torque CADILLAC DEVILLE 2003 8.G Owners Manual

[x] Cancel search | Manufacturer: CADILLAC, Model Year: 2003, Model line: DEVILLE, Model: CADILLAC DEVILLE 2003 8.GPages: 423, PDF Size: 2.91 MB

Page 105 of 423

Torque Lock

If you are parking on a hill and you don't shift your

transaxle into PARK (P) properly, the weight of

the vehicle may put too much force on the parking pawl

in the transaxle. You may ®nd it difficult to pull the

shift lever out of PARK (P). This is called ªtorque lock.º

To prevent torque lock, set the parking brake and

then shift into PARK (P) properly before you leave the

driver's seat. To ®nd out how, see

Shifting Into Park (P)

on page 2-34.

If torque lock does occur, you may need to have

another vehicle push yours a little uphill to take some of

the pressure from the parking pawl in the transaxle,

so you can pull the shift lever out of PARK (P).

Shifting Out of Park (P)

Your vehicle has an automatic transaxle shift lock

control system. You have to fully apply your regular

brakes before you can shift from PARK (P) when

the ignition is ON. See

Automatic Transaxle Operation

on page 2-27.

If you cannot shift out of PARK (P), ease the pressure

on the shift lever. Push the shift lever all the way

into PARK (P) as you maintain brake application. Then

move the shift lever into the gear you want. If you

ever hold the pedal down but still can't shift out of

PARK (P), try the following:

1. Turn the ignition key to ACCESSORY. Open and

close the driver's door to turn off the RAP feature.

2. Apply and hold the brake until the end of Step 4.

3. Shift to NEUTRAL (N).

4. Start the vehicle and then shift to the drive gear you

want.

5. Have the vehicle ®xed as soon as you can.

2-37

Page 311 of 423

Brake Wear

Your vehicle has four-wheel disc brakes.

Disc brake pads have built-in wear indicators that make

a high-pitched warning sound when the brake pads

are worn and new pads are needed. The sound

may come and go or be heard all the time your vehicle

is moving (except when you are pushing on the

brake pedal ®rmly).

{CAUTION:

The brake wear warning sound means that

soon your brakes won't work well. That could

lead to an accident. When you hear the brake

wear warning sound, have your vehicle

serviced.

Notice:Continuing to drive with worn-out brake

pads could result in costly brake repair.

Some driving conditions or climates may cause a brake

squeal when the brakes are ®rst applied or lightly

applied. This does not mean something is wrong with

your brakes.Properly torqued wheel nuts are necessary to help

prevent brake pulsation. When tires are rotated, inspect

brake pads for wear and evenly tighten wheel nuts in

the proper sequence to GM torque speci®cations.

Brake linings should always be replaced as complete

axle sets.

See

Brake System Inspection on page 6-14.

Brake Pedal Travel

See your dealer if the brake pedal does not return to

normal height, or if there is a rapid increase in

pedal travel. This could be a sign of brake trouble.

Brake Adjustment

Every time you apply the brakes, with or without the

vehicle moving, your brakes adjust for wear.

