lock BUICK CENTURY 2003 Repair Manual

[x] Cancel search | Manufacturer: BUICK, Model Year: 2003, Model line: CENTURY, Model: BUICK CENTURY 2003Pages: 344, PDF Size: 2.57 MB

Page 196 of 344

Total Weight on Your Vehicle's Tires

Be sure your vehicle's tires are in¯ated to the upper limit

for cold tires. You'll ®nd these numbers on the

Tire-Loading Information label (found inside the trunk

lid) or see

Loading Your Vehicle on page 4-33. Then be

sure you don't go over the GVW limit for your vehicle,

including the weight of the trailer tongue.

Hitches

It's important to have the correct hitch equipment.

Crosswinds, large trucks going by and rough roads are

a few reasons why you'll need the right hitch. Here

are some rules to follow:

·The rear bumper on your vehicle is not intended for

hitches. Do not attach rental hitches or other

bumper-type hitches to it. Use only a frame-mounted

hitch that does not attach to the bumper.

·Will you have to make any holes in the body of your

vehicle when you install a trailer hitch? If you do, then

be sure to seal the holes later when you remove the

hitch. If you don't seal them, deadly carbon monoxide

(CO) from your exhaust can get into your vehicle.

See

Engine Exhaust on page 2-30. Dirt and

water can, too.

Safety Chains

You should always attach chains between your vehicle

and your trailer. Cross the safety chains under the tongue

of the trailer so that the tongue will not drop to the road if

it becomes separated from the hitch. Instructions about

safety chains may be provided by the hitch manufacturer

or by the trailer manufacturer. Follow the manufacturer's

recommendation for attaching safety chains and do not

attach them to the bumper. Always leave just enough

slack so you can turn with your rig. And, never allow

safety chains to drag on the ground.

Trailer Brakes

Because you have anti-lock brakes, do not try to tap

into your vehicle's brake system. If you do, both brake

systems won't work well, or at all.

