wheel BUICK PARK AVENUE 1997 Service Manual

[x] Cancel search | Manufacturer: BUICK, Model Year: 1997, Model line: PARK AVENUE, Model: BUICK PARK AVENUE 1997Pages: 420, PDF Size: 21.93 MB

Page 254 of 420

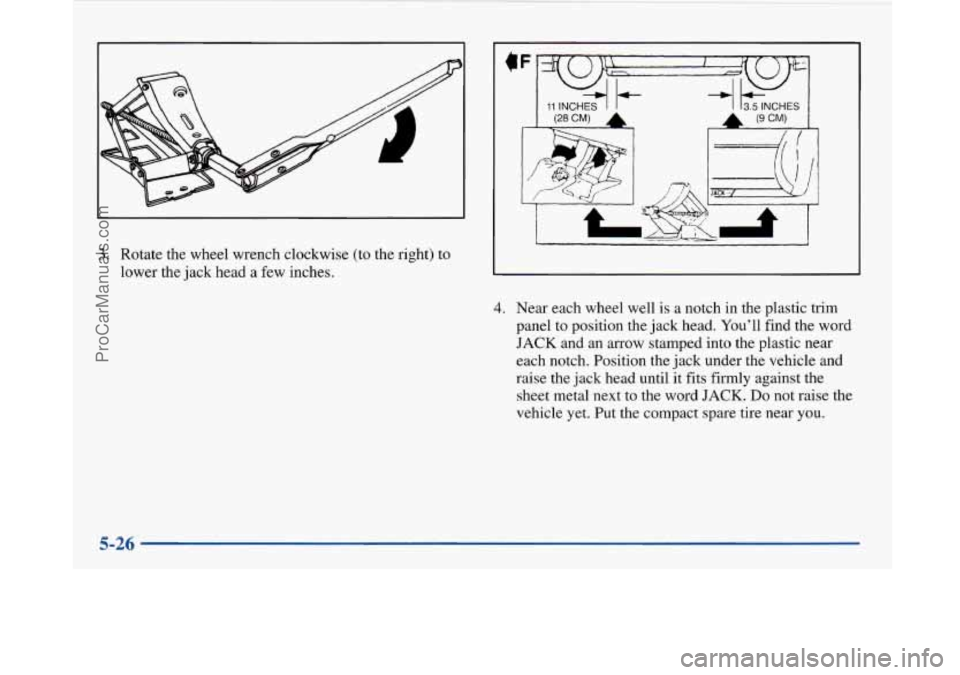

(28 CM) A I

3. Rotate the wheel wrench clockwise (to the right) to

lower the jack head a few inches.

4. Near each wheel well is a notch in the plastic trim

panel to position the jack head. You’ll find the word

JACK and an arrow stamped into the plastic near

each notch. Position the jack under the vehicle and

raise the jack head until it fits firmly against the

sheet metal next to the word

JACK. Do not raise the

vehicle yet. Put the compact spare tire near

you.

5-26

ProCarManuals.com

Page 255 of 420

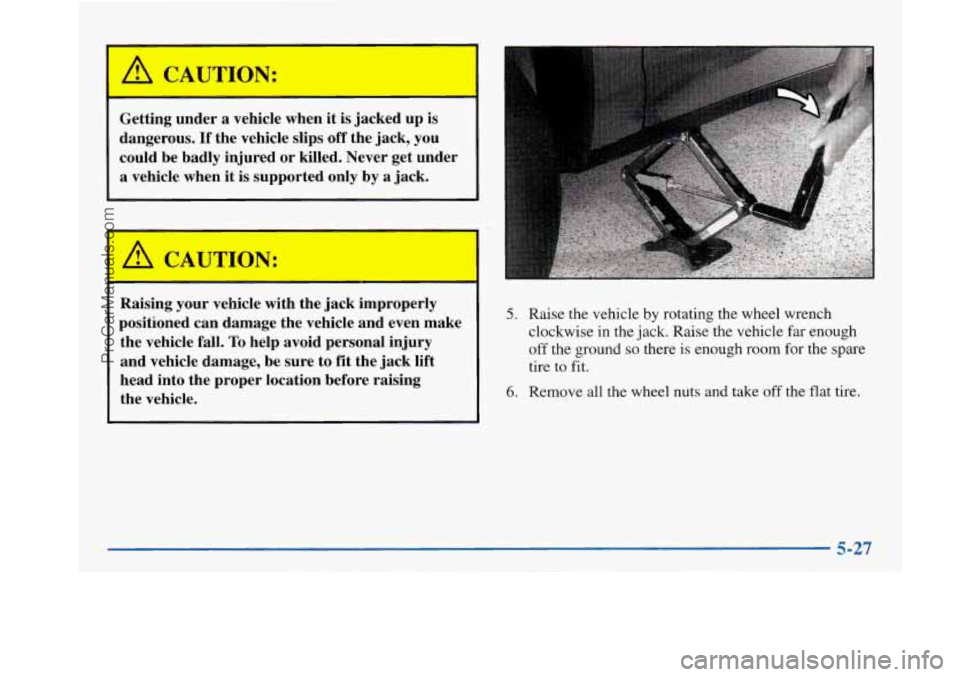

Getting under a vehicle when it is jacked up is

dangerous.

