BUICK PARK AVENUE 2004 Owner's Manual

PARK AVENUE 2004

BUICK

BUICK

https://www.carmanualsonline.info/img/43/35389/w960_35389-0.png

BUICK PARK AVENUE 2004 Owner's Manual

Trending: weight, wipers, belt, brake sensor, bulb, park assist, climate control

Page 291 of 410

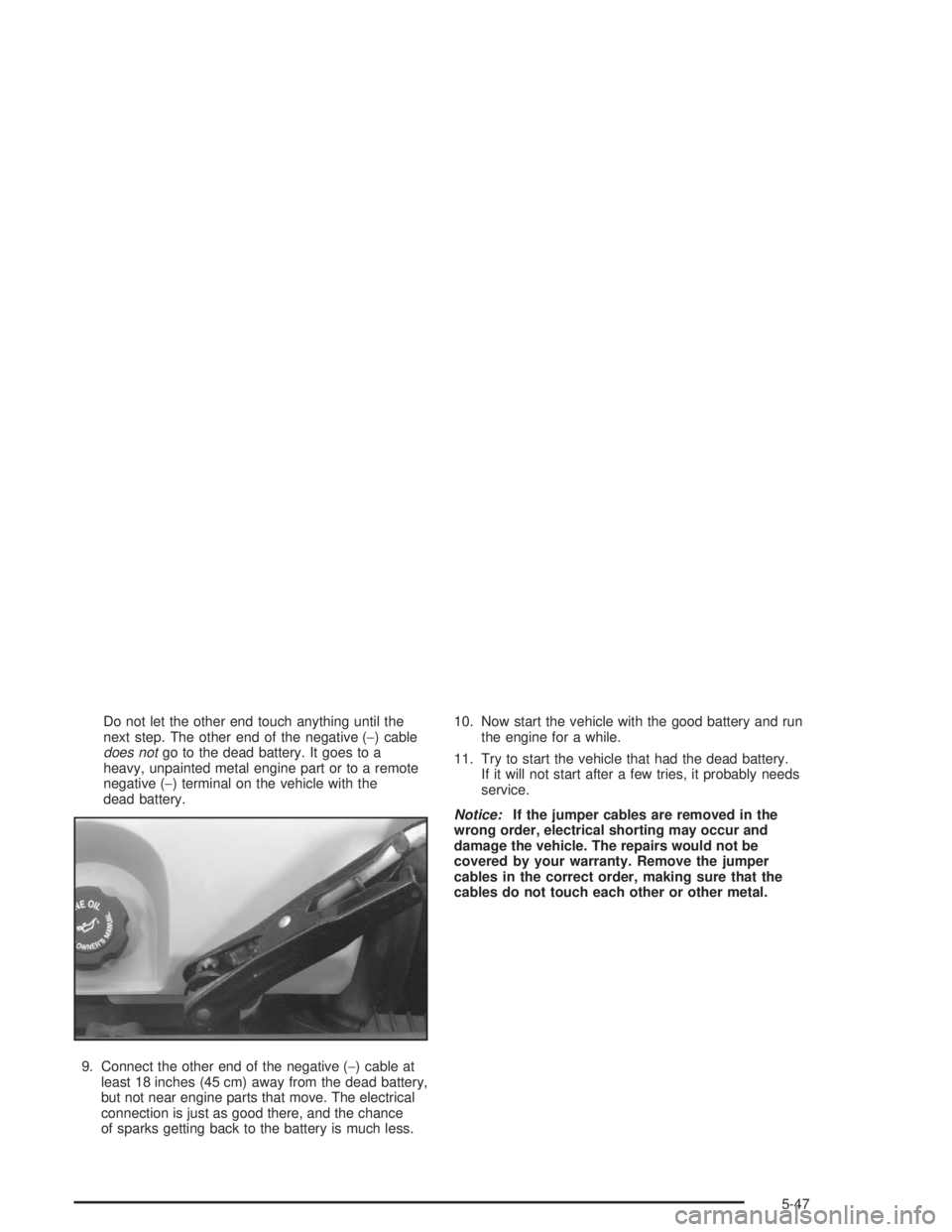

Do not let the other end touch anything until the

next step. The other end of the negative (−) cable

does notgo to the dead battery. It goes to a

heavy, unpainted metal engine part or to a remote

negative (−) terminal on the vehicle with the

dead battery.

9. Connect the other end of the negative (−) cable at

least 18 inches (45 cm) away from the dead battery,

but not near engine parts that move. The electrical

connection is just as good there, and the chance

of sparks getting back to the battery is much less.10. Now start the vehicle with the good battery and run

the engine for a while.

