ESP BMW X5 2004 E53 Central Body Electronics Workshop Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 2004, Model line: X5, Model: BMW X5 2004 E53Pages: 64, PDF Size: 4.03 MB

Page 2 of 64

INTRODUCTION

The Central Body Electronics (ZKE III) equipped on the X5 includes the following sub-

systems under the total scope of its control:

• Windshield/tailgate wiping/washing,

including windshield rain sensor (AIC).

• Interior lighting

• Central locking

• Keyless entry

• Tailgate release

The following is an overview of new or changed features found on the X5 ZKE III variant.

• Passenger’s door module is now incorporated into the passenger’s door switchblock

module.

• Sunroof module (SHD) located on the K bus.

• The Central Locking system uses a new style door lock actuator with hall effect sensors

similar to E46.

• The GM III is responsible for the Key Memory feature. It provides the added

convenience of identifying users of the vehicle. Whenever the vehicle is locked or

unlocked via the FZV keyless entry system, a unique key identification signal (key

number) is transmitted to the General Module.

The key identification signal alerts the GM to communicate with other control systems

over the K Bus to store (when locked) or reset (when unlocked) certain driver adjustable

settings for the driver using the specific key. The GM also resets certain driver

adjustable settings that it controls directly.

• Power windows/Sunroof

• DWA alarm system

• Mirror - adjustment/memory/heating

• Seat adjustment/memory