If the vehicle slips off the jack, you

could be badly injured

or killed. Never get under

a vehicle when it is supported only by a jack.

Raising

your vehicle with the jack improperly

positioned can damage the vehicle and even make

the vehicle fall.

To help avoid personal injury

and vehicle damage, be sure to

fit the jack lift

head into the proper location before raising

the vehicle.

5. Raise the vehicle by rotating the wheel wrench

clockwise in the jack. Raise the vehicle

far enough

off the ground

so there is enough room for the spare

tire to fit.

6. Remove all the wheel nuts and take off the flat tire.

5-27

ProCarManuals.com

Page 256 of 420

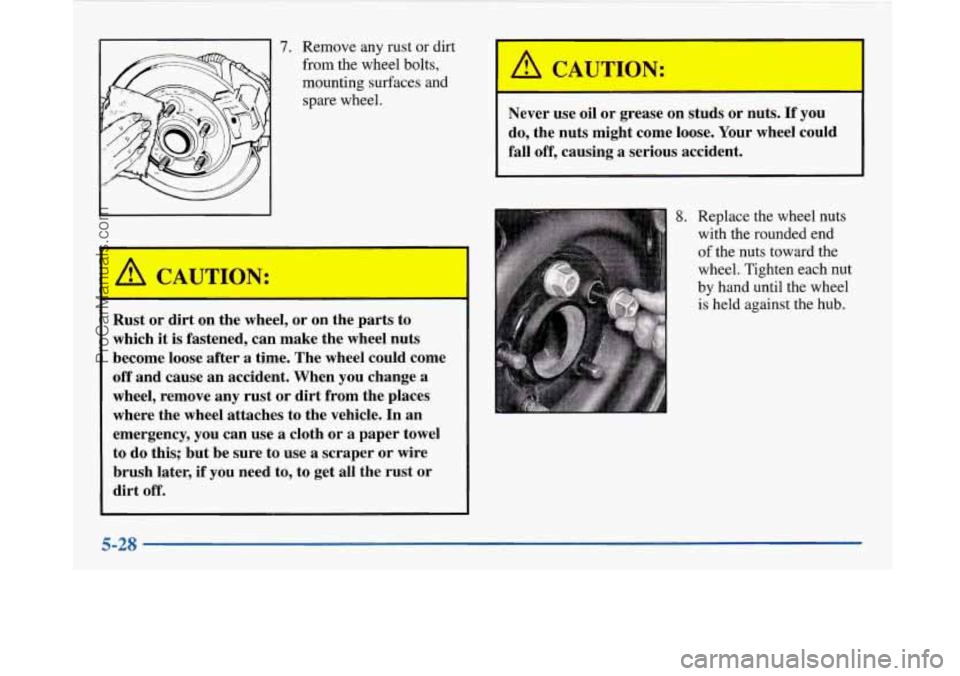

' 7. Remove any rust or dirt

from the wheel bolts,

mounting surfaces and spare wheel.

Rust or dirt on the wheel, or on the parts to

which

it is fastened, can make the wheel nuts

become loose after

a time. The wheel could come

off and cause an accident. When

you change a

wheel, remove any

rust or dirt from the places

where the wheel attaches

to the vehicle. In an

emergency,

you can use a cloth or a paper towel

to do this; but be sure to use

a scraper or wire

brush later, if you need to, to get all the rust

or

dirt off.

/1 CAUTMN:

Never use oil or grease on studs or nuts. If you

do, the nuts might come loose. Your wheel could

fall off, causing a serious accident.

8. Replace the wheel nuts

with the rounded end

of the nuts toward the

wheel. Tighten each nut

by hand until the wheel

is held against the hub.

