torque BUICK ENCLAVE 2008 Owner's Manual

[x] Cancel search | Manufacturer: BUICK, Model Year: 2008, Model line: ENCLAVE, Model: BUICK ENCLAVE 2008Pages: 436

Page 110 of 436

Leaving the Vehicle With the Engine

Running

{CAUTION:

It can be dangerous to leave the vehicle with the

engine running. The vehicle could move suddenly if

the shift lever is not fully in P (Park) with the parking

brake �rmly set. And, if you leave the vehicle with

the engine running, it could overheat and even

catch �re. You or others could be injured. Do not

leave the vehicle with the engine running.

If you have to leave the vehicle with the engine running,

be sure your vehicle is in P (Park) and the parking

brake is �rmly set before you leave it. SeeParking Brake

on page 2-27for more information.

Torque Lock

Torque lock is when the weight of the vehicle puts too

much force on the parking pawl in the transmission.

This happens when parking on a hill and shifting the

transmission into P (Park) is not done properly and then it

is difficult to shift out of P (Park). To prevent torque lock,

set the parking brake and then shift into P (Park). To �nd

out how, see “Shifting Into Park” in this section.

If torque lock does occur, your vehicle may need to be

pushed uphill by another vehicle to relieve the parking

pawl pressure, so you can shift out of P (Park).

2-30

Page 318 of 436

Brake Wear

This vehicle has disc brakes. Disc brake pads have

built-in wear indicators that make a high-pitched warning

sound when the brake pads are worn and new pads

are needed. The sound can come and go or be heard all

the time the vehicle is moving, except when applying

the brake pedal �rmly.

{CAUTION:

The brake wear warning sound means that soon

the brakes will not work well. That could lead to an

accident. When the brake wear warning sound is

heard, have the vehicle serviced.

Notice:Continuing to drive with worn-out brake

pads could result in costly brake repair.Some driving conditions or climates can cause a brake

squeal when the brakes are �rst applied or lightly

applied. This does not mean something is wrong with

the brakes.

Properly torqued wheel nuts are necessary to help

prevent brake pulsation. When tires are rotated, inspect

brake pads for wear and evenly tighten wheel nuts in

the proper sequence to torque speci�cations in

Capacities and Specifications on page 5-109.

Brake linings should always be replaced as complete

axle sets.

5-42

Page 348 of 436

Tire Inspection and Rotation

We recommend that you regularly inspect your

vehicle’s tires, including the spare tire, for signs of

wear or damage. SeeWhen It Is Time for New

Tires on page 5-73for more information.

Tires should be rotated every 5,000 to 8,000 miles

(8 000 to 13 000 km). SeeScheduled Maintenance

on page 6-4.

The purpose of a regular tire rotation is to achieve

a uniform wear for all tires on the vehicle. This

will ensure that your vehicle continues to perform

most like it did when the tires were new.

Any time you notice unusual wear, rotate the tires

as soon as possible and check wheel alignment.

Also check for damaged tires or wheels. See

When It Is Time for New Tires on page 5-73and

Wheel Replacement on page 5-79.When rotating the vehicle’s tires, always use the

correct rotation pattern shown here.

Do not include the compact spare tire in the tire

rotation.

After the tires have been rotated, adjust the front

and rear in�ation pressures as shown on the Tire

and Loading Information label. SeeInflation - Tire

Pressure on page 5-66andLoading the Vehicle on

page 4-18.

Reset the Tire Pressure Monitor System. SeeTire

Pressure Monitor Operation on page 5-69.

Make certain that all wheel nuts are properly

tightened. See “Wheel Nut Torque” under

Capacities and Specifications on page 5-109.