11. Try to start the vehicle that had the dead battery.

If it will not start after a few tries, it probably needs

service.

Notice:If the jumper cables are removed in the

wrong order, electrical shorting may occur and

damage the vehicle. The repairs would not be

covered by your warranty. Remove the jumper

cables in the correct order, making sure that the

cables do not touch each other or other metal.

5-47

Page 292 of 410

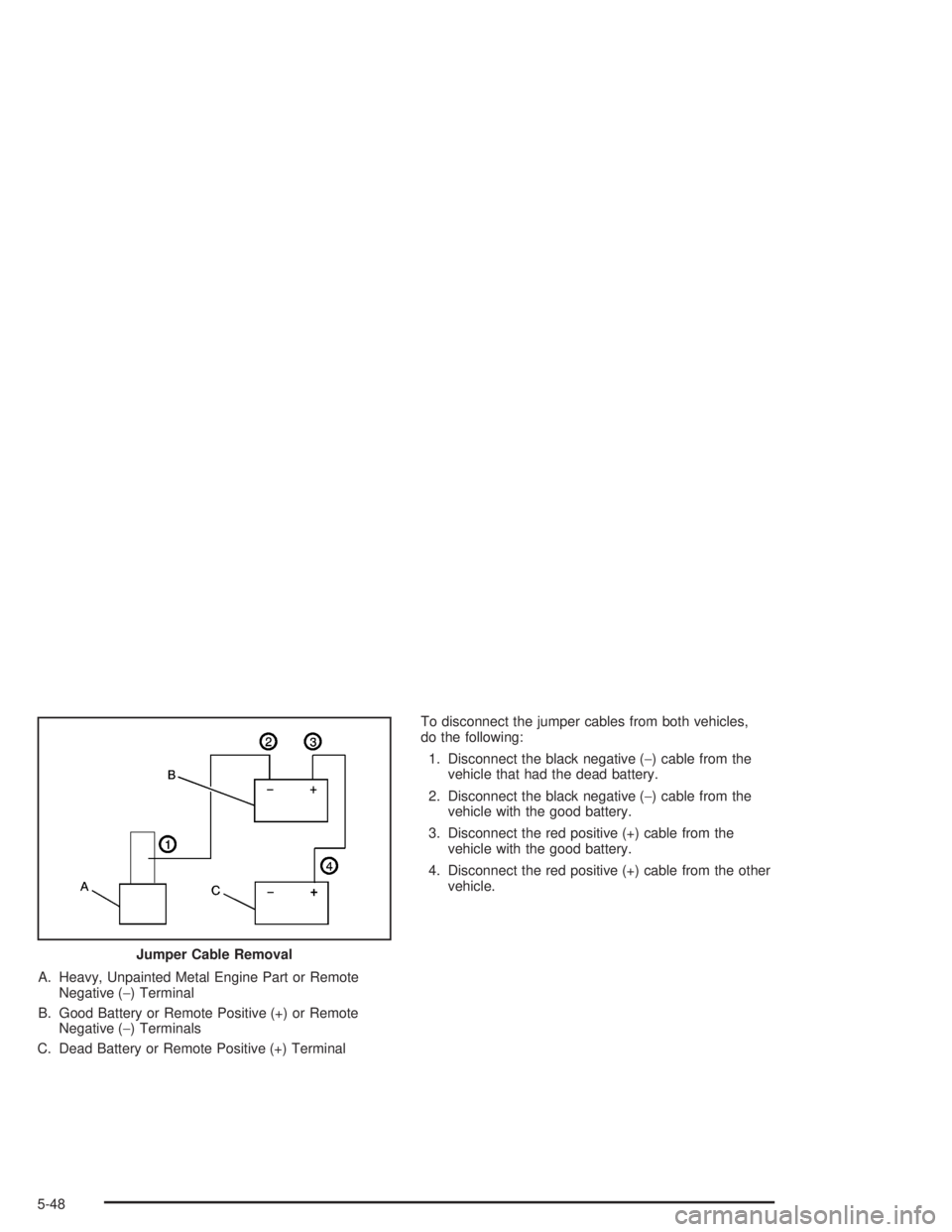

A. Heavy, Unpainted Metal Engine Part or Remote

Negative (−) Terminal

B. Good Battery or Remote Positive (+) or Remote

Negative (−) Terminals

C. Dead Battery or Remote Positive (+) TerminalTo disconnect the jumper cables from both vehicles,

do the following:

1. Disconnect the black negative (−) cable from the

vehicle that had the dead battery.

