clock CADILLAC CTS 2008 2.G User Guide

[x] Cancel search | Manufacturer: CADILLAC, Model Year: 2008, Model line: CTS, Model: CADILLAC CTS 2008 2.GPages: 490, PDF Size: 2.59 MB

Page 316 of 490

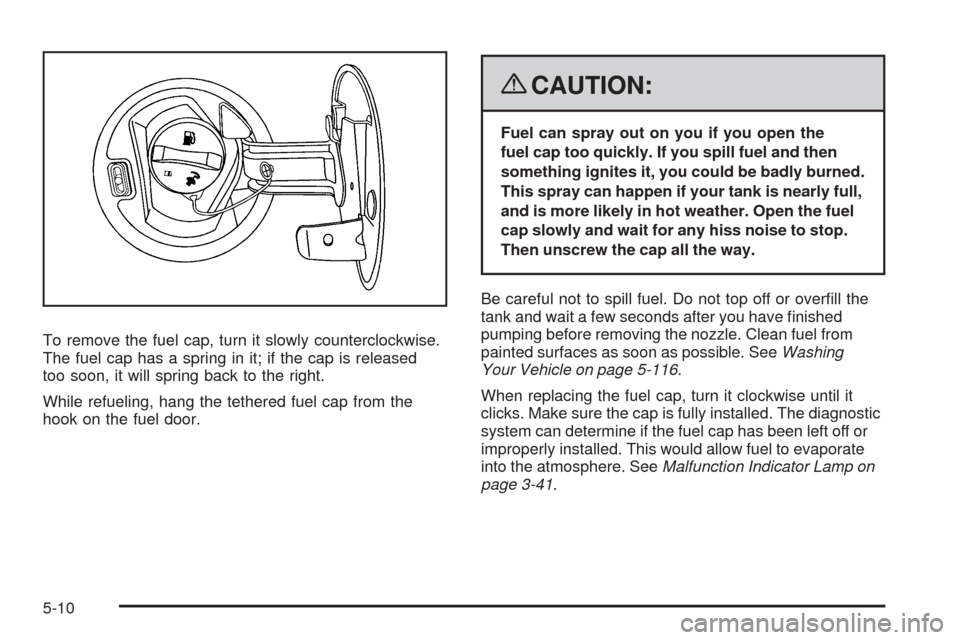

To remove the fuel cap, turn it slowly counterclockwise.

The fuel cap has a spring in it; if the cap is released

too soon, it will spring back to the right.

While refueling, hang the tethered fuel cap from the

hook on the fuel door.

{CAUTION:

Fuel can spray out on you if you open the

fuel cap too quickly. If you spill fuel and then

something ignites it, you could be badly burned.

This spray can happen if your tank is nearly full,

and is more likely in hot weather. Open the fuel

cap slowly and wait for any hiss noise to stop.

Then unscrew the cap all the way.

Be careful not to spill fuel. Do not top off or over�ll the

tank and wait a few seconds after you have �nished

pumping before removing the nozzle. Clean fuel from

painted surfaces as soon as possible. SeeWashing

Your Vehicle on page 5-116.

When replacing the fuel cap, turn it clockwise until it

clicks. Make sure the cap is fully installed. The diagnostic

system can determine if the fuel cap has been left off or

improperly installed. This would allow fuel to evaporate

into the atmosphere. SeeMalfunction Indicator Lamp on

page 3-41.

5-10

Page 343 of 490

{CAUTION:

You can be burned if you spill coolant on hot

engine parts. Coolant contains eythylene glycol

and it will burn if the engine parts are hot

enough. Do not spill coolant on a hot engine.

If no coolant is visible in the surge tank, add coolant as

follows:

1. Remove the coolant surge tank pressure cap when

the cooling system, including the coolant surge tank

pressure cap and upper radiator hose, is no longer

hot. Turn the pressure cap slowly counterclockwise

about one-quarter turn and then stop.

If you hear a hiss, wait for that to stop. A hiss

means there is still some pressure left.2. Then keep turning the pressure cap slowly, and

remove it.

5-37

Page 360 of 490

7. Locate the vertical headlamp aiming screws, which

are under the hood near each headlamp assembly.

The adjustment screw can be turned with a

6 mm hex socket.

