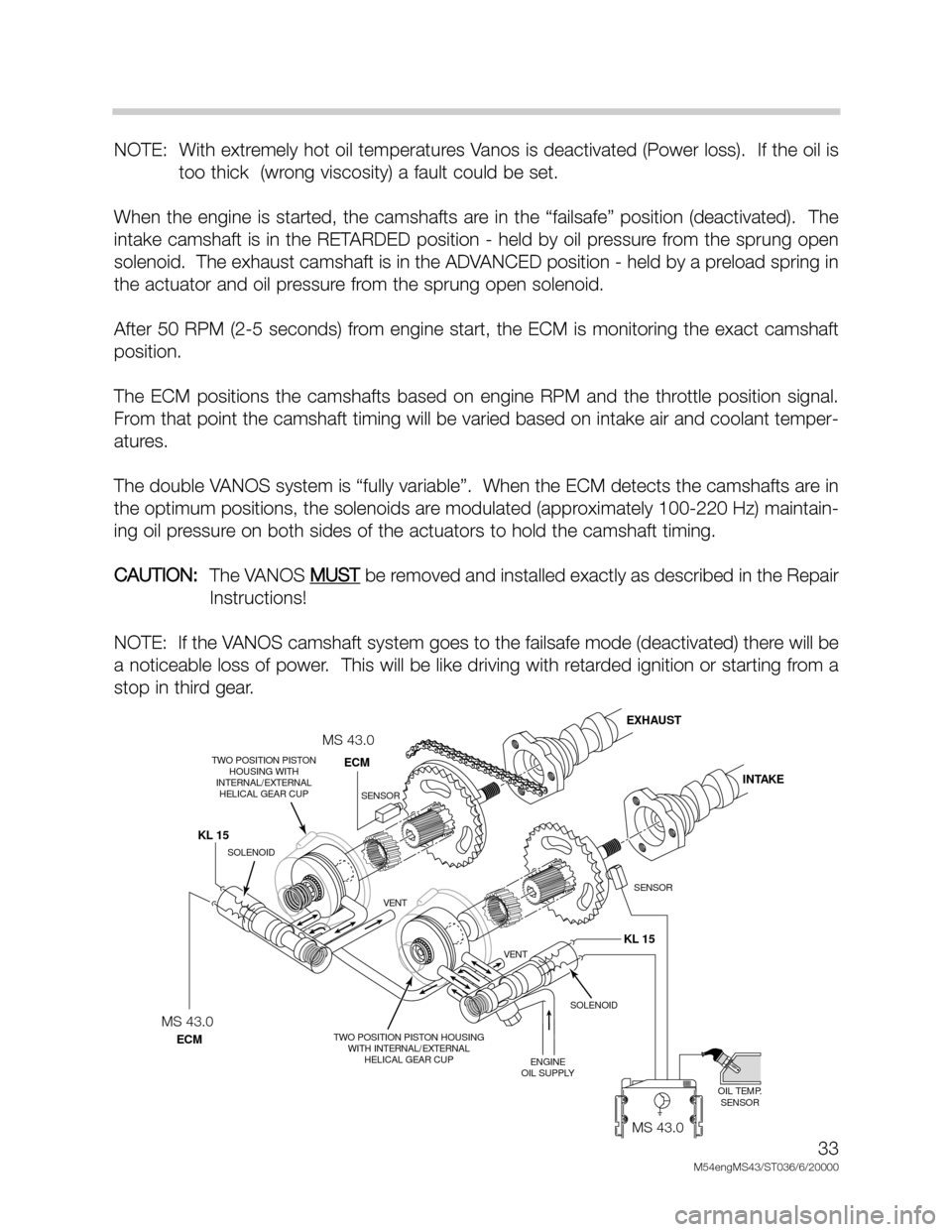

NOTE: With extremely hot oil temperatures Vanos is deactivated (Power loss). If the oil is

too thick (wrong viscosity) a fault could be set.

