CADILLAC ESCALADE EXT 2003 2.G Owners Manual

Manufacturer: CADILLAC, Model Year: 2003, Model line: ESCALADE EXT, Model: CADILLAC ESCALADE EXT 2003 2.GPages: 473, PDF Size: 3.31 MB

Page 371 of 473

6. Remove the vertical pin from the headlamp

assembly by turning the end of the pin away from

you until it unsnaps and then pulling it upward.

7. Remove the headlamp assembly by lifting it up and

then pulling it out and away from the front of the

vehicle.8. Disconnect the electrical connector from the lower

corner of the headlamp assembly. This will give you

better access to the headlamp assembly.

9. Remove the rubber,

circular-shaped bulb

cap of the affected bulb

from the headlamp

assembly.

10. Turn the bulb connector counterclockwise and

remove it with the old bulb from the headlamp

assembly.

11. Unplug the electrical connector from the old bulb.

5-60

Page 372 of 473

12. Plug in the electrical connector to the new bulb,

using care not to touch the bulb with your hands,

®ngers or anything damp or oily.

13. Place the connector with the new bulb into the

headlamp assembly and turn it clockwise until it

is tight.

14. Reinstall the rubber, circular-shaped bulb cap onto

the headlamp assembly.

15. Reconnect the electrical connector to the lower

corner of the headlamp assembly.

16. Place the headlamp assembly back into the vehicle,

being sure to align the lower locator tab with the

pocket on the vehicle (see arrow). Push the

headlamp assembly straight in and then down into

position.

17. Install the two pins and snap the ends into their

locked position.

18. Reinstall the grille and radiator cover by reversing

the removal procedure described previously.

5-61

Page 373 of 473

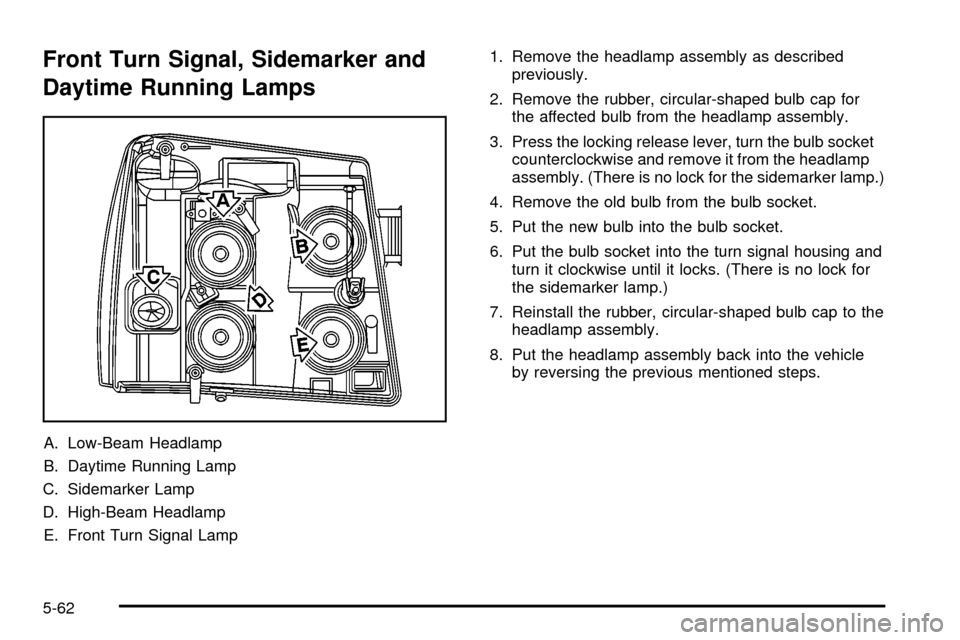

Front Turn Signal, Sidemarker and

Daytime Running Lamps

A. Low-Beam Headlamp

B. Daytime Running Lamp

C. Sidemarker Lamp

D. High-Beam Headlamp

E. Front Turn Signal Lamp1. Remove the headlamp assembly as described

previously.

2. Remove the rubber, circular-shaped bulb cap for

the affected bulb from the headlamp assembly.

3. Press the locking release lever, turn the bulb socket

counterclockwise and remove it from the headlamp

assembly. (There is no lock for the sidemarker lamp.)

4. Remove the old bulb from the bulb socket.

5. Put the new bulb into the bulb socket.

6. Put the bulb socket into the turn signal housing and

turn it clockwise until it locks. (There is no lock for

the sidemarker lamp.)

7. Reinstall the rubber, circular-shaped bulb cap to the

headlamp assembly.

8. Put the headlamp assembly back into the vehicle

by reversing the previous mentioned steps.

5-62

Page 374 of 473

Center High-Mounted Stoplamp

(CHMSL)

It is recommended that this component be replaced as

a unit by your dealer.