2. Disconnect the black negative (−) cable from the

vehicle with the good battery.

3. Disconnect the red positive (+) cable from the

vehicle with the good battery.

4. Disconnect the red positive (+) cable from the other

vehicle.

Jumper Cable Removal

5-48

Page 293 of 410

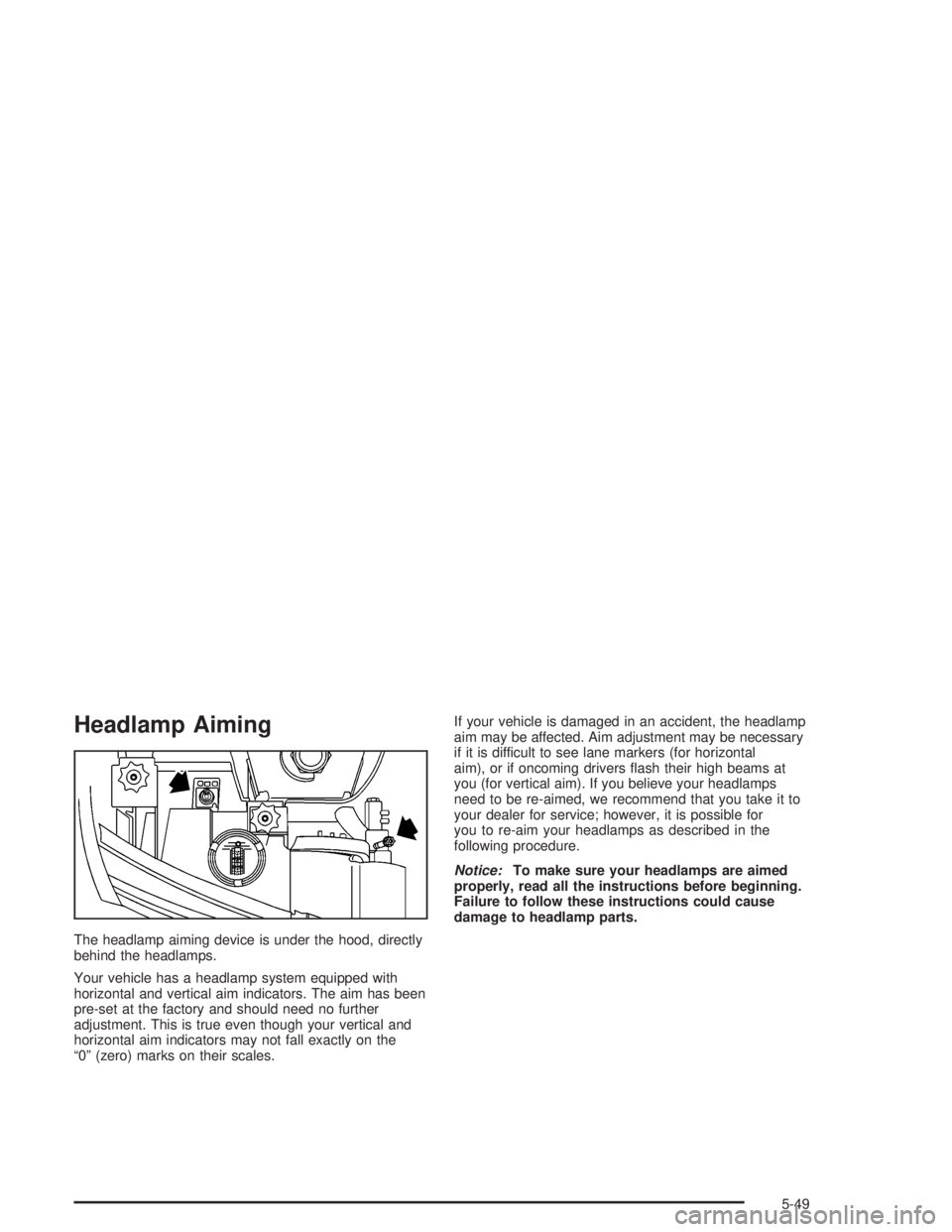

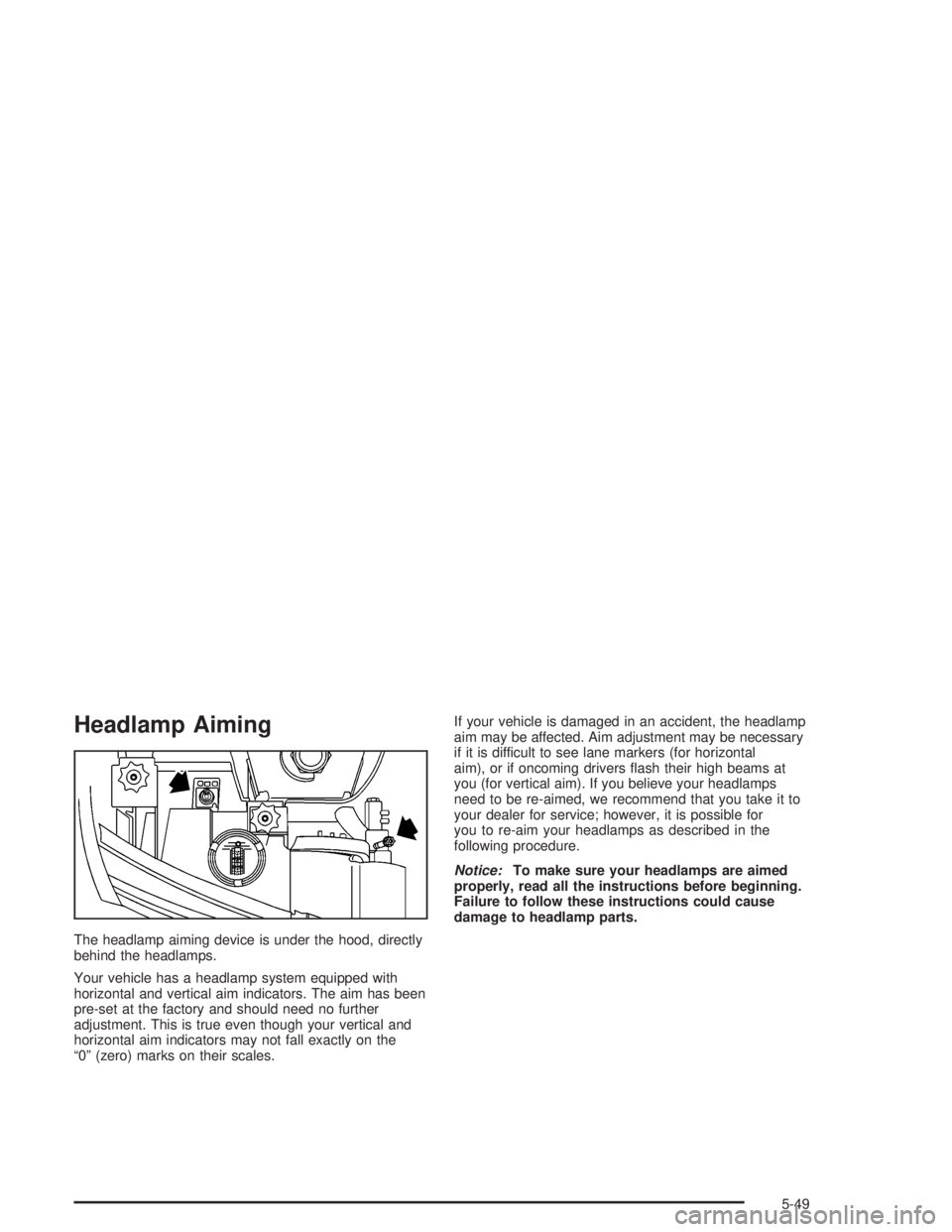

Headlamp Aiming

The headlamp aiming device is under the hood, directly

behind the headlamps.

Your vehicle has a headlamp system equipped with

horizontal and vertical aim indicators. The aim has been

pre-set at the factory and should need no further

adjustment. This is true even though your vertical and

horizontal aim indicators may not fall exactly on the

“0” (zero) marks on their scales.If your vehicle is damaged in an accident, the headlamp

aim may be affected. Aim adjustment may be necessary

if it is difficult to see lane markers (for horizontal

aim), or if oncoming drivers �ash their high beams at

you (for vertical aim). If you believe your headlamps

need to be re-aimed, we recommend that you take it to

your dealer for service; however, it is possible for

you to re-aim your headlamps as described in the

following procedure.

Notice:To make sure your headlamps are aimed

properly, read all the instructions before beginning.

Failure to follow these instructions could cause

damage to headlamp parts.

5-49

Page 294 of 410

To check the aim, the vehicle should be properly

prepared as follows:

The vehicle must have all four tires on a perfectly

level surface.

If necessary, pads may be used on an uneven

surface.

The vehicle should not have any snow, ice or mud

attached to it.

The vehicle should be fully assembled and all other

work stopped while headlamp aiming is being done.