• Steering column adjustment/memory

• Consumer cut-off/sleep mode

ZKE - 2

Page 22 of 64

ZKE - 22

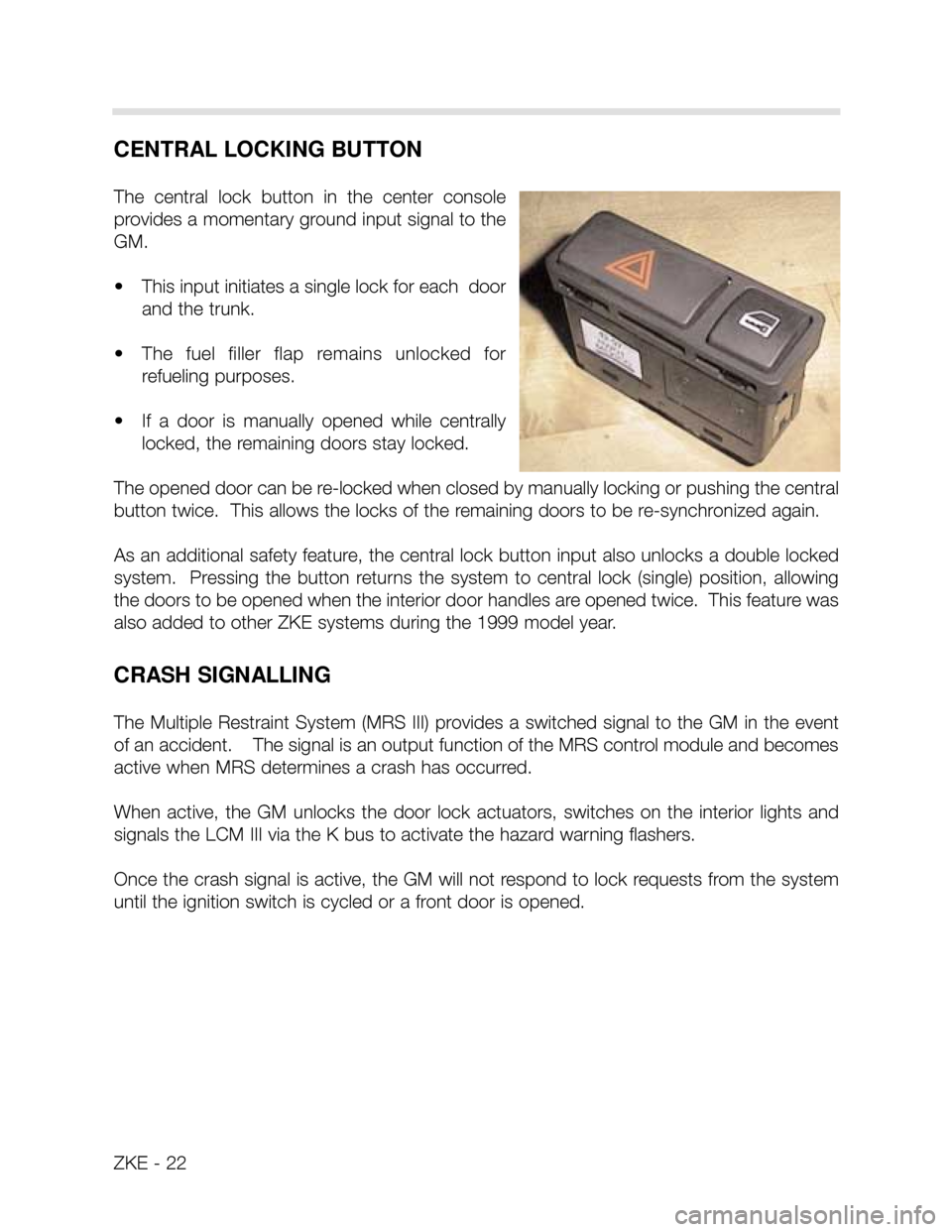

CENTRAL LOCKING BUTTON

The central lock button in the center console

provides a momentary ground input signal to the

GM.

• This input initiates a single lock for each door

and the trunk.

• The fuel filler flap remains unlocked for

refueling purposes.

• If a door is manually opened while centrally

locked, the remaining doors stay locked.

The opened door can be re-locked when closed by manually locking or pushing the central

button twice. This allows the locks of the remaining doors to be re-synchronized again.

As an additional safety feature, the central lock button input also unlocks a double locked

system. Pressing the button returns the system to central lock (single) position, allowing

the doors to be opened when the interior door handles are opened twice. This feature was

also added to other ZKE systems during the 1999 model year.

CRASH SIGNALLING

The Multiple Restraint System (MRS III) provides a switched signal to the GM in the event

of an accident. The signal is an output function of the MRS control module and becomes

active when MRS determines a crash has occurred.

When active, the GM unlocks the door lock actuators, switches on the interior lights and

signals the LCM III via the K bus to activate the hazard warning flashers.

Once the crash signal is active, the GM will not respond to lock requests from the system

until the ignition switch is cycled or a front door is opened.