A CAUTION: I

I

5-28

~

ProCarManuals.com

Page 257 of 420

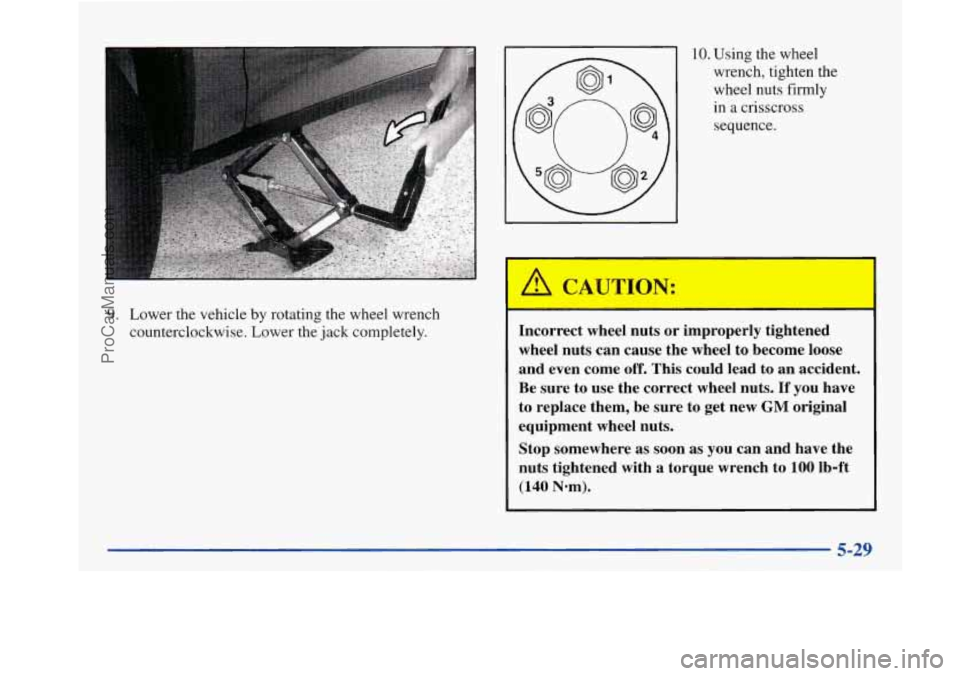

9. Lower the vehicle by rotating the wheel wrench

counterclockwise. Lower the jack completely.

10. Using the wheel

wrench, tighten the

wheel nuts firmly

in a crisscross

sequence.

A CAUTION:

- - I

Incorrect wheel nuts or improperly tightened

wheel nuts can cause the wheel to become loose

and even come off.

This could lead to an accident.

Be sure to use the correct wheel nuts.

If you have

to replace them, be sure to get new

GM original

equipment wheel nuts.

Stop somewhere as soon as you can and have the

nuts tightened with

a torque wrench to 100 lb-ft

(140 Nom).

5-29

ProCarManuals.com

Page 258 of 420

NOTICE:

Improperly tightened wheel nuts can lead to

brake pulsation and rotor damage.

To avoid

expensive brake repairs, evenly tighten the wheel

nuts in the proper sequence and to the proper

torque specification.

Don’t try to put a wheel cover on your compact spare

tire. It won’t fit. Store the wheel cover

in the trunk

until you have the flat tire repaired or replaced.

NOTICE:

Wheel covers won’t fit on your compact spare. If

you try to put a wheel cover on your compact

spare, you could damage the cover or the spare.

Storing the Flat Tire and Tools

L!b, CAUTION: I

Storing a jack, a tire or other equipment in the

passenger compartment

of the vehicle could

cause injury. In

a sudden stop or collision, loose

equipment could strike someone. Store all these

in the proper place.

After you’ve put the compact spare tire on your vehicle,

you’ll need

to store the flat tire in your trunk. Use the

following procedure to secure the flat tire in the trunk.

