lock CADILLAC DTS 2010 1.G Owners Manual

[x] Cancel search | Manufacturer: CADILLAC, Model Year: 2010, Model line: DTS, Model: CADILLAC DTS 2010 1.GPages: 480, PDF Size: 17.56 MB

Page 350 of 480

Power Steering Fluid

The power steering fluidreservoir is located next tothe underhood fuseblock on the passengerside of the vehicle.SeeEngine CompartmentOverview on page 6-12for more informationon location.

When to Check Power Steering Fluid

It is not necessary to regularly check power steering fluidunless you suspect there is a leak in the system oryou hear an unusual noise. A fluid loss in this systemcould indicate a problem. Have the system inspectedand repaired.

How to Check Power Steering Fluid

To check the power steering fluid:

1. Turn the key off and let the engine compartmentcool down.

2. Wipe the cap and the top of the reservoir clean.

3. Unscrew the cap and wipe the dipstick with a cleanrag.

4. Replace the cap and completely tighten it.

5. Remove the cap again and look at the fluid level onthe dipstick.

The level should be at the FULL COLD mark. Ifnecessary, add only enough fluid to bring the level up tothe mark.

What to Use

To determine what kind of fluid to use, seeRecommended Fluids and Lubricants on page 7-8.Always use the proper fluid.

Notice:Use of the incorrect fluid may damage thevehicle and the damages may not be covered bythe vehicle’s warranty. Always use the correct fluidlisted inRecommended Fluids and Lubricantson page 7-8.

6-30

Page 354 of 480

Properly torqued wheel nuts are necessary to helpprevent brake pulsation. When tires are rotated, inspectbrake pads for wear and evenly tighten wheel nuts inthe proper sequence to torque specifications inCapacities and Specifications on page 6-109.

Brake linings should always be replaced as completeaxle sets.

Brake Pedal Travel

See your dealer/retailer if the brake pedal does notreturn to normal height, or if there is a rapid increase inpedal travel. This could be a sign that brake servicemight be required.

Brake Adjustment

Every time the brakes are applied, with or without thevehicle moving, the brakes adjust for wear.

Replacing Brake System Parts

The braking system on a vehicle is complex. Its manyparts have to be of top quality and work well together ifthe vehicle is to have really good braking. The vehiclewas designed and tested with top-quality brake parts.When parts of the braking system are replaced — forexample, when the brake linings wear down and newones are installed — be sure to get new approvedreplacement parts. If this is not done, the brakes mightnot work properly.

For example, if someone puts in brake linings that arewrong for the vehicle, the balance between the front andrear brakes can change — for the worse. The brakingperformance expected can change in many other ways ifthe wrong replacement brake parts are installed.

Battery

Refer to the replacement number on the original batterylabel when a new battery is needed.

{DANGER:

Battery posts, terminals, and related accessories

contain lead and lead compounds, chemicals

known to the State of California to cause cancer

and reproductive harm. Wash hands after

handling.

The battery is under the rear seat cushion. To accessthe battery, seeRear Underseat Fuse Block onpage 6-104. Access to the battery is not necessary tojump start the vehicle. SeeJump Starting on page 6-36.

6-34

Page 357 of 480

2. Get the vehicles close enough so the jumper cablescan reach, but be sure the vehicles are not touchingeach other. If they are, it could cause a groundconnection you do not want. You would not be ableto start your vehicle and the bad grounding coulddamage the electrical systems.

To avoid the possibility of the vehicles rolling, setthe parking brake firmly on both vehicles involved inthe jump start procedure. Put an automatictransmission in P (Park) or a manual transmissionin NEUTRAL before setting the parking brake.

Notice:If you leave the radio or other accessorieson during the jump starting procedure, they could bedamaged. The repairs would not be covered by thewarranty. Always turn off the radio and otheraccessories when jump starting the vehicle.

3. Turn off the ignition on both vehicles. Unplugunnecessary accessories plugged into the cigarettelighter or the accessory power outlets. Turn offthe radio and all lamps that are not needed. Thiswill avoid sparks and help save both batteries.And it could save the radio!

