stop start CADILLAC ESCALADE EXT 2004 2.G Owner's Guide

[x] Cancel search | Manufacturer: CADILLAC, Model Year: 2004, Model line: ESCALADE EXT, Model: CADILLAC ESCALADE EXT 2004 2.GPages: 478, PDF Size: 3.43 MB

Page 308 of 478

When You Are Ready to Leave After

Parking on a Hill

1. Apply your regular brakes and hold the pedal down

while you:

·start your engine,

·shift into a gear, and

·release the parking brake.

2. Let up on the brake pedal.

3. Drive slowly until the trailer is clear of the chocks.

4. Stop and have someone pick up and store the

chocks.

Maintenance When Trailer Towing

Your vehicle will need service more often when you're

pulling a trailer. See the Maintenance Schedule for more

on this. Things that are especially important in trailer

operation are automatic transmission ¯uid (don't over®ll),

engine oil, axle lubricant, belts, cooling system and

brake system. Each of these is covered in this manual,

and the Index will help you ®nd them quickly. If

you're trailering, it's a good idea to review these sections

before you start your trip.

Check periodically to see that all hitch nuts and bolts

are tight.

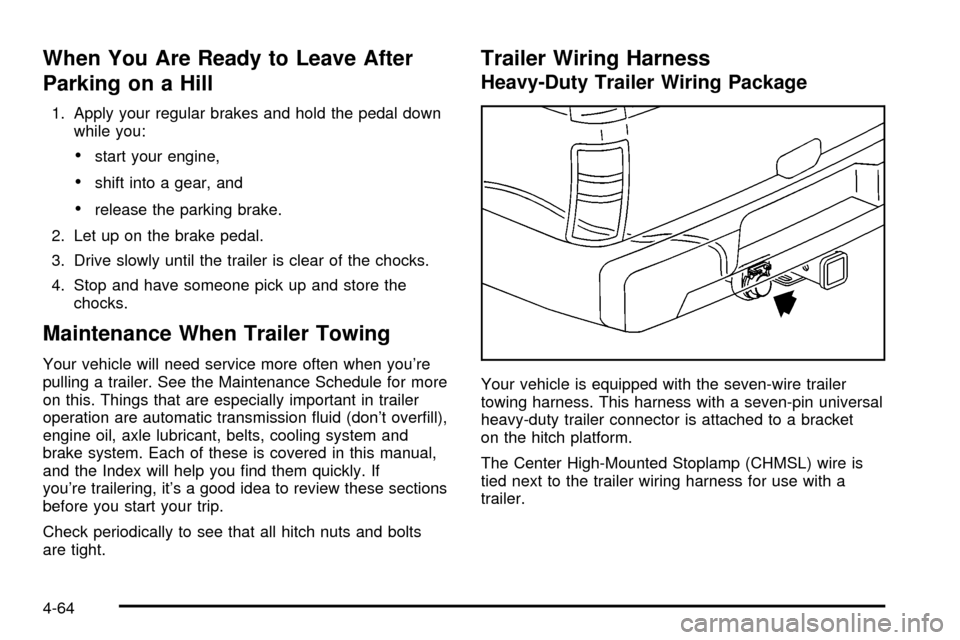

Trailer Wiring Harness

Heavy-Duty Trailer Wiring Package

Your vehicle is equipped with the seven-wire trailer

towing harness. This harness with a seven-pin universal

heavy-duty trailer connector is attached to a bracket

on the hitch platform.

The Center High-Mounted Stoplamp (CHMSL) wire is

tied next to the trailer wiring harness for use with a

trailer.