When the engine is started, the camshafts are in the “failsafe” position (deactivated). The

intake camshaft is in the RETARDED position - held by oil pressure from the sprung open

solenoid. The exhaust camshaft is in the ADVANCED position - held by a preload spring in

the actuator and oil pressure from the sprung open solenoid.

After 50 RPM (2-5 seconds) from engine start, the ECM is monitoring the exact camshaft

position.

The ECM positions the camshafts based on engine RPM and the throttle position signal.

From that point the camshaft timing will be varied based on intake air and coolant temper-

atures.

The double VANOS system is “fully variable”. When the ECM detects the camshafts are in

the optimum positions, the solenoids are modulated (approximately 100-220 Hz) maintain-

ing oil pressure on both sides of the actuators to hold the camshaft timing.

CAUTION:

The VANOS MUST

be removed and installed exactly as described in the Repair

Instructions!

NOTE: If the VANOS camshaft system goes to the failsafe mode (deactivated) there will be

a noticeable loss of power. This will be like driving with retarded ignition or starting from a

stop in third gear.

KL 15 KL 15

MS42.0

SOLENOID

OIL TEMP.

SENSOR TWO POSITION PISTON HOUSING

WITH INTERNAL/EXTERNAL

HELICAL GEAR CUP TWO POSITION PISTON

HOUSING WITH

INTERNAL/EXTERNAL

HELICAL GEAR CUP

ENGINE

OIL SUPPLY VENT VENT

SOLENOID

SENSOR SENSOR

MS42

ECMEXHAUST

INTAKE

MS42.0

ECM

MS 43.0

MS 43.0

MS 43.0

Page 35 of 48

35

M54engMS43/ST036/6/20000

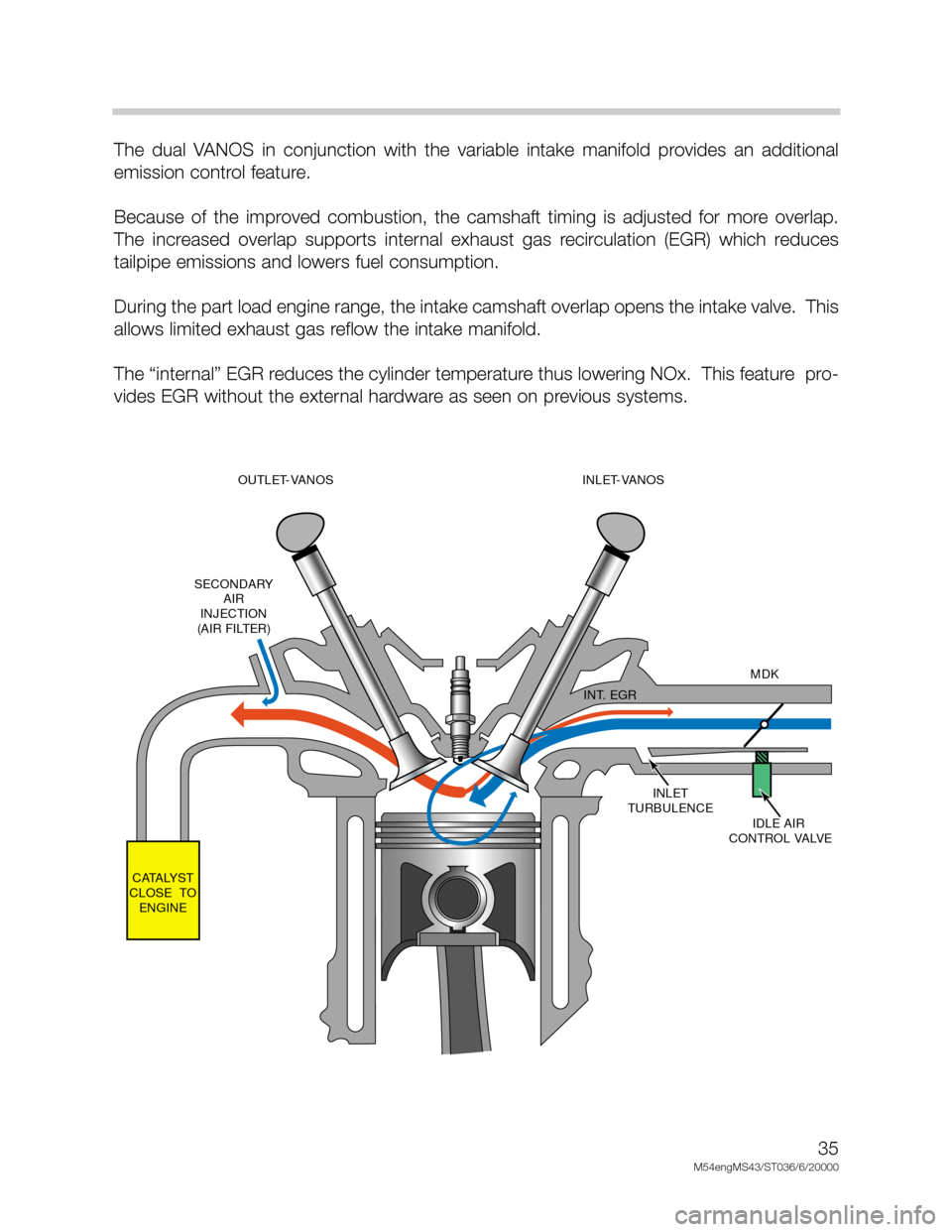

The dual VANOS in conjunction with the variable intake manifold provides an additional

emission control feature.

Because of the improved combustion, the camshaft timing is adjusted for more overlap.

The increased overlap supports internal exhaust gas recirculation (EGR) which reduces

tailpipe emissions and lowers fuel consumption.

During the part load engine range, the intake camshaft overlap opens the intake valve. This

allows limited exhaust gas reflow the intake manifold.

The “internal” EGR reduces the cylinder temperature thus lowering NOx. This feature pro-

vides EGR without the external hardware as seen on previous systems.

INLET

TURBULENCE

IDLE AIR

CONTROL VALVEMDK

INT. EGR

CATALYST

CLOSE TO

ENGINESECONDARY

AIR

INJECTION

(AIR FILTER)OUTLET-VANOS

(228/80-105)INLET-VANOS

(228/80-120)

