lock BUICK LUCERNE 2010 Owner's Manual

[x] Cancel search | Manufacturer: BUICK, Model Year: 2010, Model line: LUCERNE, Model: BUICK LUCERNE 2010Pages: 474

Page 373 of 474

7. Proceed to the passenger side rear tire, and repeatthe procedure in Step 5.

8. Proceed to the driver side rear tire, and repeat the procedure in Step 5. The horn sounds two times to

indicate the sensor identification code has been

matched to the driver side rear tire, and the TPMS

sensor matching process is no longer active. The

TIRE LEARNING ACTIVE message on the DIC

display screen goes off.

9. Turn the ignition switch to LOCK/OFF.

10. Set all four tires to the recommended air pressure level as indicated on the Tire and Loading

Information label.

11. Put the valve caps back on the valve stems.Tire Inspection and Rotation

We recommend that you regularly inspect your

vehicle's tires, including the spare tire, for signs of

wear or damage. See When It Is Time for New

Tires

on page 6‑73for more information.

Tires should be rotated every 5,000 to 8,000 miles

(8 000 to 13 000 km). See Scheduled Maintenance

on page 7‑3.

The purpose of a regular tire rotation is to achieve

a uniform wear for all tires on the vehicle. This will

ensure that your vehicle continues to perform

most like it did when the tires were new.

6-71

Page 378 of 474

Different Size Tires and Wheels

If you add wheels or tires that are a different size than

your original equipment wheels and tires, this may

affect the way your vehicle performs, including its

braking, ride and handling characteristics, stability, and

resistance to rollover. Additionally, if your vehicle has

electronic systems such as, antilock brakes, traction

control, and electronic stability control, the performance

of these systems can be affected.

{WARNING:

If you add different sized wheels, your vehicle

may not provide an acceptable level of

performance and safety if tires not recommended

for those wheels are selected. You may increase

the chance that you will crash and suffer serious

injury. Only use GM specific wheel and tire

systems developed for your vehicle, and have

them properly installed by a GM certified

technician.

See Buying New Tires

on page 6‑74andAccessories

and Modificationson page 6‑3for additional

information.

Uniform Tire Quality Grading

Quality grades can be found where applicable on

the tire sidewall between tread shoulder and

maximum section width. For example:

Treadwear 200 Traction AA

Temperature A

The following information relates to the system

developed by the United States National Highway

Traffic Safety Administration (NHTSA), which

grades tires by treadwear, traction, and

temperature performance. This applies only to

vehicles sold in the United States. The grades are

molded on the sidewalls of most passenger car

tires. The Uniform Tire Quality Grading (UTQG)

system does not apply to deep tread, winter-type

snow tires, space-saver, or temporary use spare

tires, tires with nominal rim diameters of

10 to 12 inches (25 to 30 cm), or to some

limited-production tires.

While the tires available on General Motors

passenger cars and light trucks may vary with

respect to these grades, they must also conform

to federal safety requirements and additional

General Motors Tire Performance Criteria (TPC)

standards.

6-76

Page 387 of 474

Always do a safety check first. SeeIf a Tire Goes Flaton page 6‑81. Do not remove any objects that have

penetrated the tire.

1. Remove the tire sealant and compressor kit from its storage location. See Tire Sealant and

Compressor Kit Storage on page 6‑90.

2. Unwrap the sealant/air hose (F) and the power plug (G).

3. Place the kit on the ground.

Make sure the tire valve stem is positioned close to

the ground so the hose will reach it.

4. Remove the valve stem cap from the flat tire by turning it counterclockwise.

5. Attach the sealant/air hose (F) onto the tire valve stem. Turn it clockwise until it is tight.

6. Plug the power plug (G) into the accessory power outlet in the vehicle. Unplug all items from other

accessory power outlets. See Accessory Power

Outlet(s) on page 4‑17. If the vehicle has an accessory power outlet, do

not use the cigarette lighter.

