lock CADILLAC ESCALADE EXT 2003 2.G Owners Manual

[x] Cancel search | Manufacturer: CADILLAC, Model Year: 2003, Model line: ESCALADE EXT, Model: CADILLAC ESCALADE EXT 2003 2.GPages: 473, PDF Size: 3.31 MB

Page 414 of 473

Fuses Usage

IGN 3 Ignition, Heated Seats

4WD Four-Wheel Drive System

HTR A/C Climate Control System

LOCKPower Door Lock Relay

(Lock Function)

HVAC 1Inside Rearview Mirror,

Climate Control System

L DOORDriver's Door Harness

Connection

CRUISE Cruise Control

UNLOCKPower Door Lock Relay

(Unlock Function)

RR FOG LP Rear Fog Lamp (Export Only)

BRAKE Anti-Lock Brake System

DRIVER UNLOCKPower Door Lock Relay

(Driver's Door Unlock

Function)Fuses Usage

IGN 0 PCM, TCM

TBC IGN 0 Truck Body Controller

VEH CHMSLVehicle and Trailer High

Mounted Stoplamp

LT TRLR ST/TRN Left Turn Signal/Stop Trailer

LT TRNLeft Turn Signals and

Sidemarkers

VEH STOPVehicle Stoplamps, Brake

Module, Electronic Throttle

Control Module

RT TRLR ST/TRN Right Turn Signal/Stop Trailer

RT TRNRight Turn Signals and

Sidemarkers

BODY Harness Connector

DDM Driver Door Module

AUX PWR 2Rear Cargo Area Power

Outlets

5-103

Page 415 of 473

Fuses Usage

LOCKS Power Door Lock System

ECCRear Electronic Climate

Control, Liftgate

TBC 2C Truck Body Controller

FLASH Flasher Module

CB LT DOORSLeft Power Window

Circuit Breaker

TBC 2B Truck Body Controller

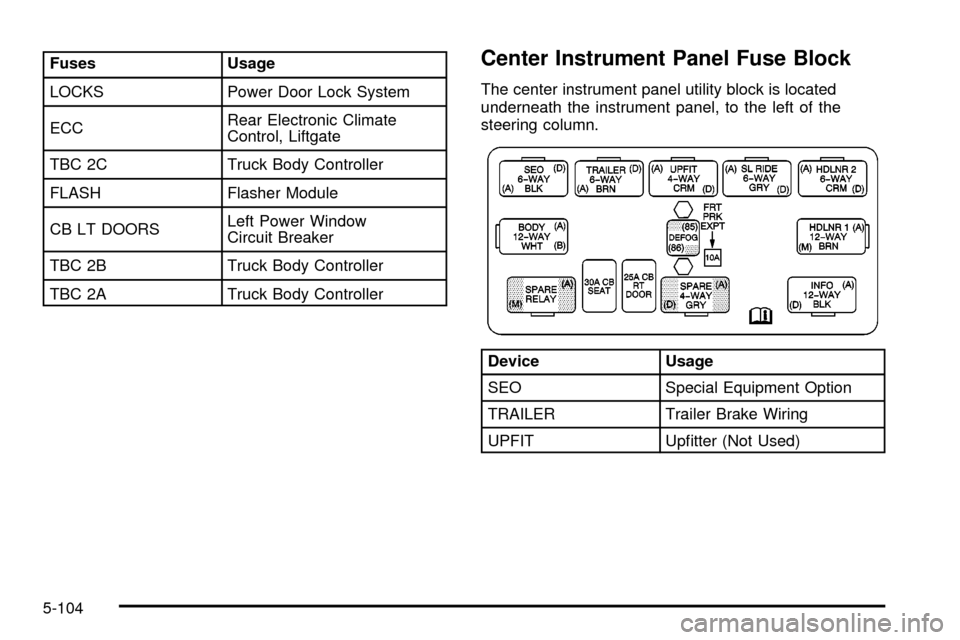

TBC 2A Truck Body ControllerCenter Instrument Panel Fuse Block

The center instrument panel utility block is located

underneath the instrument panel, to the left of the

steering column.