Page 45 of 48

45

M54engMS43/ST036/6/20000

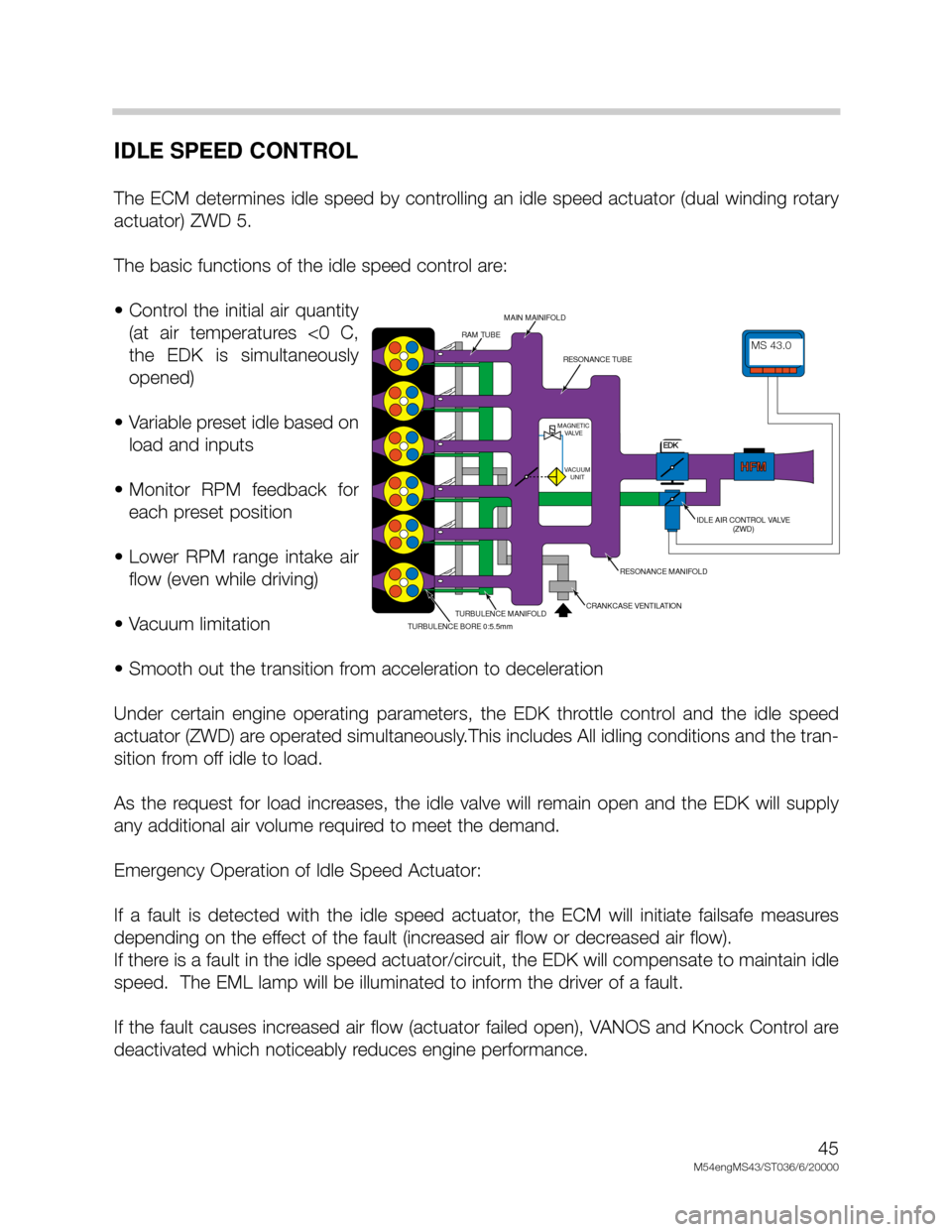

IDLE SPEED CONTROL

The ECM determines idle speed by controlling an idle speed actuator (dual winding rotary

actuator) ZWD 5.

The basic functions of the idle speed control are:

• Control the initial air quantity

(at air temperatures <0 C,

the EDK is simultaneously

opened)

• Variable preset idle based on

load and inputs

• Monitor RPM feedback for

each preset position

• Lower RPM range intake air

flow (even while driving)

• Vacuum limitation

• Smooth out the transition from acceleration to deceleration

Under certain engine operating parameters, the EDK throttle control and the idle speed

actuator (ZWD) are operated simultaneously.This includes All idling conditions and the tran-

sition from off idle to load.

As the request for load increases, the idle valve will remain open and the EDK will supply

any additional air volume required to meet the demand.

Emergency Operation of Idle Speed Actuator:

If a fault is detected with the idle speed actuator, the ECM will initiate failsafe measures

depending on the effect of the fault (increased air flow or decreased air flow).

If there is a fault in the idle speed actuator/circuit, the EDK will compensate to maintain idle

speed. The EML lamp will be illuminated to inform the driver of a fault.

If the fault causes increased air flow (actuator failed open), VANOS and Knock Control are

deactivated which noticeably reduces engine performance.

MDK

HFMHFM

MAGNETIC

VALVE

VACUUM

UNIT

MS42.0MS42.0

RAM TUBE

MAIN MAINIFOLD

RESONANCE TUBE

IDLE AIR CONTROL VALVE

(ZWD)

RESONANCE MANIFOLD

CRANKCASE VENTILATIONTURBULENCE MANIFOLD

TURBULENCE BORE 0:5.5mm

MS 43.0

EDK