Page 25 of 64

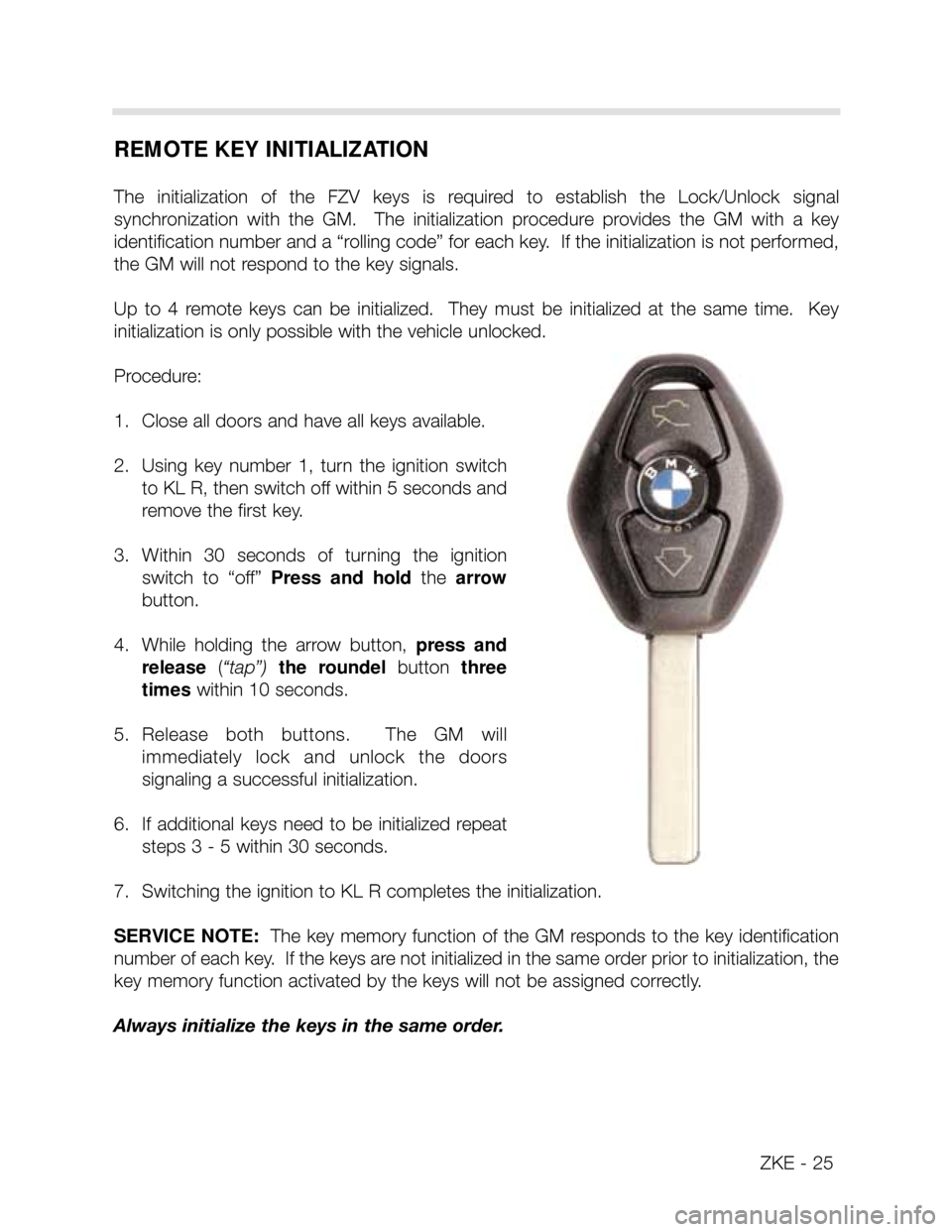

REMOTE KEY INITIALIZATION

The initialization of the FZV keys is required to establish the Lock/Unlock signal

synchronization with the GM. The initialization procedure provides the GM with a key

identification number and a “rolling code” for each key. If the initialization is not performed,

the GM will not respond to the key signals.

Up to 4 remote keys can be initialized. They must be initialized at the same time. Key

initialization is only possible with the vehicle unlocked.

Procedure:

1. Close all doors and have all keys available.

2. Using key number 1, turn the ignition switch

to KL R, then switch off within 5 seconds and

remove the first key.

3. Within 30 seconds of turning the ignition

switch to “off” Press and holdthe arrow

button.

4. While holding the arrow button, press and

release(“tap”) the roundel button three

timeswithin 10 seconds.

5. Release both buttons. The GM will

immediately lock and unlock the doors

signaling a successful initialization.

6. If additional keys need to be initialized repeat

steps 3 - 5 within 30 seconds.

7. Switching the ignition to KL R completes the initialization.

SERVICE NOTE:The key memory function of the GM responds to the key identification

number of each key. If the keys are not initialized in the same order prior to initialization, the

key memory function activated by the keys will not be assigned correctly.

Always initialize the keys in the same order.

ZKE - 25

Page 26 of 64

FZV KEY RECHARGEABLE BATTERY

From KL R, the battery inside the key head is charged inductively by the EWS ring antenna

via a coil antenna integrated in the key. The charging process is controlled by electronic

circuitry integrated in the key.

• The service life of a radio-control key used under normal conditions corresponds to the

vehicle lifespan.

• If the FZV keys are not used (ie: stored in a drawer), the battery will be discharged after

approx. 1.5 years.

• The time required to fully charge a discharged battery is approx. 30 hours.

• The remote control can be operated about 15 times after a charging period of approx.

30 minutes (driving time).

The key data is stored in a transponder chip. The transponder chip is a wireless read and

write EEPROM. It is powered via the ring coil at the steering lock. Power is applied

electromagnetically when the key is in the ignition switch from KL R.

The power supply is used both for data transfer as well as for charging the battery. This has

been made possible by new development of the transponder chip.

As with previous systems, every press of an FZV key also provides the battery charge

condition. When the FZV electronics receives a low power condition message three

successive times, the GM sets a fault indicating a low battery within a specific key. The

LCM is also informed via the bus system and alerts the driver via an instrument cluster

matrix message.

If the battery is recharged (used operate car), the fault will be automatically deleted when

five successive messages are received indicating a charged battery condition.

The battery has no affect on the EWS III communication function!

