light BUICK ENCLAVE 2010 Owners Manual

[x] Cancel search | Manufacturer: BUICK, Model Year: 2010, Model line: ENCLAVE, Model: BUICK ENCLAVE 2010Pages: 438, PDF Size: 2.47 MB

Page 280 of 438

9-38 Driving and Operating

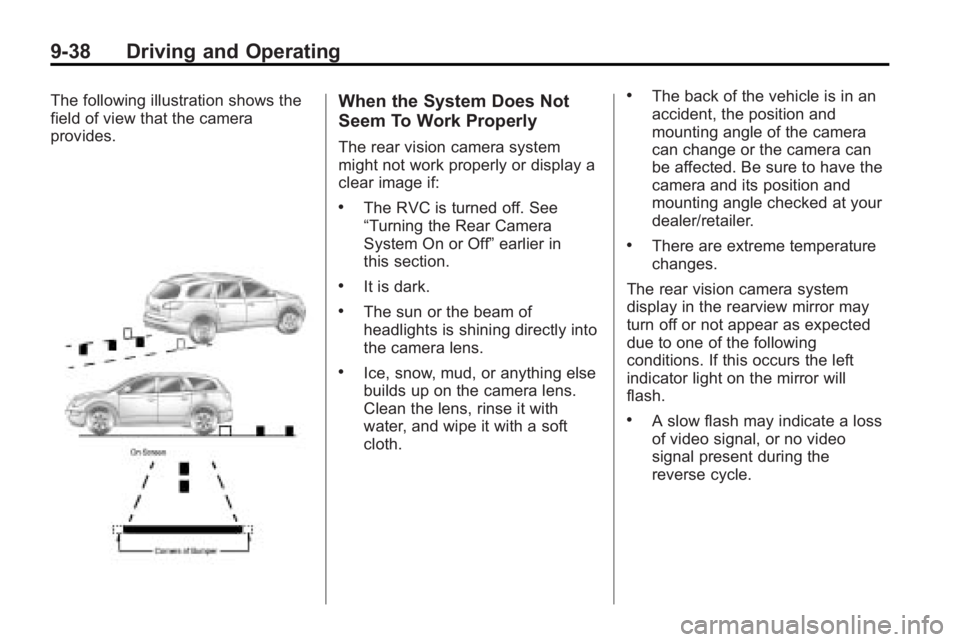

The following illustration shows the

field of view that the camera

provides.When the System Does Not

Seem To Work Properly

The rear vision camera system

might not work properly or display a

clear image if:

.The RVC is turned off. See

“Turning the Rear Camera

System On or Off”earlier in

this section.

.It is dark.

.The sun or the beam of

headlights is shining directly into

the camera lens.

.Ice, snow, mud, or anything else

builds up on the camera lens.

Clean the lens, rinse it with

water, and wipe it with a soft

cloth.

.The back of the vehicle is in an

accident, the position and

mounting angle of the camera

can change or the camera can

be affected. Be sure to have the

camera and its position and

mounting angle checked at your

dealer/retailer.

.There are extreme temperature

changes.

The rear vision camera system

display in the rearview mirror may

turn off or not appear as expected

due to one of the following

conditions. If this occurs the left

indicator light on the mirror will

flash.

.A slow flash may indicate a loss

of video signal, or no video

signal present during the

reverse cycle.

Page 281 of 438

Driving and Operating 9-39

.A fast flash may indicate that the

display has been on for the

maximum allowable time during

a reverse cycle, or the display

has reached an Over

Temperature limit.

The fast flash conditions are

used to protect the video device

from high temperature

conditions. Once conditions

return to normal the device will

reset and the green indicator will

stop flashing.

During any of these fault conditions,

the display will be blank and the

indicator will continue to flash as

long as the vehicle is in R (Reverse)

or until the conditions return to

normal.

Pressing and holding

zwhen the

left indicator light is flashing will turn

off the video display along with the

left indicator light.

Fuel

Use of the recommended fuel is an

important part of the proper

maintenance of this vehicle. To help

keep the engine clean and maintain

optimum vehicle performance, we

recommend the use of gasoline

advertised as TOP TIER Detergent

Gasoline.

