BUICK LESABRE 2003 Owner's Manual

LESABRE 2003

BUICK

BUICK

https://www.carmanualsonline.info/img/43/35394/w960_35394-0.png

BUICK LESABRE 2003 Owner's Manual

Trending: brake light, Air compressor, heater, CD changer, coolant level, abs, cruise control

Page 281 of 380

The headlamp aiming devices are under the hood near

the headlamps.

If you believe your headlamps need horizontal (left/right)

adjustment, follow the horizontal aiming procedure. If

you believe your headlamps need only vertical

(up/down) adjustment, follow only the vertical aiming

procedure.

Adjustment screws can be turned with an E8 Torx

ž

socket or T15 Torxžscrewdriver.

Headlamp Horizontal Aiming

Turn the horizontal aiming screw (A) until the

indicator (B) is lined up with zero.

Once the horizontal aim is adjusted, then adjust the

vertical aim.

5-49

Page 282 of 380

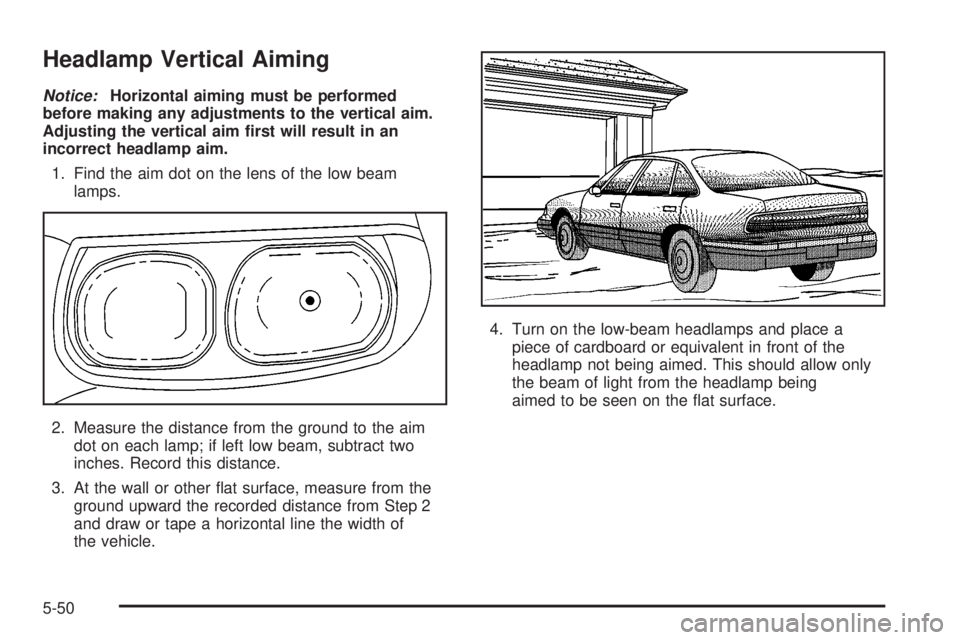

Headlamp Vertical Aiming

Notice:Horizontal aiming must be performed

before making any adjustments to the vertical aim.

Adjusting the vertical aim ®rst will result in an

incorrect headlamp aim.

1. Find the aim dot on the lens of the low beam

lamps.

2. Measure the distance from the ground to the aim

dot on each lamp; if left low beam, subtract two

inches. Record this distance.

3. At the wall or other ¯at surface, measure from the

ground upward the recorded distance from Step 2

and draw or tape a horizontal line the width of

the vehicle.4. Turn on the low-beam headlamps and place a

piece of cardboard or equivalent in front of the

headlamp not being aimed. This should allow only

the beam of light from the headlamp being

aimed to be seen on the ¯at surface.

5-50

Page 283 of 380

Notice:Do not cover a headlamp to improve beam

cut-off when aiming. Covering a headlamp may

cause excessive heat build-up which may cause

damage to the headlamp.5. Turn the vertical aiming

screw (C) until the

headlamp beam

is aimed to the

horizontal tape line.

The top edge of the cut-off should be positioned at

the bottom edge of the horizontal tape line.

6. Repeat Steps 4 and 5 for the opposite headlamp.

5-51

Page 284 of 380

Bulb Replacement

For the type of bulb to use, seeReplacement Bulbs on

page 5-56.

For any bulb changing procedure not listed in this

section, contact your dealer.

