CADILLAC ESCALADE EXT 2003 2.G Owners Manual

ESCALADE EXT 2003 2.G

CADILLAC

CADILLAC

https://www.carmanualsonline.info/img/23/7925/w960_7925-0.png

CADILLAC ESCALADE EXT 2003 2.G Owners Manual

Trending: ground clearance, oil change, jump cable, wheel size, radiator, fuel, load capacity

Page 361 of 473

All-Wheel Drive

Lubricant checks in this section also apply to these

vehicles. However, there are two additional systems that

need lubrication.

Transfer Case

When to Check Lubricant

Refer to the Maintenance Schedule to determine how

often to check the lubricant. SeePart C: Periodic

MaintenanceInspections on page 6-15.

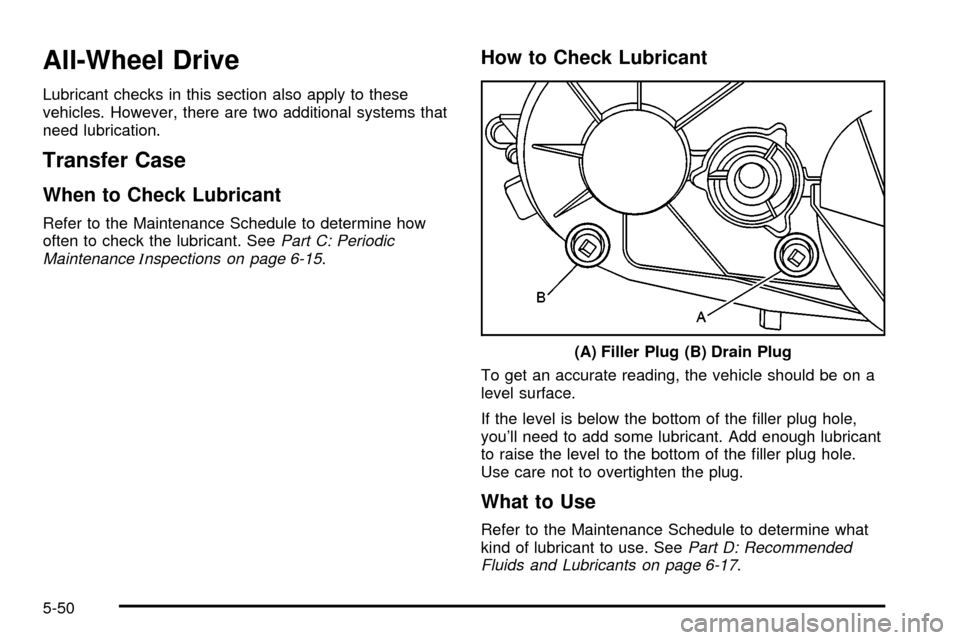

How to Check Lubricant

To get an accurate reading, the vehicle should be on a

level surface.

If the level is below the bottom of the ®ller plug hole,

you'll need to add some lubricant. Add enough lubricant

to raise the level to the bottom of the ®ller plug hole.

Use care not to overtighten the plug.

What to Use

Refer to the Maintenance Schedule to determine what

kind of lubricant to use. SeePart D: Recommended

Fluids and Lubricants on page 6-17. (A) Filler Plug (B) Drain Plug

5-50

Page 362 of 473

Rear Axle

When to Check Lubricant

Refer to the Maintenance Schedule to determine how

often to check the lubricant. SeePart A: Scheduled

Maintenance Services on page 6-4.

