flat tire CADILLAC ESCALADE 2003 2.G Owners Manual

[x] Cancel search | Manufacturer: CADILLAC, Model Year: 2003, Model line: ESCALADE, Model: CADILLAC ESCALADE 2003 2.GPages: 486, PDF Size: 3.32 MB

Page 322 of 486

Tires..............................................................5-66

In¯ation -- Tire Pressure................................5-67

Tire Inspection and Rotation...........................5-68

When It Is Time for New Tires.......................5-69

Buying New Tires.........................................5-70

Uniform Tire Quality Grading..........................5-71

Wheel Alignment and Tire Balance..................5-72

Wheel Replacement......................................5-73

Tire Chains..................................................5-74

If a Tire Goes Flat........................................5-75

Changing a Flat Tire.....................................5-76

Spare Tire...................................................5-93

Appearance Care............................................5-94

Cleaning the Inside of Your Vehicle.................5-94

Care of Safety Belts......................................5-96

Weatherstrips...............................................5-96

Cleaning the Outside of Your Vehicle..............5-97Sheet Metal Damage.....................................5-99

Finish Damage...........................................5-100

Underbody Maintenance...............................5-100

Chemical Paint Spotting...............................5-100

Vehicle Care/Appearance Materials................5-100

Vehicle Identi®cation.....................................5-102

Vehicle Identi®cation Number (VIN)................5-102

Service Parts Identi®cation Label...................5-102

Electrical System..........................................5-102

Windshield Wiper Fuses...............................5-103

Power Windows and Other Power Options......5-103

Fuses and Circuit Breakers..........................5-103

Capacities and Speci®cations........................5-112

Capacities and Speci®cations........................5-112

Normal Maintenance Replacement Parts.........5-114

Section 5 Service and Appearance Care

5-2

Page 388 of 486

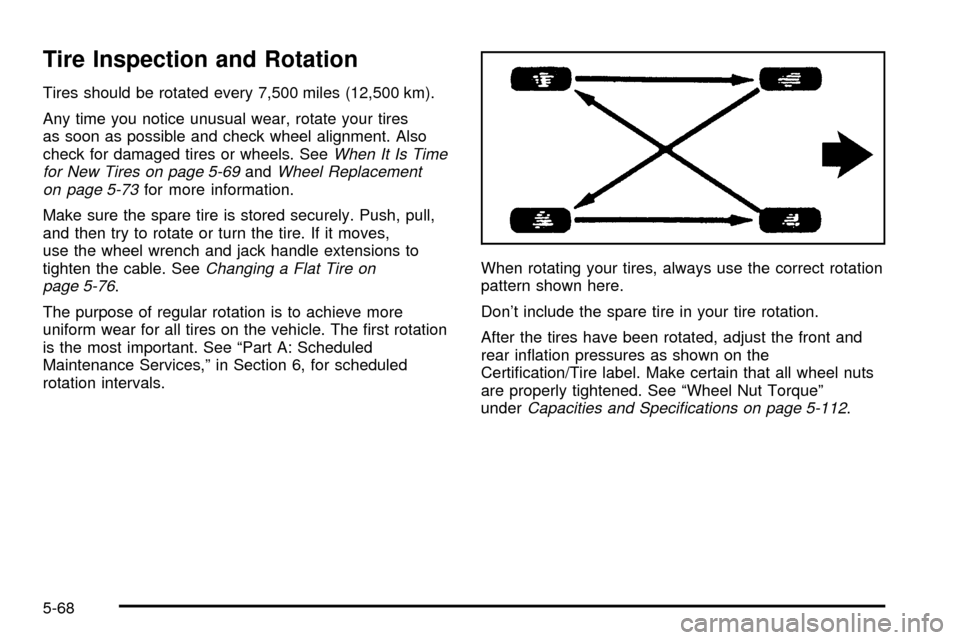

Tire Inspection and Rotation

Tires should be rotated every 7,500 miles (12,500 km).

Any time you notice unusual wear, rotate your tires

as soon as possible and check wheel alignment. Also

check for damaged tires or wheels. See

When It Is Time

for New Tires on page 5-69andWheel Replacement

on page 5-73for more information.