If the vehicle only has a cigarette lighter, use the

cigarette lighter.

Do not pinch the power plug cord in the door or

window.

7. Start the vehicle. The vehicle must be running while using the air compressor.

8. Turn the selector switch (B) clockwise to the Sealant + Air position.

9. Press the on/off (A) button to turn the tire sealant and compressor kit on.

The compressor will inject sealant and air into

the tire.

The pressure gauge (D) will initially show a high

pressure while the compressor pushes the sealant

into the tire. Once the sealant is completely

dispersed into the tire, the pressure will quickly

drop and start to rise again as the tire inflates with

air only.

6-85

Page 388 of 474

10. Inflate the tire to the recommended inflationpressure using the pressure gauge (D). The

recommended inflation pressure can be found on

the Tire and Loading Information label. See

Inflation - Tire Pressure on page 6‑65.

The pressure gauge (D) may read higher than the

actual tire pressure while the compressor is on.

Turn the compressor off to get an accurate

pressure reading. The compressor may be turned

on/off until the correct pressure is reached.

Notice: If the recommended pressure cannot be

reached after approximately 25 minutes, the vehicle

should not be driven farther. The tire is too severely

damaged and the tire sealant and compressor kit

cannot inflate the tire. Remove the power plug from

the accessory power outlet and unscrew the

inflating hose from the tire valve. See Roadside

Assistance Program on page 8‑8.

11. Press the on/off button (A) to turn the tire sealant and compressor kit off.

The tire is not sealed and will continue to leak

air until the vehicle is driven and the sealant is

distributed in the tire, therefore, Steps 12

through 18 must be done immediately after

Step 11.

Be careful while handling the tire sealant and

compressor kit as it could be warm after usage. 12. Unplug the power plug (G) from the accessory

power outlet in the vehicle.

13. Turn the sealant/air hose (F) counterclockwise to remove it from the tire valve stem.

14. Replace the tire valve stem cap.

15. Replace the sealant/air hose (F), and the power plug (G) back in their original location.

16. If the flat tire wasable to inflate to the

recommended inflation

pressure, remove the

maximum speed label

from the sealant

canister and place

it in a highly visible

location. The label is a

reminder not to exceed

55 mph (90 km/h) until

the damaged tire is

repaired or replaced.

17. Return the equipment to its original storage location in the vehicle.

18. Immediately drive the vehicle 5 miles (8 km) to distribute the sealant in the tire.

6-86

Page 390 of 474

3. Place the kit on the ground.Make sure the tire valve stem is positioned close to

the ground so the hose will reach it.

4. Remove the tire valve stem cap from the flat tire by turning it counterclockwise.

5. Attach the air only hose (E) onto the tire valve stem by turning it clockwise until it is tight.

6. Plug the power plug (G) into the accessory power outlet in the vehicle. Unplug all items from other

accessory power outlets. See Accessory Power

Outlet(s) on page 4‑17.

If the vehicle has an accessory power outlet, do

not use the cigarette lighter.

If the vehicle only has a cigarette lighter, use the

cigarette lighter.

Do not pinch the power plug cord in the door or

window.

7. Start the vehicle. The vehicle must be running while using the air compressor.

8. Turn the selector switch (B) counterclockwise to the Air Only position.

9. Press the on/off (A) button to turn the compressor on.

The compressor will inflate the tire with air only. 10. Inflate the tire to the recommended inflation

pressure using the pressure gauge (D). The

recommended inflation pressure can be found on

the Tire and Loading Information label. See

Inflation - Tire Pressure on page 6‑65.

The pressure gauge (D) may read higher than the

actual tire pressure while the compressor is on.

Turn the compressor off to get an accurate

reading. The compressor may be turned on/off until

the correct pressure is reached.

11. Press the on/off button (A) to turn the tire sealant and compressor kit off.

Be careful while handling the tire sealant and

compressor kit as it could be warm after usage.