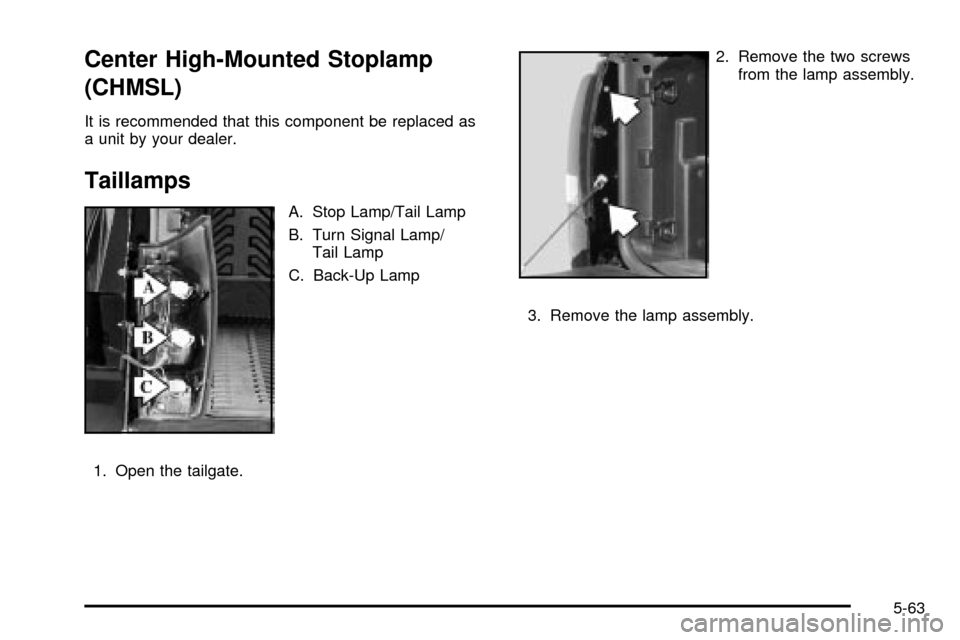

Taillamps

A. Stop Lamp/Tail Lamp

B. Turn Signal Lamp/

Tail Lamp

C. Back-Up Lamp

1. Open the tailgate.2. Remove the two screws

from the lamp assembly.

3. Remove the lamp assembly.

5-63

Page 375 of 473

4. Press the release tab

and turn the bulb socket

counterclockwise to

remove it from the

taillamp housing.

5. Pull the bulb straight out from the socket.

6. Press a new bulb into the socket, insert it into the

taillamp housing and turn the socket clockwise into

the taillamp housing until it clicks.

7. Reinstall the rear lamp assembly and tighten the

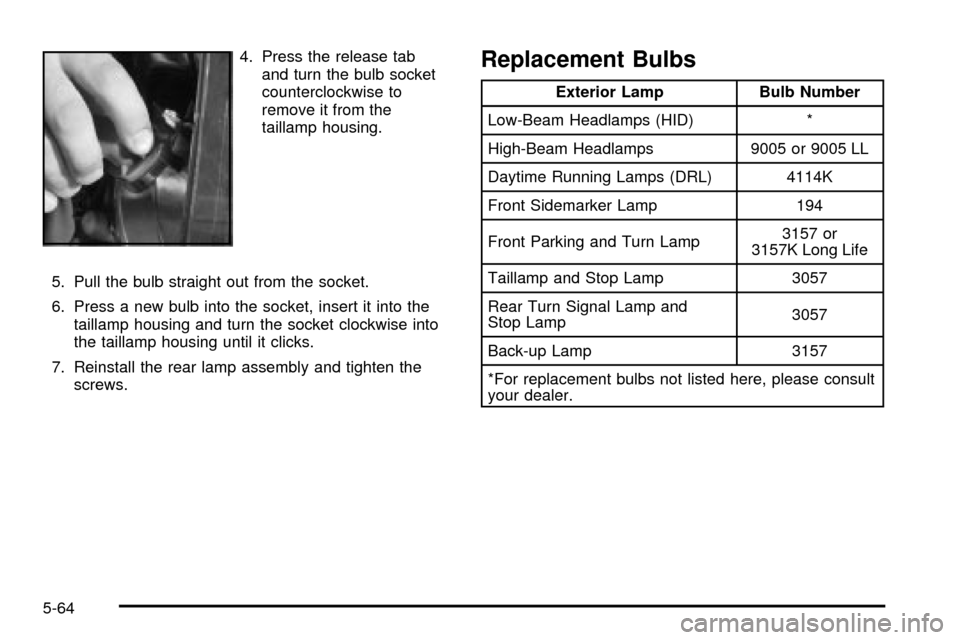

screws.Replacement Bulbs

Exterior Lamp Bulb Number

Low-Beam Headlamps (HID) *

High-Beam Headlamps 9005 or 9005 LL

Daytime Running Lamps (DRL) 4114K

Front Sidemarker Lamp 194

Front Parking and Turn Lamp3157 or

3157K Long Life

Taillamp and Stop Lamp 3057

Rear Turn Signal Lamp and

Stop Lamp3057

Back-up Lamp 3157

*For replacement bulbs not listed here, please consult

your dealer.