There should not be any cargo or loading of the

vehicle, except it should have a full tank of fuel and

one person or 160 lbs (75 kg) on the driver’s seat.

Close all doors.

Tires should be properly in�ated.

Rock the vehicle to stabilize the suspension.

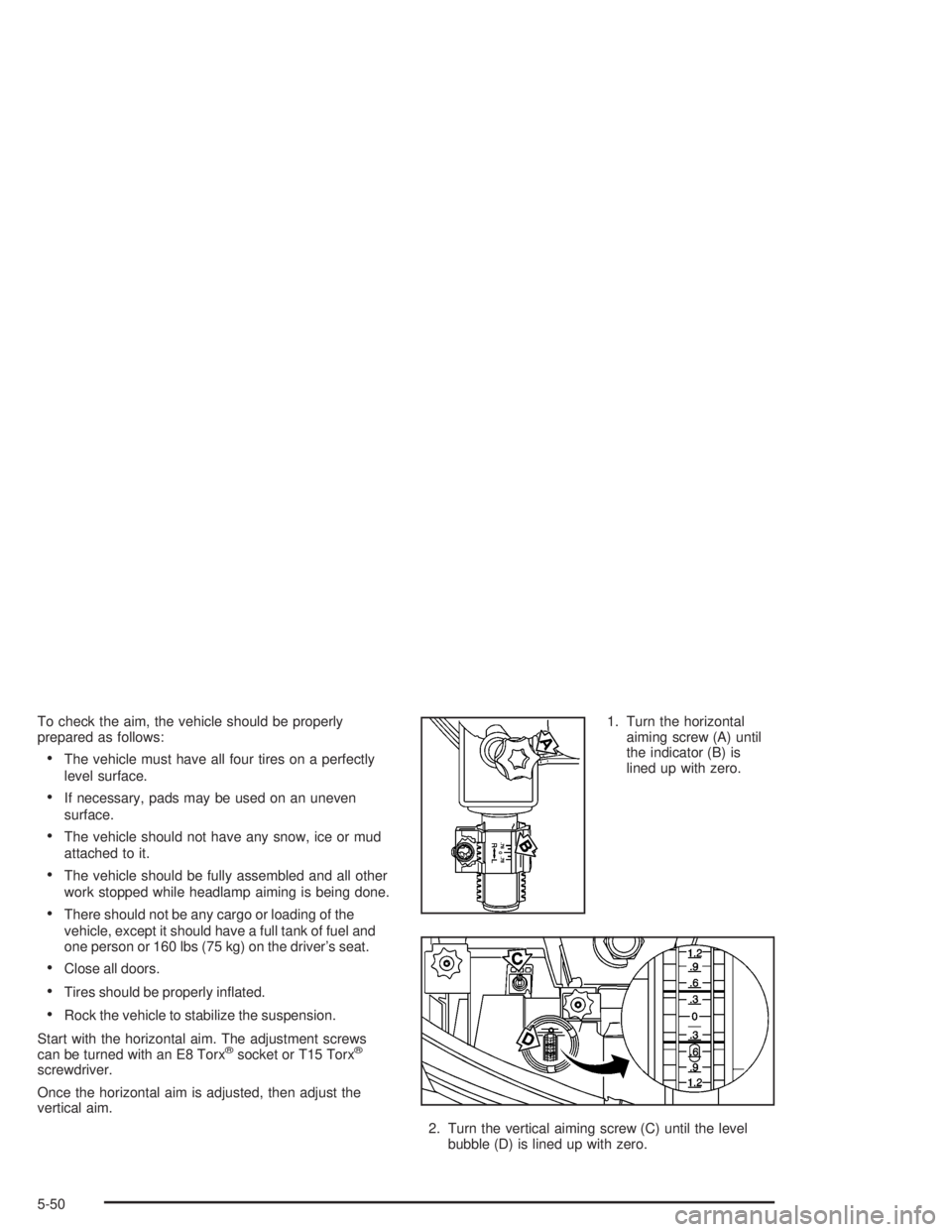

Start with the horizontal aim. The adjustment screws

can be turned with an E8 Torx

®socket or T15 Torx®

screwdriver.

Once the horizontal aim is adjusted, then adjust the

vertical aim.1. Turn the horizontal

aiming screw (A) until

the indicator (B) is

lined up with zero.

2. Turn the vertical aiming screw (C) until the level

bubble (D) is lined up with zero.

5-50

Page 295 of 410

Bulb Replacement

For the type of bulb to use, seeReplacement Bulbs on

page 5-60.

