height BUICK LACROSSE 2009 Owner's Manual

[x] Cancel search | Manufacturer: BUICK, Model Year: 2009, Model line: LACROSSE, Model: BUICK LACROSSE 2009Pages: 428

Page 10 of 428

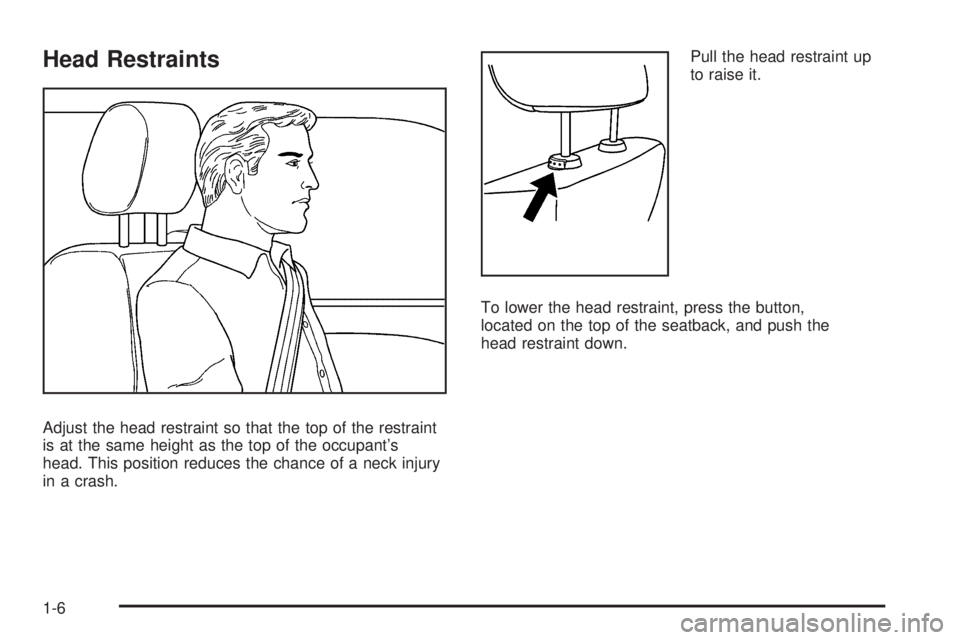

Head Restraints

Adjust the head restraint so that the top of the restraint

is at the same height as the top of the occupant’s

head. This position reduces the chance of a neck injury

in a crash.Pull the head restraint up

to raise it.

To lower the head restraint, press the button,

located on the top of the seatback, and push the

head restraint down.

1-6

Page 27 of 428

4. If equipped with a shoulder belt height adjuster,

move it to the height that is right for you. See

“Shoulder Belt Height Adjustment” later in this

section for instructions on use and important safety

information.

