torque BUICK ENCLAVE 2010 Owner's Manual

[x] Cancel search | Manufacturer: BUICK, Model Year: 2010, Model line: ENCLAVE, Model: BUICK ENCLAVE 2010Pages: 438, PDF Size: 2.47 MB

Page 62 of 438

3-12 Seats and Restraints

{WARNING

A safety belt that is improperly

routed, not properly attached,

or twisted will not provide the

protection needed in a crash.

The person wearing the belt could

be seriously injured. After raising

the rear seatback, always check

to be sure that the safety belts

are properly routed and attached,

and are not twisted.

4. Reconnect the center safety belt mini-latch to the mini-buckle.

Do not let it twist.

5. Pull on the safety belt to be sure the mini-latch is secure.

Removing the Third Row Seats

1. Remove the cargo management

system, if it is in the vehicle. See

Cargo Management System

on

page 4‑3.

2. Remove anything on or under the seat. Notice:

Folding a rear seat with

the safety belts still fastened may

cause damage to the seat or the

safety belts. Always unbuckle the

safety belts and return them to

their normal stowed position

before folding a rear seat.

3. Fold the seatback down. See “Folding the Seatback” earlier in

this section.

4. Remove the rear bolts located on the floor on each side of

the seat.

5. Remove the seat by tilting it slightly upward, and then pulling

it out of the rear of the vehicle in

one motion.

6. Replace the bolts in the floor holes for storage.

Installing the Third Row Seats

1. Before installing the seat theseatback must be folded

forward. See “Folding the

Seatback” earlier in this section. The seats must be placed in the

proper locations to attach

correctly. The wider seat must

be installed on the driver side

and the narrower seat on the

passenger side. Remove the

bolts from the holes in the floor

before installing the seats.

2. Place the seat on the vehicle floor so that the front seat hooks

are on the vehicle bars.

3. Reinstall the bolts, and torque to 55Y (41 lb ft). Pull up on the

seat to make sure it is locked in

place.

4. Raise the seatback to its upright position. Push and pull on the

seatback to make sure it is

locked into place.

5. Push the headrest up into position. Push and pull on the

headrest to make sure it is

locked into place.

6. Reconnect the center safety belt mini-latch to the mini-buckle.

Do not let it twist.

Page 262 of 438

9-20 Driving and Operating

Shifting Into Park

{WARNING

It can be dangerous to get out of

the vehicle if the shift lever is not

fully in P (Park) with the parking

brake firmly set. The vehicle can

roll. If you have left the engine

running, the vehicle can move

suddenly. You or others could be

injured. To be sure the vehicle will

not move, even when you are on

fairly level ground, use the steps

that follow. If you are pulling a

trailer, seeDriving Characteristics

and Towing Tips on page 9‑45.

1. Hold the brake pedal down and set the parking brake. See

Parking Brake

on page 9‑27for

more information.

2. Move the shift lever into P (Park) by holding in the button on the

shift lever and pushing the shift

lever all the way toward the front

of the vehicle. 3. Turn the ignition key to

LOCK/OFF.

4. Remove the key and take it with you. If you can leave the vehicle

with the ignition key in your

hand, the vehicle is in P (Park).

Leaving the Vehicle with the

Engine Running

{WARNING

It can be dangerous to leave the

vehicle with the engine running.

The vehicle could move suddenly

if the shift lever is not fully in

P (Park) with the parking brake

firmly set. And, if you leave the

vehicle with the engine running, it

could overheat and even catch

fire. You or others could be

injured. Do not leave the vehicle

with the engine running.

If you have to leave the vehicle with

the engine running, be sure the

vehicle is in P (Park) and the

parking brake is firmly set before you leave it. After you have moved

the shift lever into P (Park), hold the

regular brake pedal down. Then,

see if you can move the shift lever

away from P (Park) without first

pushing the button.

If you can, it means that the shift

lever was not fully locked in

P (Park).

Torque Lock

Torque lock is when the weight of

the vehicle puts too much force on

the parking pawl in the

transmission. This happens when

parking on a hill and shifting the

transmission into P (Park) is not

done properly and then it is difficult

to shift out of P (Park). To prevent

torque lock, set the parking brake

and then shift into P (Park). To find

out how, see

“Shifting Into Park”

listed previously.

If torque lock does occur, your

vehicle may need to be pushed

uphill by another vehicle to relieve

the parking pawl pressure, so you

can shift out of P (Park).

Page 321 of 438

Vehicle Care 10-23

Some driving conditions or climates

can cause a brake squeal when the

brakes are first applied or lightly

applied. This does not mean

something is wrong with the brakes.