5-40

Page 335 of 423

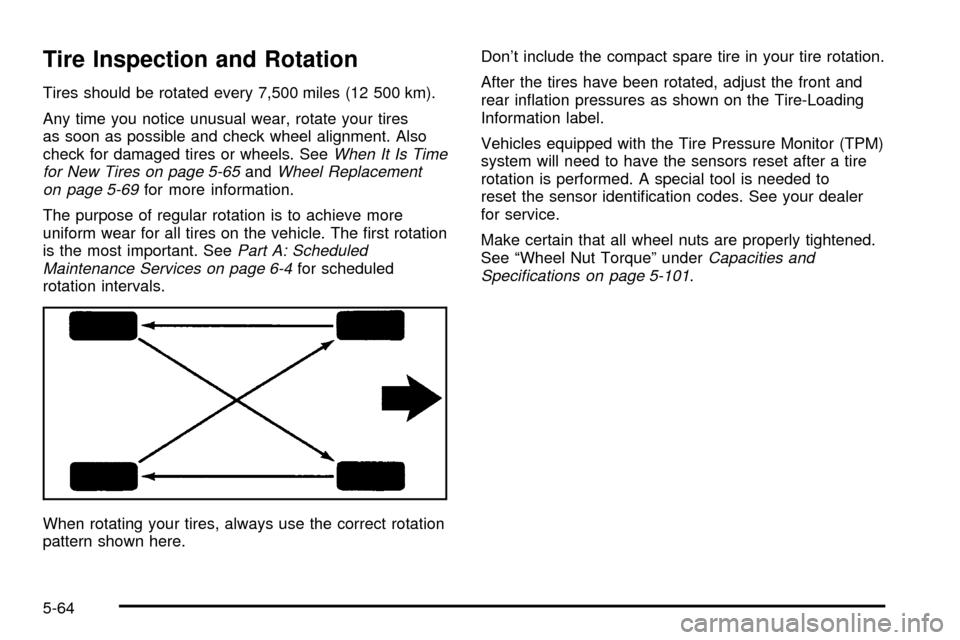

Tire Inspection and Rotation

Tires should be rotated every 7,500 miles (12 500 km).

Any time you notice unusual wear, rotate your tires

as soon as possible and check wheel alignment. Also

check for damaged tires or wheels. See

When It Is Time

for New Tires on page 5-65andWheel Replacement

on page 5-69for more information.

The purpose of regular rotation is to achieve more

uniform wear for all tires on the vehicle. The ®rst rotation

is the most important. See

Part A: Scheduled

Maintenance Services on page 6-4for scheduled

rotation intervals.

When rotating your tires, always use the correct rotation

pattern shown here.Don't include the compact spare tire in your tire rotation.

After the tires have been rotated, adjust the front and

rear in¯ation pressures as shown on the Tire-Loading

Information label.

Vehicles equipped with the Tire Pressure Monitor (TPM)

system will need to have the sensors reset after a tire

rotation is performed. A special tool is needed to

reset the sensor identi®cation codes. See your dealer

for service.

Make certain that all wheel nuts are properly tightened.

See ªWheel Nut Torqueº underCapacities and

Speci®cations on page 5-101.

5-64

Page 351 of 423

12. Tighten the wheel nuts

®rmly in a crisscross

sequence as shown.

13. If your vehicle is equipped with wheel nut covers,

screw them on with your ®ngers, then tighten

one-quarter turn with the wheel wrench.

{CAUTION:

Incorrect wheel nuts or improperly tightened

wheel nuts can cause the wheel to come loose

and even come off. This could lead to an

accident. Be sure to use the correct wheel

nuts. If you have to replace them, be sure to

get new GM original equipment wheel nuts.

Stop somewhere as soon as you can and have

the nuts tightened with a torque wrench to the

proper torque speci®cation. See ªCapacities

and Speci®cationsº in the Index for wheel nut

torque speci®cation.

5-80

Page 352 of 423

Notice:Improperly tightened wheel nuts can lead

to brake pulsation and rotor damage. To avoid

expensive brake repairs, evenly tighten the wheel

nuts in the proper sequence and to the proper

torque speci®cation. See ªCapacities and

Speci®cationsº in the index for the wheel nut torque

speci®cation.

Don't try to put a wheel cover on your compact spare

tire. It won't ®t. Store the wheel cover and lug nut caps in

the trunk until you have the ¯at tire repaired or

replaced.

Notice:Wheel covers won't ®t on your compact

spare. If you try to put a wheel cover on your

compact spare, you could damage the cover or

the spare.

Storing the Flat Tire and Tools

{CAUTION:

Storing a jack, a tire, or other equipment in the

passenger compartment of the vehicle could

cause injury. In a sudden stop or collision,

loose equipment could strike someone. Store

all these in the proper place.

After you've put the compact spare tire on your vehicle,

you'll need to store the ¯at tire in your trunk.

Store the ¯at tire as far forward in the trunk as possible.

Store the jack and wheel wrench in their compartment

in the trunk. For storage, the jack must be raised

until the screw end is ¯ush with the edge of the jack.