ZKE - 26

Page 29 of 64

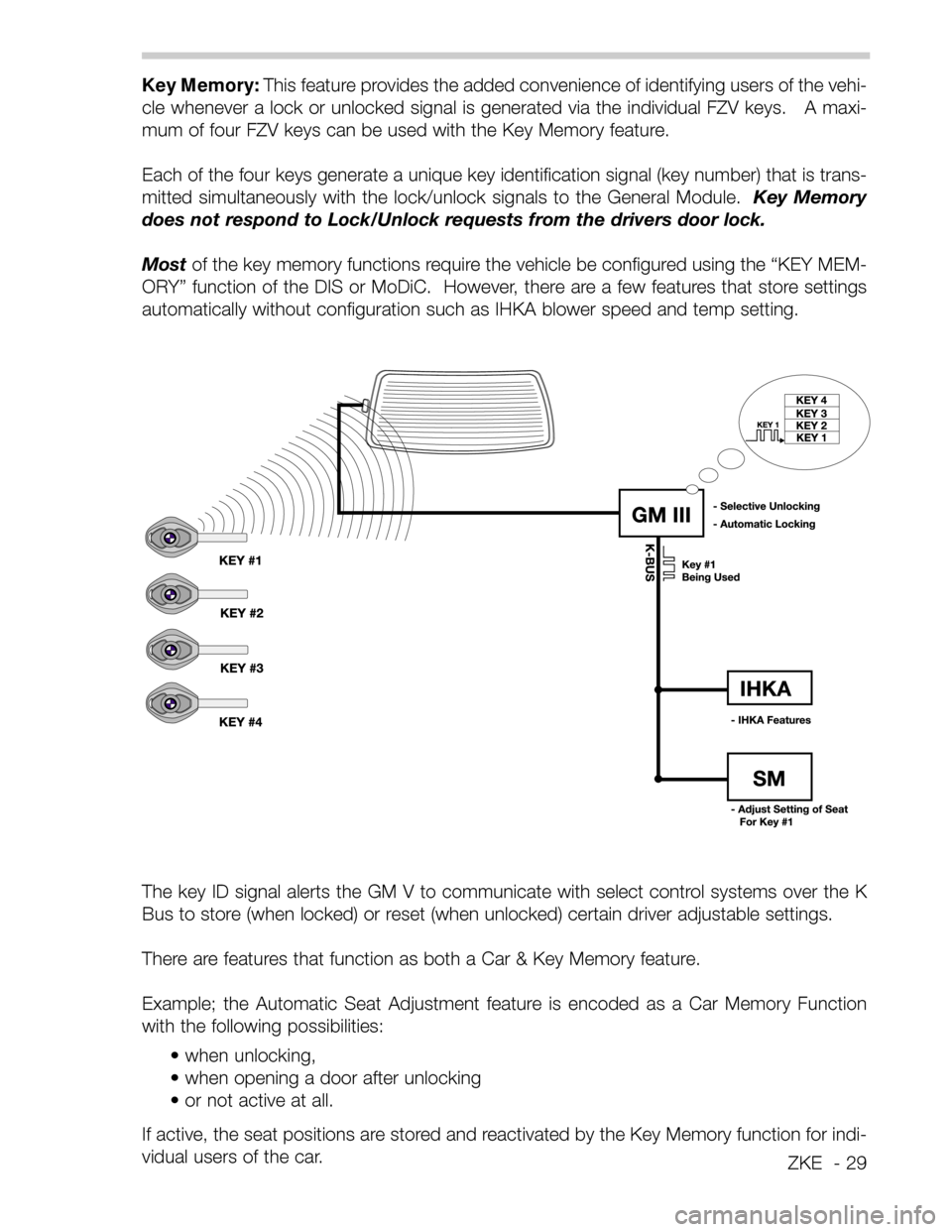

Key Memory: This feature provides the added convenience of identifying users of the vehi-

cle whenever a lock or unlocked signal is generated via the individual FZV keys. A maxi-

mum of four FZV keys can be used with the Key Memory feature.

Each of the four keys generate a unique key identification signal (key number) that is trans-

mitted simultaneously with the lock/unlock signals to the General Module. Key Memory

does not respond to Lock/Unlock requests from the drivers door lock.

Mostof the key memory functions require the vehicle be configured using the “KEY MEM-

ORY” function of the DIS or MoDiC. However, there are a few features that store settings

automatically without configuration such as IHKA blower speed and temp setting.

The key ID signal alerts the GM V to communicate with select control systems over the K

Bus to store (when locked) or reset (when unlocked) certain driver adjustable settings.

There are features that function as both a Car & Key Memory feature.

Example; the Automatic Seat Adjustment feature is encoded as a Car Memory Function

with the following possibilities:

• when unlocking,

• when opening a door after unlocking

• or not active at all.