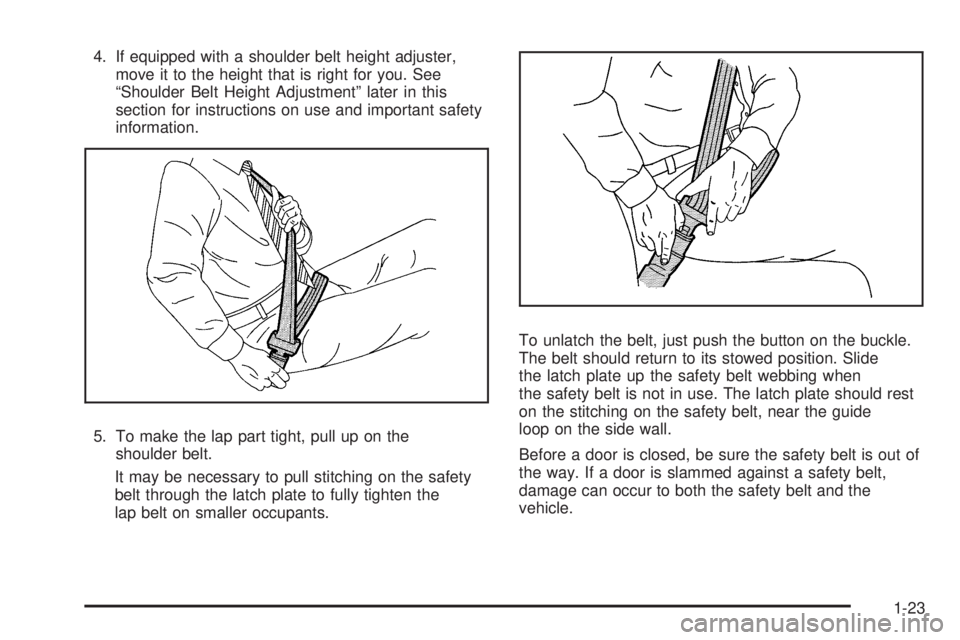

5. To make the lap part tight, pull up on the

shoulder belt.

It may be necessary to pull stitching on the safety

belt through the latch plate to fully tighten the

lap belt on smaller occupants.To unlatch the belt, just push the button on the buckle.

The belt should return to its stowed position. Slide

the latch plate up the safety belt webbing when

the safety belt is not in use. The latch plate should rest

on the stitching on the safety belt, near the guide

loop on the side wall.

Before a door is closed, be sure the safety belt is out of

the way. If a door is slammed against a safety belt,

damage can occur to both the safety belt and the

vehicle.

1-23

Page 28 of 428

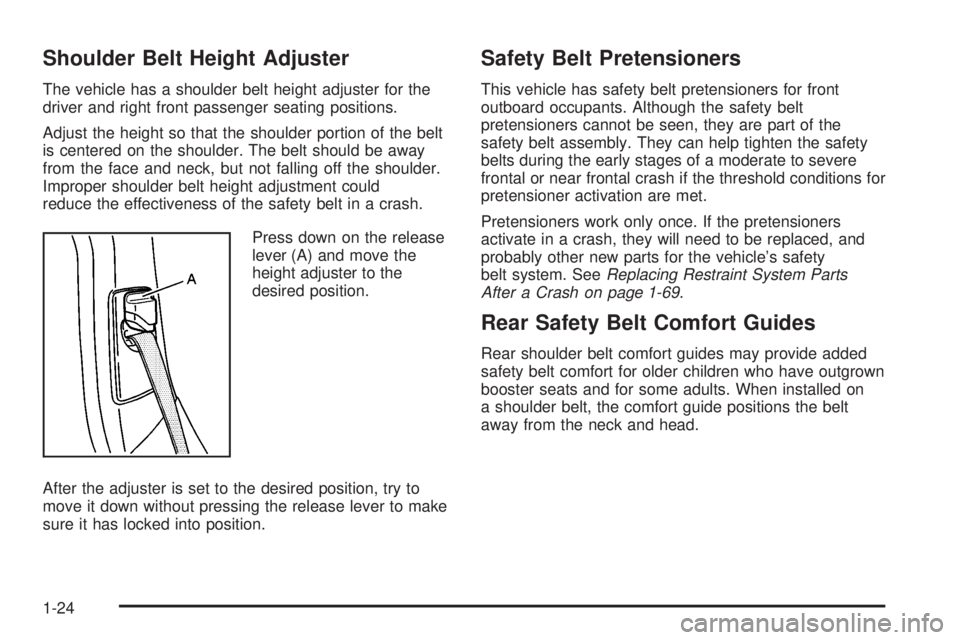

Shoulder Belt Height Adjuster

The vehicle has a shoulder belt height adjuster for the

driver and right front passenger seating positions.

Adjust the height so that the shoulder portion of the belt

is centered on the shoulder. The belt should be away

from the face and neck, but not falling off the shoulder.

Improper shoulder belt height adjustment could

reduce the effectiveness of the safety belt in a crash.

Press down on the release

lever (A) and move the

height adjuster to the

desired position.

After the adjuster is set to the desired position, try to

move it down without pressing the release lever to make

sure it has locked into position.

Safety Belt Pretensioners

This vehicle has safety belt pretensioners for front

outboard occupants. Although the safety belt

pretensioners cannot be seen, they are part of the

safety belt assembly. They can help tighten the safety

belts during the early stages of a moderate to severe

frontal or near frontal crash if the threshold conditions for

pretensioner activation are met.