Make sure the spare tire is stored securely. Push, pull,

and then try to rotate or turn the tire. If it moves,

use the wheel wrench and jack handle extensions to

tighten the cable. See

Changing a Flat Tire on

page 5-76.

The purpose of regular rotation is to achieve more

uniform wear for all tires on the vehicle. The ®rst rotation

is the most important. See ªPart A: Scheduled

Maintenance Services,º in Section 6, for scheduled

rotation intervals.When rotating your tires, always use the correct rotation

pattern shown here.

Don't include the spare tire in your tire rotation.

After the tires have been rotated, adjust the front and

rear in¯ation pressures as shown on the

Certi®cation/Tire label. Make certain that all wheel nuts

are properly tightened. See ªWheel Nut Torqueº

under

Capacities and Speci®cations on page 5-112.

5-68

Page 389 of 486

{CAUTION:

Rust or dirt on a wheel, or on the parts to

which it is fastened, can make wheel nuts

become loose after a time. The wheel could

come off and cause an accident. When you

change a wheel, remove any rust or dirt from

places where the wheel attaches to the vehicle.

In an emergency, you can use a cloth or a

paper towel to do this; but be sure to use a

scraper or wire brush later, if you need to, to

get all the rust or dirt off. See ªChanging a Flat

Tireº in the Index.

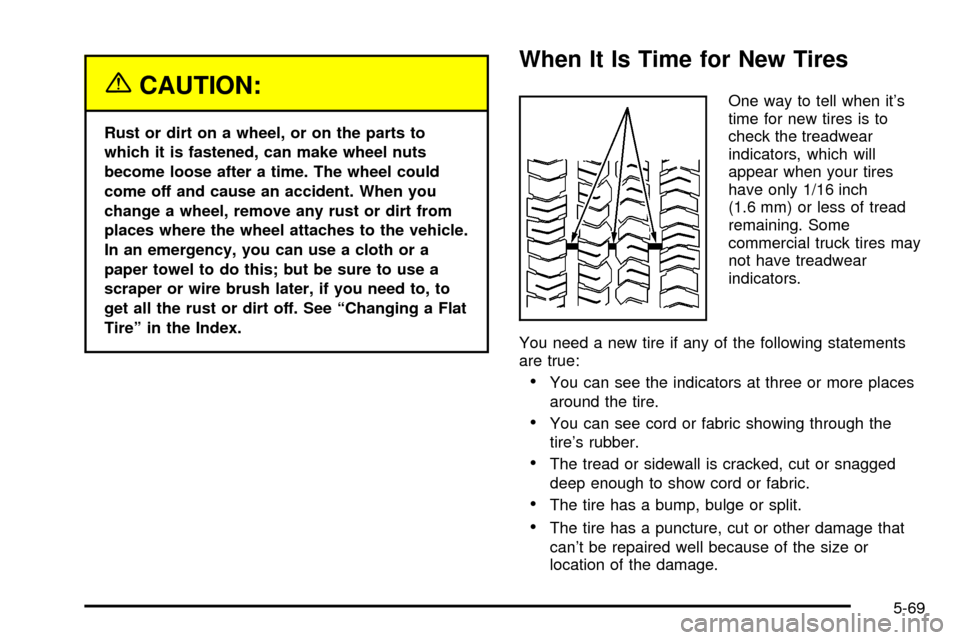

When It Is Time for New Tires

One way to tell when it's

time for new tires is to

check the treadwear

indicators, which will

appear when your tires

have only 1/16 inch

(1.6 mm) or less of tread

remaining. Some

commercial truck tires may

not have treadwear

indicators.

You need a new tire if any of the following statements

are true:

·You can see the indicators at three or more places

around the tire.

·You can see cord or fabric showing through the

tire's rubber.

·The tread or sidewall is cracked, cut or snagged

deep enough to show cord or fabric.

·The tire has a bump, bulge or split.

·The tire has a puncture, cut or other damage that

can't be repaired well because of the size or

location of the damage.

5-69

Page 393 of 486

Wheel Replacement

Replace any wheel that is bent, cracked, or badly rusted

or corroded. If wheel nuts keep coming loose, the

wheel, wheel bolts and wheel nuts should be replaced.

If the wheel leaks air, replace it (except some

aluminum wheels, which can sometimes be repaired).