Look for the TOP TIER label on the

fuel pump to ensure gasoline meets

enhanced detergency standards

developed by auto companies. A list

of marketers providing TOP TIER

Detergent Gasoline can be found at

www.toptiergas.com.

Page 285 of 438

Driving and Operating 9-43

While refueling, hang the tethered

fuel cap from the hook on the

fuel door.

{WARNING

Fuel can spray out on you if you

open the fuel cap too quickly.

If you spill fuel and then

something ignites it, you could be

badly burned. This spray can

happen if the tank is nearly full,

and is more likely in hot weather.

Open the fuel cap slowly and wait

for any hiss noise to stop. Then

unscrew the cap all the way.Be careful not to spill fuel. Do not

top off or overfill the tank and wait a

few seconds after you have finished

pumping before removing the

nozzle. Clean fuel from painted

surfaces as soon as possible.

See

Exterior Care on page 10‑88.

When replacing the fuel cap,

turn it clockwise until it clicks.

Make sure the cap is fully installed.

The diagnostic system can

determine if the fuel cap has been

left off or improperly installed. This

would allow fuel to evaporate into

the atmosphere. See Malfunction

Indicator Lamp on page 5‑18.

{WARNING

If a fire starts while you are

refueling, do not remove the

nozzle. Shut off the flow of fuel by

shutting off the pump or by

notifying the station attendant.

Leave the area immediately.

Notice: If a new fuel cap is

needed, be sure to get the right

type of cap from your dealer/

retailer. The wrong type fuel cap

might not fit properly, might

cause the malfunction indicator

lamp to light, and could damage

the fuel tank and emissions

system. See Malfunction Indicator

Lamp on page 5‑18.

Page 289 of 438

Driving and Operating 9-47

Tow/Haul Mode

Tow/Haul assists when pulling a

heavy trailer or a large or heavy

load. The purpose of the Tow/Haul

mode is to:

.Reduce the frequency and

improve the predictability of

transmission shifts.

.Provide the same solid shift feel

as when the vehicle is unloaded.

.Improve control of vehicle speed

while requiring less throttle pedal

activity.

.Increase the charging system

voltage to assist in recharging a

battery installed in a trailer.

Press this button located on the

console to turn on and turn off the

Tow/Haul mode.

The Tow/Haul light on the

instrument panel comes on to

indicate that Tow/Haul mode has

been selected.

Tow/Haul may be turned off by

pressing the button again, at which

time the indicator light on the

instrument panel will turn off. The

vehicle will automatically turn off

Tow/Haul every time it is started.Tow/Haul is designed to be most

effective when the vehicle and

trailer combined weight is at least

75 percent of the vehicle's Gross

Combined Weight Rating (GCWR).

See

Trailer Towing

on page 9‑50.

Tow/Haul is most useful when

pulling a heavy trailer or a large or

heavy load under the following

driving conditions:

.Travelling through rolling terrain.

.Travelling in stop and go traffic.

.Travelling in busy parking lots

where improved low speed

control of the vehicle is desired.

Operating the vehicle in Tow/Haul

when lightly loaded or with no trailer

will not cause damage but there is

no benefit. Such a selection when

unloaded may result in unpleasant

engine and transmission driving

characteristics and reduced fuel

economy.

Page 296 of 438

9-54 Driving and Operating

Weight-Distributing Hitches and

Weight Carrying Hitches

A. Body-to-Ground Distance

B. Front of Vehicle

When using a weight-distributing

hitch, the hitch must be adjusted so

that the distance (A) remains the

same both before and after coupling

the trailer to the tow vehicle.

Safety Chains

Always attach chains between the

vehicle and the trailer. Cross the

safety chains under the tongue of

the trailer to help prevent the tongue

from contacting the road if it

becomes separated from the hitch.

Always leave just enough slack so

the rig can turn. Never allow safety

chains to drag on the ground.

Trailer Brakes

A loaded trailer that weighs more

than 450 kg (1,000 lbs) needs to

have its own brake system that is

adequate for the weight of the

trailer. Be sure to read and follow

the instructions for the trailer brakes

so they are installed, adjusted and

maintained properly.

Because the vehicle has antilock

brakes, do not try to tap into the

vehicle's hydraulic brake system.

If you do, both brake systems will

not work well, or at all.