8. Turn the vertical aiming screw until the headlamp

beam is aimed to the horizontal tape line. Turn it

clockwise or counterclockwise to raise or lower the

angle of the beam.

The top edge of the cut-off should be positioned at

the bottom edge of the horizontal tape line.9. Make sure that the light from the headlamp is

positioned at the bottom edge of the horizontal tape

line. The lamp on the left (A) shows the correct

headlamp aim. The lamp on the right (B) shows

the incorrect headlamp aim.

10. Repeat Steps 7 through 9 for the opposite

headlamp. Driver Side Shown

5-54

Page 362 of 490

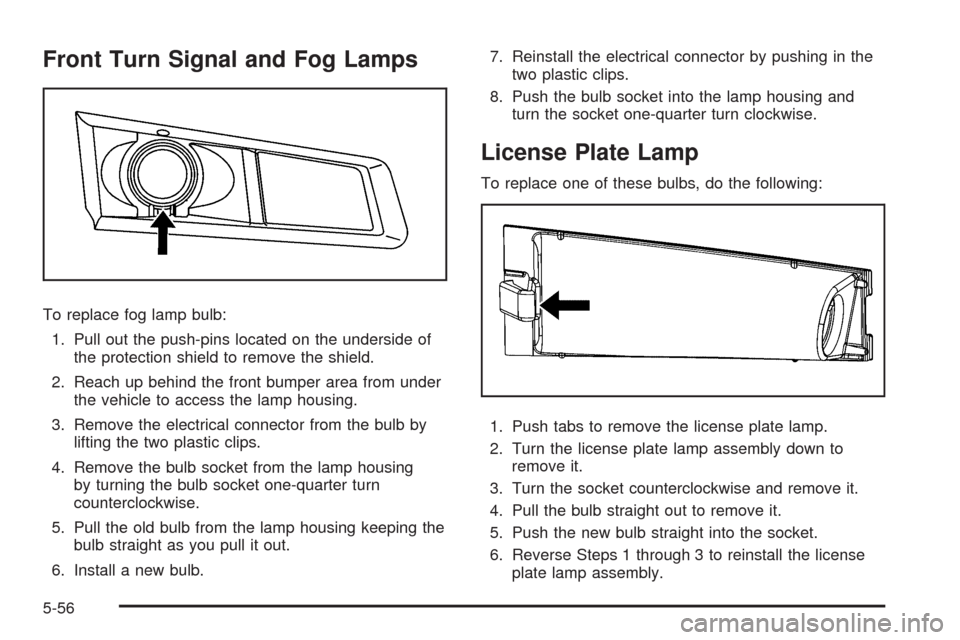

Front Turn Signal and Fog Lamps

To replace fog lamp bulb:

1. Pull out the push-pins located on the underside of

the protection shield to remove the shield.

2. Reach up behind the front bumper area from under

the vehicle to access the lamp housing.

3. Remove the electrical connector from the bulb by

lifting the two plastic clips.

4. Remove the bulb socket from the lamp housing

by turning the bulb socket one-quarter turn

counterclockwise.

5. Pull the old bulb from the lamp housing keeping the

bulb straight as you pull it out.

6. Install a new bulb.7. Reinstall the electrical connector by pushing in the

two plastic clips.

8. Push the bulb socket into the lamp housing and

turn the socket one-quarter turn clockwise.

License Plate Lamp

To replace one of these bulbs, do the following:

1. Push tabs to remove the license plate lamp.

2. Turn the license plate lamp assembly down to

remove it.

3. Turn the socket counterclockwise and remove it.

4. Pull the bulb straight out to remove it.

5. Push the new bulb straight into the socket.

6. Reverse Steps 1 through 3 to reinstall the license

plate lamp assembly.

5-56

Page 391 of 490

Accessing the Tire Sealant and

Compressor Kit

A. Tire Sealant and Compressor Kit

B. Foam Container

C. Wing Nut

To access the tire sealant and compressor kit:

1. Open the trunk. SeeTrunk on page 2-21for more

information.

2. Locate the tire sealant and compressor kit (A) in the

center of the cargo area.3. Remove the tire sealant and compressor kit by

turning the wing nut (C counterclockwise).

4. Remove the sealant and compressor kit from its

foam container (B).

Tire Sealant

Read and follow the safe handling instructions on the

sealant canister.