5-64

Page 376 of 473

Windshield Wiper Blade

Replacement

Windshield wiper blades should be inspected at least

twice a year for wear and cracking. SeeWiper Blade

CheckunderAt Least Twice a Year on page 6-12for

more information.

Replacement blades come in different types and are

removed in different ways. For proper type and length,

see

Normal Maintenance Replacement Parts on

page 5-111. Here's how to remove the shephard's

hook type.

To replace the windshield wiper blade assembly do the

following:

1. Lift the wiper arm and turn the blade until it is

facing away from the windshield.2. Push the release lever and slide the wiper assembly

toward the driver's side of the vehicle.

3. Install a new blade by reversing Steps 1 and 2.

5-65

Page 377 of 473

Tires

Your new vehicle comes with high-quality tires made by

a leading tire manufacturer. If you ever have questions

about your tire warranty and where to obtain service,

see your Cadillac Warranty booklet for details.

{CAUTION:

Poorly maintained and improperly used tires

are dangerous.

·Overloading your tires can cause

overheating as a result of too much

friction. You could have an air-out and a

serious accident. See ªLoading Your

Vehicleº in the Index.

CAUTION: (Continued)

CAUTION: (Continued)

·

Underin¯ated tires pose the same danger

as overloaded tires. The resulting accident

could cause serious injury. Check all tires

frequently to maintain the recommended

pressure. Tire pressure should be checked

when your tires are cold.

·Overin¯ated tires are more likely to be

cut, punctured or broken by a sudden

impact Ð such as when you hit a pothole.

Keep tires at the recommended pressure.

·Worn, old tires can cause accidents.

If your tread is badly worn, or if your

tires have been damaged, replace them.

5-66

Page 378 of 473

In¯ation Ð Tire Pressure

The Certi®cation/Tire label, which is on the rear edge of

the driver's door, shows the correct in¯ation pressures

for your tires when they're cold. ªColdº means your

vehicle has been sitting for at least three hours or driven

no more than 1 mile (1.6 km).

Notice:Don't let anyone tell you that underin¯ation

or overin¯ation is all right. It's not. If your tires

don't have enough air (underin¯ation), you can get

the following:

·Too much ¯exing

·Too much heat

·Tire overloading

·Bad wear

·Bad handling

·Bad fuel economyIf your tires have too much air (overin¯ation),

you can get the following:

·Unusual wear

·Bad handling

·Rough ride

·Needless damage from road hazards

When to Check

Check your tires once a month or more.

Also, check the tire pressure of the spare tire.

How to Check

Use a good quality pocket-type gage to check tire

pressure. You can't tell if your tires are properly in¯ated

simply by looking at them. Radial tires may look

properly in¯ated even when they're underin¯ated.

Be sure to put the valve caps back on the valve stems.

They help prevent leaks by keeping out dirt and

moisture.

5-67

Page 379 of 473

Tire Inspection and Rotation

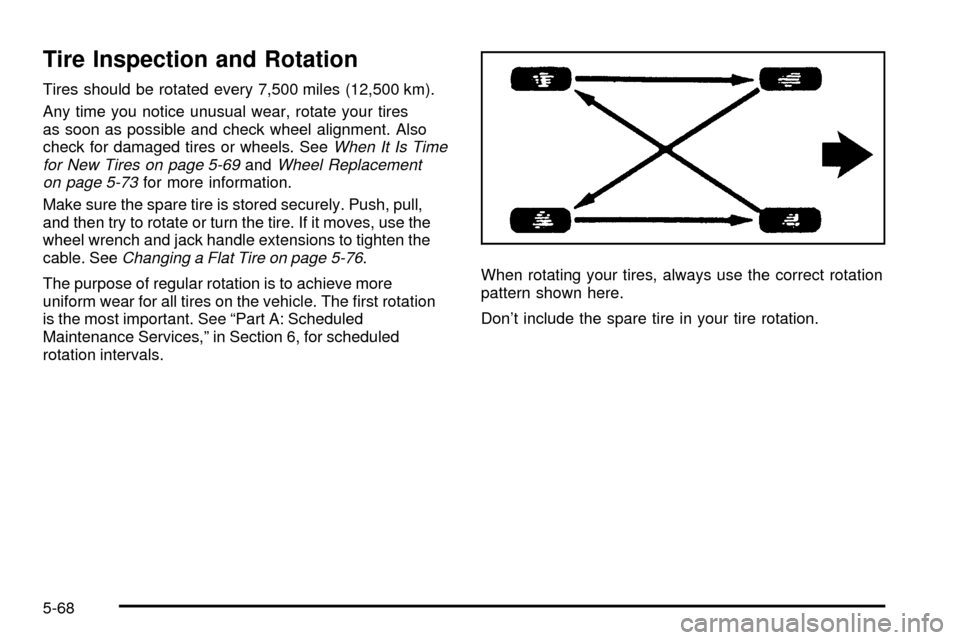

Tires should be rotated every 7,500 miles (12,500 km).