If active, the seat positions are stored and reactivated by the Key Memory function for indi-

vidual users of the car.

ZKE - 29

Page 37 of 64

ZKE - 37

POWER WINDOWS

The power window operation on the E53 is similar to previous systems. Features of the

system include:

• Control of the front and rear door window motors is carried out directly by the GM.

• One-touch operation in both directions on all four windows.

• Cable type window regulator used for all windows.

• Anti-trap detection is provided by the pressure sensitive finger guard .

• Push/pull window switches

• The rear window switches located in the rear doors can be deactivated by the pressing

child lock out switch in the center console.

• Convenience closing/opening of the windows from the driver's lock cylinder or

convenience opening only from the FZV remote key (FZV operation can be owner

customized with the Car Memory Function).

• Window operation with the ignition switched off until a door is opened or 16 minutes has

elapsed after the key is switched off.

• Window load switching is through relays integral of the GM for rear windows and in the

respective door switchblock modules for the front windows. The current draw is

monitored for end limit position. The maximum run time for the window motors is limited

to 8 seconds. This allows the motors to be switched off if the end limit load sensing fails.

Page 42 of 64

ZKE - 42

SHD SELF DIAGNOSIS

The SHD monitors its operation and stores fault codes if a defect is determined: The SHD

monitors the following conditions:

• SHD motor relays:The relays are checked for sticking contacts (plausibility) and non

functional contacts.

• Hall effect position sensors:The SHD must detect a pulse frequency from the hall

effect sensor(s) during operation.

• Sunroof Switch: The SHD monitors the signal plausibility of the coded signaling from

the sunroof switch.

SUNROOF FAULT RESPONSE CHARACTERISTICS

If a fault occurs with any of these functions, the SHD responds as follows:

• Overrides the end run detection.

• Switches the motor off if the relay contacts stick for more than 500 ms.

• Switches the motor off if pulses are not received.

EMERGENCY OPERATION OF SUNROOF

If the sunroof motor does not respond to the switch signals, the hex key in the trunk lid tool

kit is used to manually turn the motor shaft drive as on previous systems

Page 43 of 64

ZKE - 43

INTERIOR LIGHTING

The GM controls the interior lighting automatically with the status change of several moni-

tored inputs. The lighting can also be manually controlled using the interior light switch.

COMPONENTS

DOOR CONTACTS: The door lock actuators contain a hall effect sensor for the purpose

of monitoring door open/closed status (hall sensor 3 in the driver's door actuator). The hall

effect sensor is located directly behind the rotary latch plate encased in the actuator. The

sensor is activated by the rotary latch plate's position. A change in current flow informs the

General module when a door is opened or closed.