4-38

Page 208 of 344

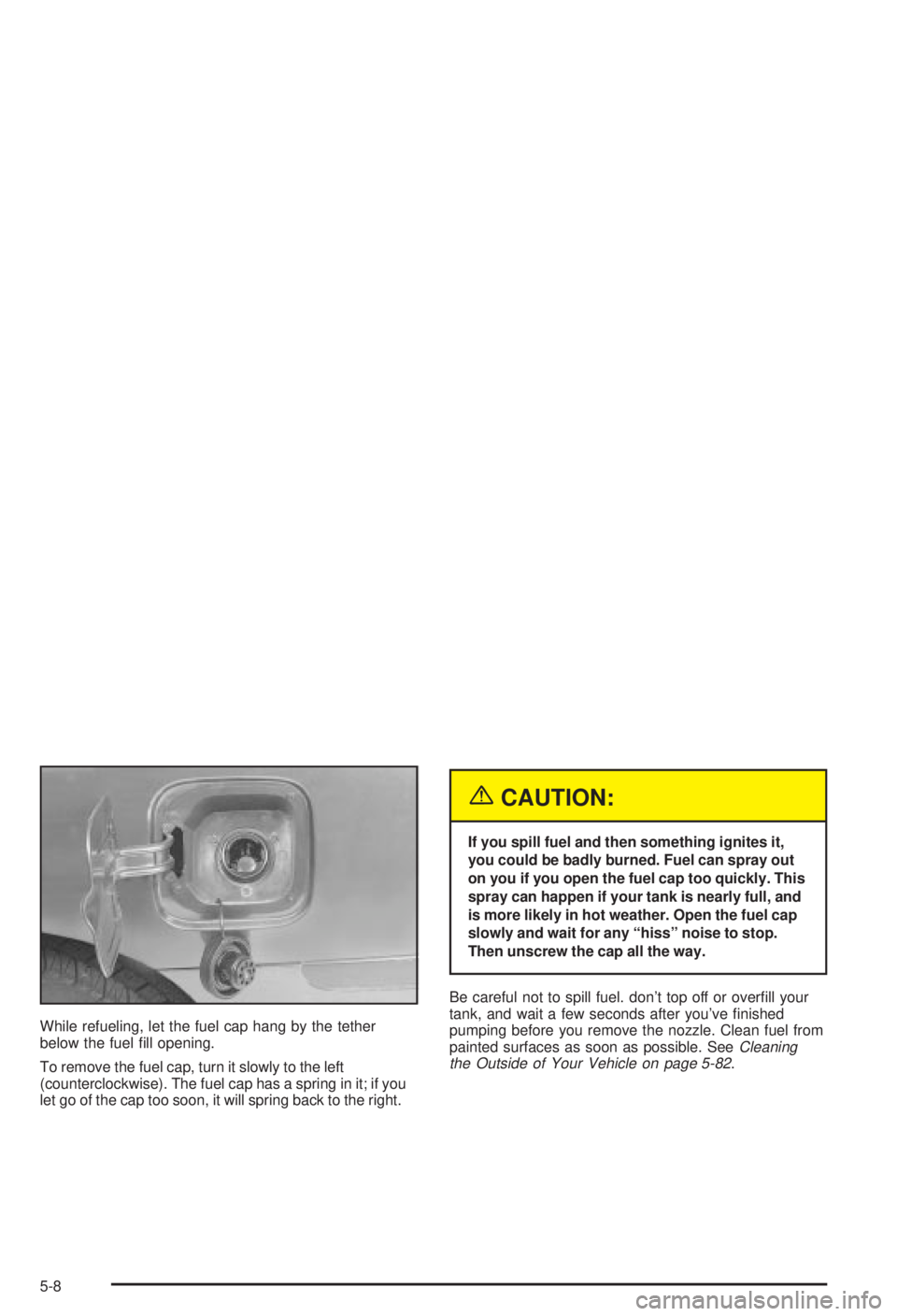

While refueling, let the fuel cap hang by the tether

below the fuel ®ll opening.

To remove the fuel cap, turn it slowly to the left

(counterclockwise). The fuel cap has a spring in it; if you

let go of the cap too soon, it will spring back to the right.

{CAUTION:

If you spill fuel and then something ignites it,

you could be badly burned. Fuel can spray out

on you if you open the fuel cap too quickly. This

spray can happen if your tank is nearly full, and

is more likely in hot weather. Open the fuel cap

slowly and wait for any ªhissº noise to stop.

Then unscrew the cap all the way.

Be careful not to spill fuel. don't top off or over®ll your

tank, and wait a few seconds after you've ®nished

pumping before you remove the nozzle. Clean fuel from

painted surfaces as soon as possible. See

Cleaning

the Outside of Your Vehicle on page 5-82.

5-8

Page 209 of 344

When you put the fuel cap back on, turn it to the right

(clockwise) until you hear a clicking sound. Make

sure you fully install the cap. The diagnostic system can

determine if the fuel cap has been left off or improperly

installed. This would allow fuel to evaporate into the

atmosphere. See

Malfunction Indicator Lamp on

page 3-31.

{CAUTION:

If a ®re starts while you're refueling, don't

remove the nozzle. Shut off the ¯ow of fuel by

shutting off the pump or by notifying the

station attendant. Leave the area immediately.

Notice:If you need a new fuel cap, be sure to get

the right type. Your dealer can get one for you.

If you get the wrong type, it may not ®t properly.

This may cause your malfunction indicator lamp to

light and may damage your fuel tank and emissions

system. See ªMalfunction Indicator Lampº in the

Index.

Filling a Portable Fuel Container

{CAUTION:

Never ®ll a portable fuel container while it is in

your vehicle. Static electricity discharge from

the container can ignite the gasoline vapor.

You can be badly burned and your vehicle

damaged if this occurs. To help avoid injury to

you and others:

·Dispense gasoline only into approved

containers.

·Do not ®ll a container while it is inside a

vehicle, in a vehicle's trunk, pickup bed or

on any surface other than the ground.

·Bring the ®ll nozzle in contact with the

inside of the ®ll opening before operating

the nozzle. Contact should be maintained

until the ®lling is complete.

·Don't smoke while pumping gasoline.

5-9

Page 213 of 344

A. Windshield Washer Fluid Reservoir. SeeWindshield

Washer Fluid on page 5-38.

B. Battery. See

Battery on page 5-42.

C. Underhood Fuse Block. See

Fuses and Circuit

Breakers on page 5-89.

D. Remote Positive (+) Battery Terminal. See

Jump

Starting on page 5-43.

E. Radiator Pressure Cap. See

Radiator Pressure Cap

on page 5-26.

F. Engine Coolant Recovery Tank. See

Engine Coolant

on page 5-23.