Halogen Bulbs

{CAUTION:

Halogen bulbs have pressurized gas inside

and can burst if you drop or scratch the bulb.

You or others could be injured. Be sure to read

and follow the instructions on the bulb

package.

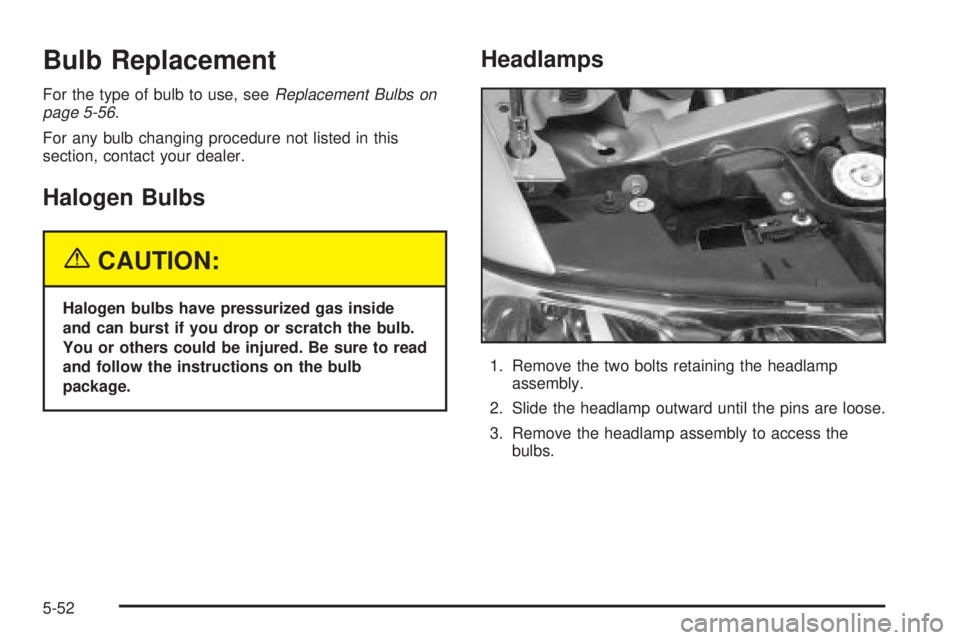

Headlamps

1. Remove the two bolts retaining the headlamp

assembly.

2. Slide the headlamp outward until the pins are loose.

3. Remove the headlamp assembly to access the

bulbs.