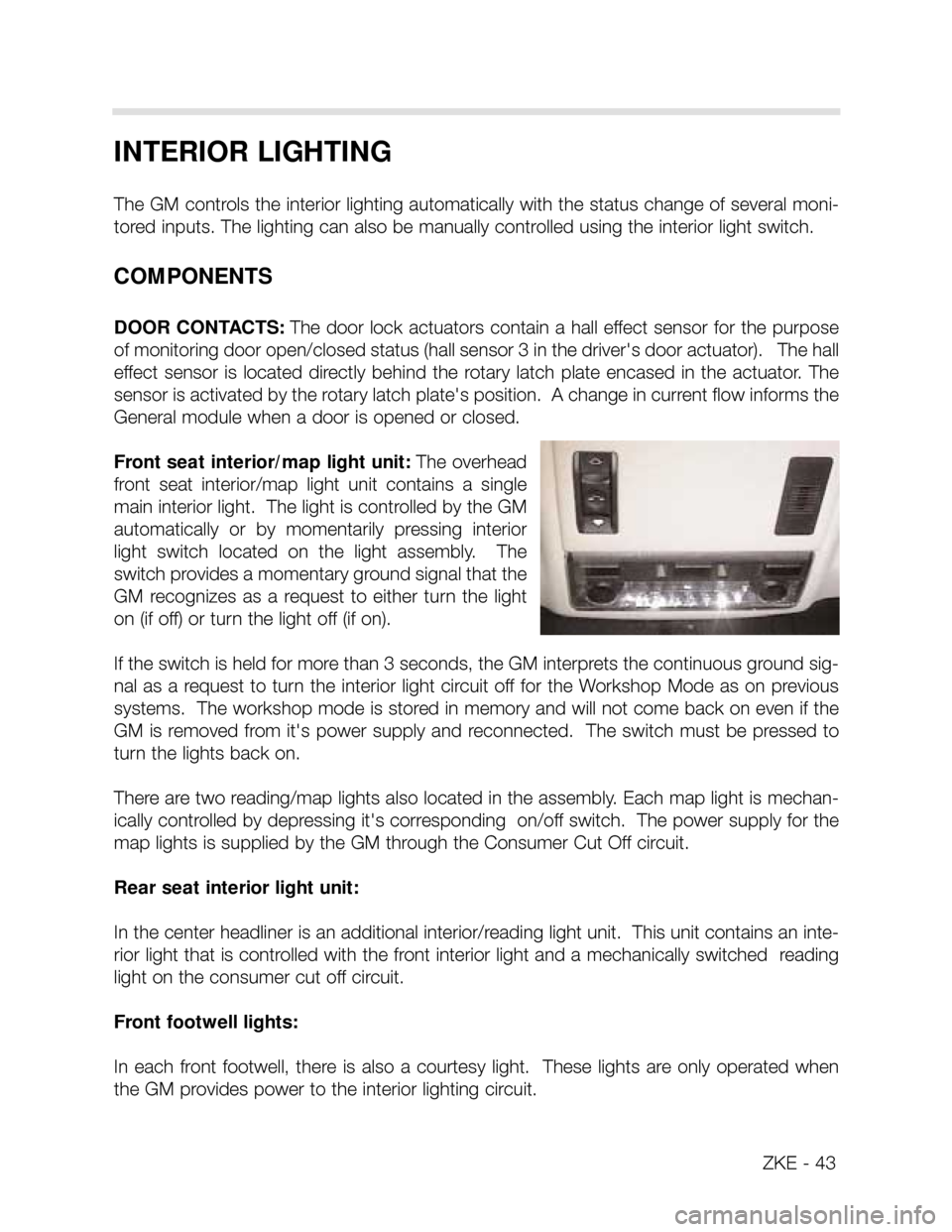

Front seat interior/map light unit: The overhead

front seat interior/map light unit contains a single

main interior light. The light is controlled by the GM

automatically or by momentarily pressing interior

light switch located on the light assembly. The

switch provides a momentary ground signal that the

GM recognizes as a request to either turn the light

on (if off) or turn the light off (if on).

If the switch is held for more than 3 seconds, the GM interprets the continuous ground sig-

nal as a request to turn the interior light circuit off for the Workshop Mode as on previous

systems. The workshop mode is stored in memory and will not come back on even if the

GM is removed from it's power supply and reconnected. The switch must be pressed to

turn the lights back on.

There are two reading/map lights also located in the assembly. Each map light is mechan-

ically controlled by depressing it's corresponding on/off switch. The power supply for the

map lights is supplied by the GM through the Consumer Cut Off circuit.

Rear seat interior light unit:

In the center headliner is an additional interior/reading light unit. This unit contains an inte-

rior light that is controlled with the front interior light and a mechanically switched reading

light on the consumer cut off circuit.

Front footwell lights:

In each front footwell, there is also a courtesy light. These lights are only operated when

the GM provides power to the interior lighting circuit.