G. Power Steering Fluid Reservoir. See

Power Steering

Fluid on page 5-36.

H. Electric Engine Cooling Fan. See

Jump Starting on

page 5-43.

I. Engine Oil Fill Cap. See

Engine Oil on page 5-13.

J. Engine Oil Dipstick. See

Engine Oil on page 5-13.

K. Automatic Transaxle Fluid Dipstick. See

Automatic

Transaxle Fluid on page 5-19.

L. Brake Fluid Reservoir. See

Brakes on page 5-39.

M. Engine Air Cleaner/Filter. See

Engine Air

Cleaner/Filter on page 5-18.

Engine Oil

Checking Engine Oil

It's a good idea to check your engine oil every time you

get fuel. In order to get an accurate reading, the oil

must be warm and the vehicle must be on level ground.

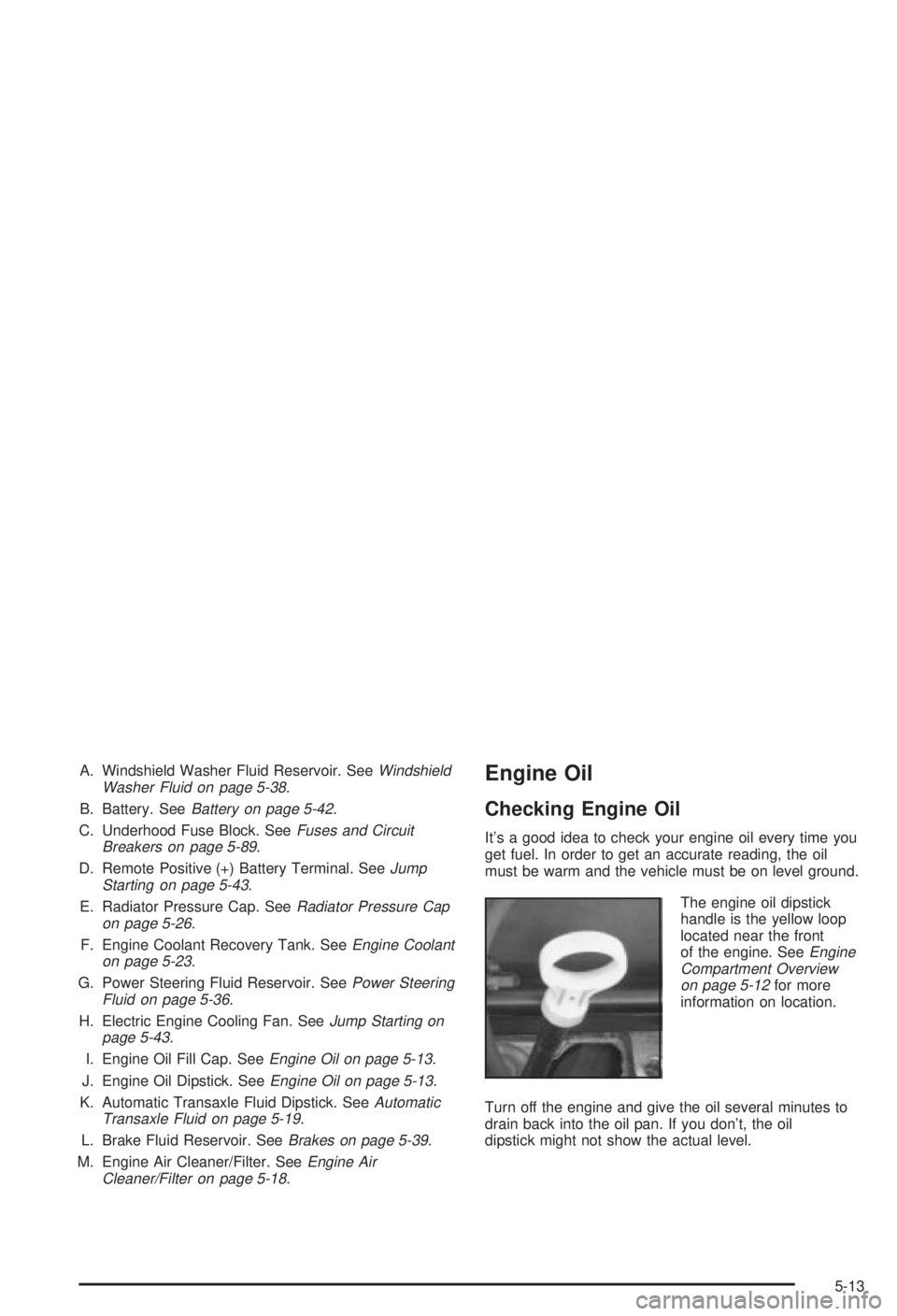

The engine oil dipstick

handle is the yellow loop

located near the front

of the engine. See

Engine

Compartment Overview

on page 5-12

for more

information on location.

