window CADILLAC CTS 2008 2.G Owner's Guide

[x] Cancel search | Manufacturer: CADILLAC, Model Year: 2008, Model line: CTS, Model: CADILLAC CTS 2008 2.GPages: 490, PDF Size: 2.59 MB

Page 369 of 490

(B) Tire Width:The three-digit number indicates

the tire section width in millimeters from sidewall

to sidewall.

(C) Aspect Ratio

:A two-digit number that

indicates the tire height-to-width measurements.

For example, if the tire size aspect ratio is 60, as

shown in item C of the illustration, it would mean

that the tire’s sidewall is 60 percent as high as it

is wide.

(D) Construction Code

:A letter code is used to

indicate the type of ply construction in the tire. The

letter R means radial ply construction; the letter D

means diagonal or bias ply construction; and the

letter B means belted-bias ply construction.

(E) Rim Diameter

:Diameter of the wheel in

inches.

(F) Service Description

:These characters

represent the load range and speed rating of the

tire. The load index represents the load carry

capacity a tire is certi�ed to carry. The load index

can range from 1 to 279. The speed rating is the

maximum speed a tire is certi�ed to carry a load.

Speed ratings range from A to Z.

Tire Terminology and De�nitions

Air Pressure:The amount of air inside the

tire pressing outward on each square inch of the

tire. Air pressure is expressed in pounds per

square inch (psi) or kilopascal (kPa).

Accessory Weight

:This means the combined

weight of optional accessories. Some examples of

optional accessories are, automatic transmission,

power steering, power brakes, power windows,

power seats, and air conditioning.

Aspect Ratio

:The relationship of a tire’s height

to its width.

Belt

:A rubber coated layer of cords that is

located between the plies and the tread. Cords

may be made from steel or other reinforcing

materials.

Bead

:The tire bead contains steel wires wrapped

by steel cords that hold the tire onto the rim.

Bias Ply Tire

:A pneumatic tire in which the plies

are laid at alternate angles less than 90 degrees

to the centerline of the tread.

5-63

Page 392 of 490

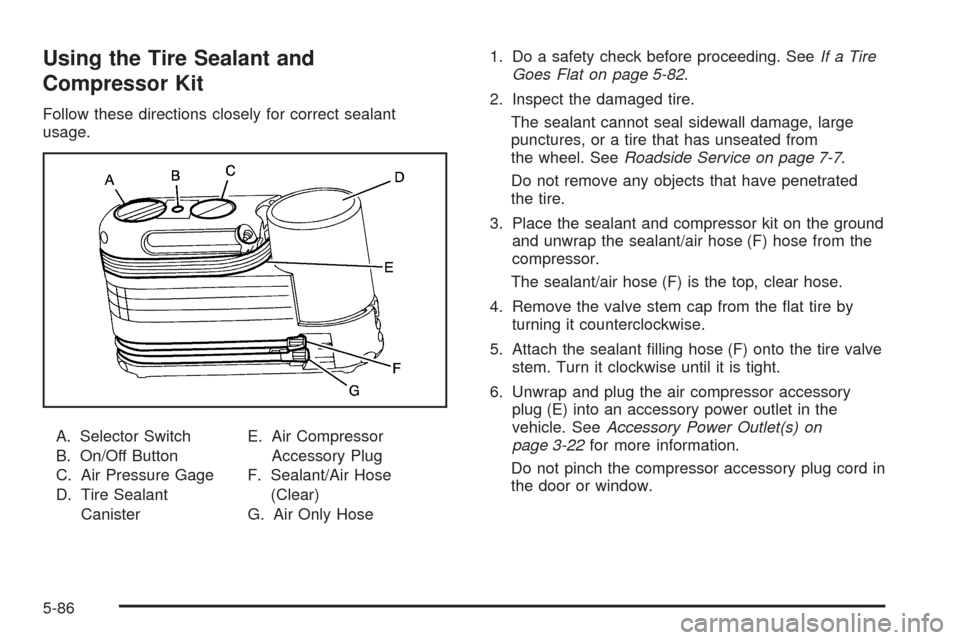

Using the Tire Sealant and

Compressor Kit

Follow these directions closely for correct sealant

usage.

A. Selector Switch

B. On/Off Button

C. Air Pressure Gage

D. Tire Sealant

CanisterE. Air Compressor

Accessory Plug

F. Sealant/Air Hose

(Clear)

G. Air Only Hose1. Do a safety check before proceeding. SeeIf a Tire

Goes Flat on page 5-82.