The sealant can temporarily seal small punctures in the

tread area of the tire. The sealant cannot seal sidewall

damage, large punctures, or a tire that has unseated

from the wheel. SeeRoadside Service on page 7-7if

you need assistance.

The sealant can only be used to seal one tire. After

usage, the sealant canister and sealant �lling hose

assembly must be replaced at a dealer/retailer. See

Removal and Installation of Sealant Canister later in

this section.

Check the tire sealant expiration date on the sealant

canister. The sealant might not be effective beyond

the expiration date. If needed, see your dealer/retailer

for a replacement canister.

5-85

Page 392 of 490

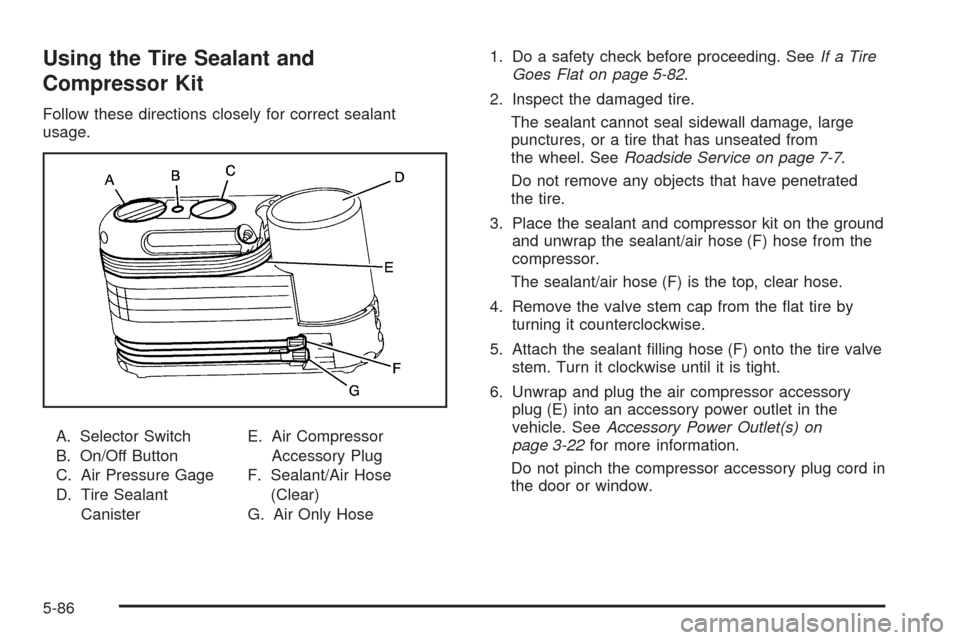

Using the Tire Sealant and

Compressor Kit

Follow these directions closely for correct sealant

usage.

A. Selector Switch

B. On/Off Button

C. Air Pressure Gage

D. Tire Sealant

CanisterE. Air Compressor

Accessory Plug

F. Sealant/Air Hose

(Clear)

G. Air Only Hose1. Do a safety check before proceeding. SeeIf a Tire

Goes Flat on page 5-82.

2. Inspect the damaged tire.

The sealant cannot seal sidewall damage, large

punctures, or a tire that has unseated from

the wheel. SeeRoadside Service on page 7-7.

Do not remove any objects that have penetrated

the tire.

3. Place the sealant and compressor kit on the ground

and unwrap the sealant/air hose (F) hose from the

compressor.

The sealant/air hose (F) is the top, clear hose.

4. Remove the valve stem cap from the �at tire by

turning it counterclockwise.

5. Attach the sealant �lling hose (F) onto the tire valve

stem. Turn it clockwise until it is tight.

6. Unwrap and plug the air compressor accessory

plug (E) into an accessory power outlet in the

vehicle. SeeAccessory Power Outlet(s) on

page 3-22for more information.

Do not pinch the compressor accessory plug cord in

the door or window.

5-86

Page 393 of 490

{CAUTION:

Idling the engine in a closed-in place or with

the climate control system off can cause

deadly carbon monoxide (CO). SeeEngine

Exhaust on page 2-48.

7. Start the vehicle. SeeStarting the Engine on

page 2-35for more information. The vehicle must

be running while using the air compressor.

{CAUTION:

Overin�ation could cause the tire to rupture,

and you or others could be injured. Be sure to

read the in�ator instructions, and in�ate the

tire to its recommended pressure. Do not

exceed 36 psi (248 kPa).