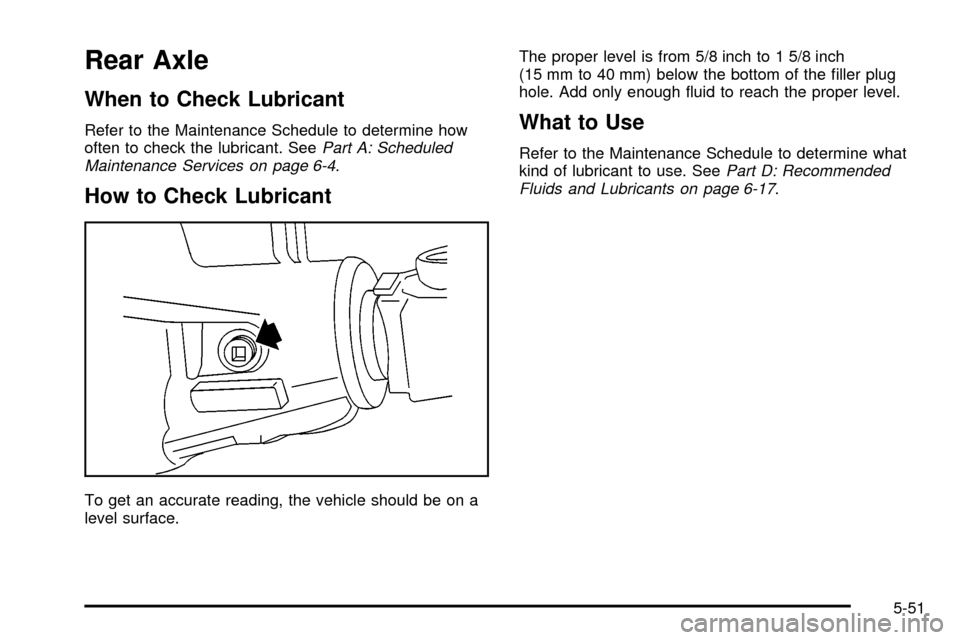

How to Check Lubricant

To get an accurate reading, the vehicle should be on a

level surface.The proper level is from 5/8 inch to 1 5/8 inch

(15 mm to 40 mm) below the bottom of the ®ller plug

hole. Add only enough ¯uid to reach the proper level.

What to Use

Refer to the Maintenance Schedule to determine what

kind of lubricant to use. SeePart D: Recommended

Fluids and Lubricants on page 6-17.

5-51

Page 363 of 473

Front Axle

When to Check and Change Lubricant

Refer to the Maintenance Schedule to determine how

often to check the lubricant and when to change it. See

Part A: Scheduled Maintenance Services on page 6-4.

How to Check Lubricant

To get an accurate reading, the vehicle should be on a

level surface.If the level is below the bottom of the ®ller plug hole,

you may need to add some lubricant.

When the differential is cold, add enough lubricant to

raise the level to 1/2 inch (12 mm) below the ®ller

plug hole.

When the differential is at operating temperature

(warm), add enough lubricant to raise the level to the

bottom of the ®ller plug hole.

What to Use

Refer to the Maintenance Schedule to determine what

kind of lubricant to use. SeePart D: Recommended

Fluids and Lubricants on page 6-17.

5-52

Page 364 of 473

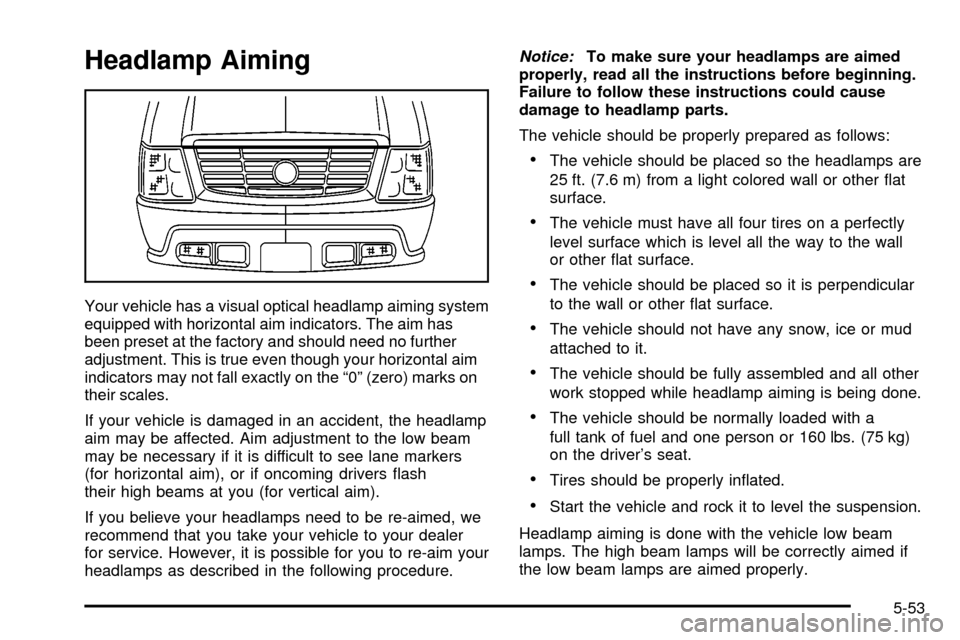

Headlamp Aiming

Your vehicle has a visual optical headlamp aiming system

equipped with horizontal aim indicators. The aim has

been preset at the factory and should need no further

adjustment. This is true even though your horizontal aim

indicators may not fall exactly on the ª0º (zero) marks on

their scales.

If your vehicle is damaged in an accident, the headlamp

aim may be affected. Aim adjustment to the low beam

may be necessary if it is difficult to see lane markers

(for horizontal aim), or if oncoming drivers ¯ash

their high beams at you (for vertical aim).