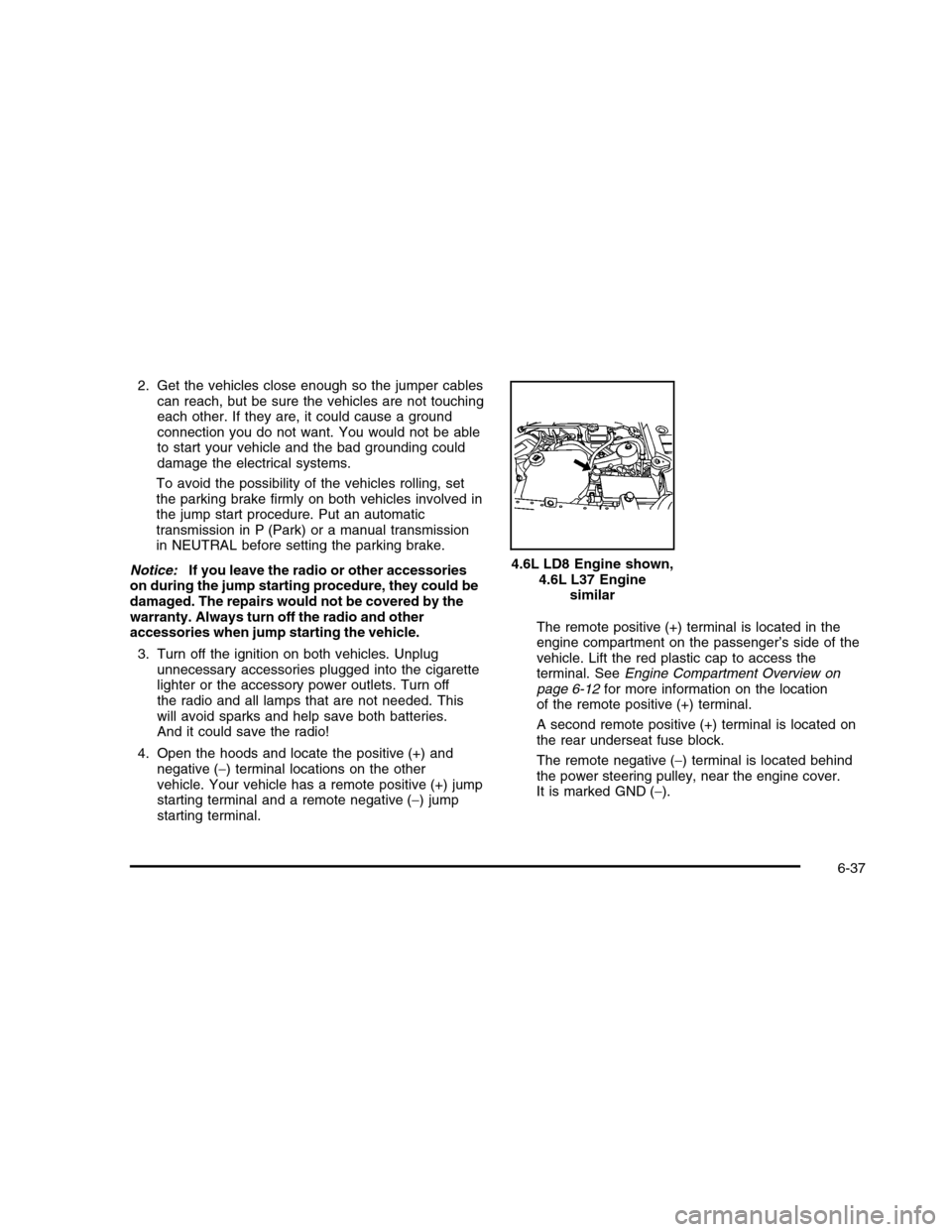

4. Open the hoods and locate the positive (+) andnegative (!) terminal locations on the othervehicle. Your vehicle has a remote positive (+) jumpstarting terminal and a remote negative (!) jumpstarting terminal.

The remote positive (+) terminal is located in theengine compartment on the passenger’s side of thevehicle. Lift the red plastic cap to access theterminal. SeeEngine Compartment Overview onpage 6-12for more information on the locationof the remote positive (+) terminal.

A second remote positive (+) terminal is located onthe rear underseat fuse block.

The remote negative (!) terminal is located behindthe power steering pulley, near the engine cover.It is marked GND (!).

4.6L LD8 Engine shown,4.6L L37 Enginesimilar

6-37

Page 362 of 480

4. At a wall, measure from the ground upward (A) tothe recorded distance from Step 3 and mark it.

5. Draw or tape a horizontal line (B) the width of thevehicle at the wall where it was marked in Step 4.

Notice:Do not cover a headlamp to improve beamcut-off when aiming. Covering a headlamp maycause excessive heat build-up which may causedamage to the headlamp.