Device Usage

SEO Special Equipment Option

TRAILER Trailer Brake Wiring

UPFIT Up®tter (Not Used)

5-104

Page 416 of 473

Device Usage

SL RIDERide Control Harness

Connection

HDLR 2 Headliner Wiring Connector

BODY Body Wiring Connector

DEFOG Rear Defogger Relay

HDLNR 1 Headliner Wiring Connector 1

SPARE RELAY Not Used

CB SEATDriver and Passenger Seat

Module Circuit Breaker

CB RT DOORRight Power Window Circuit

Breaker

SPARE Not Used

INFOInfotainment Harness

ConnectionUnderhood Fuse Block

The underhood fuse block in the engine compartment

on the driver's side of the vehicle near the battery.

Lift the cover for access to the fuse/relay block.

To remove fuses, hold the end of the fuse between your

thumb and index ®nger and pull straight out.

See

Engine Compartment Overview on page 5-12for

more information on its location.

5-105

Page 418 of 473

*1Ð Gasoline Engine and Fuel Injection Rail #2.

*2Ð Gasoline Engine and Fuel Injection Rail #1.

*3Ð Gasoline Engine; Oxygen Sensors.

*4Ð Gasoline Engine; Oxygen Sensors.

*5Ð PCM Ignition

Fuses Usage

GLOW PLUG Not Used

CUST FEED Accessory Power

STUD #1 Auxiliary Power

MBECMid Bussed Electrical Center

Power Feed, Front Seats,

Right Doors

BLOWER Front Climate Control Fan

LBECLeft Bussed Electrical

Center, Door Modules,

Door Locks, Auxiliary Power

Outlet Ð Rear Cargo Area

and Instrument Panel

STUD 2Accessory Power/Trailer

Wiring Brake Feed

Fuses Usage

ABS Anti-Lock Brakes

VSES/ECAS Vehicle Stability

IGN A Ignition Power

IGN B Ignition Power

LBEC 1Left Bussed Electrical Center,

Left Doors, Truck Body

Controller, Flasher Module

TRL PARK Parking Lamps Trailer Wiring

RR PARKRight Rear Parking and

Sidemarker Lamps

LR PARKLeft Rear Parking and

Sidemarker Lamps

PARK LP Parking Lamps Relay

STARTER Starter Relay

INTPARK Interior Lamps

STOP LP Stoplamps

TBC BATTTruck Body Controller

Battery Feed

5-107

Page 419 of 473

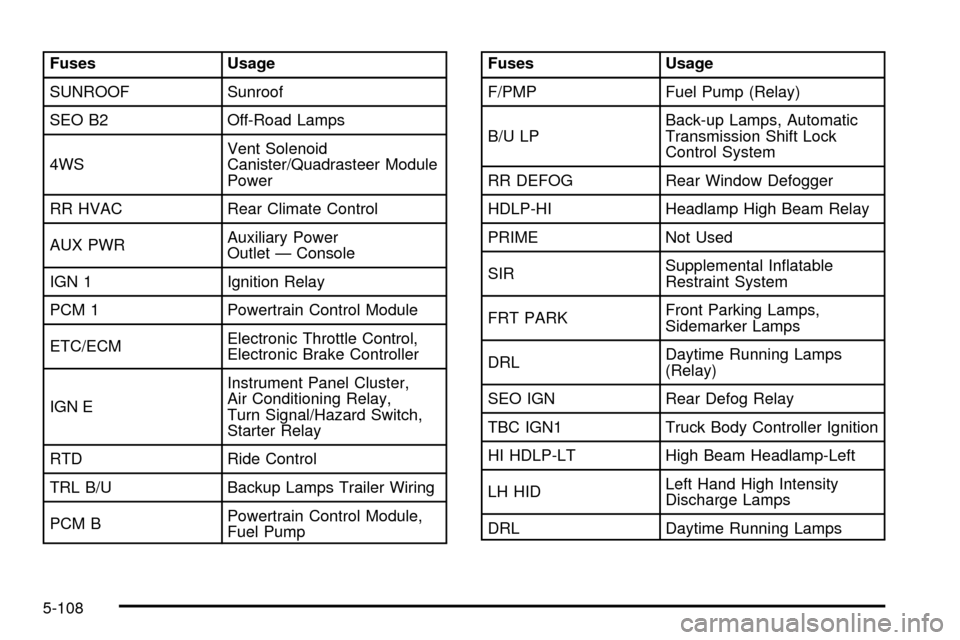

Fuses Usage

SUNROOF Sunroof

SEO B2 Off-Road Lamps

4WSVent Solenoid

Canister/Quadrasteer Module

Power

RR HVAC Rear Climate Control

AUX PWRAuxiliary Power

Outlet Ð Console

IGN 1 Ignition Relay

PCM 1 Powertrain Control Module

ETC/ECMElectronic Throttle Control,

Electronic Brake Controller

IGN EInstrument Panel Cluster,

Air Conditioning Relay,

Turn Signal/Hazard Switch,

Starter Relay

RTD Ride Control

TRL B/U Backup Lamps Trailer Wiring

PCM BPowertrain Control Module,

Fuel PumpFuses Usage

F/PMP Fuel Pump (Relay)

B/U LPBack-up Lamps, Automatic

Transmission Shift Lock

Control System

RR DEFOG Rear Window Defogger

HDLP-HI Headlamp High Beam Relay

PRIME Not Used

SIRSupplemental In¯atable

Restraint System

FRT PARKFront Parking Lamps,

Sidemarker Lamps

DRLDaytime Running Lamps

(Relay)