For any bulb changing procedure not listed in this

section, contact your dealer.

Halogen Bulbs

{CAUTION:

Halogen bulbs have pressurized gas inside and

can burst if you drop or scratch the bulb. You or

others could be injured. Be sure to read and

follow the instructions on the bulb package.

Headlamps

Each headlamp is attached by thumb screws.

5-51

Page 296 of 410

1. Remove the thumb screws by turning them

counterclockwise.2. Pull the headlamp assembly away from the vehicle.

5-52

Page 297 of 410

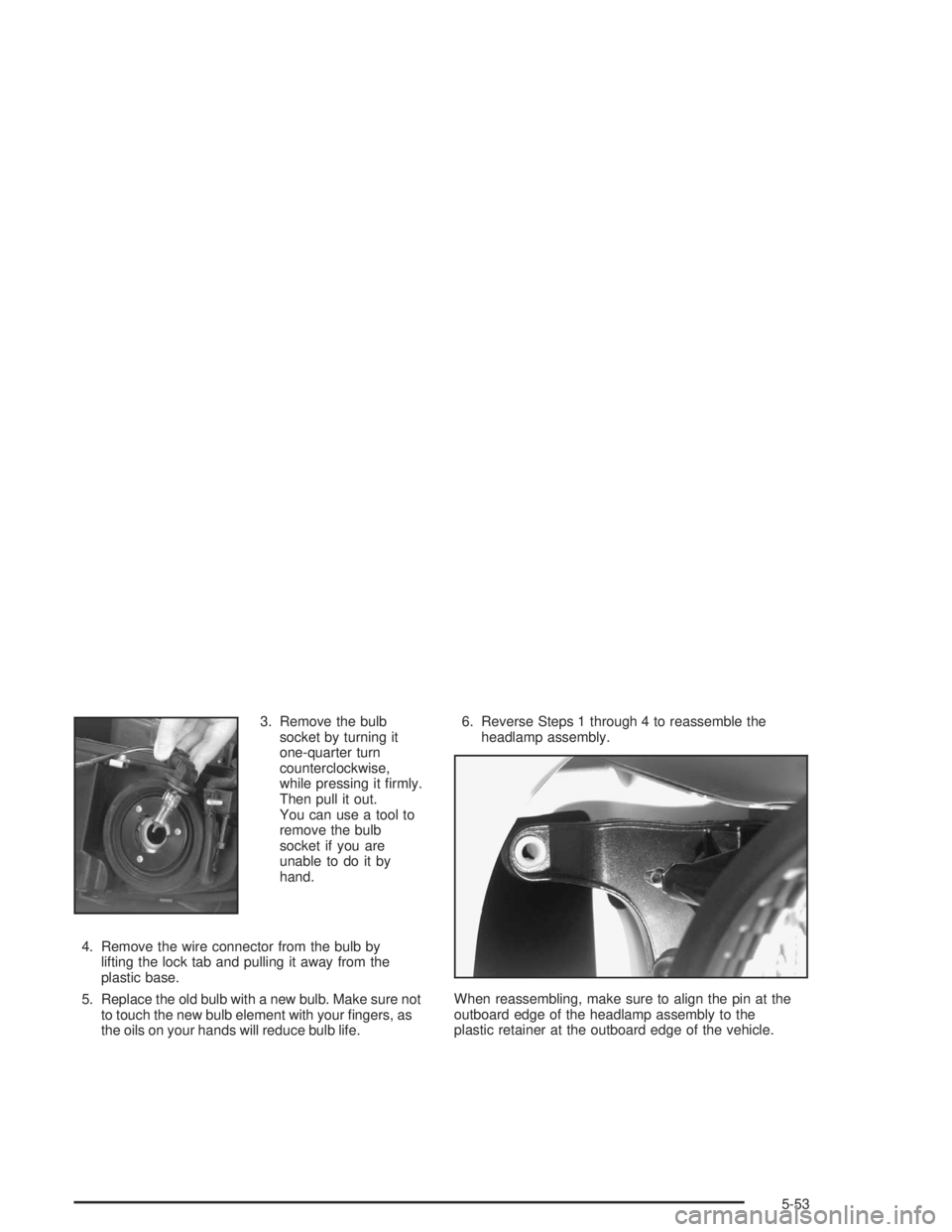

3. Remove the bulb

socket by turning it

one-quarter turn

counterclockwise,

while pressing it �rmly.

Then pull it out.

You can use a tool to

remove the bulb

socket if you are

unable to do it by

hand.