Any time you notice unusual wear, rotate your tires

as soon as possible and check wheel alignment. Also

check for damaged tires or wheels. See

When It Is Time

for New Tires on page 5-69andWheel Replacement

on page 5-73for more information.

Make sure the spare tire is stored securely. Push, pull,

and then try to rotate or turn the tire. If it moves, use the

wheel wrench and jack handle extensions to tighten the

cable. See

Changing a Flat Tire on page 5-76.

The purpose of regular rotation is to achieve more

uniform wear for all tires on the vehicle. The ®rst rotation

is the most important. See ªPart A: Scheduled

Maintenance Services,º in Section 6, for scheduled

rotation intervals.When rotating your tires, always use the correct rotation

pattern shown here.

Don't include the spare tire in your tire rotation.

5-68

Page 380 of 473

After the tires have been rotated, adjust the front and rear

in¯ation pressures as shown on the Certi®cation/Tire

label. Make certain that all wheel nuts are properly

tightened. See ªWheel Nut Torqueº under

Capacities and

Speci®cations on page 5-110.

{CAUTION:

Rust or dirt on a wheel, or on the parts to

which it is fastened, can make wheel nuts

become loose after a time. The wheel could

come off and cause an accident. When you

change a wheel, remove any rust or dirt from

places where the wheel attaches to the vehicle.

In an emergency, you can use a cloth or a

paper towel to do this; but be sure to use a

scraper or wire brush later, if you need to,

to get all the rust or dirt off. See ªChanging a

Flat Tireº in the Index.

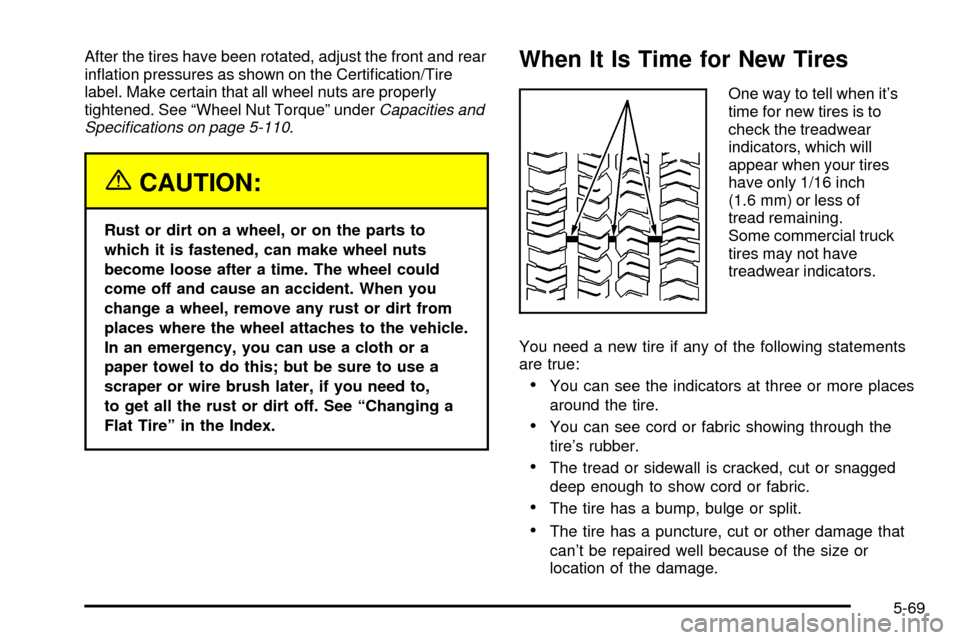

When It Is Time for New Tires

One way to tell when it's

time for new tires is to

check the treadwear

indicators, which will

appear when your tires

have only 1/16 inch

(1.6 mm) or less of

tread remaining.

Some commercial truck

tires may not have

treadwear indicators.

You need a new tire if any of the following statements

are true:

·You can see the indicators at three or more places

around the tire.

·You can see cord or fabric showing through the

tire's rubber.

·The tread or sidewall is cracked, cut or snagged

deep enough to show cord or fabric.

·The tire has a bump, bulge or split.

·The tire has a puncture, cut or other damage that

can't be repaired well because of the size or

location of the damage.

5-69