2. Inspect the damaged tire.

The sealant cannot seal sidewall damage, large

punctures, or a tire that has unseated from

the wheel. SeeRoadside Service on page 7-7.

Do not remove any objects that have penetrated

the tire.

3. Place the sealant and compressor kit on the ground

and unwrap the sealant/air hose (F) hose from the

compressor.

The sealant/air hose (F) is the top, clear hose.

4. Remove the valve stem cap from the �at tire by

turning it counterclockwise.

5. Attach the sealant �lling hose (F) onto the tire valve

stem. Turn it clockwise until it is tight.

6. Unwrap and plug the air compressor accessory

plug (E) into an accessory power outlet in the

vehicle. SeeAccessory Power Outlet(s) on

page 3-22for more information.

Do not pinch the compressor accessory plug cord in

the door or window.

5-86

Page 402 of 490

7. Plug the air compressor accessory plug (C) into an

accessory power outlet in the vehicle. SeeAccessory

Power Outlet(s) on page 3-22for more information.

Do not slam door or close window on the

compressor accessory plug cord.

{CAUTION:

Idling the engine in a closed-in place or with

the climate control system off can cause

deadly carbon monoxide (CO). SeeEngine

Exhaust on page 2-48.

8. Start the vehicle. SeeStarting the Engine on

page 2-35for more information. The vehicle must

be running while using the air compressor.

{CAUTION:

Overin�ation could cause the tire to rupture,

and you or others could be injured. Be sure to

read the in�ator instructions, and in�ate the

tire to its recommended pressure. Do not

exceed 36 psi (248 kPa).

9. Push the On/Off switch to the I (on) position.

The tire sealant and compressor kit will inject

sealant and air into the tire.

The pressure gage (E) will initially show a high

pressure while the compressor pushes the sealant

into the tire. Once the sealant is completely

dispersed into the tire, the pressure will quickly drop

and start to rise again as the tire in�ates with air only.

5-96

Page 405 of 490

Using the Air Compressor without

Sealant to In�ate an Underin�ated Tire

(Not Punctured)

To use the air compressor to in�ate a tire with air only

and not sealant:

1. Unlock the air only (F) from the sealant canister (B)

by pulling up on the lever.

2. Pull the air only hose (F) from the sealant

canister (B).3. Remove the tire valve stem cap by turning it

counterclockwise.

4. Push the air only hose (F) onto the tire valve stem

and push the lever down to secure in place.

5. Remove the air compressor accessory plug (C)

from the unit.

6. Plug the air compressor accessory plug (C) into an

accessory power outlet in the vehicle. SeeAccessory

Power Outlet(s) on page 3-22for more information.

Do not slam the door or close the window on the

compressor accessory plug cord.

{CAUTION:

Idling the engine in a closed-in place or with

the climate control system off can cause

deadly carbon monoxide (CO). SeeEngine

Exhaust on page 2-48.

7. Start the vehicle. SeeStarting the Engine on

page 2-35for more information. The vehicle must

be running while using the air compressor.

5-99

Page 418 of 490

Appearance Care

Interior Cleaning

Your vehicle’s interior will continue to look its best if it is

cleaned often. Although not always visible, dust and dirt

can accumulate on your upholstery. Dirt can damage

carpet, fabric, leather, and plastic surfaces. Regular

vacuuming is recommended to remove particles from

your upholstery. It is important to keep your upholstery

from becoming and remaining heavily soiled. Soils should

be removed as quickly as possible. Your vehicle’s interior

may experience extremes of heat that could cause stains

to set rapidly.

Lighter colored interiors may require more frequent

cleaning. Use care because newspapers and garments

that transfer color to your home furnishings may also

transfer color to your vehicle’s interior.

When cleaning your vehicle’s interior, only use cleaners

speci�cally designed for the surfaces being cleaned.

Permanent damage may result from using cleaners on

surfaces for which they were not intended. Use glass

cleaner only on glass. Remove any accidental over-spray

from other surfaces immediately. To prevent over-spray,

apply cleaner directly to the cleaning cloth.Notice:If you use abrasive cleaners when cleaning

glass surfaces on your vehicle, you could scratch

the glass and/or cause damage to the rear window

defogger. When cleaning the glass on your

vehicle, use only a soft cloth and glass cleaner.

Many cleaners contain solvents that may become

concentrated in your vehicle’s breathing space.

Before using cleaners, read and adhere to all safety

instructions on the label. While cleaning your vehicle’s

interior, maintain adequate ventilation by opening

your vehicle’s doors and windows.

