tire size BUICK LUCERNE 2010 Owner's Manual

[x] Cancel search | Manufacturer: BUICK, Model Year: 2010, Model line: LUCERNE, Model: BUICK LUCERNE 2010Pages: 474

Page 29 of 474

Tire Sealant and Compressor Kit

This vehicle may come with a jack and spare tire or a

tire sealant and compressor kit. The kit can be used to

seal small punctures in the tread area of the tire.

SeeTire Sealant and Compressor Kit

on page 6‑82for

complete operating information.

Engine Oil Life System

The engine oil life system calculates engine oil life

based on vehicle use and displays a DIC message

when it is necessary to change the engine oil and filter.

The oil life system should be reset to 100% only

following an oil change.

Resetting the Oil Life System

1. Display the OIL LIFE REMAINING on the DIC.

2. Press and hold the SET/RESET button on the DIC for more than five seconds. The oil life will change

to 100%.

See Engine Oil Life System on page 6‑20.

Fuel E85 (85% Ethanol)

Vehicles that have the 3.9L V6 engine (VIN Code M)

have a yellow fuel cap and can use either unleaded

gasoline or ethanol fuel containing up to 85% ethanol

(E85). See Fuel E85 (85% Ethanol)

on page 6‑8.

In all other engines, use only the unleaded gasoline

described under Gasoline Octane on page 6‑6.

Driving for Better Fuel Economy

Driving habits can affect fuel mileage. Here are some

driving tips to get the best fuel economy possible.

.Avoid fast starts and accelerate smoothly.

.Brake gradually and avoid abrupt stops.

.Avoid idling the engine for long periods of time.

.When road and weather conditions are

appropriate, use cruise control, if equipped.

.Always follow posted speed limits or drive more

slowly when conditions require.

.Keep vehicle tires properly inflated.

.Combine several trips into a single trip.

.Replace the vehicle's tires with the same TPC

Spec number molded into the tire's sidewall near

the size.

.Follow recommended scheduled maintenance.

1-23

Page 288 of 474

The Tire and Loading Information label also lists

the tire size of the original equipment tires (C) and

the recommended cold tire inflation pressures (D).

For more information on tires and inflation, see

Tires

on page 6‑57andInflation - Tire Pressureon

page 6‑65

.

There is also important loading information on

the Certification label. It tells you the Gross

Vehicle Weight Rating (GVWR) and the Gross

Axle Weight Rating (GAWR) for the front and

rear axle, see “Certification Label” later in this

section.

Steps for Determining Correct Load Limit

1.Locate the statement “The combined weight

of occupants and cargo should never exceed

XXX kg or XXX lbs” on your vehicle's placard.

2.Determine the combined weight of the driver

and passengers that will be riding in your

vehicle.

3.Subtract the combined weight of the driver

and passengers from XXX kg or XXX lbs.

4.The resulting figure equals the available

amount of cargo and luggage load capacity.

For example, if the“XXX”amount equals

1400 lbs and there will be five 150 lb

passengers in your vehicle, the amount of

available cargo and luggage load capacity is

650 lbs (1400 −750 (5 x 150) = 650 lbs).

5-20

Page 304 of 474

Section 6 Service and Appearance Care

When It Is Time for New Tires . . . . . . . . . . . . . . . . . 6-73

Buying New Tires . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-74

Different Size Tires and Wheels . . . . . . . . . . . . . . . 6-76

Uniform Tire Quality Grading . . . . . . . . . . . . . . . . . . . 6-76

Wheel Alignment and Tire Balance . . . . . . . . . . . . 6-78

Wheel Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-78

Tire Chains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-80

If a Tire Goes Flat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-81

Tire Sealant and Compressor Kit . . . . . . . . . . . . . . 6-82

Tire Sealant and Compressor Kit Storage . . . . . . 6-90

Changing a Flat Tire . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-90

Removing the Spare Tire and Tools . . . . . . . . . . . . 6-92

Removing the Flat Tire and Installing theSpare Tire . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-93

Storing a Flat or Spare Tire and Tools . . . . . . . . . 6-98

Compact Spare Tire . . . . . . . . . . . . . . . . . . . . . . . . . . 6-100

Appearance Care . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-101

Interior Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-101

Fabric/Carpet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-102

Leather . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-103

Instrument Panel, Vinyl, and Other Plastic Surfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-103

Care of Safety Belts . . . . . . . . . . . . . . . . . . . . . . . . . . 6-104 Weatherstrips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-104