See your dealer if any of these conditions exist.

Your dealer will know the kind of wheel you need.

Each new wheel should have the same load-carrying

capacity, diameter, width, offset and be mounted

the same way as the one it replaces.

If you need to replace any of your wheels, wheel bolts

or wheel nuts, replace them only with new GM

original equipment parts. This way, you will be sure to

have the right wheel, wheel bolts and wheel nuts

for your vehicle.{CAUTION:

Using the wrong replacement wheels, wheel

bolts or wheel nuts on your vehicle can be

dangerous. It could affect the braking and

handling of your vehicle, make your tires lose

air and make you lose control. You could have

a collision in which you or others could be

injured. Always use the correct wheel, wheel

bolts and wheel nuts for replacement.

Notice:The wrong wheel can also cause problems

with bearing life, brake cooling, speedometer or

odometer calibration, headlamp aim, bumper height,

vehicle ground clearance and tire clearance to the

body and chassis.

See

Changing a Flat Tire on page 5-76for more

information.

5-73

Page 395 of 486

If a Tire Goes Flat

It's unusual for a tire to ªblowoutº while you're driving,

especially if you maintain your tires properly. If air goes

out of a tire, it's much more likely to leak out slowly.

But if you should ever have a ªblowout,º here are a few

tips about what to expect and what to do:

If a front tire fails, the ¯at tire will create a drag that

pulls the vehicle toward that side. Take your foot off the

accelerator pedal and grip the steering wheel ®rmly.

Steer to maintain lane position, and then gently brake to

a stop well out of the traffic lane.

A rear blowout, particularly on a curve, acts much like a

skid and may require the same correction you'd use

in a skid. In any rear blowout, remove your foot from the

accelerator pedal. Get the vehicle under control by

steering the way you want the vehicle to go. It may be

very bumpy and noisy, but you can still steer. Gently

brake to a stop, well off the road if possible.{CAUTION:

Lifting a vehicle and getting under it to do

maintenance or repairs is dangerous without

the appropriate safety equipment and training.

The jack provided with your vehicle is

designed only for changing a ¯at tire. If it is

used for anything else, you or others could be

badly injured or killed if the vehicle slips off

the jack. Use the jack provided with your

vehicle only for changing a ¯at tire.

If a tire goes ¯at, the next part shows how to use your

jacking equipment to change a ¯at tire safely.

5-75

Page 396 of 486

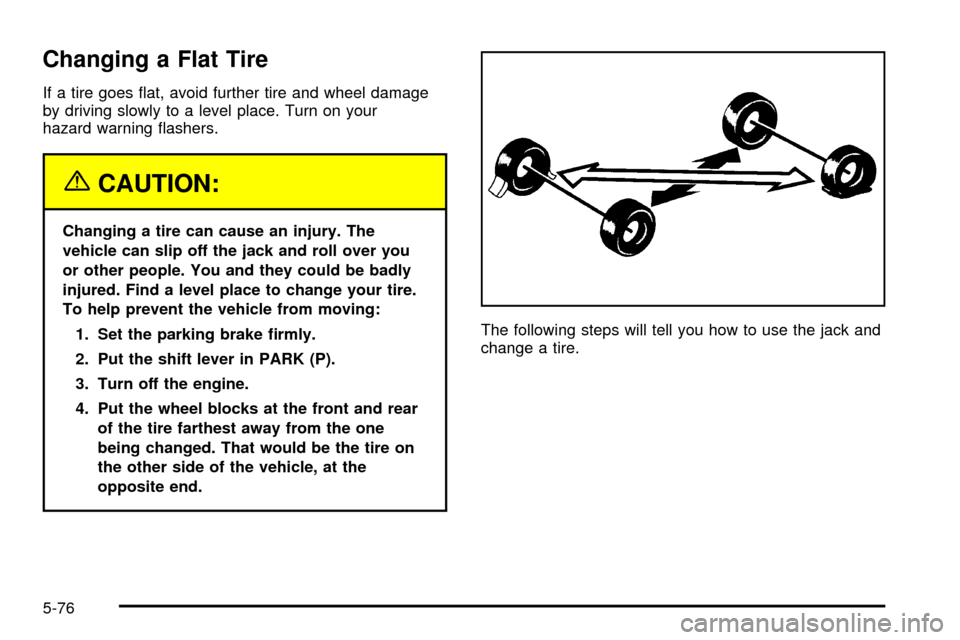

Changing a Flat Tire

If a tire goes ¯at, avoid further tire and wheel damage

by driving slowly to a level place. Turn on your

hazard warning ¯ashers.