5-30

~

ProCarManuals.com

Page 259 of 420

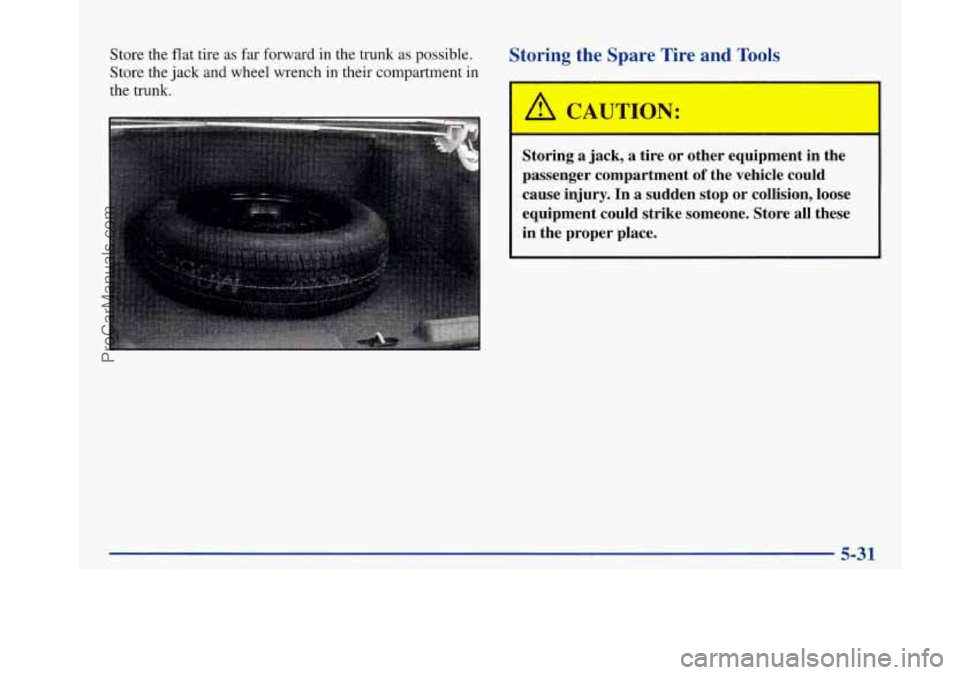

Store the flat tire as far forward in the trunk as possible.

Store the jack and wheel wrench in their compartment in

the trunk. Storing the Spare Tire and Tools

A CAUTION:

Storing a jack, a tire or other equipment in the

passenger compartment

of the vehicle could

cause injury. In a sudden stop or collision,

loose

equipment could strike someone. Store all these

in the proper place.

ProCarManuals.com

Page 261 of 420

NOTICE:

When the compact spare is installed, don’t take

your vehicle through an automatic car wash with

guide rails. The compact spare can get caught on

the rails. That can damage the tire and wheel,

and maybe other parts

of your vehicle.

Don’t use your compact spare on other vehicles.

And don’t mix your compact spare tire or wheel with

other wheels or tires. They won’t fit. Keep your spare

tire and its wheel together.

If You’re Stuck: In Sand, Mud, Ice

or

Snow

What you don’t want to do when your vehicle is stuck is

to spin your wheels too fast. The method known as

“rocking” can help you get out when you’re stuck, but

you must use caution.

I NOTICE: I

Tire chains won’t fit your compact spare. Using

them can damage your vehicle and can damage

the chains too. Don’t use tire chains on your

compact spare.

If you let your tires spin at high speed, they can

explode, and you or others could be injured. And,

the transaxle or other parts

of the vehicle can

overheat. That could cause an engine

compartment fire or other damage. When you’re

stuck, spin the wheels as little as possible. Don’t

spin the wheels above

35 mph (55 km/h) as shown

on the speedometer.

ProCarManuals.com

Page 262 of 420

1 NOTICE:

Spinning your wheels can destroy parts of your

vehicle as well

as the tires. If you spin the wheels

too fast while shifting your transaxle back and

forth, you can destroy your transaxle.

For information about using tire chains on your vehicle,

see “Tire Chains” in the Index.

Rocking Your Vehicle To Get It Out

First, turn your steering wheel left and right. That will

clear the area around your front wheels. If your vehicle

has traction control, you should turn the system off. (See

“Traction Control System” in the Index.) Then shift

back and forth between REVERSE (R) and a forward

gear, spinning the wheels as little as possible. Release

the accelerator pedal while you shift, and press lightly

on the accelerator pedal when the transaxle is in gear. If

that doesn’t get you out after a few tries, you may need

to be towed out.

If you do need to be towed out, see

“Towing Your Vehicle” in the Index.

ProCarManuals.com

Page 297 of 420

Some driving conditions or climates may cause a brake

squeal when the brakes are first applied or lightly

applied. This does not mean something is wrong with

your brakes.

Properly torqued wheel nuts are necessary to help

prevent brake pulsation. When tires are rotated, inspect

brake pads for wear and evenly torque wheel nuts in the

proper sequence to GM specifications.

Your rear drum brakes don’t have wear indicators, but if

you ever hear a rear brake rubbing noise, have the rear

brake linings inspected.

Also, the rear brake drums should

be removed and inspected each time the tires

are removed

for rotation

or changing. When you have the front brakes

replaced, have the rear brakes inspected, too.

Brake linings should always be replaced as complete

axle sets.

See “Brake System Inspection’’ in Section

7 of this

manual under Part

C “Periodic Maintenance

Inspections”.

Brake Pedal Travel

See your dealer if the brake pedal does not return to

normal height, or if there is a rapid increase in pedal

travel. This could be a sign of brake trouble.