Washing Your Vehicle . . . . . . . . . . . . . . . . . . . . . . . . 6-104

Cleaning Exterior Lamps/Lenses . . . . . . . . . . . . . 6-105

Finish Care . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-105

Windshield and Wiper Blades . . . . . . . . . . . . . . . . 6-106

Aluminum or Chrome-Plated Wheels

and Trim . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-106

Tires . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-107

Sheet Metal Damage . . . . . . . . . . . . . . . . . . . . . . . . . 6-107

Finish Damage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-108

Underbody Maintenance . . . . . . . . . . . . . . . . . . . . . 6-108

Chemical Paint Spotting . . . . . . . . . . . . . . . . . . . . . . 6-108

Vehicle Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-109

Vehicle Identification Number (VIN) . . . . . . . . . . . 6-109

Service Parts Identification Label . . . . . . . . . . . . . 6-109

Electrical System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-110

Add-On Electrical Equipment . . . . . . . . . . . . . . . . . 6-110

Power Windows and Other Power Options . . . 6-110

Fuses and Circuit Breakers . . . . . . . . . . . . . . . . . . . 6-110

Underhood Fuse Block . . . . . . . . . . . . . . . . . . . . . . . 6-110

Rear Underseat Fuse Block . . . . . . . . . . . . . . . . . . 6-113

Capacities and Specifications . . . . . . . . . . . . . . . . . .6-118

6-2

Page 360 of 474

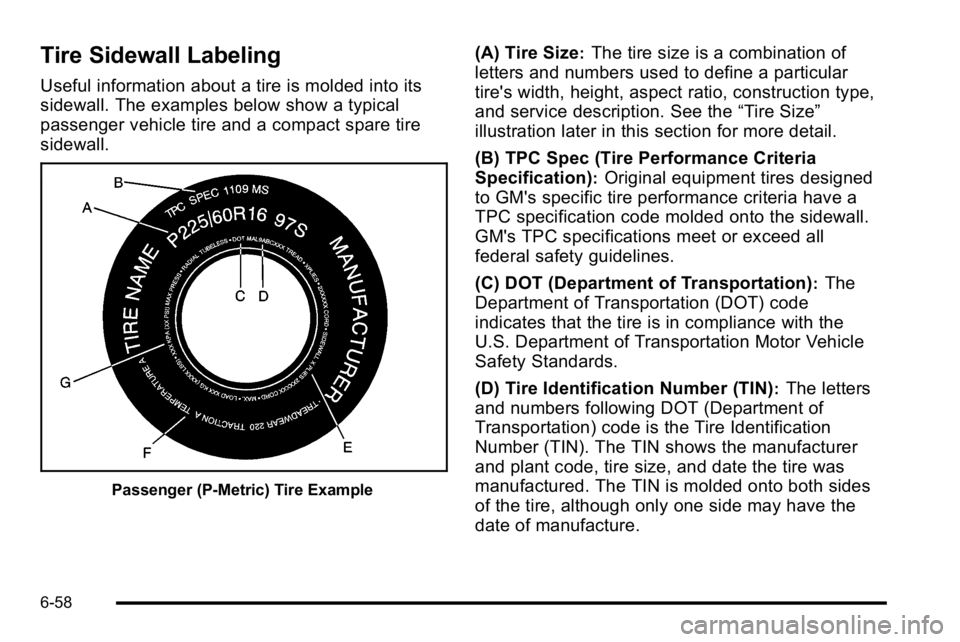

Tire Sidewall Labeling

Useful information about a tire is molded into its

sidewall. The examples below show a typical

passenger vehicle tire and a compact spare tire

sidewall.

Passenger (P‐Metric) Tire Example

(A) Tire Size:The tire size is a combination of

letters and numbers used to define a particular

tire's width, height, aspect ratio, construction type,

and service description. See the “Tire Size”

illustration later in this section for more detail.

(B) TPC Spec (Tire Performance Criteria

Specification)

:Original equipment tires designed

to GM's specific tire performance criteria have a

TPC specification code molded onto the sidewall.

GM's TPC specifications meet or exceed all

federal safety guidelines.

(C) DOT (Department of Transportation)

:The

Department of Transportation (DOT) code

indicates that the tire is in compliance with the

U.S. Department of Transportation Motor Vehicle

Safety Standards.

(D) Tire Identification Number (TIN)

:The letters

and numbers following DOT (Department of

Transportation) code is the Tire Identification

Number (TIN). The TIN shows the manufacturer

and plant code, tire size, and date the tire was

manufactured. The TIN is molded onto both sides

of the tire, although only one side may have the

date of manufacture.