SEO IGN Rear Defog Relay

TBC IGN1 Truck Body Controller Ignition

HI HDLP-LT High Beam Headlamp-Left

LH HIDLeft Hand High Intensity

Discharge Lamps

DRL Daytime Running Lamps

5-108

Page 420 of 473

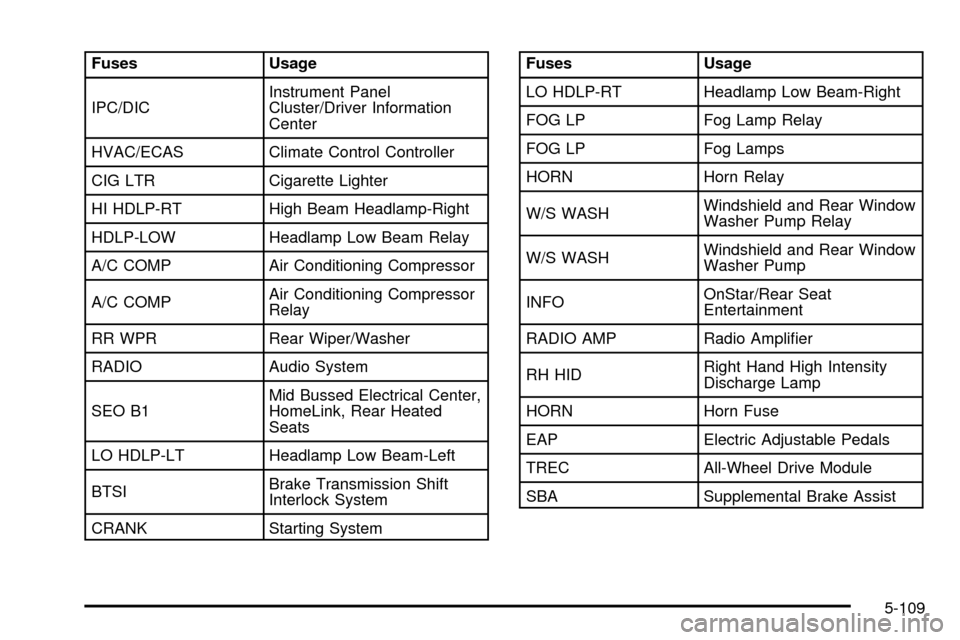

Fuses Usage

IPC/DICInstrument Panel

Cluster/Driver Information

Center

HVAC/ECAS Climate Control Controller

CIG LTR Cigarette Lighter

HI HDLP-RT High Beam Headlamp-Right

HDLP-LOW Headlamp Low Beam Relay

A/C COMP Air Conditioning Compressor

A/C COMPAir Conditioning Compressor

Relay

RR WPR Rear Wiper/Washer

RADIO Audio System

SEO B1Mid Bussed Electrical Center,

HomeLink, Rear Heated

Seats

LO HDLP-LT Headlamp Low Beam-Left

BTSIBrake Transmission Shift

Interlock System

CRANK Starting SystemFuses Usage

LO HDLP-RT Headlamp Low Beam-Right

FOG LP Fog Lamp Relay

FOG LP Fog Lamps

HORN Horn Relay

W/S WASHWindshield and Rear Window

Washer Pump Relay

W/S WASHWindshield and Rear Window

Washer Pump

INFOOnStar/Rear Seat

Entertainment

RADIO AMP Radio Ampli®er

RH HIDRight Hand High Intensity

Discharge Lamp

HORN Horn Fuse

EAP Electric Adjustable Pedals

TREC All-Wheel Drive Module

SBA Supplemental Brake Assist

5-109

Page 435 of 473

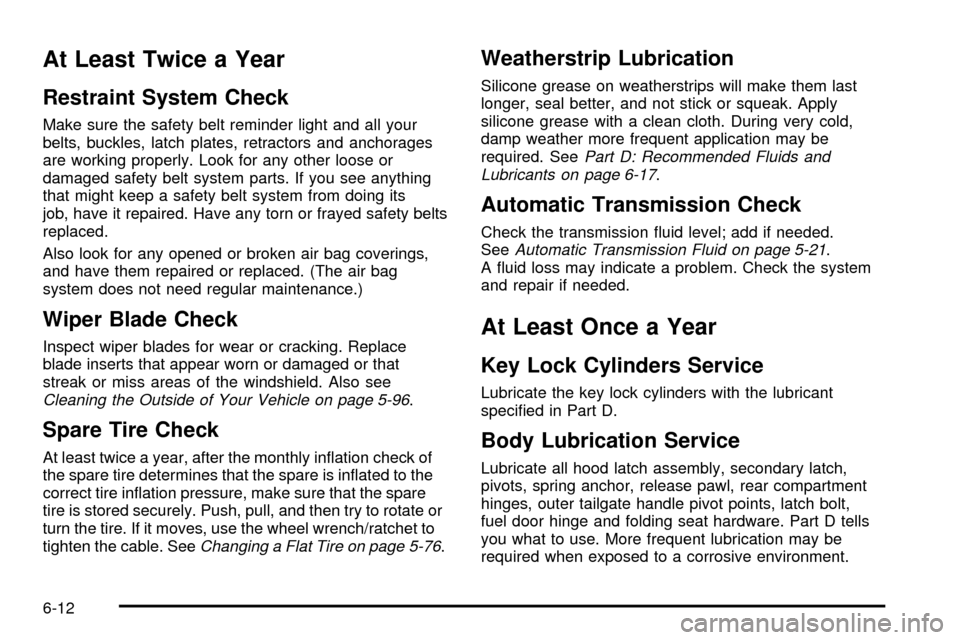

At Least Twice a Year

Restraint System Check

Make sure the safety belt reminder light and all your

belts, buckles, latch plates, retractors and anchorages

are working properly. Look for any other loose or

damaged safety belt system parts. If you see anything