Dust may be removed from small buttons and knobs

using a small brush with soft bristles.

Your dealer/retailer has a product for cleaning your

vehicle’s glass. Should it become necessary, you can

also obtain a product from your dealer/retailer to remove

odors from your vehicle’s upholstery.

5-112

Page 428 of 490

Electrical System

Add-On Electrical Equipment

Notice:Do not add anything electrical to your

vehicle unless you check with your dealer/retailer

�rst. Some electrical equipment can damage

your vehicle and the damage would not be covered

by your warranty. Some add-on electrical equipment

can keep other components from working as they

should.

Add-on equipment can drain your vehicle’s battery, even

if your vehicle is not operating.

Your vehicle has an airbag system. Before attempting to

add anything electrical to your vehicle, seeServicing

Your Airbag-Equipped Vehicle on page 1-70.

Windshield Wiper Fuses

The windshield wiper motor is protected by an internal

circuit breaker. If the wiper motor overheats due to

heavy snow, the wipers will stop until the motor cools

and will then restart.

Power Windows and Other Power

Options

Circuit breakers in the fuse block protect the power

windows and other power accessories. When the current

load is too heavy, the circuit breaker opens and closes,

protecting the circuit until the problem is �xed or

goes away.

5-122

Page 433 of 490

Relays Usage

FUEL/PUMP Fuel Pump

LCK Lock

LF FRT/

PWR/SEATLeft Front Power Seat

LF/POS/LP Left Position LampRelays Usage

PWR CLMN Power Steering Column

PWR/WNDW Power Window

REAR/FOG Not Used

RT FRT/

PWR/SEATRight Front Power Seat

5-127

Page 434 of 490

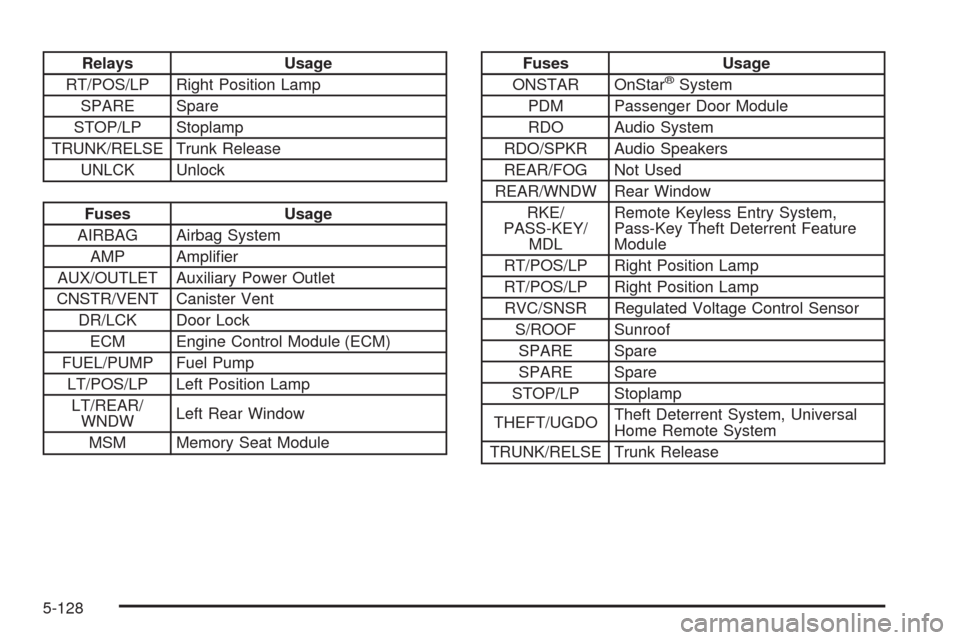

Relays Usage

RT/POS/LP Right Position Lamp

SPARE Spare

STOP/LP Stoplamp

TRUNK/RELSE Trunk Release

UNLCK Unlock

Fuses Usage

AIRBAG Airbag System

AMP Ampli�er

AUX/OUTLET Auxiliary Power Outlet

CNSTR/VENT Canister Vent

DR/LCK Door Lock

ECM Engine Control Module (ECM)

FUEL/PUMP Fuel Pump

LT/POS/LP Left Position Lamp

LT/REAR/

WNDWLeft Rear Window

MSM Memory Seat Module

Fuses Usage

ONSTAR OnStar®System

PDM Passenger Door Module

RDO Audio System

RDO/SPKR Audio Speakers

REAR/FOG Not Used

REAR/WNDW Rear Window

RKE/

PASS-KEY/

MDLRemote Keyless Entry System,

Pass-Key Theft Deterrent Feature

Module

RT/POS/LP Right Position Lamp

RT/POS/LP Right Position Lamp

RVC/SNSR Regulated Voltage Control Sensor

S/ROOF Sunroof

SPARE Spare

SPARE Spare

STOP/LP Stoplamp

THEFT/UGDOTheft Deterrent System, Universal

Home Remote System

TRUNK/RELSE Trunk Release

5-128

Page 480 of 490

Customer Assistance Information (cont.)