Trailer Wiring Harness

Basic Trailer Wiring

The trailer wiring harness, with a

seven-pin connector, is located at

the rear of the vehicle and is tied to

the vehicle's frame. The harness

connector can be plugged into a

seven-pin universal heavy-duty

trailer connector available through

your dealer/retailer.

The seven-wire harness contains

the following trailer circuits:

.Yellow: Left Stop/Turn Signal

.Dark Green: Right Stop/Turn

Signal

.Brown: Taillamps

.Black: Ground

.Light Green: Back-up Lamps

.Red/Black: Battery Feed

.Dark Blue: Trailer Brake*

*The fuse for this circuit is installed

in the underhood electrical center,

but the wires are not connected.

Page 297 of 438

Driving and Operating 9-55

They should be connected by your

dealer/retailer or a qualified service

center.

If the back-up lamp circuit is not

functional, contact your dealer/

retailer.

If a remote (non-vehicle) battery is

being charged, press the Tow/Haul

mode switch located on the center

console near the climate controls.

This will boost the vehicle system

voltage and properly charge the

battery. If the trailer is too light for

Tow/Haul mode, turn on the

headlamps (Non-HID only) as a

second way to boost the vehicle

system and charge the battery.Electric Trailer Brake Control

Wiring Provisions

These wiring provisions for an

electric trailer brake controller are

included with the vehicle as part of

the trailer wiring package. The

instrument panel contains blunt cut

wires behind the steering column for

the electric trailer brake controller.

The harness contains the following

wires:

.Red/Black: Power Supply

.White: Brake Switch Signal

.Gray: Illumination

.Dark Blue: Trailer Brake Signal

.Black: Ground

The electric trailer brake controller

should be installed by your dealer/

retailer or a qualified service center.

Conversions and

Add-Ons

Add-On Electrical

Equipment

Notice: Do not add anything

electrical to the vehicle unless

you check with your dealer/

retailer first. Some electrical

equipment can damage the

vehicle and the damage would

not be covered by the vehicle's

warranty. Some add-on electrical

equipment can keep other

components from working as

they should.

Add-on equipment can drain the

vehicle battery, even if the vehicle is

not operating.

The vehicle has an airbag system.

Before attempting to add anything

electrical to the vehicle, see

Servicing the Airbag-Equipped

Vehicle

on page 3‑41and Adding

Equipment to the Airbag-Equipped

Vehicle on page 3‑42.