{CAUTION:

Changing a tire can cause an injury. The

vehicle can slip off the jack and roll over you

or other people. You and they could be badly

injured. Find a level place to change your tire.

To help prevent the vehicle from moving:

1. Set the parking brake ®rmly.

2. Put the shift lever in PARK (P).

3. Turn off the engine.

4. Put the wheel blocks at the front and rear

of the tire farthest away from the one

being changed. That would be the tire on

the other side of the vehicle, at the

opposite end.The following steps will tell you how to use the jack and

change a tire.

5-76

Page 400 of 486

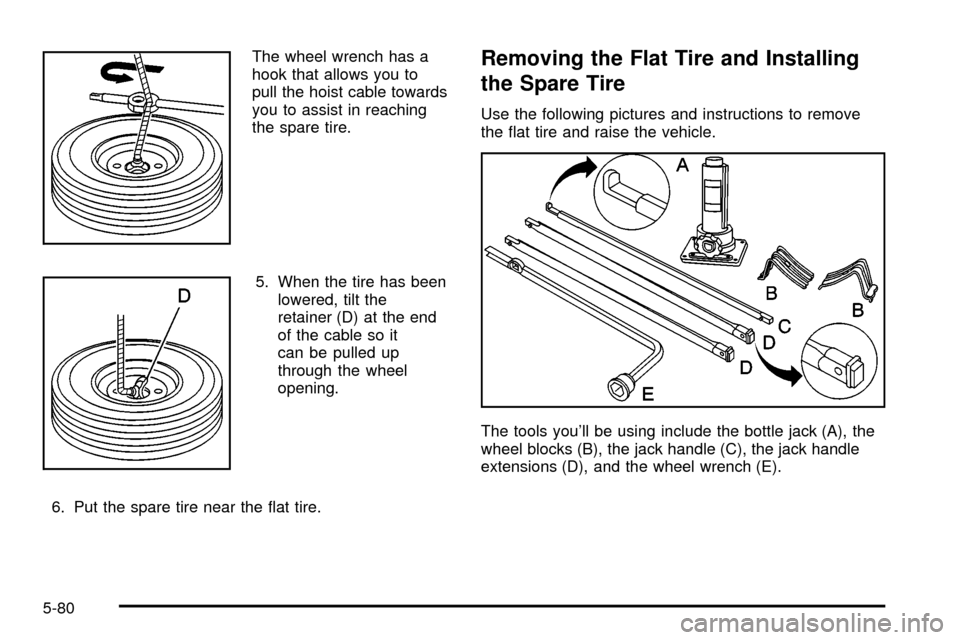

The wheel wrench has a

hook that allows you to

pull the hoist cable towards

you to assist in reaching

the spare tire.

5. When the tire has been

lowered, tilt the

retainer (D) at the end

of the cable so it

can be pulled up

through the wheel

opening.

6. Put the spare tire near the ¯at tire.Removing the Flat Tire and Installing

the Spare Tire

Use the following pictures and instructions to remove

the ¯at tire and raise the vehicle.

The tools you'll be using include the bottle jack (A), the

wheel blocks (B), the jack handle (C), the jack handle

extensions (D), and the wheel wrench (E).