Turn off the engine and give the oil several minutes to

drain back into the oil pan. If you don't, the oil

dipstick might not show the actual level.

5-13

Page 218 of 344

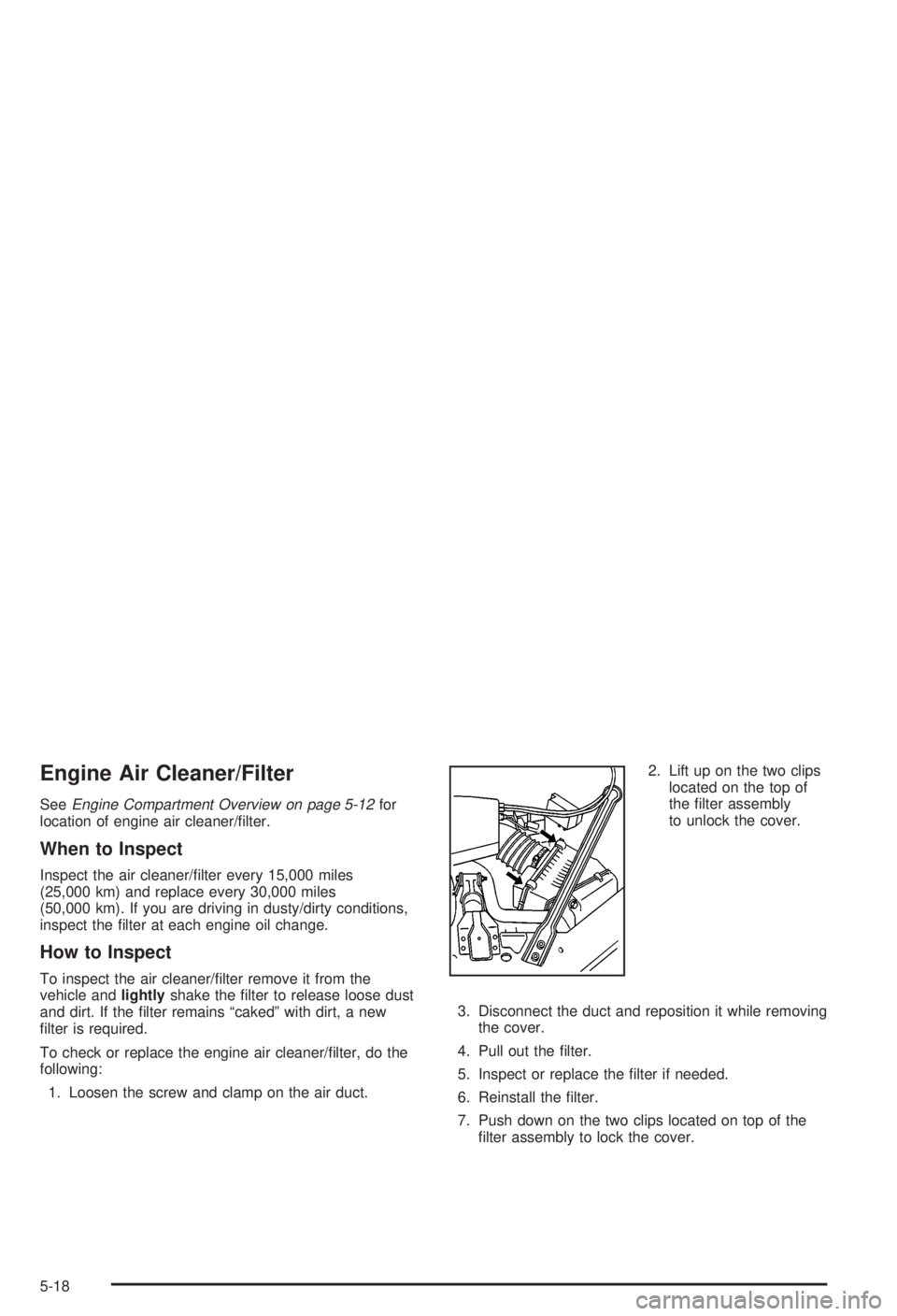

Engine Air Cleaner/Filter

SeeEngine Compartment Overview on page 5-12for

location of engine air cleaner/®lter.