that might keep a safety belt system from doing its

job, have it repaired. Have any torn or frayed safety belts

replaced.

Also look for any opened or broken air bag coverings,

and have them repaired or replaced. (The air bag

system does not need regular maintenance.)

Wiper Blade Check

Inspect wiper blades for wear or cracking. Replace

blade inserts that appear worn or damaged or that

streak or miss areas of the windshield. Also see

Cleaning the Outside of Your Vehicle on page 5-96.

Spare Tire Check

At least twice a year, after the monthly in¯ation check of

the spare tire determines that the spare is in¯ated to the

correct tire in¯ation pressure, make sure that the spare

tire is stored securely. Push, pull, and then try to rotate or

turn the tire. If it moves, use the wheel wrench/ratchet to

tighten the cable. See

Changing a Flat Tire on page 5-76.

Weatherstrip Lubrication

Silicone grease on weatherstrips will make them last

longer, seal better, and not stick or squeak. Apply

silicone grease with a clean cloth. During very cold,

damp weather more frequent application may be

required. See

Part D: Recommended Fluids and

Lubricants on page 6-17.

Automatic Transmission Check

Check the transmission ¯uid level; add if needed.

SeeAutomatic Transmission Fluid on page 5-21.

A ¯uid loss may indicate a problem. Check the system

and repair if needed.

At Least Once a Year

Key Lock Cylinders Service

Lubricate the key lock cylinders with the lubricant

speci®ed in Part D.