4. Remove the wire connector from the bulb by

lifting the lock tab and pulling it away from the

plastic base.

5. Replace the old bulb with a new bulb. Make sure not

to touch the new bulb element with your �ngers, as

the oils on your hands will reduce bulb life.6. Reverse Steps 1 through 4 to reassemble the

headlamp assembly.

When reassembling, make sure to align the pin at the

outboard edge of the headlamp assembly to the

plastic retainer at the outboard edge of the vehicle.

5-53

Page 298 of 410

Front Turn Signal Lamps

1. Once the headlamp assembly has been removed,

reach down from the top of the vehicle, and while

pressing the lock tab on the socket, turn the socket

one-quarter turn counterclockwise and pull it out.

2. Remove the old bulb

by pulling it straight out

of the socket.

3. Replace the bulb and turn the bulb assembly back

into place.

Rear Turn Signal, Stoplamps and

Back-Up Lamps

5-54

Page 299 of 410

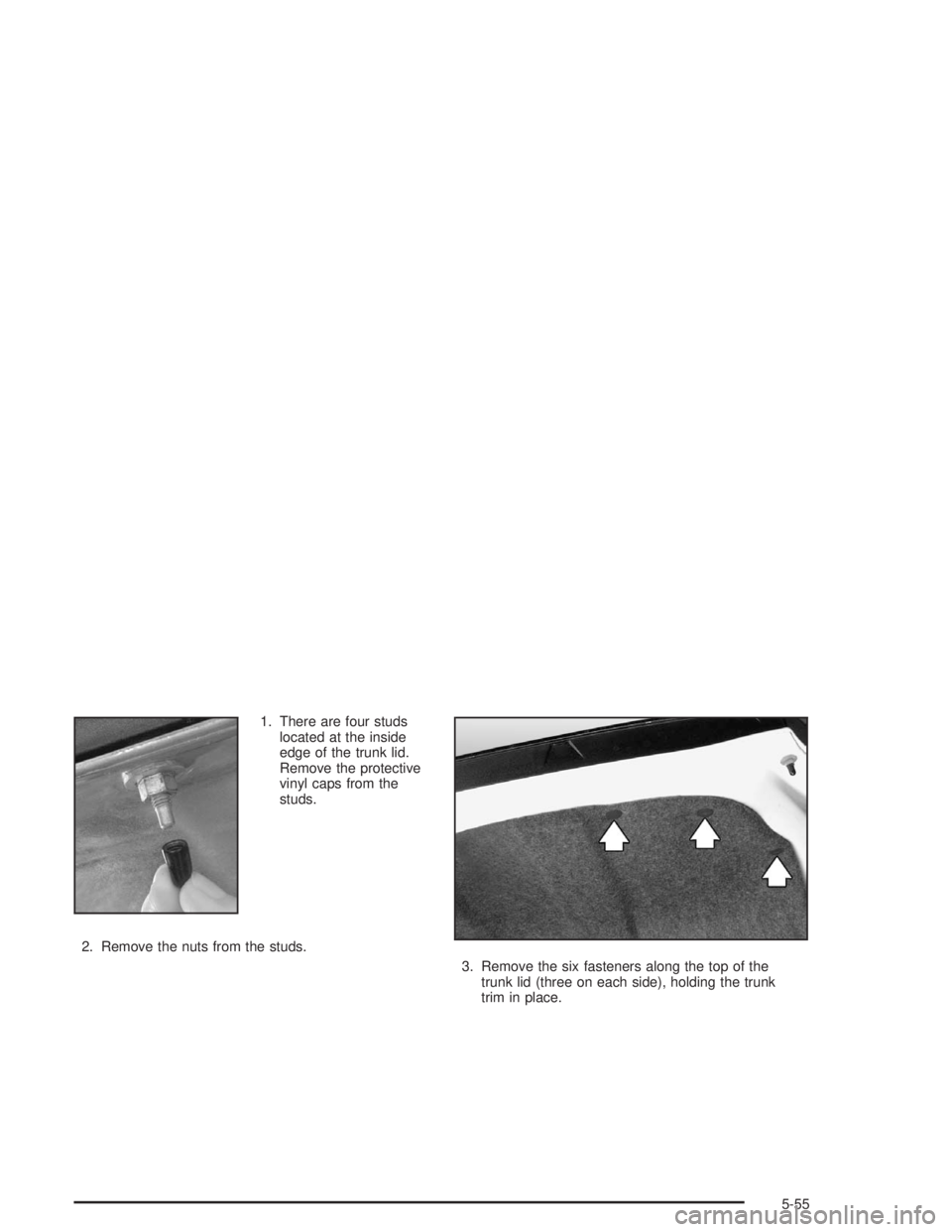

1. There are four studs

located at the inside

edge of the trunk lid.