6-58

Page 362 of 474

(B) Tire Ply Material:The type of cord and

number of plies in the sidewall and under the

tread.

(C) Tire Identification Number (TIN)

:The letters

and numbers following the DOT (Department of

Transportation) code is the Tire Identification

Number (TIN). The TIN shows the manufacturer

and plant code, tire size, and date the tire was

manufactured. The TIN is molded onto both sides

of the tire, although only one side may have the

date of manufacture.

(D) Maximum Cold Inflation Load Limit

:

Maximum load that can be carried and the

maximum pressure needed to support that load. (E) Tire Inflation

:The temporary use tire or

compact spare tire should be inflated to 60 psi

(420 kPa). For more information on tire pressure

and inflation see Inflation - Tire Pressure

on

page 6‑65

.

(F) Tire Size

:A combination of letters and

numbers define a tire's width, height, aspect ratio,

construction type, and service description. The

letter T as the first character in the tire size means

the tire is for temporary use only.

(G) TPC Spec (Tire Performance Criteria

Specification)

:Original equipment tires designed

to GM's specific tire performance criteria have a

TPC specification code molded onto the sidewall.

GM's TPC specifications meet or exceed all

federal safety guidelines.

6-60

Page 363 of 474

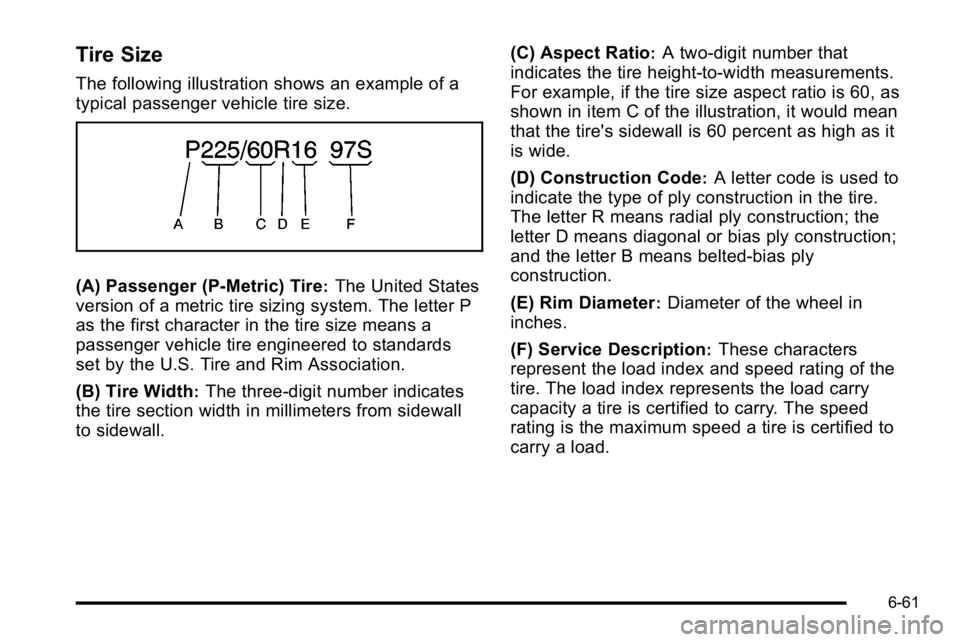

Tire Size

The following illustration shows an example of a

typical passenger vehicle tire size.

(A) Passenger (P‐Metric) Tire:The United States

version of a metric tire sizing system. The letter P

as the first character in the tire size means a

passenger vehicle tire engineered to standards

set by the U.S. Tire and Rim Association.

(B) Tire Width

:The three‐digit number indicates

the tire section width in millimeters from sidewall

to sidewall. (C) Aspect Ratio

:A two‐digit number that

indicates the tire height‐to‐width measurements.

For example, if the tire size aspect ratio is 60, as

shown in item C of the illustration, it would mean

that the tire's sidewall is 60 percent as high as it

is wide.

(D) Construction Code

:A letter code is used to

indicate the type of ply construction in the tire.

The letter R means radial ply construction; the

letter D means diagonal or bias ply construction;

and the letter B means belted‐bias ply

construction.

(E) Rim Diameter

:Diameter of the wheel in

inches.

(F) Service Description

:These characters

represent the load index and speed rating of the

tire. The load index represents the load carry

capacity a tire is certified to carry. The speed

rating is the maximum speed a tire is certified to

carry a load.