5-52

Page 285 of 380

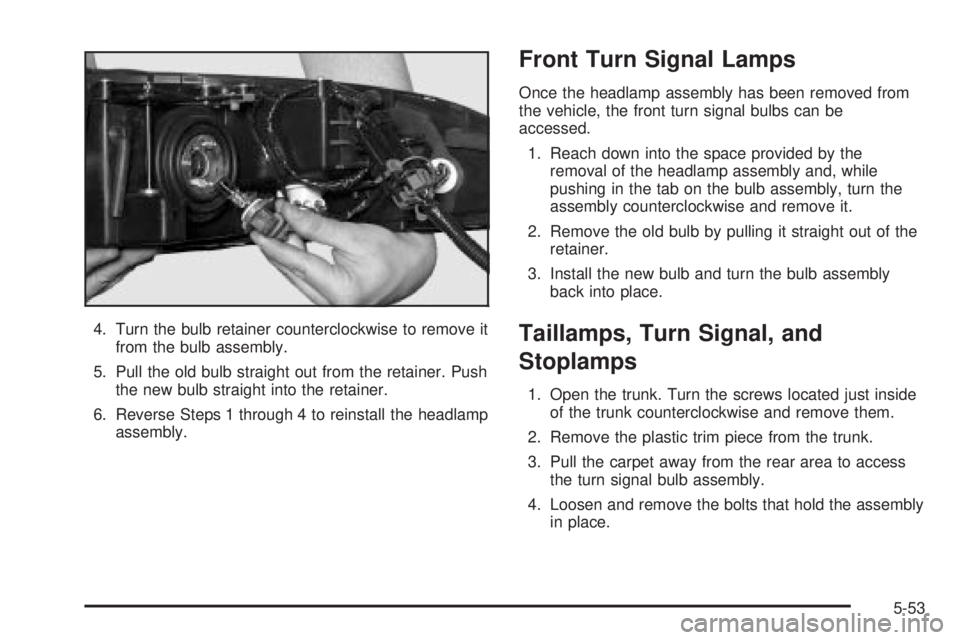

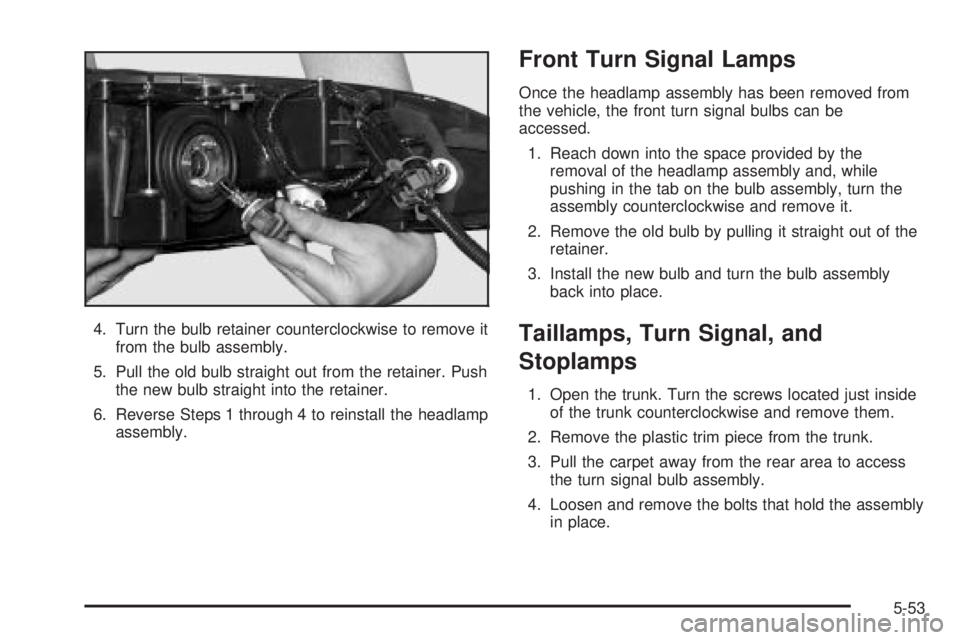

4. Turn the bulb retainer counterclockwise to remove it

from the bulb assembly.

5. Pull the old bulb straight out from the retainer. Push

the new bulb straight into the retainer.

6. Reverse Steps 1 through 4 to reinstall the headlamp

assembly.

Front Turn Signal Lamps

Once the headlamp assembly has been removed from

the vehicle, the front turn signal bulbs can be

accessed.

1. Reach down into the space provided by the

removal of the headlamp assembly and, while

pushing in the tab on the bulb assembly, turn the

assembly counterclockwise and remove it.

2. Remove the old bulb by pulling it straight out of the

retainer.

3. Install the new bulb and turn the bulb assembly

back into place.

Taillamps, Turn Signal, and

Stoplamps

1. Open the trunk. Turn the screws located just inside

of the trunk counterclockwise and remove them.

2. Remove the plastic trim piece from the trunk.

3. Pull the carpet away from the rear area to access

the turn signal bulb assembly.

4. Loosen and remove the bolts that hold the assembly

in place.