Pretensioners work only once. If the pretensioners

activate in a crash, they will need to be replaced, and

probably other new parts for the vehicle’s safety

belt system. SeeReplacing Restraint System Parts

After a Crash on page 1-69.

Rear Safety Belt Comfort Guides

Rear shoulder belt comfort guides may provide added

safety belt comfort for older children who have outgrown

booster seats and for some adults. When installed on

a shoulder belt, the comfort guide positions the belt

away from the neck and head.

1-24

Page 34 of 428

The manufacturer’s instructions that come with the

booster seat, state the weight and height limitations for

that booster. Use a booster seat with a lap-shoulder

belt until the child passes the below �t test:

Sit all the way back on the seat. Do the knees bend

at the seat edge? If yes, continue. If no, return to

the booster seat.

Buckle the lap-shoulder belt. Does the shoulder belt

rest on the shoulder? If yes, continue. If no, try

using the rear safety belt comfort guide. See “Rear

Safety Belt Comfort Guides” underLap-Shoulder

Belt on page 1-22for more information. If the

shoulder belt still does not rest on the shoulder,

then return to the booster seat.

Does the lap belt �t low and snug on the hips,

touching the thighs? If yes, continue. If no, return to

the booster seat.

Can proper safety belt �t be maintained for

length of trip? If yes, continue. If no, return to the

booster seat.

If you have the choice, a child should sit in a position

with a lap-shoulder belt and get the additional restraint a

shoulder belt can provide.

Q:What is the proper way to wear safety belts?

A:An older child should wear a lap-shoulder belt and

get the additional restraint a shoulder belt can

provide. The shoulder belt should not cross the face

or neck. The lap belt should �t snugly below the

hips, just touching the top of the thighs. This applies

belt force to the child’s pelvic bones in a crash. It

should never be worn over the abdomen, which

could cause severe or even fatal internal injuries in

a crash.

Also see “Rear Safety Belt Comfort Guides” under

Lap-Shoulder Belt on page 1-22.

According to accident statistics, children and infants are

safer when properly restrained in the rear seating

positions than in the front seating positions.

In a crash, children who are not buckled up can strike

other people who are buckled up, or can be thrown

out of the vehicle. Older children need to use safety

belts properly.

1-30

Page 40 of 428

Q:What are the different types of add-on child

restraints?

A:Add-on child restraints, which are purchased by the

vehicle’s owner, are available in four basic types.

Selection of a particular restraint should take

into consideration not only the child’s weight, height,

and age but also whether or not the restraint will

be compatible with the motor vehicle in which it will

be used.

For most basic types of child restraints, there are

many different models available. When purchasing a

child restraint, be sure it is designed to be used

in a motor vehicle. If it is, the restraint will have a

label saying that it meets federal motor vehicle

safety standards.

The restraint manufacturer’s instructions that come

with the restraint state the weight and height

limitations for a particular child restraint. In addition,

there are many kinds of restraints available for

children with special needs.

{CAUTION:

To reduce the risk of neck and head injury during

a crash, infants need complete support. This is

because an infant’s neck is not fully developed

and its head weighs so much compared with the

rest of its body. In a crash, an infant in a

rear-facing child restraint settles into the restraint,

so the crash forces can be distributed across the

strongest part of an infant’s body, the back and

shoulders. Infants should always be secured in

rear-facing child restraints.

1-36

Page 71 of 428

Adding Equipment to Your

Airbag-Equipped Vehicle

Q:Is there anything I might add to or change

about the vehicle that could keep the airbags

from working properly?

A:Yes. If you add things that change the vehicle’s

frame, bumper system, height, front end or side

sheet metal, they may keep the airbag system from

working properly. Changing or moving any parts

of the front seats, safety belts, the airbag sensing

and diagnostic module, steering wheel, instrument

panel, roof-rail airbag modules, ceiling headliner

or pillar garnish trim, front sensors, or airbag wiring

can affect the operation of the airbag system.

In addition, the vehicle has a passenger sensing

system for the right front passenger position, which

includes sensors that are part of the passenger’s

seat. The passenger sensing system may not

operate properly if the original seat trim is replaced

with non-GM covers, upholstery or trim, or with

GM covers, upholstery or trim designed for a

different vehicle. Any object, such as an aftermarket

seat heater or a comfort enhancing pad or device,

installed under or on top of the seat fabric,

could also interfere with the operation of thepassenger sensing system. This could either

prevent proper deployment of the passenger

airbag(s) or prevent the passenger sensing system

from properly turning off the passenger airbag(s).