8. Turn the selector switch (A) counterclockwise to the

sealant and air position.9. Push the On/Off button (B).

The sealant and compressor kit will inject sealant

and air into the tire. Sealant may leak from the

puncture until the vehicle is driven and the hole

has sealed.

The pressure gage (C) will initially show a high

pressure while the compressor pushes the sealant

into the tire. Once the sealant is completely

dispersed into the tire, the pressure will quickly drop

and start to rise again as the tire in�ates with air.

10. In�ate the tire to the recommended in�ation

pressure, found on the Tire and Loading Information

label located on the vehicle’s center pillar (B-pillar)

below the vehicle’s door latch, using the air pressure

gage on the top of the unit.

The pressure gage reads high while the compressor

is running. Turn the compressor off to get an

accurate pressure reading.

Notice:If the recommended pressure cannot be

reached after approximately 25 minutes, the vehicle

should not be driven farther. The tire is too severely

damaged and the tire sealant and compressor kit

cannot in�ate the tire. Remove the air compressor

plug from the accessory power outlet and unscrew

the in�ating hose from the tire valve. SeeRoadside

Service on page 7-7.

11. Turn the compressor off by pushing the On/Off

button (B).

5-87

Page 394 of 490

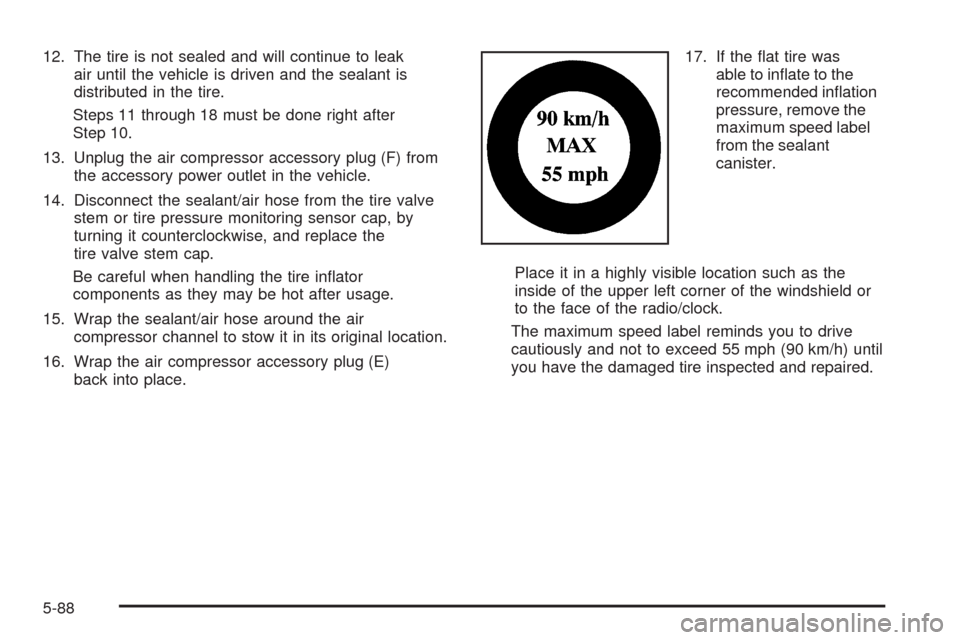

12. The tire is not sealed and will continue to leak

air until the vehicle is driven and the sealant is

distributed in the tire.

Steps 11 through 18 must be done right after

Step 10.

13. Unplug the air compressor accessory plug (F) from

the accessory power outlet in the vehicle.

14. Disconnect the sealant/air hose from the tire valve

stem or tire pressure monitoring sensor cap, by

turning it counterclockwise, and replace the

tire valve stem cap.

Be careful when handling the tire in�ator

components as they may be hot after usage.

15. Wrap the sealant/air hose around the air

compressor channel to stow it in its original location.

16. Wrap the air compressor accessory plug (E)

back into place.17. If the �at tire was

able to in�ate to the

recommended in�ation

pressure, remove the

maximum speed label

from the sealant

canister.

Place it in a highly visible location such as the

inside of the upper left corner of the windshield or

to the face of the radio/clock.

The maximum speed label reminds you to drive

cautiously and not to exceed 55 mph (90 km/h) until

you have the damaged tire inspected and repaired.