Page 55 of 64

MIRROR OPERATION

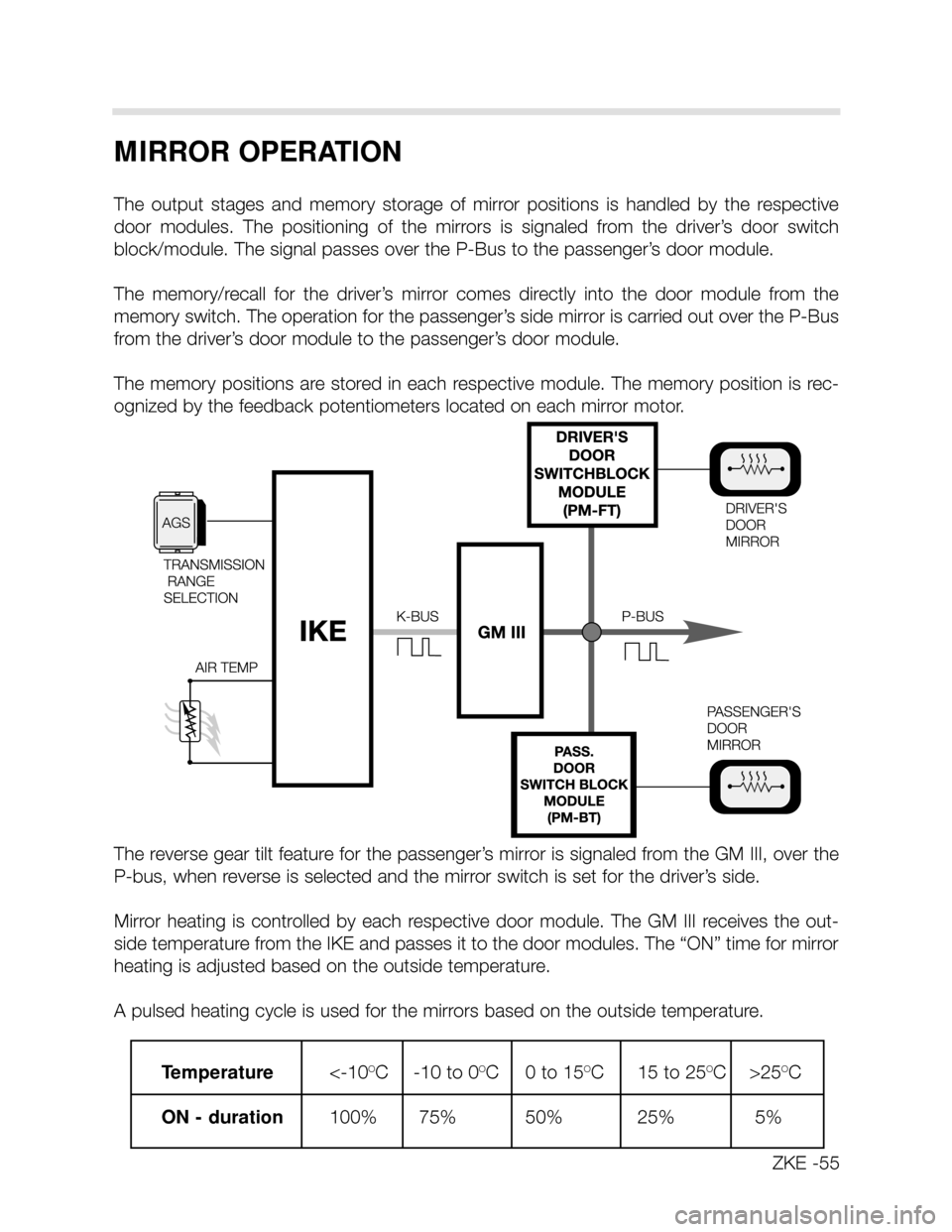

The output stages and memory storage of mirror positions is handled by the respective

door modules. The positioning of the mirrors is signaled from the driver’s door switch

block/module. The signal passes over the P-Bus to the passenger’s door module.

The memory/recall for the driver’s mirror comes directly into the door module from the

memory switch. The operation for the passenger’s side mirror is carried out over the P-Bus

from the driver’s door module to the passenger’s door module.

The memory positions are stored in each respective module. The memory position is rec-

ognized by the feedback potentiometers located on each mirror motor.

The reverse gear tilt feature for the passenger’s mirror is signaled from the GM III, over the

P-bus, when reverse is selected and the mirror switch is set for the driver’s side.

Mirror heating is controlled by each respective door module. The GM III receives the out-

side temperature from the IKE and passes it to the door modules. The “ON” time for mirror

heating is adjusted based on the outside temperature.

A pulsed heating cycle is used for the mirrors based on the outside temperature.