SeePassenger Sensing System on page 1-61.

If you have any questions, call Customer

Assistance. The phone numbers and addresses for

Customer Assistance are in Step Two of the

Customer Satisfaction Procedure in this manual.

SeeCustomer Satisfaction Procedure on page 7-2.

Q:Because I have a disability, I have to get

my vehicle modi�ed. How can I �nd out whether

this will affect my airbag system?

A:If you have questions, call Customer Assistance.

The phone numbers and addresses for Customer

Assistance are in Step Two of the Customer

Satisfaction Procedure in this manual. See

Customer Satisfaction Procedure on page 7-2.

In addition, your dealer/retailer and the service manual

have information about the location of the airbag

sensors, sensing and diagnostic module and airbag

wiring.

1-67

Page 309 of 428

Brake Wear

This vehicle has disc brakes. Disc brake pads have

built-in wear indicators that make a high-pitched warning

sound when the brake pads are worn and new pads are

needed. The sound can come and go or be heard all the

time the vehicle is moving, except when applying the

brake pedal �rmly.

{CAUTION:

The brake wear warning sound means that soon

the brakes will not work well. That could lead to an

accident. When the brake wear warning sound is

heard, have the vehicle serviced.

Notice:Continuing to drive with worn-out brake

pads could result in costly brake repair.Some driving conditions or climates can cause a brake

squeal when the brakes are �rst applied or lightly applied.

This does not mean something is wrong with the brakes.

Properly torqued wheel nuts are necessary to help

prevent brake pulsation. When tires are rotated, inspect

brake pads for wear and evenly tighten wheel nuts

in the proper sequence to torque speci�cations

inCapacities and Specifications on page 5-106.

Brake linings should always be replaced as complete

axle sets.Brake Pedal Travel

See your dealer/retailer if the brake pedal does not

return to normal height, or if there is a rapid increase

in pedal travel. This could be a sign that brake service

might be required.

Brake Adjustment

Every time the brakes are applied, with or without the

vehicle moving, the brakes adjust for wear.

5-39

Page 318 of 428

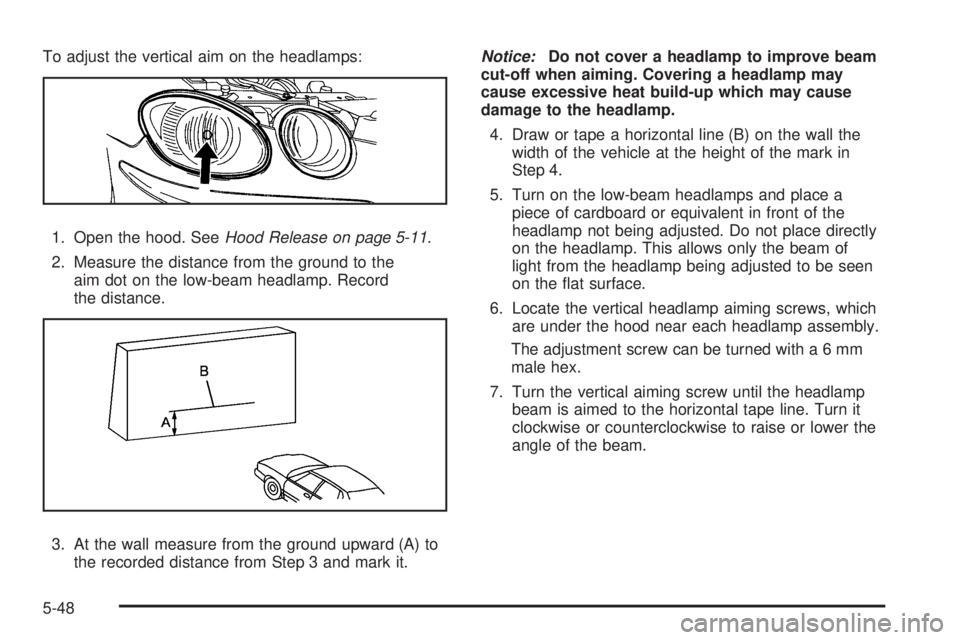

To adjust the vertical aim on the headlamps:

1. Open the hood. SeeHood Release on page 5-11.

2. Measure the distance from the ground to the

aim dot on the low-beam headlamp. Record

the distance.