12. Unplug the power plug (G) from the accessory power outlet in the vehicle.

13. Disconnect the air only hose (E) from the tire valve stem, by turning it counterclockwise, and replace

the tire valve stem cap.

14. Replace the air only hose (E) and the power plug (G) and cord back in its original location.

15. Place the equipment in the original storage location in the vehicle.

6-88

Page 392 of 474

Tire Sealant and Compressor Kit

Storage

The tire sealant and compressor kit is located in the

trunk.1. Open the trunk. See Trunk on page 3‑12

2. Lift the cover.

3. Turn the retainer clockwise and remove the tire sealant and compressor kit.

To store the tire sealant and compressor kit, reverse the

steps.

Changing a Flat Tire

If a tire goes flat, avoid further tire and wheel damage

by driving slowly to a level place. Turn on the hazard

warning flashers. See Hazard Warning Flashers

on

page 4‑3.

{WARNING:

Changing a tire can be dangerous. The vehicle

can slip off the jack and roll over or fall on you or

other people. You and they could be badly injured

or even killed. Find a level place to change your

tire. To help prevent the vehicle from moving:

1. Set the parking brake firmly.

2. Put the shift lever in P (Park). (Continued)

6-90

Page 393 of 474

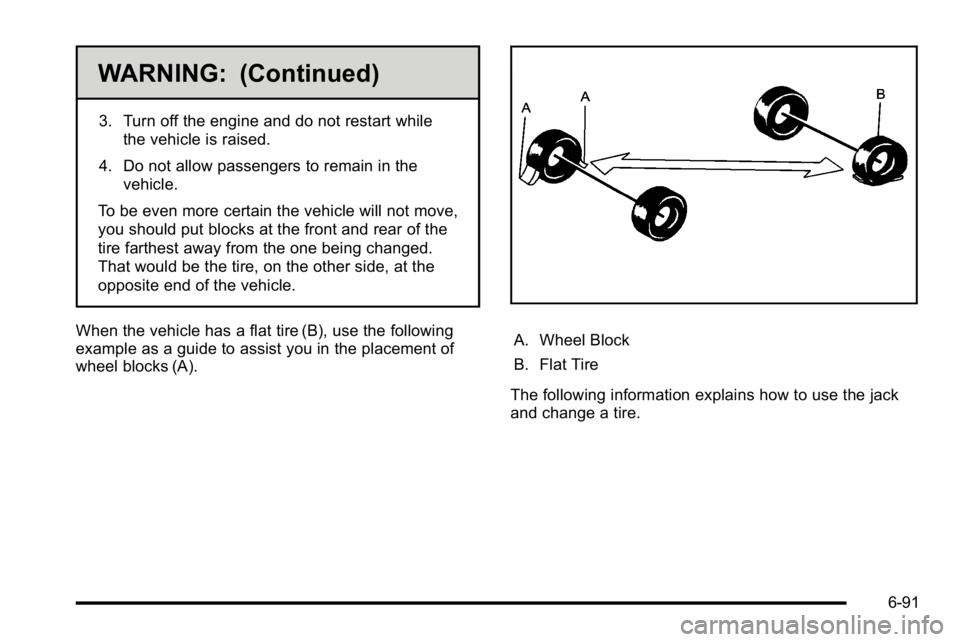

WARNING: (Continued)

3. Turn off the engine and do not restart whilethe vehicle is raised.

4. Do not allow passengers to remain in the vehicle.

To be even more certain the vehicle will not move,

you should put blocks at the front and rear of the

tire farthest away from the one being changed.

That would be the tire, on the other side, at the

opposite end of the vehicle.

When the vehicle has a flat tire (B), use the following

example as a guide to assist you in the placement of

wheel blocks (A).

A. Wheel Block

B. Flat Tire

The following information explains how to use the jack

and change a tire.