5-81

Page 373 of 423

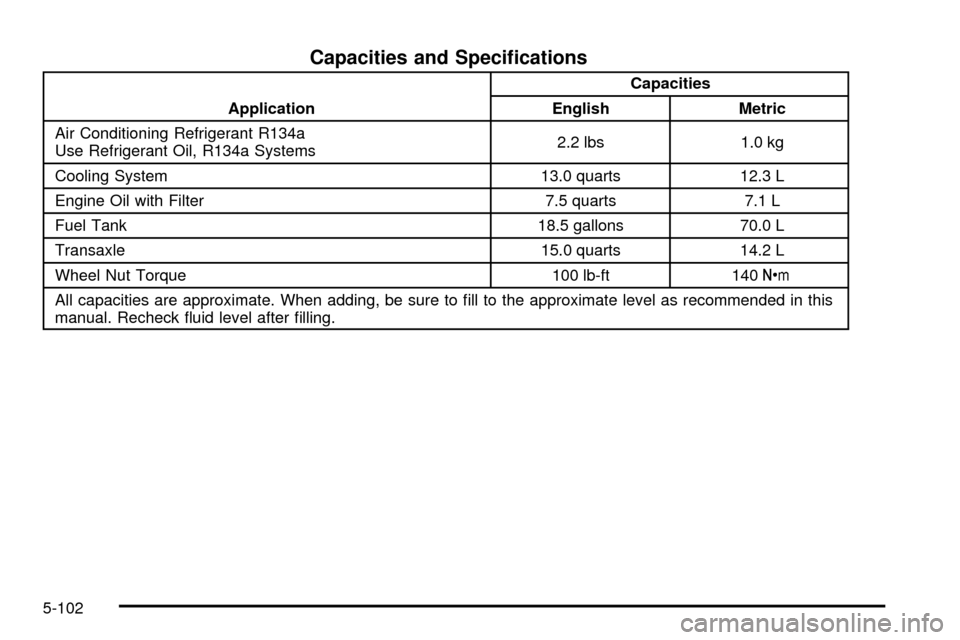

Capacities and Speci®cations

ApplicationCapacities

English Metric

Air Conditioning Refrigerant R134a

Use Refrigerant Oil, R134a Systems2.2 lbs 1.0 kg

Cooling System 13.0 quarts 12.3 L

Engine Oil with Filter 7.5 quarts 7.1 L

Fuel Tank 18.5 gallons 70.0 L

Transaxle 15.0 quarts 14.2 L

Wheel Nut Torque 100 lb-ft 140Y

All capacities are approximate. When adding, be sure to ®ll to the approximate level as recommended in this

manual. Recheck ¯uid level after ®lling.

5-102

Page 421 of 423

Tire In¯ation Check........................................... 6-9

Tire Pressure Display......................................3-78

Tires.............................................................5-60

Buying New Tires........................................5-66

Chains.......................................................5-70

Changing a Flat Tire....................................5-72

Compact Spare Tire.....................................5-83

If a Tire Goes Flat.......................................5-71

In¯ation Ð Tire Pressure..............................5-61

Inspection and Rotation................................5-64

Pressure Monitor System..............................5-62

Uniform Tire Quality Grading.........................5-67

Wheel Alignment and Tire Balance.................5-68

Wheel Replacement.....................................5-69

When It Is Time for New Tires......................5-65

To Use the Engine Coolant Heater....................2-26

Top Strap Anchor Location...............................1-41

Top Strap......................................................1-39

Torque Lock...................................................2-37

Total Weight on Your Vehicle's Tires..................4-37

Towing..........................................................4-31

Recreational Vehicle.....................................4-31

Towing a Trailer..........................................4-34

Your Vehicle...............................................4-31Traction.........................................................4-10

Continuous Variable Road Sensing Suspension

(CVRSS).................................................4-10

Control System (TCS).................................... 4-9

Control System Warning Light.......................3-48

Trailer Brakes.................................................4-38

Transaxle Operation, Automatic.........................2-27

Transaxle.......................................................5-21

Fluid, Automatic...........................................5-21

Transmission, Transaxle, Transfer Case Unit

Repair Manual............................................7-11

Transportation Options...................................... 7-8

Trip Computer................................................3-79

Oil Life Indicator..........................................3-79

Trip Odometer................................................3-43

Trunk Lid Tie Down.........................................2-12

Trunk Lock Release........................................2-12

Trunk............................................................2-11

Turn and Lane-Change Signals.......................... 3-9

Turn Signal/Multifunction Lever........................... 3-8

Turn Signals When Towing a Trailer..................4-39

Twilight Sentinel

ž............................................3-17

16