3. At the wall measure from the ground upward (A) to

the recorded distance from Step 3 and mark it.Notice:Do not cover a headlamp to improve beam

cut-off when aiming. Covering a headlamp may

cause excessive heat build-up which may cause

damage to the headlamp.

4. Draw or tape a horizontal line (B) on the wall the

width of the vehicle at the height of the mark in

Step 4.

5. Turn on the low-beam headlamps and place a

piece of cardboard or equivalent in front of the

headlamp not being adjusted. Do not place directly

on the headlamp. This allows only the beam of

light from the headlamp being adjusted to be seen

on the �at surface.

6. Locate the vertical headlamp aiming screws, which

are under the hood near each headlamp assembly.

The adjustment screw can be turned with a 6 mm

male hex.

7. Turn the vertical aiming screw until the headlamp

beam is aimed to the horizontal tape line. Turn it

clockwise or counterclockwise to raise or lower the

angle of the beam.

5-48

Page 325 of 428

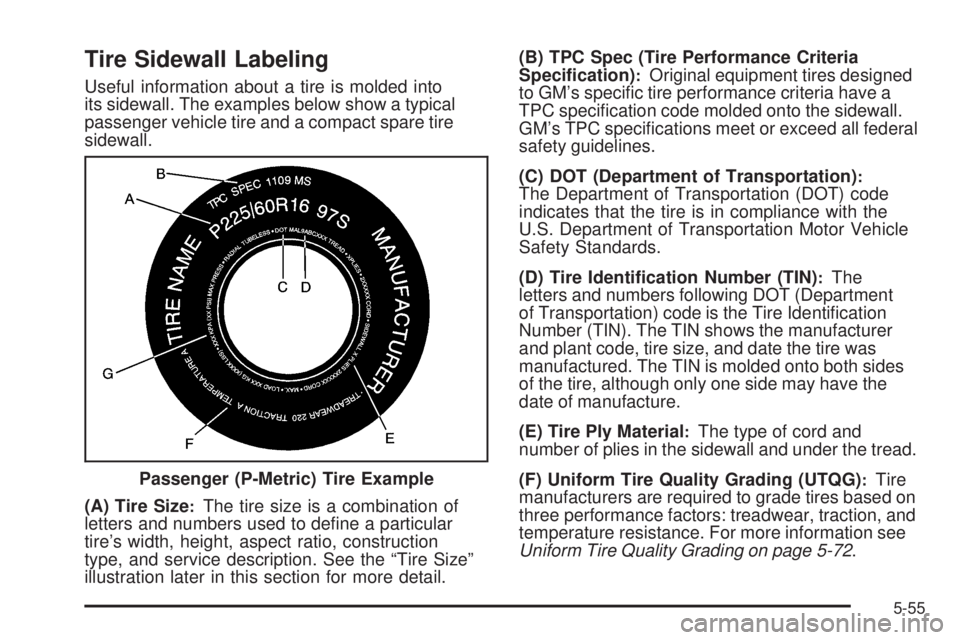

Tire Sidewall Labeling

Useful information about a tire is molded into

its sidewall. The examples below show a typical

passenger vehicle tire and a compact spare tire

sidewall.

(A) Tire Size

:The tire size is a combination of

letters and numbers used to de�ne a particular

tire’s width, height, aspect ratio, construction

type, and service description. See the “Tire Size”

illustration later in this section for more detail.(B) TPC Spec (Tire Performance Criteria

Speci�cation)

:Original equipment tires designed

to GM’s speci�c tire performance criteria have a

TPC speci�cation code molded onto the sidewall.

GM’s TPC speci�cations meet or exceed all federal

safety guidelines.

(C) DOT (Department of Transportation)

:The Department of Transportation (DOT) code

indicates that the tire is in compliance with the

U.S. Department of Transportation Motor Vehicle

Safety Standards.