Remove the protective

vinyl caps from the

studs.

2. Remove the nuts from the studs.

3. Remove the six fasteners along the top of the

trunk lid (three on each side), holding the trunk

trim in place.

5-55

Page 300 of 410

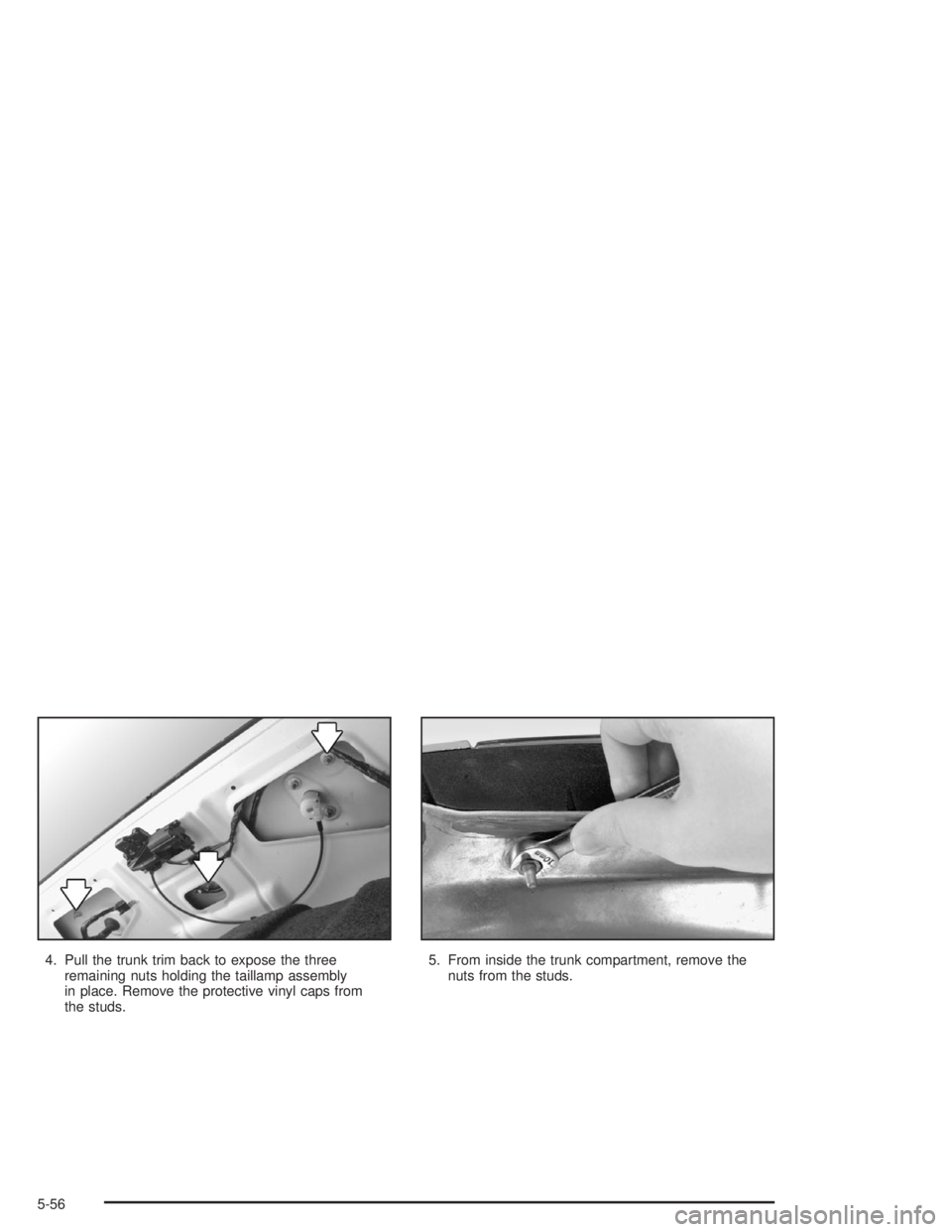

4. Pull the trunk trim back to expose the three

remaining nuts holding the taillamp assembly

in place. Remove the protective vinyl caps from

the studs.5. From inside the trunk compartment, remove the

nuts from the studs.

5-56

Trending: glove box, checking oil, change key battery, audio, battery location, brake fluid, steering wheel adjustment