5-53

Page 286 of 380

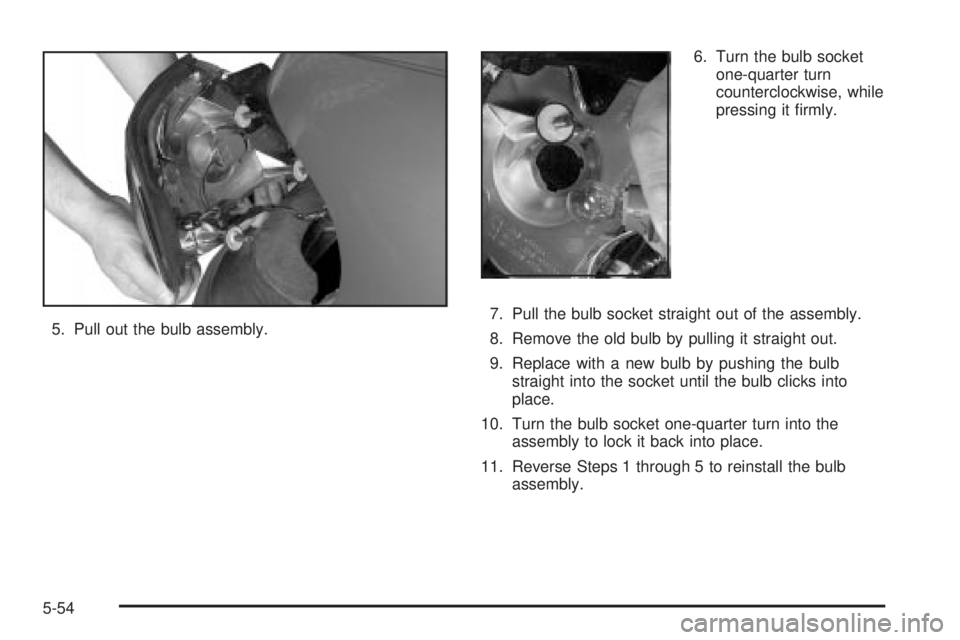

5. Pull out the bulb assembly.6. Turn the bulb socket

one-quarter turn

counterclockwise, while

pressing it ®rmly.

7. Pull the bulb socket straight out of the assembly.

8. Remove the old bulb by pulling it straight out.

9. Replace with a new bulb by pushing the bulb

straight into the socket until the bulb clicks into

place.

10. Turn the bulb socket one-quarter turn into the

assembly to lock it back into place.

11. Reverse Steps 1 through 5 to reinstall the bulb

assembly.

5-54

Page 287 of 380

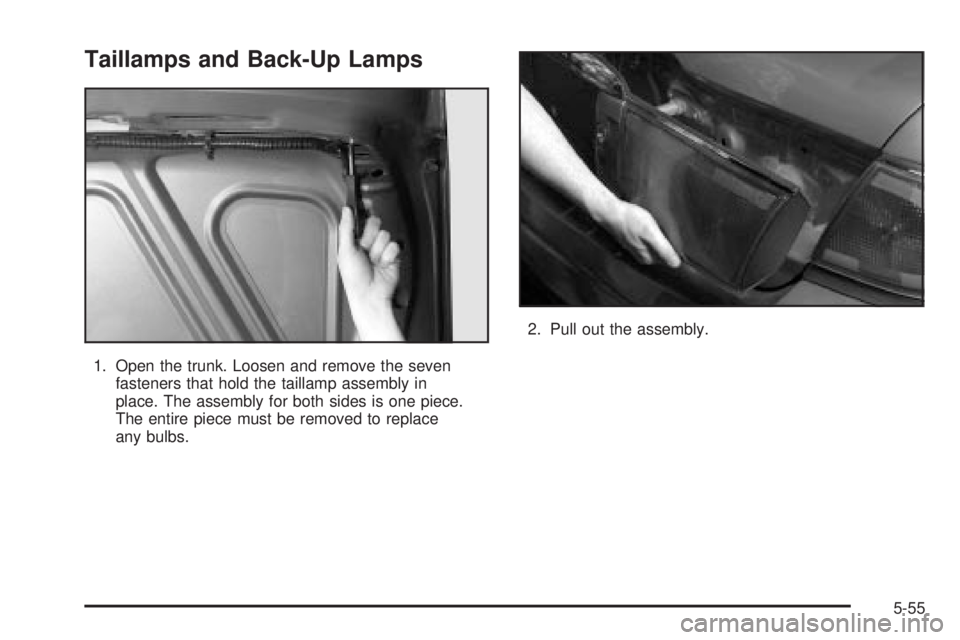

Taillamps and Back-Up Lamps

1. Open the trunk. Loosen and remove the seven

fasteners that hold the taillamp assembly in

place. The assembly for both sides is one piece.

The entire piece must be removed to replace

any bulbs.2. Pull out the assembly.