6. Turn on the low-beam headlamps and place apiece of cardboard or equivalent in front of theheadlamp not being aimed. This should allow onlythe beam of light from the headlamp beingaimed to be seen on the flat surface.

7. Locate the vertical headlamp aiming screws. Theyare located under the hood near each headlampassembly. First lift the flap to access either of them.Each one is the top outboard screw by the “ V” on thecover panel next to the aiming flap.

The adjustment screw can be turned with a 6 mmhex wrench.

8. Turn the vertical aiming screw until the headlampbeam is aimed to the horizontal tape line. Turn itclockwise or counterclockwise to raise or lower theangle of the beam.

The top edge of the cut-off should be positioned atthe bottom edge of the horizontal tape line.

6-42

Page 381 of 480

The TPMS sensor matching process is outlined below:

1. Set the parking brake.

2. Turn the ignition switch to ON/RUN with theengine off.

3. Press the Remote Keyless Entry (RKE) transmitter’slock and unlock buttons at the same time forapproximately five seconds. The horn sounds twiceto signal the receiver is in relearn mode andTIRE LEARNING ACTIVE message displays on theDIC screen.

4. Start with the driver side front tire.

5. Remove the valve cap from the valve cap stem.Activate the TPMS sensor by increasing ordecreasing the tire’s air pressure for five seconds,or until a horn chirp sounds. The horn chirp,which may take up to 30 seconds to sound,confirms that the sensor identification code hasbeen matched to this tire and wheel position.

6. Proceed to the passenger side front tire, and repeatthe procedure in Step 5.

7. Proceed to the passenger side rear tire, and repeatthe procedure in Step 5.

8. Proceed to the driver side rear tire, and repeat theprocedure in Step 5. The horn sounds two times toindicate the sensor identification code has beenmatched to the driver side rear tire, and theTPMS sensor matching process is no longer active.The TIRE LEARNING ACTIVE message on theDIC display screen goes off.

9. Turn the ignition switch to LOCK/OFF.

10. Set all four tires to the recommended air pressurelevel as indicated on the Tire and LoadingInformation label.

11. Put the valve caps back on the valve stems.

6-61

Page 386 of 480

{WARNING:

If you use bias-ply tires on the vehicle, thewheel rim flanges could develop cracks aftermany miles of driving. A tire and/or wheelcould fail suddenly, causing a crash. Useonly radial-ply tires with the wheels onthe vehicle.

If you must replace your vehicle’s tires with those thatdo not have a TPC Spec number, make sure theyare the same size, load range, speed rating, andconstruction type (radial and bias-belted tires) as yourvehicle’s original tires.

Vehicles that have a tire pressure monitoring systemcould give an inaccurate low-pressure warning ifnon-TPC Spec rated tires are installed on your vehicle.Non-TPC Spec rated tires may give a low-pressurewarning that is higher or lower than the proper warninglevel you would get with TPC Spec rated tires. SeeTire Pressure Monitor System on page 6-57.

Your vehicle’s original equipment tires are listed on theTire and Loading Information Label. SeeLoadingthe Vehicle on page 5-18, for more information aboutthe Tire and Loading Information Label and its locationon your vehicle.

Different Size Tires and Wheels

If you add wheels or tires that are a different size thanyour original equipment wheels and tires, this mayaffect the way your vehicle performs, including itsbraking, ride and handling characteristics, stability, andresistance to rollover. Additionally, if your vehiclehas electronic systems such as, antilock brakes, tractioncontrol, and electronic stability control, the performanceof these systems can be affected.

{WARNING:

If you add different sized wheels, your vehicle may

not provide an acceptable level of performance

and safety if tires not recommended for those

wheels are selected. You may increase the

chance that you will crash and suffer serious

injury. Only use GM specific wheel and tire

systems developed for your vehicle, and have

them properly installed by a GM certified

technician.

SeeBuying New Tires on page 6-64andAccessoriesand Modifications on page 6-3for additional information.

6-66

Page 394 of 480

Using the Tire Sealant and Compressor

Kit to Temporarily Seal and Inflate a

Punctured Tire

Follow the directions closely for correct sealant usage.

When using the tire sealant and compressor kit duringcold temperatures, warm the kit in a heated environmentfor 5 minutes. This will help to inflate the tire faster.

Always do a safety check first. SeeIf a Tire Goes Flaton page 6-70. Do not remove any objects that havepenetrated the tire.

1. Remove the tire sealant and compressor kit from itsstorage location. SeeTire Sealant and CompressorKit Storage on page 6-79.