(D) Tire Identi�cation Number (TIN)

:The

letters and numbers following DOT (Department

of Transportation) code is the Tire Identi�cation

Number (TIN). The TIN shows the manufacturer

and plant code, tire size, and date the tire was

manufactured. The TIN is molded onto both sides

of the tire, although only one side may have the

date of manufacture.

(E) Tire Ply Material

:The type of cord and

number of plies in the sidewall and under the tread.

(F) Uniform Tire Quality Grading (UTQG)

:Tire

manufacturers are required to grade tires based on

three performance factors: treadwear, traction, and

temperature resistance. For more information see

Uniform Tire Quality Grading on page 5-72. Passenger (P-Metric) Tire Example

5-55

Page 326 of 428

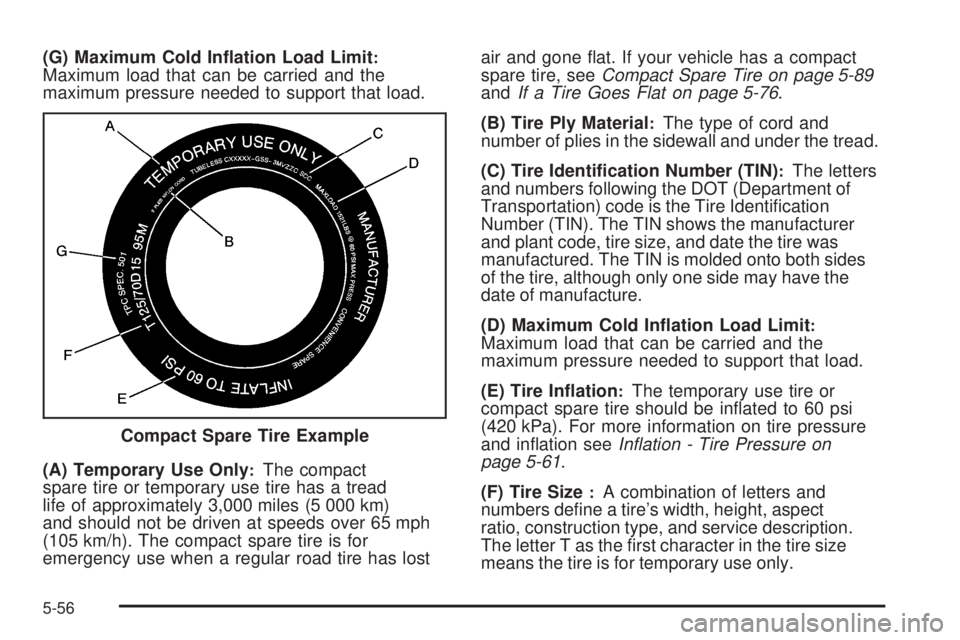

(G) Maximum Cold In�ation Load Limit:Maximum load that can be carried and the

maximum pressure needed to support that load.

(A) Temporary Use Only

:The compact

spare tire or temporary use tire has a tread

life of approximately 3,000 miles (5 000 km)

and should not be driven at speeds over 65 mph

(105 km/h). The compact spare tire is for

emergency use when a regular road tire has lostair and gone �at. If your vehicle has a compact

spare tire, seeCompact Spare Tire on page 5-89

andIf a Tire Goes Flat on page 5-76.

(B) Tire Ply Material

:The type of cord and

number of plies in the sidewall and under the tread.

(C) Tire Identi�cation Number (TIN)

:The letters

and numbers following the DOT (Department of

Transportation) code is the Tire Identi�cation

Number (TIN). The TIN shows the manufacturer

and plant code, tire size, and date the tire was

manufactured. The TIN is molded onto both sides

of the tire, although only one side may have the

date of manufacture.

(D) Maximum Cold In�ation Load Limit

:Maximum load that can be carried and the

maximum pressure needed to support that load.

(E) Tire In�ation

:The temporary use tire or

compact spare tire should be in�ated to 60 psi

(420 kPa). For more information on tire pressure

and in�ation seeInflation - Tire Pressure on

page 5-61.

(F) Tire Size

:A combination of letters and

numbers de�ne a tire’s width, height, aspect

ratio, construction type, and service description.

The letter T as the �rst character in the tire size

means the tire is for temporary use only. Compact Spare Tire Example

5-56