Body Lubrication Service

Lubricate all hood latch assembly, secondary latch,

pivots, spring anchor, release pawl, rear compartment

hinges, outer tailgate handle pivot points, latch bolt,

fuel door hinge and folding seat hardware. Part D tells

you what to use. More frequent lubrication may be

required when exposed to a corrosive environment.

6-12

Page 436 of 473

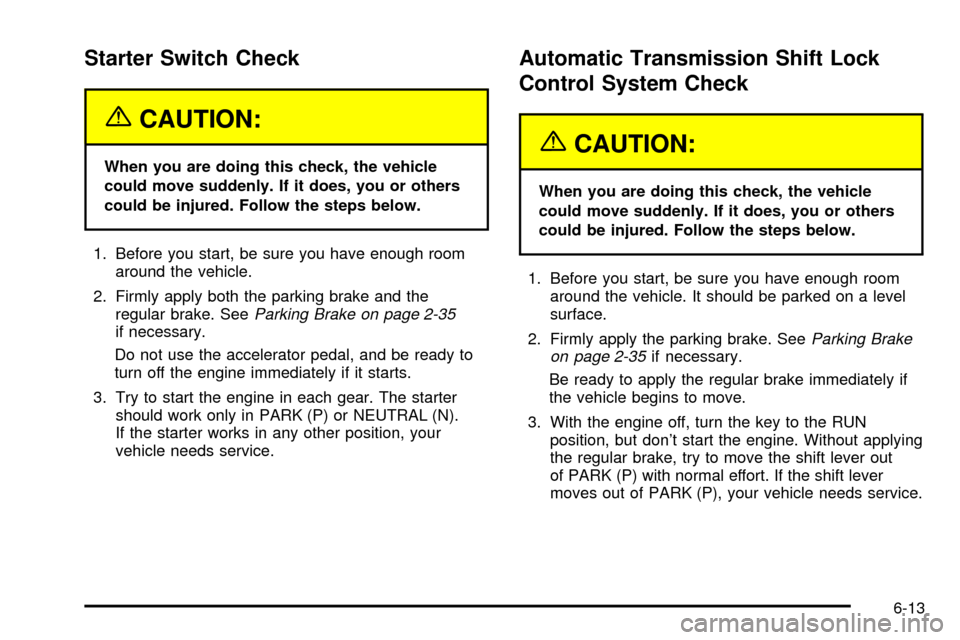

Starter Switch Check

{CAUTION:

When you are doing this check, the vehicle

could move suddenly. If it does, you or others

could be injured. Follow the steps below.

1. Before you start, be sure you have enough room

around the vehicle.

2. Firmly apply both the parking brake and the

regular brake. See

Parking Brake on page 2-35if necessary.

Do not use the accelerator pedal, and be ready to

turn off the engine immediately if it starts.

3. Try to start the engine in each gear. The starter

should work only in PARK (P) or NEUTRAL (N).

If the starter works in any other position, your

vehicle needs service.

Automatic Transmission Shift Lock

Control System Check

{CAUTION:

When you are doing this check, the vehicle

could move suddenly. If it does, you or others

could be injured. Follow the steps below.

1. Before you start, be sure you have enough room

around the vehicle. It should be parked on a level

surface.

2. Firmly apply the parking brake. See

Parking Brake

on page 2-35if necessary.

Be ready to apply the regular brake immediately if

the vehicle begins to move.

3. With the engine off, turn the key to the RUN

position, but don't start the engine. Without applying

the regular brake, try to move the shift lever out

of PARK (P) with normal effort. If the shift lever

moves out of PARK (P), your vehicle needs service.

6-13

Page 437 of 473

Ignition Transmission Lock Check

While parked, and with the parking brake set, try to turn

the ignition key to LOCK in each shift lever position.

·The key should turn to LOCK only when the

shift lever is in PARK (P).

·The key should come out only in LOCK.

Parking Brake and Automatic

Transmission Park (P) Mechanism

Check

{CAUTION:

When you are doing this check, your vehicle

could begin to move. You or others could be

injured and property could be damaged.

Make sure there is room in front of your

vehicle in case it begins to roll. Be ready to

apply the regular brake at once should the

vehicle begin to move.Park on a fairly steep hill, with the vehicle facing

downhill. Keeping your foot on the regular brake,

set the parking brake.