6-91

Page 394 of 474

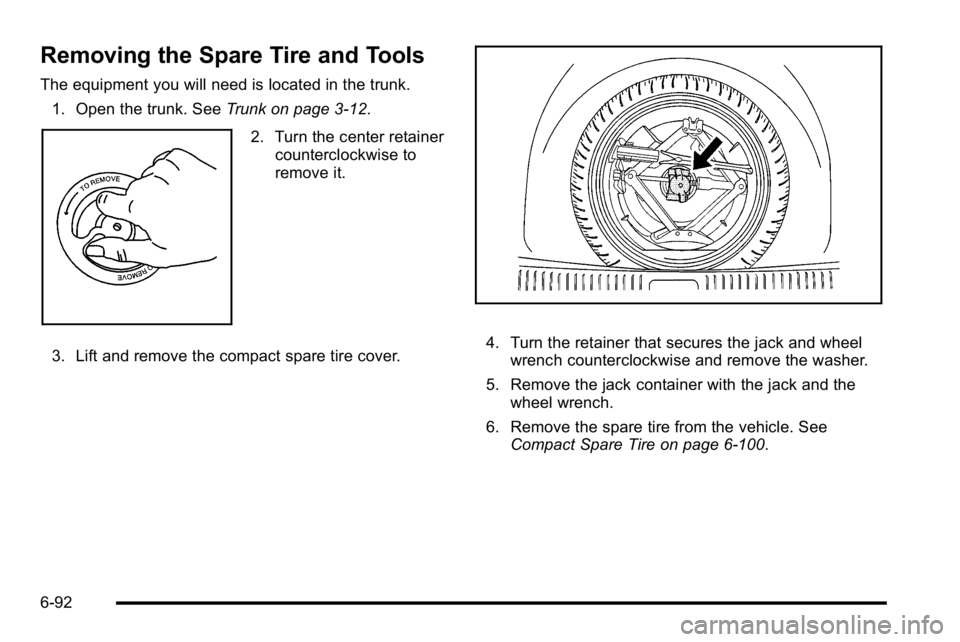

Removing the Spare Tire and Tools

The equipment you will need is located in the trunk.1. Open the trunk. See Trunk on page 3‑12.

2. Turn the center retainer

counterclockwise to

remove it.