Properly torqued wheel nuts are

necessary to help prevent brake

pulsation. When tires are rotated,

inspect brake pads for wear and

evenly tighten wheel nuts in the

proper sequence to torque

specifications inCapacities and

Specifications on page 12‑2.

Brake linings should always be

replaced as complete axle sets.

Brake Pedal Travel

See your dealer/retailer if the brake

pedal does not return to normal

height, or if there is a rapid increase

in pedal travel. This could be a sign

that brake service might be

required.

Brake Adjustment

Every time the brakes are applied,

with or without the vehicle moving,

the brakes adjust for wear.

Replacing Brake System Parts

The braking system on a vehicle is

complex. Its many parts have to be

of top quality and work well together

if the vehicle is to have really good

braking. The vehicle was designed

and tested with top-quality brake

parts. When parts of the braking

system are replaced, be sure to get

new, approved replacement parts.

If this is not done, the brakes might

not work properly. For example,

installing disc brake pads that are

wrong for the vehicle, can change

the balance between the front and

rear brakes —for the worse. The

braking performance expected can

change in many other ways if the

wrong replacement brake parts are

installed.

Brake Fluid

The brake master cylinder reservoir

is filled with DOT 3 brake fluid as

indicated on the reservoir cap. See

Engine Compartment Overview

on

page 10‑6for the location of the

reservoir.

There are only two reasons why the

brake fluid level in the reservoir

might go down:

.The brake fluid level goes down

because of normal brake lining

wear. When new linings are

installed, the fluid level goes

back up.

Page 348 of 438

10-50 Vehicle Care

Tire Inspection

We recommend that you

regularly inspect your vehicle's

tires, including the spare tire,

if the vehicle has one, for signs

of wear or damage. SeeWhen It

Is Time for New Tires

on

page 10‑51

for more information.

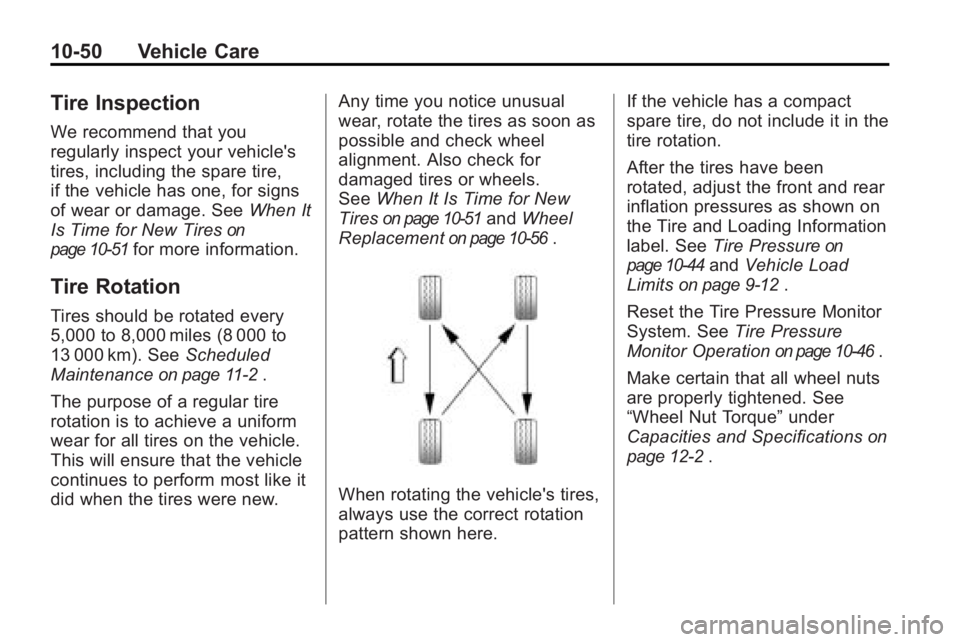

Tire Rotation

Tires should be rotated every

5,000 to 8,000 miles (8 000 to

13 000 km). See Scheduled

Maintenance

on page 11‑2.

The purpose of a regular tire

rotation is to achieve a uniform

wear for all tires on the vehicle.

This will ensure that the vehicle

continues to perform most like it

did when the tires were new. Any time you notice unusual

wear, rotate the tires as soon as

possible and check wheel

alignment. Also check for

damaged tires or wheels.

See

When It Is Time for New

Tires

on page 10‑51and Wheel

Replacement

on page 10‑56.

When rotating the vehicle's tires,

always use the correct rotation

pattern shown here. If the vehicle has a compact

spare tire, do not include it in the

tire rotation.

After the tires have been

rotated, adjust the front and rear

inflation pressures as shown on

the Tire and Loading Information

label. See

Tire Pressure

on

page 10‑44

and Vehicle Load

Limits

on page 9‑12.