Page 299 of 438

Vehicle Care 10-1

Vehicle Care

General Information

General Information . . . . . . . . . . 10-2

California Proposition65 Warning . . . . . . . . . . . . . . . . . 10-3

California Perchlorate Materials Requirements . . . . 10-3

Accessories and Modifications . . . . . . . . . . . . . . . 10-3

Vehicle Checks

Doing Your OwnService Work . . . . . . . . . . . . . . . 10-4

Hood . . . . . . . . . . . . . . . . . . . . . . . . 10-4

Engine Compartment Overview . . . . . . . . . . . . . . . . . . . 10-6

Engine Cover . . . . . . . . . . . . . . . . 10-7

Engine Oil . . . . . . . . . . . . . . . . . . . 10-8

Engine Oil Life System . . . . . 10-10

Automatic Transmission Fluid . . . . . . . . . . . . . . . . . . . . . . 10-11

Engine Air Cleaner/Filter . . . . 10-12

Cooling System . . . . . . . . . . . . 10-14

Engine Coolant . . . . . . . . . . . . . 10-14

Engine Overheating . . . . . . . . 10-18 Overheated Engine

Protection

Operating Mode . . . . . . . . . . . 10-20

Power Steering Fluid . . . . . . . 10-20

Washer Fluid . . . . . . . . . . . . . . . 10-21

Brakes . . . . . . . . . . . . . . . . . . . . . 10-22

Brake Fluid . . . . . . . . . . . . . . . . . 10-23

Battery . . . . . . . . . . . . . . . . . . . . . 10-25

All-Wheel Drive . . . . . . . . . . . . . 10-25

Starter Switch Check . . . . . . . 10-25

Automatic Transmission Shift Lock Control System

Check . . . . . . . . . . . . . . . . . . . . . 10-26

Ignition Transmission Lock Check . . . . . . . . . . . . . . . . . . . . . 10-26

Park Brake and P (Park) Mechanism Check . . . . . . . . 10-26

Wiper Blade Replacement . . . . . . . . . . . . . . 10-27

Windshield Replacement . . . 10-28

Headlamp Aiming

Headlamp Aiming . . . . . . . . . . 10-28

Bulb Replacement

Bulb Replacement . . . . . . . . . . 10-28

Halogen Bulbs . . . . . . . . . . . . . . 10-28

High Intensity Discharge (HID) Lighting . . . . . . . . . . . . . 10-29 Taillamps, Turn Signal,

Sidemarker, and

Stoplamps . . . . . . . . . . . . . . . . 10-29

License Plate Lamp . . . . . . . . 10-30

Replacement Bulbs . . . . . . . . . 10-30

Electrical System

High Voltage Devices and Wiring . . . . . . . . . . . . . . . . . . . . . 10-30

Electrical System Overload . . . . . . . . . . . . . . . . . . 10-31

Fuses and Circuit Breakers . . . . . . . . . . . . . . . . . . 10-31

Engine Compartment Fuse Block . . . . . . . . . . . . . . . . . . . . . 10-31

Instrument Panel Fuse Block . . . . . . . . . . . . . . . . . . . . . 10-35

Wheels and Tires

Tires . . . . . . . . . . . . . . . . . . . . . . . . 10-37

Tire Sidewall Labeling . . . . . . 10-38

Tire Designations . . . . . . . . . . . 10-40

Tire Terminology and

Definitions . . . . . . . . . . . . . . . . 10-41

Tire Pressure . . . . . . . . . . . . . . . 10-44

Tire Pressure Monitor System . . . . . . . . . . . . . . . . . . . 10-45

Tire Pressure Monitor Operation . . . . . . . . . . . . . . . . . 10-46

Page 310 of 438

10-12 Vehicle Care

Notice:Use of the incorrect

automatic transmission fluid may

damage the vehicle, and the

damages may not be covered by

the vehicle's warranty. Always

use the automatic transmission

fluid listed in Recommended

Fluids and Lubricants

on

page 11‑7.

The transmission fluid will not reach

the end of the dipstick unless the

transmission is at operating

temperature. If you need to check

the transmission fluid level, please

take the vehicle to your dealer/

retailer.

Engine Air Cleaner/Filter

When to Inspect the Engine Air

Cleaner/Filter

Inspect the air cleaner/filter at the

Maintenance IIintervals and replace

it at the first oil change after each

80 000 km (50,000 mile) interval.

See Scheduled Maintenance

on

page 11‑2for more information.

If you are driving in dusty/dirty

conditions, inspect the filter at each

engine oil change.

See Engine Compartment Overview

on page 10‑6for the location of the

engine air cleaner/filter.