6-61

Page 366 of 474

Recommended Inflation Pressure:Vehicle

manufacturer's recommended tire inflation

pressure as shown on the tire placard. See

Inflation - Tire Pressure

on page 6‑65and Loading

the Vehicle

on page 5‑19.

Radial Ply Tire

:A pneumatic tire in which the

ply cords that extend to the beads are laid at

90 degrees to the centerline of the tread.

Rim

:A metal support for a tire and upon which

the tire beads are seated.

Sidewall

:The portion of a tire between the tread

and the bead.

Speed Rating

:An alphanumeric code assigned

to a tire indicating the maximum speed at which a

tire can operate.

Traction

:The friction between the tire and the

road surface. The amount of grip provided.

Tread

:The portion of a tire that comes into

contact with the road.

Treadwear Indicators

:Narrow bands, sometimes

called wear bars, that show across the tread

of a tire when only 1/16 inch (1.6 mm) of tread

remains. See When It Is Time for New Tires

on

page 6‑73

. UTQGS (Uniform Tire Quality Grading

Standards)

:A tire information system that

provides consumers with ratings for a tire's

traction, temperature, and treadwear. Ratings are

determined by tire manufacturers using

government testing procedures. The ratings are

molded into the sidewall of the tire. See Uniform

Tire Quality Grading

on page 6‑76.

Vehicle Capacity Weight

:The number of

designated seating positions multiplied by 150 lbs

(68 kg) plus the rated cargo load. See Loading the

Vehicle

on page 5‑19.

Vehicle Maximum Load on the Tire

:Load on an

individual tire due to curb weight, accessory

weight, occupant weight, and cargo weight.

Vehicle Placard

:A label permanently attached

to a vehicle showing the vehicle's capacity

weight and the original equipment tire size and

recommended inflation pressure. See “Tire and

Loading Information Label” underLoading the

Vehicle

on page 5‑19.

6-64

Page 368 of 474

How to Check

Use a good quality pocket-type gauge to check

tire pressure. You cannot tell if your tires are

properly inflated simply by looking at them.

Radial tires may look properly inflated even

when they are under‐inflated. Check the tire's

inflation pressure when the tires are cold.

Cold means your vehicle has been sitting for

at least three hours or driven no more than

1 mile (1.6 km).

Remove the valve cap from the tire valve stem.

Press the tire gauge firmly onto the valve to get a

pressure measurement. If the cold tire inflation

pressure matches the recommended pressure on

the Tire and Loading Information label, no further

adjustment is necessary. If the inflation pressure

is low, add air until you reach the recommended

amount.

If you overfill the tire, release air by pushing on

the metal stem in the center of the tire valve.

Re‐check the tire pressure with the tire gauge.

Be sure to put the valve caps back on the valve

stems. They help prevent leaks by keeping out dirt

and moisture.

Tire Pressure Monitor System

The Tire Pressure Monitor System (TPMS) uses radio

and sensor technology to check tire pressure levels.

The TPMS sensors monitor the air pressure in your

vehicle's tires and transmit tire pressure readings to a

receiver located in the vehicle.

Each tire, including the spare (if provided), should be

checked monthly when cold and inflated to the inflation

pressure recommended by the vehicle manufacturer

on the vehicle placard or tire inflation pressure label.

(If your vehicle has tires of a different size than the size

indicated on the vehicle placard or tire inflation pressure

label, you should determine the proper tire inflation

pressure for those tires.)

As an added safety feature, your vehicle has been

equipped with a tire pressure monitoring system

(TPMS) that illuminates a low tire pressure telltale when

one or more of your tires is significantly under‐inflated.

Accordingly, when the low tire pressure telltale

illuminates, you should stop and check your tires as

soon as possible, and inflate them to the proper

pressure. Driving on a significantly under‐inflated tire

causes the tire to overheat and can lead to tire failure.

Under‐inflation also reduces fuel efficiency and tire

tread life, and may affect the vehicle's handling and

stopping ability.

6-66

Page 370 of 474

If the warning light comes on, stop as soon as possible

and inflate the tires to the recommended pressure

shown on the tire loading information label. See

Loading the Vehicle on page 5‑19.

At the same time a message to check the pressure in a

specific tire appears on the Driver Information Center

(DIC) display. The low tire pressure warning light and

the DIC warning message come on at each ignition

cycle until the tires are inflated to the correct inflation

pressure. Using the DIC, tire pressure levels can be

viewed by the driver. For additional information and

details about the DIC operation and displays seeDIC

Operation and Displays

on page 4‑47and DIC

Warnings and Messages on page 4‑55.