Reset the Tire Pressure Monitor

System. See Tire Pressure

Monitor Operation

on page 10‑46.

Make certain that all wheel nuts

are properly tightened. See

“Wheel Nut Torque” under

Capacities and Specifications

on

page 12‑2

.

Page 372 of 438

10-74 Vehicle Care

{WARNING

Wheel nuts that are improperly or

incorrectly tightened can cause

the wheels to become loose or

come off. The wheel nuts should

be tightened with a torque wrench

to the proper torque specification

after replacing. Follow the torque

specification supplied by the

aftermarket manufacturer when

using accessory locking wheel

nuts. SeeCapacities and

Specifications

on page 12‑2for

original equipment wheel nut

torque specifications.

Notice: Improperly tightened

wheel nuts can lead to brake

pulsation and rotor damage.

To avoid expensive brake repairs,

evenly tighten the wheel nuts in

the proper sequence and to the

proper torque specification.

See Capacities and Specifications

on page 12‑2for the wheel nut

torque specification.

14. Tighten the wheel nuts firmly in a crisscross sequence, as

shown.

Notice: Wheel covers will not fit

on your vehicle's compact spare.

If you try to put a wheel cover on

the compact spare, the cover or

the spare could be damaged.

Storing the Spare Tire

{WARNING

The underbody-mounted spare

tire needs to be stored with the

valve stem pointing down. If the

spare tire is stored with the valve

stem pointing upwards, the

secondary latch will not work

properly and the spare tire could

loosen and suddenly fall from the

vehicle. If this happened when

the vehicle was being driven, the

tire might contact a person or

another vehicle, causing injury

and damage to itself. Be sure the

underbody-mounted spare tire is

stored with the valve stem

pointing down.

Page 408 of 438

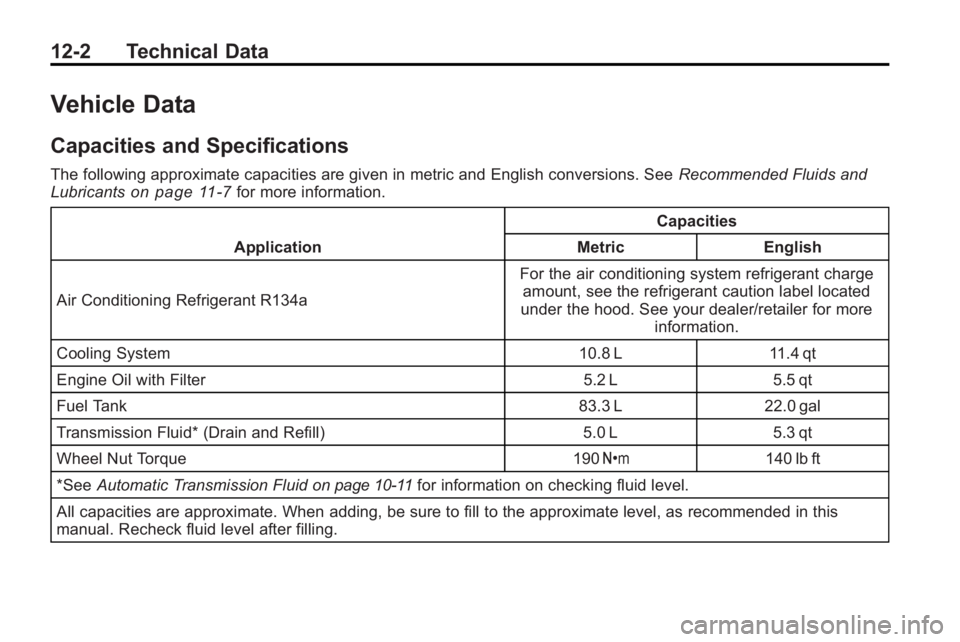

12-2 Technical Data

Vehicle Data

Capacities and Specifications

The following approximate capacities are given in metric and English conversions. SeeRecommended Fluids and

Lubricantson page 11‑7for more information.

Application Capacities

Metric English

Air Conditioning Refrigerant R134a For the air conditioning system refrigerant charge

amount, see the refrigerant caution label located

under the hood. See your dealer/retailer for more information.

Cooling System 10.8 L 11.4 qt

Engine Oil with Filter 5.2 L 5.5 qt

Fuel Tank 83.3 L 22.0 gal

Transmission Fluid* (Drain and Refill) 5.0 L 5.3 qt

Wheel Nut Torque 190 Y140 lb ft

*See Automatic Transmission Fluid

on page 10‑11for information on checking fluid level.

All capacities are approximate. When adding, be sure to fill to the approximate level, as recommended in this

manual. Recheck fluid level after filling.