5-72

Page 364 of 436

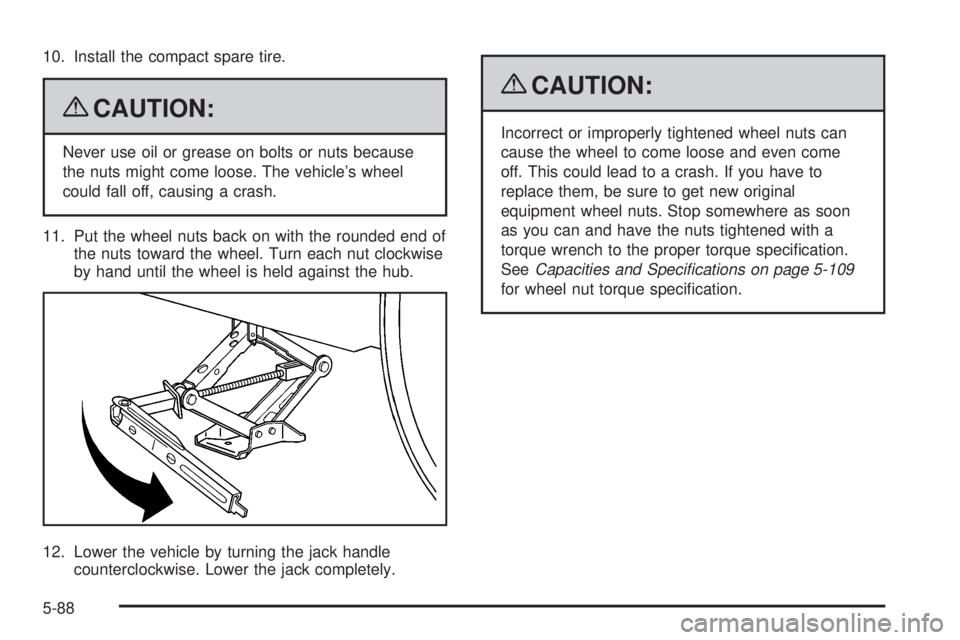

10. Install the compact spare tire.

{CAUTION:

Never use oil or grease on bolts or nuts because

the nuts might come loose. The vehicle’s wheel

could fall off, causing a crash.

11. Put the wheel nuts back on with the rounded end of

the nuts toward the wheel. Turn each nut clockwise

by hand until the wheel is held against the hub.

12. Lower the vehicle by turning the jack handle

counterclockwise. Lower the jack completely.

{CAUTION:

Incorrect or improperly tightened wheel nuts can

cause the wheel to come loose and even come

off. This could lead to a crash. If you have to

replace them, be sure to get new original

equipment wheel nuts. Stop somewhere as soon

as you can and have the nuts tightened with a

torque wrench to the proper torque speci�cation.

SeeCapacities and Specifications on page 5-109

for wheel nut torque speci�cation.