The low tire pressure warning light may come on in cool

weather when the vehicle is first started, and then turn

off as you start to drive. This could be an early indicator

that the air pressure in the tire(s) are getting low and

need to be inflated to the proper pressure. A Tire and Loading Information label, attached to your

vehicle, shows the size of your vehicle's original

equipment tires and the correct inflation pressure for

your vehicle's tires when they are cold. See

Loading the

Vehicle

on page 5‑19, for an example of the Tire and

Loading Information label and its location on your

vehicle. Also see Inflation - Tire Pressure on page 6‑65.

Your vehicle's TPMS can warn you about a low tire

pressure condition but it does not replace normal tire

maintenance. See Tire Inspection and Rotation

on

page 6‑71and Tires on page 6‑57.

Notice: Using non‐approved tire sealants could

damage the Tire Pressure Monitor System (TPMS)

sensors. TPMS sensor damage caused by using an

incorrect tire sealant is not covered by the vehicle

warranty. Always use the GM approved tire sealant

available through your dealer.

Factory-installed Tire Inflator Kits use a GM approved

liquid tire sealant. Using non-approved tire sealants

could damage the TPMS sensors. See Tire Sealant and

Compressor Kit

on page 6‑82for information regarding

the inflator kit materials and instructions.

6-68

Page 375 of 474

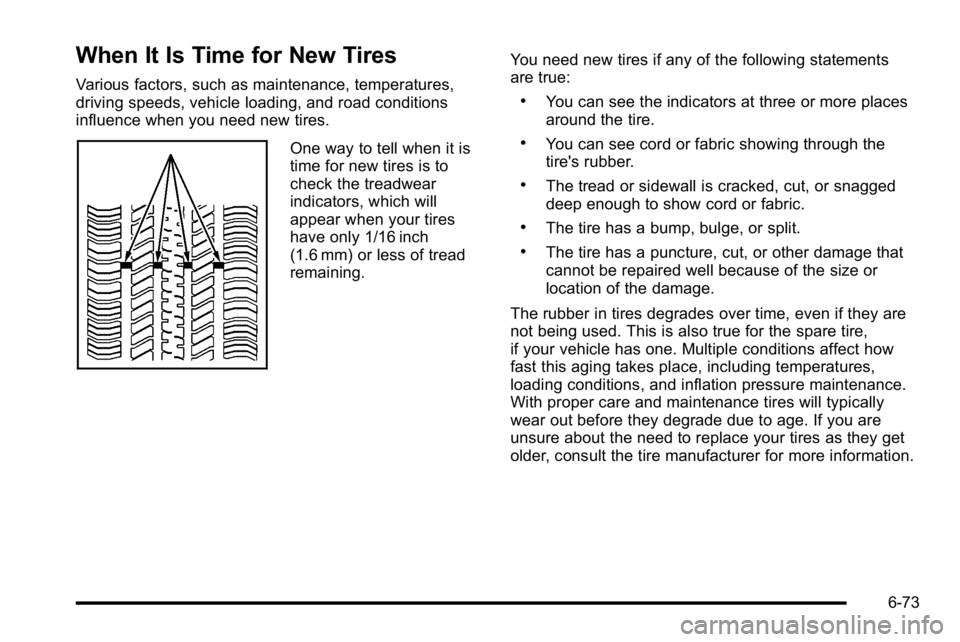

When It Is Time for New Tires

Various factors, such as maintenance, temperatures,

driving speeds, vehicle loading, and road conditions

influence when you need new tires.

One way to tell when it is

time for new tires is to

check the treadwear

indicators, which will

appear when your tires

have only 1/16 inch

(1.6 mm) or less of tread

remaining.You need new tires if any of the following statements

are true:

.You can see the indicators at three or more places

around the tire.

.You can see cord or fabric showing through the

tire's rubber.

.The tread or sidewall is cracked, cut, or snagged

deep enough to show cord or fabric.

.The tire has a bump, bulge, or split.

.The tire has a puncture, cut, or other damage that

cannot be repaired well because of the size or

location of the damage.

The rubber in tires degrades over time, even if they are

not being used. This is also true for the spare tire,

if your vehicle has one. Multiple conditions affect how

fast this aging takes place, including temperatures,

loading conditions, and inflation pressure maintenance.

With proper care and maintenance tires will typically

wear out before they degrade due to age. If you are

unsure about the need to replace your tires as they get

older, consult the tire manufacturer for more information.

6-73