If you believe your headlamps need to be re-aimed, we

recommend that you take your vehicle to your dealer

for service. However, it is possible for you to re-aim your

headlamps as described in the following procedure.

Notice:To make sure your headlamps are aimed

properly, read all the instructions before beginning.

Failure to follow these instructions could cause

damage to headlamp parts.

The vehicle should be properly prepared as follows:

·The vehicle should be placed so the headlamps are

25 ft. (7.6 m) from a light colored wall or other ¯at

surface.

·The vehicle must have all four tires on a perfectly

level surface which is level all the way to the wall

or other ¯at surface.

·The vehicle should be placed so it is perpendicular

to the wall or other ¯at surface.

·The vehicle should not have any snow, ice or mud

attached to it.

·The vehicle should be fully assembled and all other

work stopped while headlamp aiming is being done.

·The vehicle should be normally loaded with a

full tank of fuel and one person or 160 lbs. (75 kg)

on the driver's seat.

·Tires should be properly in¯ated.

·Start the vehicle and rock it to level the suspension.

Headlamp aiming is done with the vehicle low beam

lamps. The high beam lamps will be correctly aimed if

the low beam lamps are aimed properly.

5-53

Page 365 of 473

The headlamp aiming devices are under the hood near

the headlamps.

If you believe your headlamps need horizontal (H)

(left/right) adjustment, follow the horizontal aiming

procedure. If you believe your headlamps need only

vertical (V) (up/down) adjustment, follow only the vertical

aiming procedure.

Adjustment screws can be turned with an E8 Torx

ž

socket or T15 Torxžscrewdriver.

Headlamp Horizontal Aiming

Turn the horizontal aiming screw (A) until the

indicator (B) is lined up with zero.

Once the horizontal aim is adjusted, then adjust the

vertical aim.

5-54

Page 366 of 473

Headlamp Vertical Aiming

Notice:Horizontal aiming must be performed

before making any adjustments to the vertical aim.

Adjusting the vertical aim ®rst will result in an

incorrect headlamp aim.

1. Find the aim dot on the lens of the low beam

lamps.

2. Measure the distance from the ground to the aim

dot on each low beam lamp. Record this distance.3. At the wall or other ¯at surface, measure from the

ground upward the recorded distance from Step 2

and draw or tape a horizontal line the width of

the vehicle.

5-55

Page 367 of 473

4. Turn on the low-beam headlamps and place a

piece of cardboard or equivalent in front of the

headlamp not being aimed. This should allow only

the beam of light from the headlamp being

aimed to be seen on the ¯at surface.

Notice:Do not cover a headlamp to improve beam

cut-off when aiming. Covering a headlamp may

cause excessive heat build-up which may cause

damage to the headlamp.5. Turn the vertical aiming screw (V) until the

headlamp beam is aimed to the horizontal tape line.

The top edge of the cut-off should be positioned

at the bottom edge of the horizontal tape line.

6. Repeat steps 4 and 5 for the opposite headlamp.

5-56

Page 368 of 473

Bulb Replacement

SeeReplacement Bulbs on page 5-64for the proper

type of bulbs to use.

For any bulb changing procedure not listed in this

section, contact your dealer.

High Intensity Discharge (HID)

Lighting

{CAUTION:

The low beam high intensity discharge lighting

system operates at a very high voltage. If you

try to service any of the system components,

you could be seriously injured. Have your

dealer or a quali®ed technician service them.

After your vehicle's HID headlamp bulb has been

replaced, you may notice that the beam is a slightly

different shade than it was originally. This is normal.

Halogen Bulbs

{CAUTION:

Halogen bulbs have pressurized gas inside and

can burst if you drop or scratch the bulb. You or

others could be injured. Be sure to read and

follow the instructions on the bulb package.

5-57

Page 369 of 473

Headlamps

A. Low-Beam Headlamp (HID)

B. Daytime Running Lamp

C. Sidemarker Lamp

D. High-Beam Headlamp

E. Front Parking and Turn Signal Lamp1. Open the hood of the vehicle.

2. Pry up the eight fastener plugs on the radiator

cover and pull the fasteners out.

3. Lift off the radiator cover.

5-58

Page 370 of 473

4. Pull the top left or right corner of the grill out so the

clips release. This will give you the needed

clearance for removing the headlamp assembly.5. Remove the horizontal pin from the headlamp

assembly by lifting the end of the pin upward

until it unsnaps and then pulling it toward the center

of the vehicle.

5-59

Trending: ABS, instrument cluster, remote control, change key battery, compression ratio, remove seats, clock setting