5-88

Page 397 of 490

3. Attach the air only hose (G) onto the valve stem to

secure into place.

4. Plug the air compressor accessory plug (E) into an

accessory power outlet in the vehicle. SeeAccessory

Power Outlet(s) on page 3-22for more information.

{CAUTION:

Idling the engine in a closed-in place or with

the climate control system off can cause

deadly carbon monoxide (CO). SeeEngine

Exhaust on page 2-48.

5. Start the vehicle. SeeStarting the Engine on

page 2-35for more information. The vehicle must

be running while using the air compressor.

{CAUTION:

Overin�ation could cause the tire to rupture,

and you or others could be injured. Be sure to

read the in�ator instructions, and in�ate the

tire to its recommended pressure. Do not

exceed 36 psi (248 kPa).

6. Turn the selector switch (A) clockwise to the air

only position.

7. Push the On/Off button (B).

8. In�ate the tire up to the recommended in�ation

pressure using the air pressure gage (C) on the

top of the unit.

The pressure gage read high while the compressor

is running. Turn the compressor off to get an

accurate reading.

5-91

Page 401 of 490

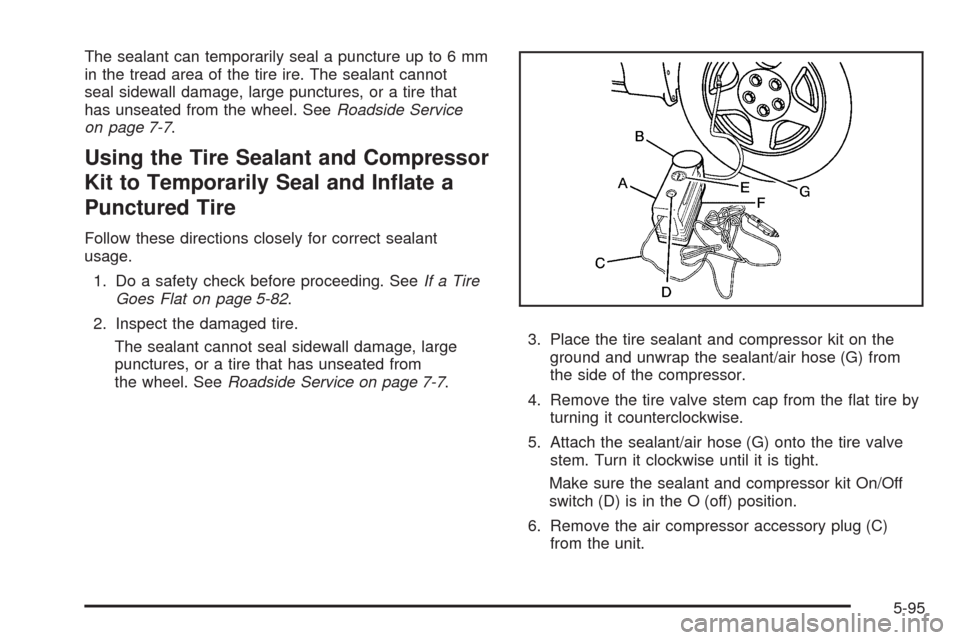

The sealant can temporarily seal a puncture up to 6 mm

in the tread area of the tire ire. The sealant cannot

seal sidewall damage, large punctures, or a tire that

has unseated from the wheel. SeeRoadside Service

on page 7-7.

Using the Tire Sealant and Compressor

Kit to Temporarily Seal and In�ate a

Punctured Tire

Follow these directions closely for correct sealant

usage.

1. Do a safety check before proceeding. SeeIf a Tire

Goes Flat on page 5-82.

2. Inspect the damaged tire.

The sealant cannot seal sidewall damage, large

punctures, or a tire that has unseated from

the wheel. SeeRoadside Service on page 7-7.3. Place the tire sealant and compressor kit on the

ground and unwrap the sealant/air hose (G) from

the side of the compressor.

4. Remove the tire valve stem cap from the �at tire by

turning it counterclockwise.

5. Attach the sealant/air hose (G) onto the tire valve

stem. Turn it clockwise until it is tight.

Make sure the sealant and compressor kit On/Off

switch (D) is in the O (off) position.

6. Remove the air compressor accessory plug (C)

from the unit.

5-95