When to Inspect

Inspect the air cleaner/®lter every 15,000 miles

(25,000 km) and replace every 30,000 miles

(50,000 km). If you are driving in dusty/dirty conditions,

inspect the ®lter at each engine oil change.

How to Inspect

To inspect the air cleaner/®lter remove it from the

vehicle andlightlyshake the ®lter to release loose dust

and dirt. If the ®lter remains ªcakedº with dirt, a new

®lter is required.

To check or replace the engine air cleaner/®lter, do the

following:

1. Loosen the screw and clamp on the air duct.2. Lift up on the two clips

located on the top of

the ®lter assembly

to unlock the cover.

3. Disconnect the duct and reposition it while removing

the cover.

4. Pull out the ®lter.

5. Inspect or replace the ®lter if needed.

6. Reinstall the ®lter.

7. Push down on the two clips located on top of the

®lter assembly to lock the cover.

5-18

Page 233 of 344

How to Add Coolant to the Radiator

Notice:Your engine has a speci®c radiator

®ll procedure. Failure to follow this procedure could

cause your engine to overheat and be severely

damaged.

1. You can remove the radiator pressure cap when

the cooling system, including the radiator pressure

cap and upper radiator hose, is no longer hot.

Turn the pressure cap slowly counterclockwise until

it ®rst stops. (Don't press down while turning the

pressure cap.)If you hear a hiss, wait for that to stop. A hiss

means there is still some pressure left.

2. Then keep turning the pressure cap, but now push

down as you turn it. Remove the pressure cap.