3. Lift and remove the compact spare tire cover.

4. Turn the retainer that secures the jack and wheel wrench counterclockwise and remove the washer.

5. Remove the jack container with the jack and the wheel wrench.

6. Remove the spare tire from the vehicle. See Compact Spare Tire on page 6‑100.

6-92

Page 395 of 474

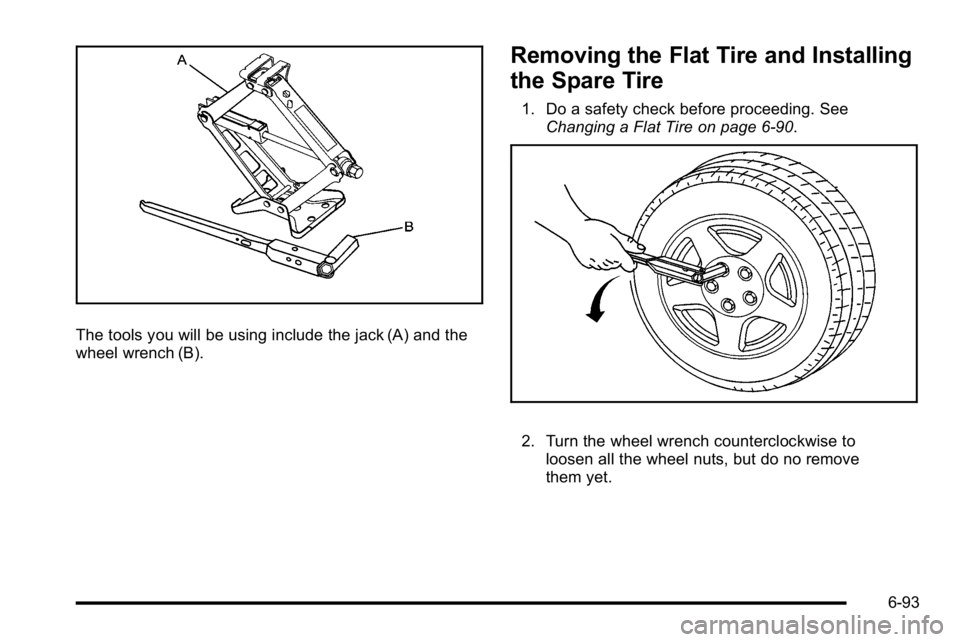

The tools you will be using include the jack (A) and the

wheel wrench (B).

Removing the Flat Tire and Installing

the Spare Tire

1. Do a safety check before proceeding. SeeChanging a Flat Tire on page 6‑90.

2. Turn the wheel wrench counterclockwise toloosen all the wheel nuts, but do no remove

them yet.

6-93

Page 396 of 474

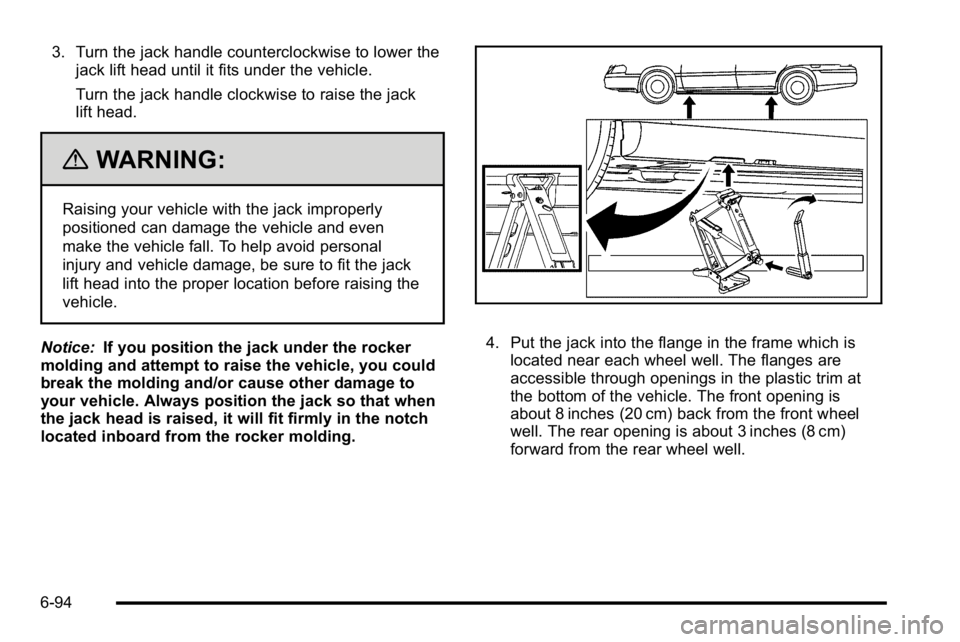

3. Turn the jack handle counterclockwise to lower thejack lift head until it fits under the vehicle.

Turn the jack handle clockwise to raise the jack

lift head.

{WARNING:

Raising your vehicle with the jack improperly

positioned can damage the vehicle and even

make the vehicle fall. To help avoid personal

injury and vehicle damage, be sure to fit the jack

lift head into the proper location before raising the

vehicle.

Notice: If you position the jack under the rocker

molding and attempt to raise the vehicle, you could

break the molding and/or cause other damage to

your vehicle. Always position the jack so that when

the jack head is raised, it will fit firmly in the notch

located inboard from the rocker molding.

4. Put the jack into the flange in the frame which is located near each wheel well. The flanges are

accessible through openings in the plastic trim at

the bottom of the vehicle. The front opening is

about 8 inches (20 cm) back from the front wheel

well. The rear opening is about 3 inches (8 cm)

forward from the rear wheel well.

6-94