5-80

Page 403 of 486

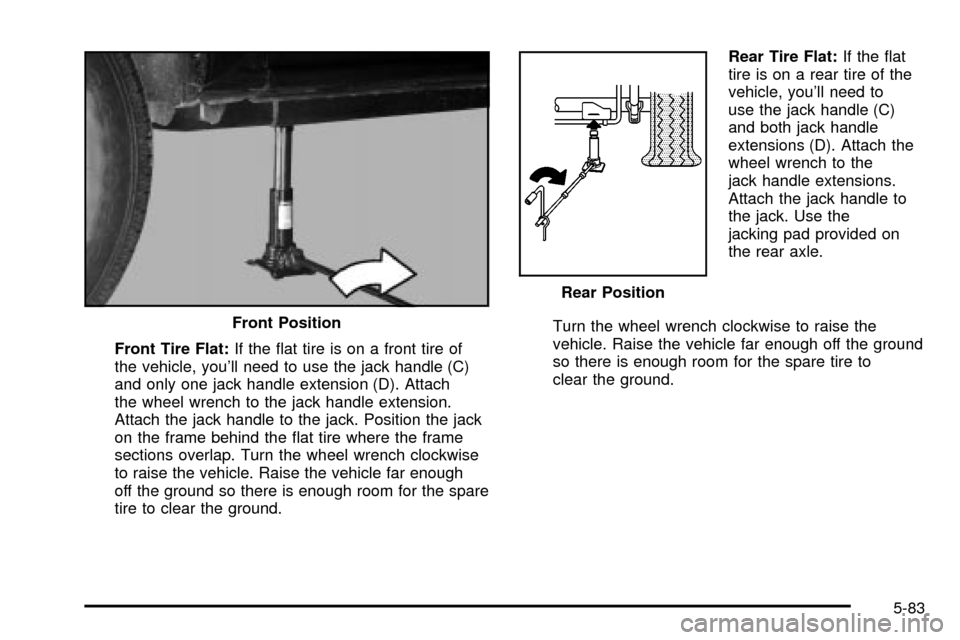

Front Tire Flat:If the ¯at tire is on a front tire of

the vehicle, you'll need to use the jack handle (C)

and only one jack handle extension (D). Attach

the wheel wrench to the jack handle extension.

Attach the jack handle to the jack. Position the jack

on the frame behind the ¯at tire where the frame

sections overlap. Turn the wheel wrench clockwise

to raise the vehicle. Raise the vehicle far enough

off the ground so there is enough room for the spare

tire to clear the ground.Rear Tire Flat:If the ¯at

tire is on a rear tire of the

vehicle, you'll need to

use the jack handle (C)

and both jack handle

extensions (D). Attach the

wheel wrench to the

jack handle extensions.

Attach the jack handle to

the jack. Use the

jacking pad provided on

the rear axle.

Turn the wheel wrench clockwise to raise the

vehicle. Raise the vehicle far enough off the ground

so there is enough room for the spare tire to

clear the ground. Front Position

Rear Position

5-83

Page 406 of 486

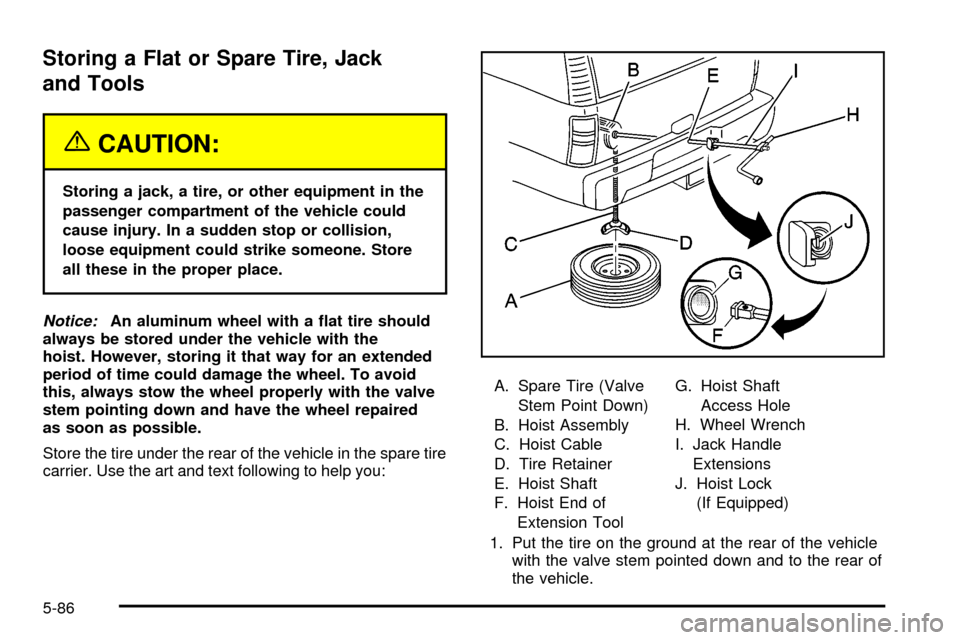

Storing a Flat or Spare Tire, Jack

and Tools

{CAUTION:

Storing a jack, a tire, or other equipment in the

passenger compartment of the vehicle could

cause injury. In a sudden stop or collision,

loose equipment could strike someone. Store

all these in the proper place.