5-33

Page 250 of 344

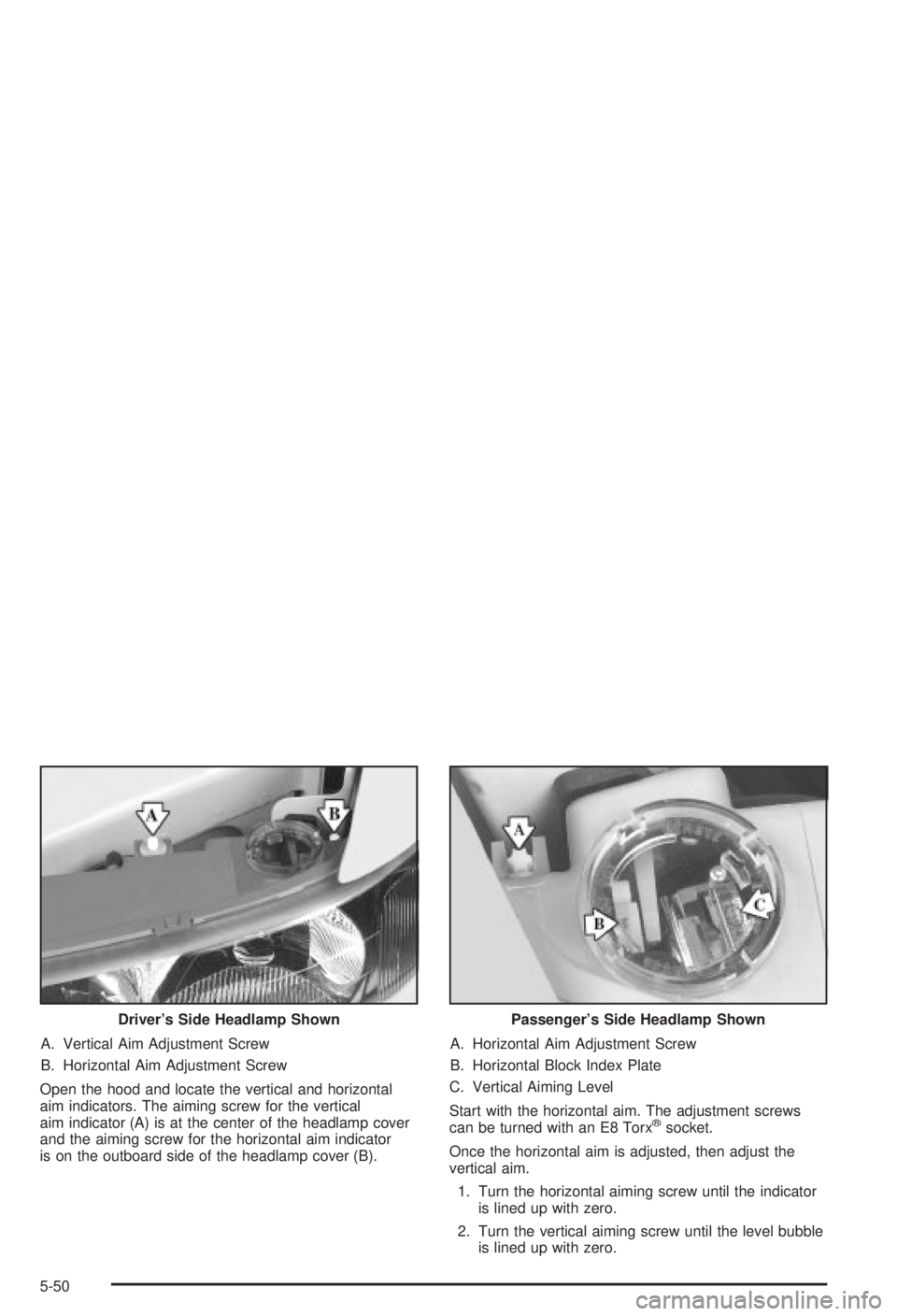

A. Vertical Aim Adjustment Screw

B. Horizontal Aim Adjustment Screw

Open the hood and locate the vertical and horizontal

aim indicators. The aiming screw for the vertical

aim indicator (A) is at the center of the headlamp cover

and the aiming screw for the horizontal aim indicator

is on the outboard side of the headlamp cover (B).A. Horizontal Aim Adjustment Screw

B. Horizontal Block Index Plate

C. Vertical Aiming Level

Start with the horizontal aim. The adjustment screws

can be turned with an E8 Torx

žsocket.

Once the horizontal aim is adjusted, then adjust the

vertical aim.

1. Turn the horizontal aiming screw until the indicator

is lined up with zero.

2. Turn the vertical aiming screw until the level bubble

is lined up with zero. Driver's Side Headlamp Shown

Passenger's Side Headlamp Shown

5-50

Page 252 of 344

5. Remove the rubber access cover from behind the

bulb you are replacing.

6. Turn the bulb socket one-quarter turn and remove it

from the headlamp assembly.

7. Lift the plastic locking tab on the electrical connector

and pull the connector from the headlamp bulb

socket.

8. Connect the new headlamp bulb to the electrical

connector, making sure the connector tab snaps

into place.9. Insert the bulb socket into the headlamp assembly.

10. Reverse all steps to reassemble the headlamp

assembly, then check the lamps.

Front Turn Signal and Parking

Lamps

1. Remove the headlamp assembly. Refer to the

removal procedure earlier in this section.

2. Remove the rubber bulb access cover.

3. Twist the sidemarker lamp socket, located on the

outboard side of the headlamp assembly,

counterclockwise and pull it from the headlamp

assembly.

4. Holding the base of the socket, pull the old bulb

from the socket.

5. Push the new bulb into the socket.

6. Reverse Steps 1 through 3 to reinstall the lamp

assembly.

5-52

Page 253 of 344

Center High-Mounted Stoplamp

(CHMSL)

1. Open the trunk.

2. Reach through the access opening in the trunk lid.3. Remove the old bulb by turning it one-quarter turn

counterclockwise.

4. Push the new bulb into the bulb socket.

5. Turn the socket one-quarter turn clockwise to

reinstall.

5-53

Page 254 of 344

Taillamps, Turn Signal, and

Stoplamps1. Open the trunk.

2. If your vehicle is equipped with a convenience net,

remove it.

3. Remove the three plastic wing nuts (A).

There is one wing nut located on the outside of the

carpet. The other two are located underneath

the carpet.

4. Pull the taillamp housing (B) away from the body of

the vehicle.

5. Squeeze the tab on the socket and turn the socket

counterclockwise.

6. Pull out the socket.

7. Pull the old bulb out of the socket. (There are two

bulbs on each taillamp.)

8. Push in a new bulb.

9. Reverse these steps to reinstall the lamp assembly.

5-54