Brake Adjustment

Every time you apply the brakes, with or without the

vehicle moving, your brakes adjust for wear.

Replacing Brake System Parts

The braking system on a modern vehicle is complex. Its

many parts have to be of top quality and work well

together

if the vehicle is to have really good braking.

Your vehicle was designed and tested with top-quality

GM brake parts. When you replace parts of your braking

system

-- for example, when your brake linings wear

down and you have to have new ones put in

-- be sure

you get new approved GM replacement parts.

If you

don’t, your brakes may no longer work properly. For

example, if someone puts in brake linings that are wrong

for your vehicle, the balance between your front and

rear brakes can change

-- for the worse. The braking

performance you’ve come to expect can change in many

other ways if someone puts in the wrong replacement

brake parts.

6-33

ProCarManuals.com

Page 314 of 420

To reset (calibrate) the system:

1. Turn the ignition switch to RUN.

2. Press the GAGES button on the DIC until TIRE

PRESSURE appears on the display.

3. Press and hold the DIC RESET button for about

five seconds. After five seconds, the display will

show TIRE PRESSURE RESET. If

TIRE

PRESSURE RESET does not appear on the display

after about five seconds, see your dealer for service.

After you release the DIC RESET button, TIRE

PRESSURE NORMAL will appear on the display.

The system completes the calibration process during

driving. During the first

10 to 20 miles (15 to 30 km) of

driving, the system will not alert you if

a tire is high or

low. After

20 to 80 miles (30 to 125 km), the system

will only alert you about pressure differences of

12 psi

(85 kPa) or more. After about 80 miles (125 km) of

driving, the system will alert you if one tire is

10 psi

(69 kPa) different from the other three tires.

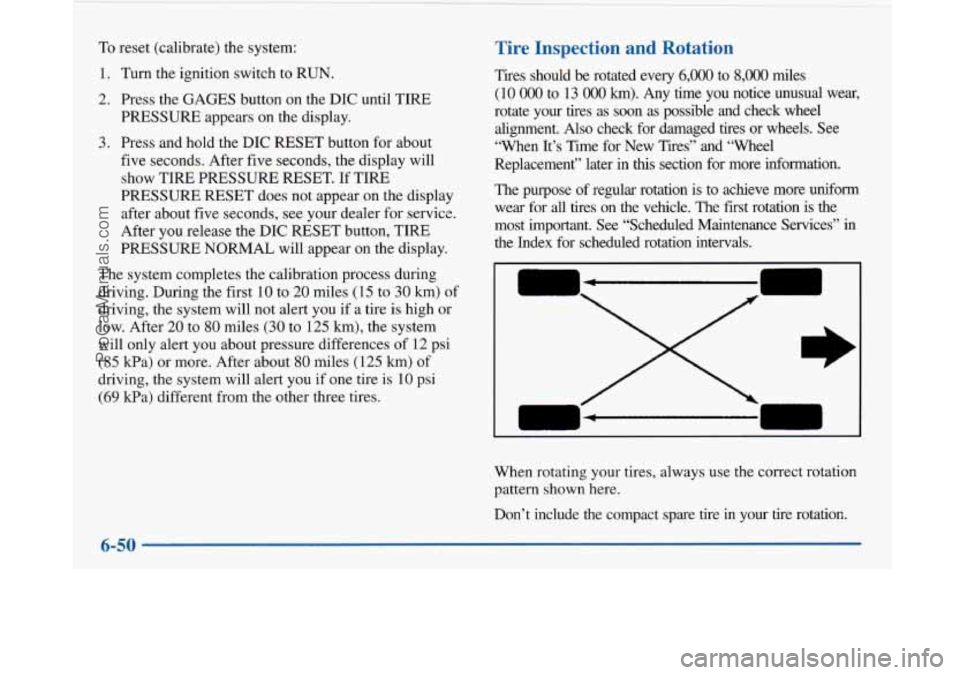

Tire Inspection and Rotation

Tires should be rotated every 6,000 to 8,000 miles

(10 000 to 13 000 km). Any time you notice unusual wear,

rotate your tires

as soon as possible and check wheel

alignment. Also check for damaged tires or wheels. See

“When It’s Time for New Tires” and “Wheel

Replacement’’ later in

this section for more information.

The purpose of regular rotation is to achieve more uniform

wear for

all tires on the vehicle. The fist rotation is the

most important. See “Scheduled Maintenance Services” in

the Index for scheduled rotation intervals.

I

7

When rotating your tires, always use the correct rotation

pattern shown here.

Don’t include the compact spare tire

in your tire rotation

6-50

ProCarManuals.com