5-55

Page 288 of 380

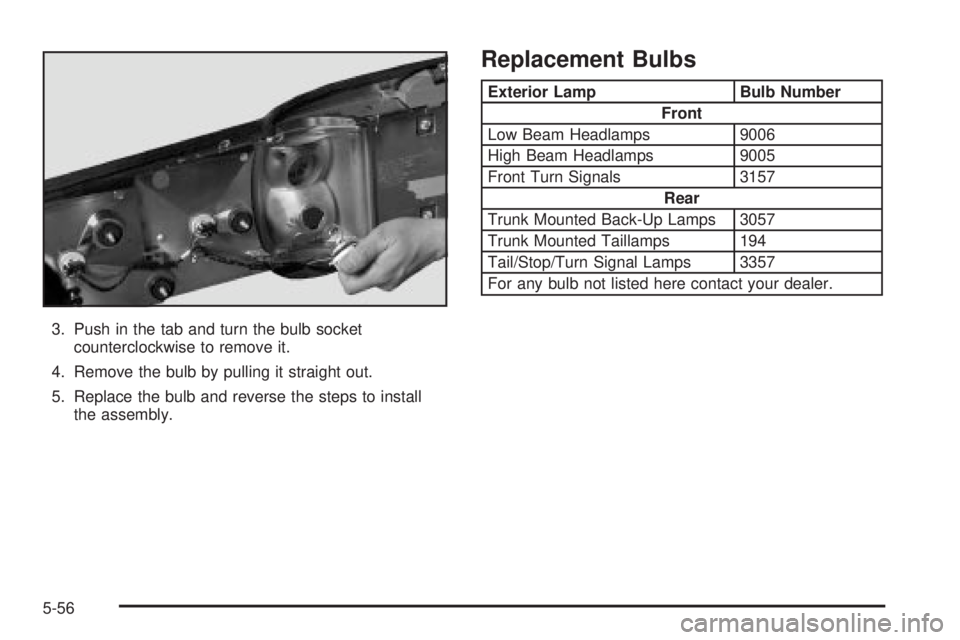

3. Push in the tab and turn the bulb socket

counterclockwise to remove it.

4. Remove the bulb by pulling it straight out.

5. Replace the bulb and reverse the steps to install

the assembly.

Replacement Bulbs

Exterior Lamp Bulb Number

Front

Low Beam Headlamps 9006

High Beam Headlamps 9005

Front Turn Signals 3157

Rear

Trunk Mounted Back-Up Lamps 3057

Trunk Mounted Taillamps 194

Tail/Stop/Turn Signal Lamps 3357

For any bulb not listed here contact your dealer.

5-56

Page 289 of 380

Windshield Wiper Blade

Replacement

Windshield wiper blades should be inspected at least

twice a year for wear or cracking. See ªWiper Blade

Checkº under

Part B: Owner Checks and Services on

page 6-17for more information.

Replacement blades come in different types and are

removed in different ways.

To replace the wiper blade assembly, do the following:

1. Lift the windshield wiper arm away from the

windshield.

2. Push the tab on the wiper blade assembly and pull

the assembly down enough to release it from the

ªUº hooked end of the wiper arm. Slide the

assembly away from the arm.

3. Remove the blade.

4. To reinstall the wiper blade assembly, slide it over

the wiper arm to engage the ªUº hooked end on the

wiper blade assembly. Pull up on the assembly

to lock it into place.

For the proper windshield wiper blade replacement

length and type, see

Normal Maintenance Replacement

Parts on page 5-94.

5-57

Page 290 of 380

Tires

Your new vehicle comes with high-quality tires made by

a leading tire manufacturer. If you ever have questions

about your tire warranty and where to obtain service,

see your Buick Warranty booklet for details.

{CAUTION:

Poorly maintained and improperly used tires

are dangerous.

·Overloading your tires can cause

overheating as a result of too much

friction. You could have an air-out and a

serious accident. See ªLoading Your

Vehicleº in the Index.

·Underin¯ated tires pose the same danger

as overloaded tires. The resulting accident

could cause serious injury. Check all tires

frequently to maintain the recommended

pressure. Tire pressure should be checked

when your tires are cold.

CAUTION: (Continued)

CAUTION: (Continued)

·

Overin¯ated tires are more likely to be

cut, punctured or broken by a sudden

impact Ð such as when you hit a pothole.

Keep tires at the recommended pressure.

·Worn, old tires can cause accidents. If

your tread is badly worn, or if your tires

have been damaged, replace them.

In¯ation -- Tire Pressure

The Tire-Loading Information label, which is on the rear

edge of the driver's door, shows the correct in¯ation

pressures for your tires when they're cold. ªColdº means

your vehicle has been sitting for at least three hours

or driven no more than 1 mile (1.6 km).

5-58

Trending: ECO mode, bulb, wiring, cruise control, steering wheel, flat tire, low beam