·To check the parking brake's holding ability:

With the engine running and transmission in

NEUTRAL (N), slowly remove foot pressure from

the regular brake pedal. Do this until the vehicle is

held by the parking brake only.

·To check the PARK (P) mechanism's holding ability:

With the engine running, shift to PARK (P). Then

release the parking brake followed by the regular

brake.

Underbody Flushing Service

At least every spring, use plain water to ¯ush any

corrosive materials from the underbody. Take care to

clean thoroughly any areas where mud and other debris

can collect.

6-14

Page 440 of 473

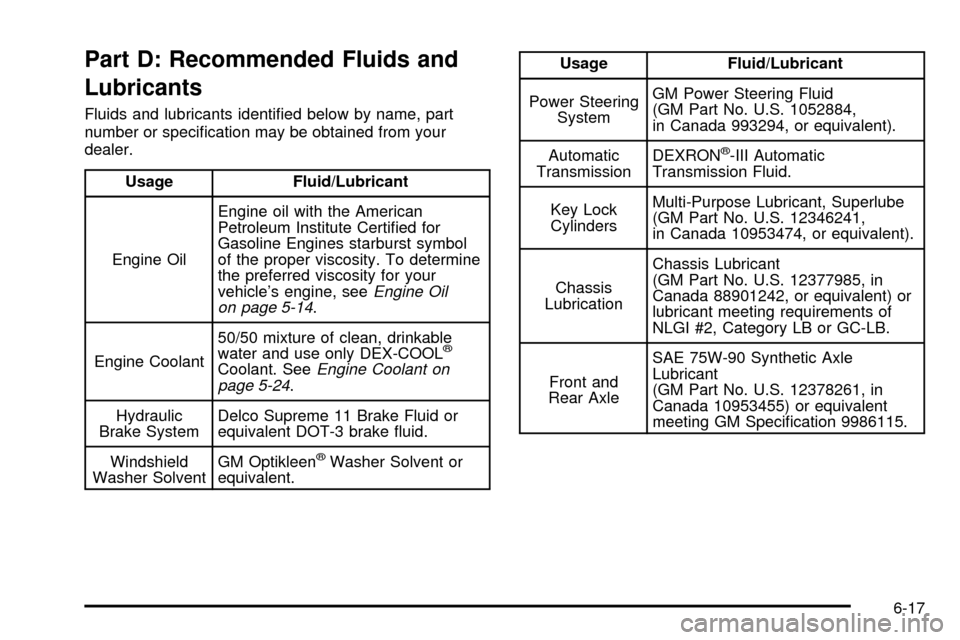

Part D: Recommended Fluids and

Lubricants

Fluids and lubricants identi®ed below by name, part

number or speci®cation may be obtained from your

dealer.

Usage Fluid/Lubricant

Engine OilEngine oil with the American

Petroleum Institute Certi®ed for

Gasoline Engines starburst symbol

of the proper viscosity. To determine

the preferred viscosity for your

vehicle's engine, see

Engine Oil

on page 5-14.

Engine Coolant50/50 mixture of clean, drinkable

water and use only DEX-COOL

ž

Coolant. SeeEngine Coolant on

page 5-24.

Hydraulic

Brake SystemDelco Supreme 11 Brake Fluid or

equivalent DOT-3 brake ¯uid.

Windshield

Washer SolventGM Optikleen

žWasher Solvent or

equivalent.

Usage Fluid/Lubricant

Power Steering

SystemGM Power Steering Fluid

(GM Part No. U.S. 1052884,

in Canada 993294, or equivalent).

Automatic

TransmissionDEXRON

ž-III Automatic

Transmission Fluid.

Key Lock

CylindersMulti-Purpose Lubricant, Superlube

(GM Part No. U.S. 12346241,

in Canada 10953474, or equivalent).

Chassis

LubricationChassis Lubricant

(GM Part No. U.S. 12377985, in

Canada 88901242, or equivalent) or

lubricant meeting requirements of

NLGI #2, Category LB or GC-LB.

Front and

Rear AxleSAE 75W-90 Synthetic Axle

Lubricant

(GM Part No. U.S. 12378261, in

Canada 10953455) or equivalent

meeting GM Speci®cation 9986115.

6-17