ZKE -55

Temperature<-10OC -10 to 0OC 0 to 15OC 15 to 25OC >25OC

ON - duration 100% 75% 50% 25% 5%

Page 57 of 64

SEAT OPERATION

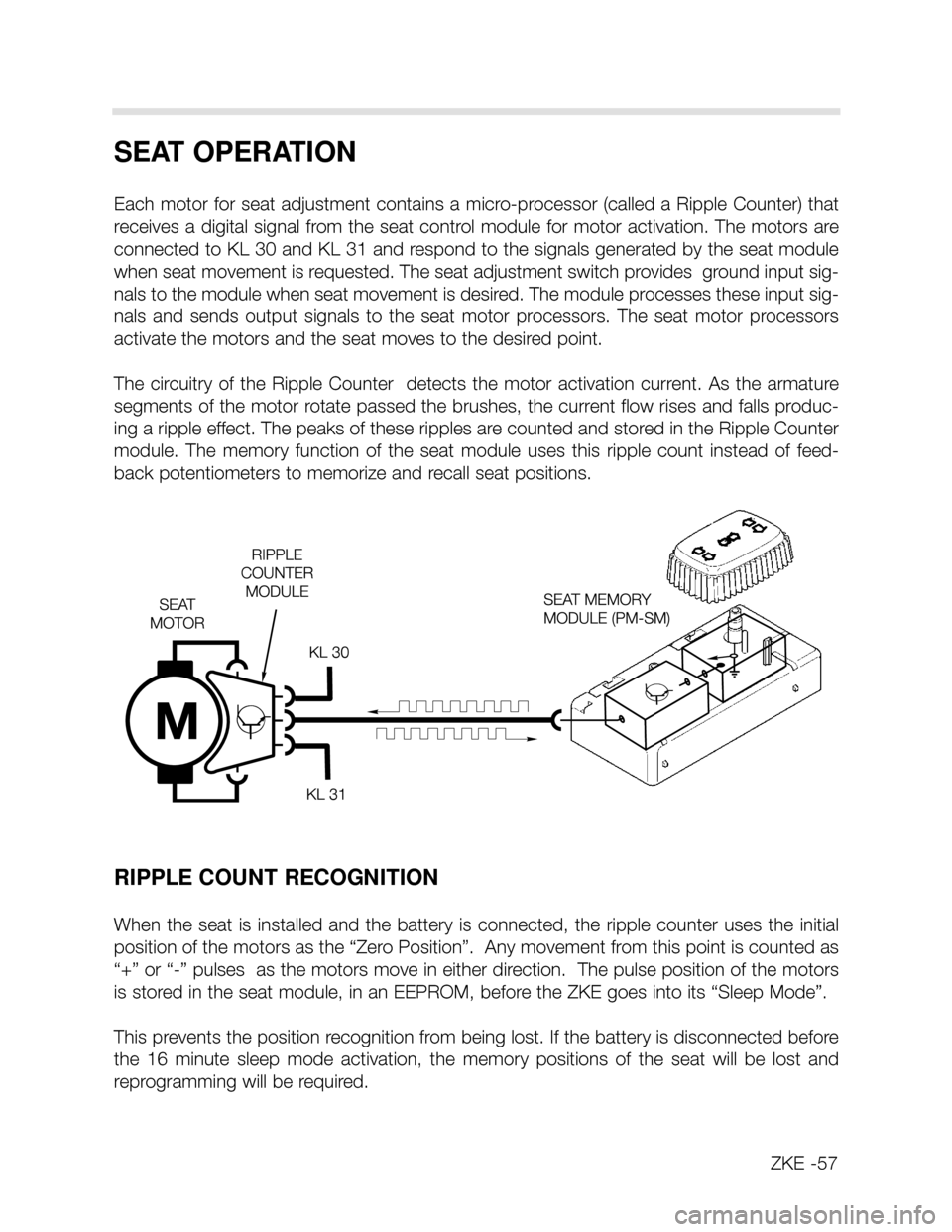

Each motor for seat adjustment contains a micro-processor (called a Ripple Counter) that

receives a digital signal from the seat control module for motor activation. The motors are

connected to KL 30 and KL 31 and respond to the signals generated by the seat module

when seat movement is requested. The seat adjustment switch provides ground input sig-

nals to the module when seat movement is desired. The module processes these input sig-

nals and sends output signals to the seat motor processors. The seat motor processors

activate the motors and the seat moves to the desired point.

The circuitry of the Ripple Counter detects the motor activation current. As the armature

segments of the motor rotate passed the brushes, the current flow rises and falls produc-

ing a ripple effect. The peaks of these ripples are counted and stored in the Ripple Counter

module. The memory function of the seat module uses this ripple count instead of feed-

back potentiometers to memorize and recall seat positions.

RIPPLE COUNT RECOGNITION

When the seat is installed and the battery is connected, the ripple counter uses the initial

position of the motors as the “Zero Position”. Any movement from this point is counted as

“+” or “-” pulses as the motors move in either direction. The pulse position of the motors

is stored in the seat module, in an EEPROM, before the ZKE goes into its “Sleep Mode”.

This prevents the position recognition from being lost. If the battery is disconnected before

the 16 minute sleep mode activation, the memory positions of the seat will be lost and

reprogramming will be required.

ZKE -57