Notice:An aluminum wheel with a ¯at tire should

always be stored under the vehicle with the

hoist. However, storing it that way for an extended

period of time could damage the wheel. To avoid

this, always stow the wheel properly with the valve

stem pointing down and have the wheel repaired

as soon as possible.

Store the tire under the rear of the vehicle in the spare tire

carrier. Use the art and text following to help you:A. Spare Tire (Valve

Stem Point Down)

B. Hoist Assembly

C. Hoist Cable

D. Tire Retainer

E. Hoist Shaft

F. Hoist End of

Extension ToolG. Hoist Shaft

Access Hole

H. Wheel Wrench

I. Jack Handle

Extensions

J. Hoist Lock

(If Equipped)

1. Put the tire on the ground at the rear of the vehicle

with the valve stem pointed down and to the rear of

the vehicle.

5-86

Page 410 of 486

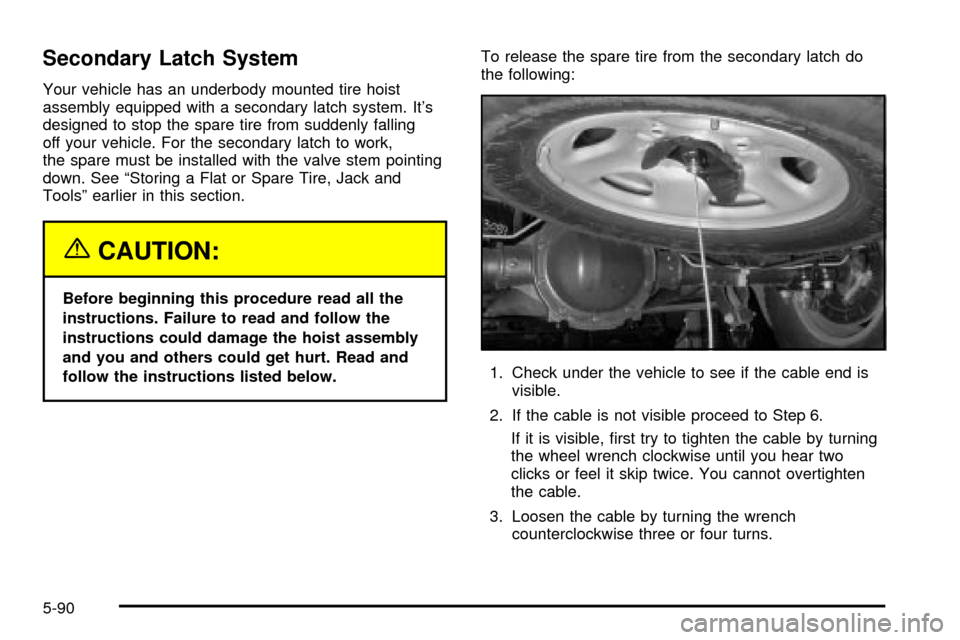

Secondary Latch System

Your vehicle has an underbody mounted tire hoist

assembly equipped with a secondary latch system. It's

designed to stop the spare tire from suddenly falling

off your vehicle. For the secondary latch to work,

the spare must be installed with the valve stem pointing

down. See ªStoring a Flat or Spare Tire, Jack and

Toolsº earlier in this section.

{CAUTION:

Before beginning this procedure read all the

instructions. Failure to read and follow the

instructions could damage the hoist assembly

and you and others could get hurt. Read and

follow the instructions listed below.To release the spare tire from the secondary latch do

the following:

1. Check under the vehicle to see if the cable end is

visible.

2. If the cable is not visible proceed to Step 6.

If it is visible, ®rst try to tighten the cable by turning

the wheel wrench clockwise until you hear two

clicks or feel it skip twice. You cannot overtighten

the cable.

3. Loosen the cable by turning the wrench

counterclockwise three or four turns.

5-90