Customer Satisfaction Procedure..................... 7-2

GM Mobility Reimbursement Program............... 7-7

Reporting Safety Defects to General Motors.....7-17

Reporting Safety Defects to the

Canadian Government..............................7-17

Reporting Safety Defects to the

United States Government.........................7-16

Roadside Service.......................................... 7-7

Service Publications Ordering Information........7-17

D

Daytime Running Lamps..................................3-18

Defensive Driving............................................. 4-2

Delayed Locking.............................................2-19

DIC Compass.................................................3-53

Diesel

Running Out of Fuel....................................2-49

Disc, MP3....................................................3-106

Doing Your Own Service Work........................... 5-5

Door

Central Door Unlocking System.....................2-19

Delayed Locking..........................................2-19

Locks........................................................2-18

Power Door Locks.......................................2-19

Programmable Automatic Door Locks.............2-20

Rear Door Security Locks.............................2-20Driver Information Center (DIC).........................3-48

DIC Operation and Displays..........................3-48

DIC Vehicle Customization............................3-69

DIC Warnings and Messages........................3-56

Driving

At Night.....................................................4-14

Before a Long Trip......................................4-16

Defensive..................................................... 4-2

Drunken....................................................... 4-2

Highway Hypnosis.......................................4-16

Hill and Mountain Roads..............................4-16

In Rain and on Wet Roads...........................4-15

Rocking Your Vehicle to Get it Out.................4-22

Winter........................................................4-17

Dual Climate Control System............................3-24

E

EDR .............................................................7-18

Electrical System

Add-On Equipment.....................................5-122

Fuses and Circuit Breakers.........................5-123

Power Windows and Other Power Options....5-122

Rear Compartment Fuse Block....................5-126

Underhood Fuse Block...............................5-123

Windshield Wiper Fuses.............................5-122

4

Page 486 of 490

Power (cont.)

Lumbar Controls........................................... 1-6

Retained Accessory (RAP)............................2-35

Seat ............................................................ 1-5

Steering Fluid.............................................5-39

Tilt Wheel and Telescopic Steering Column....... 3-7

Windows....................................................2-25

Privacy..........................................................7-18

Event Data Recorders..................................7-19

Navigation System.......................................7-20

OnStar .......................................................7-20

Radio Frequency Identi�cation.......................7-20

Programmable Automatic Door Locks.................2-20

R

Radio Frequency Identi�cation (RFID), Privacy....7-20

Radio(s)........................................................3-83

Radios

Navigation/Radio System,

see Navigation Manual............................3-111

Reception.................................................3-125

Theft-Deterrent..........................................3-124

Rainsense™ Wipers........................................3-10

Reading Lamps..............................................3-21

Rear Axle......................................................5-51

Limited-Slip.................................................. 4-7

Rear Door Security Locks................................2-20Rearview Mirror, Automatic Dimming with

OnStar

®.....................................................2-50

Reclining Seatbacks.......................................... 1-8

Recommended Fluids and Lubricants.................6-14

Recreational Vehicle Towing.............................4-28

Remote, Keyless Access System........................ 2-9

Remote Keyless Entry (RKE) System.................. 2-6

Remote Keyless Entry (RKE) System, Operation . . . 2-7

Remote Vehicle Start.......................................2-16

Removing the Flat Tire and Installing the

Spare Tire................................................5-105

Removing the Spare Tire and Tools.................5-104

Replacement Bulbs.........................................5-57

Replacement Parts, Maintenance......................6-16

Reporting Safety Defects

Canadian Government..................................7-17

General Motors...........................................7-17

United States Government............................7-16

Restraint System Check

Checking the Restraint Systems....................1-72

Replacing Restraint System Parts

After a Crash..........................................1-73

Retained Accessory Power (RAP)......................2-35

Roadside

Service........................................................ 7-7

Rocking Your Vehicle to Get it Out....................4-22

Routing, Engine Drive Belt...............................6-17

Running Out of Fuel........................................2-49

10