2. Unwrap the sealant/air hose (F) and the powerplug (G).

3. Place the kit on the ground.

Make sure the tire valve stem is positioned close tothe ground so the hose will reach it.

4. Remove the valve stem cap from the flat tire byturning it counterclockwise.

5. Attach the sealant/air hose (F) onto the tire valvestem. Turn it clockwise until it is tight.

6. Plug the power plug (G) into the accessory poweroutlet in the vehicle. Unplug all items from otheraccessory power outlets. SeeAccessory PowerOutlet(s) on page 4-34.

If the vehicle has an accessory power outlet, do notuse the cigarette lighter.

If the vehicle only has a cigarette lighter, use thecigarette lighter.

Do not pinch the power plug cord in the door orwindow.

6-74

Page 395 of 480

7. Start the vehicle. The vehicle must be running whileusing the air compressor.

8. Turn the selector switch (B) clockwise to theSealant + Air position.

9. Press the on/off (A) button to turn the tire sealantand compressor kit on.

The compressor will inject sealant and air intothe tire.

The pressure gage (D) will initially show a highpressure while the compressor pushes the sealantinto the tire. Once the sealant is completelydispersed into the tire, the pressure will quicklydrop and start to rise again as the tire inflates withair only.

10. Inflate the tire to the recommended inflationpressure using the pressure gage (D). Therecommended inflation pressure can be foundon the Tire and Loading Information label.SeeInflation - Tire Pressure on page 6-54.

The pressure gage (D) may read higher than theactual tire pressure while the compressor is on.Turn the compressor off to get an accurate pressurereading. The compressor may be turned on/offuntil the correct pressure is reached.

Notice:If the recommended pressure cannot bereached after approximately 25 minutes, the vehicleshould not be driven farther. The tire is tooseverely damaged and the tire sealant andcompressor kit cannot inflate the tire. Remove thepower plug from the accessory power outletand unscrew the inflating hose from the tire valve.SeeRoadside Service on page 8-7.

11. Press the on/off button (A) to turn the tire sealantand compressor kit off.

The tire is not sealed and will continue to leak airuntil the vehicle is driven and the sealant isdistributed in the tire, therefore, Steps 12 through18 must be done immediately after Step 11.

Be careful while handling the tire sealant andcompressor kit as it could be warm after usage.