How to Inspect the Engine Air

Cleaner/Filter

To inspect the air cleaner/filter,

remove the filter from the vehicle

and lightly shake the filter (away

from vehicle) to release loose dust

and dirt. If the filter remains caked

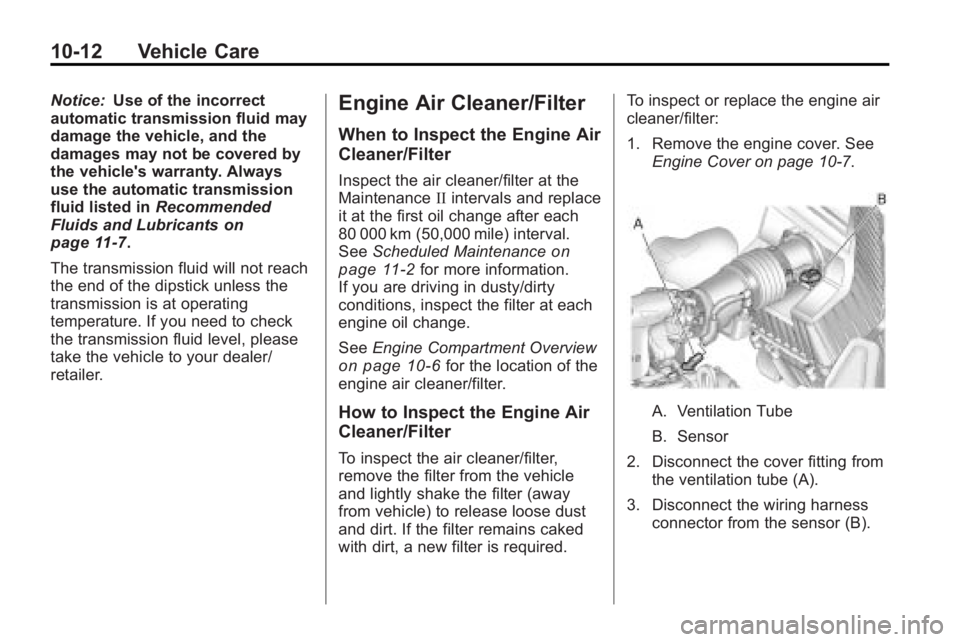

with dirt, a new filter is required. To inspect or replace the engine air

cleaner/filter:

1. Remove the engine cover. See

Engine Cover on page 10‑7.

A. Ventilation Tube

B. Sensor

2. Disconnect the cover fitting from the ventilation tube (A).

3. Disconnect the wiring harness connector from the sensor (B).

Page 316 of 438

10-18 Vehicle Care

6. Fill the coolant recovery tank tothe FULL COLD mark.

7. Reinstall the cap on the coolant recovery tank but leave the

radiator pressure cap off.8. Start the engine and let it rununtil the upper radiator hose

feels warm. Any time during this

procedure, watch out for the

engine cooling fan(s).

9. If the coolant level inside the radiator filler neck is low, add

more of the proper DEX-COOL

coolant mixture through the filler

neck until the level is back up to

the base of the filler neck.

Replace the pressure cap. Be

sure to secure it tightly. Notice:

If the pressure cap is not

tightly installed, coolant loss and

possible engine damage may

occur. Be sure the cap is properly

and tightly secured.

Engine Overheating

The vehicle has several indicators

to warn of engine overheating.

There is an engine coolant

temperature gage on the instrument

panel cluster. See Engine Coolant

Temperature Gage on page 5‑15.

The vehicle may also display an

ENGINE OVERHEATED IDLE

ENGINE and ENGINE

OVERHEATED STOP ENGINE

message in the Driver Information

Center (DIC). See Warning Lights,

Gages, and Indicators

on

page 5‑12.

You may decide not to lift the hood

when this warning appears, but

instead get service help right away.

See Roadside Assistance Program

on page 13‑6.

Page 321 of 438

Vehicle Care 10-23

Some driving conditions or climates

can cause a brake squeal when the

brakes are first applied or lightly

applied. This does not mean

something is wrong with the brakes.

Properly torqued wheel nuts are

necessary to help prevent brake

pulsation. When tires are rotated,

inspect brake pads for wear and

evenly tighten wheel nuts in the

proper sequence to torque

specifications inCapacities and

Specifications on page 12‑2.

Brake linings should always be

replaced as complete axle sets.

Brake Pedal Travel

See your dealer/retailer if the brake

pedal does not return to normal

height, or if there is a rapid increase

in pedal travel. This could be a sign

that brake service might be

required.

Brake Adjustment

Every time the brakes are applied,

with or without the vehicle moving,

the brakes adjust for wear.

Replacing Brake System Parts

The braking system on a vehicle is

complex. Its many parts have to be

of top quality and work well together

if the vehicle is to have really good

braking. The vehicle was designed

and tested with top-quality brake

parts. When parts of the braking

system are replaced, be sure to get

new, approved replacement parts.

If this is not done, the brakes might

not work properly. For example,

installing disc brake pads that are

wrong for the vehicle, can change

the balance between the front and

rear brakes —for the worse. The

braking performance expected can

change in many other ways if the

wrong replacement brake parts are

installed.

Brake Fluid

The brake master cylinder reservoir

is filled with DOT 3 brake fluid as

indicated on the reservoir cap. See

Engine Compartment Overview

on

page 10‑6for the location of the

reservoir.

There are only two reasons why the

brake fluid level in the reservoir

might go down:

.The brake fluid level goes down

because of normal brake lining

wear. When new linings are

installed, the fluid level goes

back up.