5-88

Page 365 of 436

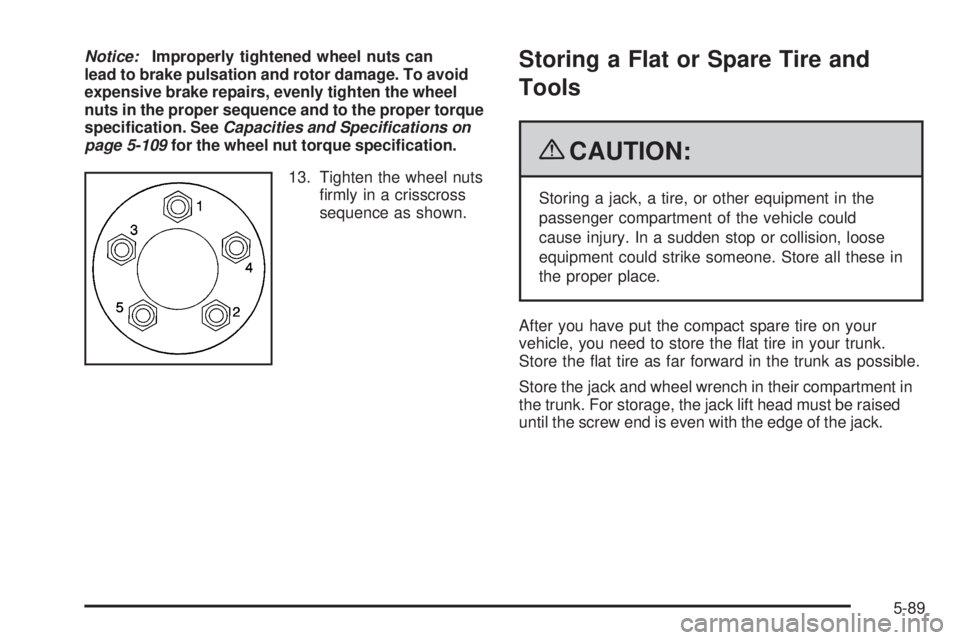

Notice:Improperly tightened wheel nuts can

lead to brake pulsation and rotor damage. To avoid

expensive brake repairs, evenly tighten the wheel

nuts in the proper sequence and to the proper torque

speci�cation. SeeCapacities and Specifications on

page 5-109for the wheel nut torque speci�cation.

13. Tighten the wheel nuts

�rmly in a crisscross

sequence as shown.Storing a Flat or Spare Tire and

Tools

{CAUTION:

Storing a jack, a tire, or other equipment in the

passenger compartment of the vehicle could

cause injury. In a sudden stop or collision, loose

equipment could strike someone. Store all these in

the proper place.

After you have put the compact spare tire on your

vehicle, you need to store the �at tire in your trunk.

Store the �at tire as far forward in the trunk as possible.

Store the jack and wheel wrench in their compartment in

the trunk. For storage, the jack lift head must be raised

until the screw end is even with the edge of the jack.

5-89

Page 386 of 436

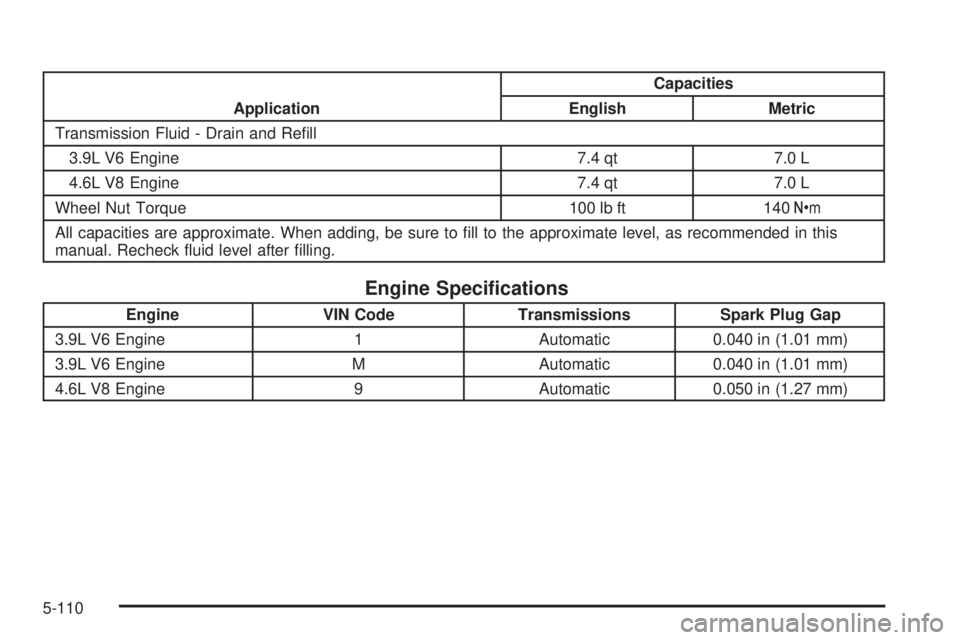

ApplicationCapacities

English Metric

Transmission Fluid - Drain and Re�ll

3.9L V6 Engine 7.4 qt 7.0 L

4.6L V8 Engine 7.4 qt 7.0 L

Wheel Nut Torque 100 lb ft 140Y

All capacities are approximate. When adding, be sure to �ll to the approximate level, as recommended in this

manual. Recheck �uid level after �lling.

Engine Speci�cations

Engine VIN Code Transmissions Spark Plug Gap

3.9L V6 Engine 1 Automatic 0.040 in (1.01 mm)

3.9L V6 Engine M Automatic 0.040 in (1.01 mm)

4.6L V8 Engine 9 Automatic 0.050 in (1.27 mm)

5-110