12. Unplug the power plug (G) from the accessorypower outlet in the vehicle.

13. Turn the sealant/air hose (F) counterclockwise toremove it from the tire valve stem.

14. Replace the tire valve stem cap.

15. Replace the sealant/air hose (F), and the powerplug (G) back in their original location.

6-75

Page 397 of 480

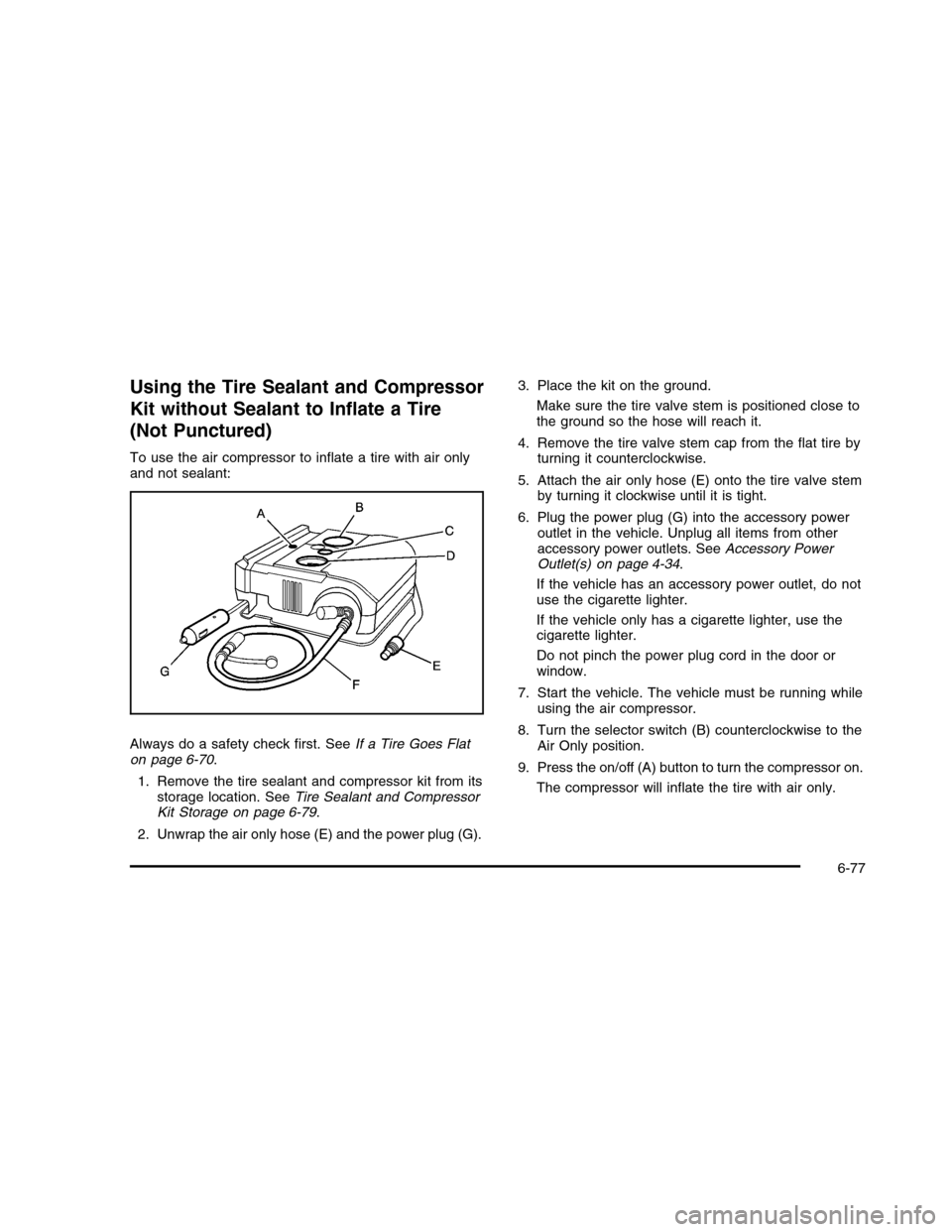

Using the Tire Sealant and Compressor

Kit without Sealant to Inflate a Tire

(Not Punctured)

To use the air compressor to inflate a tire with air onlyand not sealant:

Always do a safety check first. SeeIf a Tire Goes Flaton page 6-70.

1. Remove the tire sealant and compressor kit from itsstorage location. SeeTire Sealant and CompressorKit Storage on page 6-79.

2. Unwrap the air only hose (E) and the power plug (G).

3. Place the kit on the ground.

Make sure the tire valve stem is positioned close tothe ground so the hose will reach it.

4. Remove the tire valve stem cap from the flat tire byturning it counterclockwise.

5. Attach the air only hose (E) onto the tire valve stemby turning it clockwise until it is tight.

6. Plug the power plug (G) into the accessory poweroutlet in the vehicle. Unplug all items from otheraccessory power outlets. SeeAccessory PowerOutlet(s) on page 4-34.

If the vehicle has an accessory power outlet, do notuse the cigarette lighter.

If the vehicle only has a cigarette lighter, use thecigarette lighter.

Do not pinch the power plug cord in the door orwindow.

7. Start the vehicle. The vehicle must be running whileusing the air compressor.

8. Turn the selector switch (B) counterclockwise to theAir Only position.

9. Press the on/off (A) button to turn the compressor on.

The compressor will inflate the tire with air only.

6-77

Page 398 of 480

10. Inflate the tire to the recommended inflationpressure using the pressure gage (D). Therecommended inflation pressure can be found onthe Tire and Loading Information label.SeeInflation - Tire Pressure on page 6-54.

The pressure gage (D) may read higher than theactual tire pressure while the compressor is on.Turn the compressor off to get an accurate reading.The compressor may be turned on/off until thecorrect pressure is reached.

11. Press the on/off button (A) to turn the tire sealantand compressor kit off.

Be careful while handling the tire sealant andcompressor kit as it could be warm after usage.

12. Unplug the power plug (G) from the accessorypower outlet in the vehicle.

13. Disconnect the air only hose (E) from the tire valvestem, by turning it counterclockwise, and replacethe tire valve stem cap.

14. Replace the air only hose (E) and the powerplug (G) and cord back in its original location.

15. Place the equipment in the original storage locationin the vehicle.

Removal and Installation of the Sealant

Canister

To remove the sealant canister:

1. Remove the plastic cover.

2. Unscrew the connector (B) from the canister (A).

3. Pull up on the canister (A) to remove it.

4. Replace with a new canister which is available fromyour dealer/retailer.

5. Push the new canister into place.

6. Screw the connector (B) to the canister (A).

7. Slide the plastic cover back on.

6-78