4-64

Page 311 of 478

Service............................................................5-3

Doing Your Own Service Work.........................5-3

Adding Equipment to the Outside of Your

Vehicle......................................................5-4

Fuel................................................................5-4

Gasoline Octane............................................5-4

Gasoline Speci®cations....................................5-5

California Fuel...............................................5-5

Additives.......................................................5-5

Fuels in Foreign Countries...............................5-6

Filling Your Tank............................................5-6

Filling a Portable Fuel Container.......................5-8

Checking Things Under the Hood.....................5-8

Hood Release................................................5-9

Engine Compartment Overview.......................5-10

Engine Oil...................................................5-11

Engine Air Cleaner/Filter................................5-16

Automatic Transmission Fluid.........................5-19

Engine Coolant.............................................5-22

Coolant Surge Tank Pressure Cap..................5-25

Engine Overheating.......................................5-26

Cooling System............................................5-28

Engine Fan Noise.........................................5-34Power Steering Fluid.....................................5-35

Windshield Washer Fluid................................5-36

Brakes........................................................5-38

Battery........................................................5-41

Jump Starting...............................................5-42

All-Wheel Drive..............................................5-48

Rear Axle.......................................................5-49

Front Axle......................................................5-50

Headlamp Aiming...........................................5-51

Headlamp Horizontal Aiming...........................5-52

Headlamp Vertical Aiming..............................5-53

Bulb Replacement..........................................5-55

High Intensity Discharge (HID) Lighting............5-55

Halogen Bulbs..............................................5-55

Headlamps..................................................5-56

Front Turn Signal, Sidemarker and Daytime

Running Lamps.........................................5-60

Center High-Mounted Stoplamp (CHMSL).........5-61

Taillamps.....................................................5-61

Replacement Bulbs.......................................5-62

Windshield Wiper Blade Replacement..............5-62

Section 5 Service and Appearance Care

5-1

Page 325 of 478

When to Change Engine Oil

(GM Oil Life System)

Your vehicle has a computer system that lets you know

when to change the engine oil and ®lter. This is

based on engine revolutions and engine temperature,

and not on mileage. Based on driving conditions,

the mileage at which an oil change will be indicated can

vary considerably. For the oil life system to work

properly, you must reset the system every time the oil is

changed.

When the system has calculated that oil life has been

diminished, it will indicate that an oil change is

necessary. A CHANGE ENGINE OIL message will

come on. Change your oil as soon as possible within

the next two times you stop for fuel. It is possible that, if

you are driving under the best conditions, the oil life

system may not indicate that an oil change is necessary

for over a year. However, your engine oil and ®lter

must be changed at least once a year and at this time

the system must be reset. Your dealer has GM-trained

service people who will perform this work using

genuine GM parts and reset the system. It is also

important to check your oil regularly and keep it at the

proper level.

If the system is ever reset accidentally, you must

change your oil at 3,000 miles (5 000 km) since your

last oil change. Remember to reset the oil life system

whenever the oil is changed.

How to Reset the CHANGE ENGINE OIL

Message

The GM Oil Life System calculates when to change

your engine oil and ®lter based on vehicle use. Anytime

your oil is changed, reset the system so it can

calculate when the next oil change is required. If a

situation occurs where you change your oil prior to a

CHANGE ENGINE OIL message being turned on, reset

the system.

To reset the CHANGE ENGINE OIL message, see ªGM

Oil Life Systemº under

DIC Operation and Displays

on page 3-49for vehicles equipped with the DIC, or do

the following:

1. Turn the ignition key to RUN with the engine off.

2. Fully press and release the accelerator pedal slowly

three times within ®ve seconds.

If the OIL LIFE RESET message ¯ashes for

10 seconds, the system is resetting.

3. Turn the key to LOCK.

If the CHANGE ENGINE OIL message comes back on

when you start your vehicle, the engine oil life system

has not reset. Repeat the procedure. If it still does

not reset, see your dealer for service.

5-15

Page 361 of 478

Headlamp Aiming

Your vehicle has a visual optical headlamp aiming

system equipped with horizontal aim indicators. The aim

has been preset at the factory and should need no

further adjustment. This is true even though your

horizontal aim indicators may not fall exactly on the ª0º

(zero) marks on their scales.

If your vehicle is damaged in an accident, the headlamp

aim may be affected. Aim adjustment to the low beam

may be necessary if it is difficult to see lane markers (for

horizontal aim), or if oncoming drivers ¯ash their high

beams at you (for vertical aim).

If you believe your headlamps need to be re-aimed, we

recommend that you take your vehicle to your dealer

for service. However, it is possible for you to re-aim your

headlamps as described in the following procedure.

Notice:To make sure your headlamps are aimed

properly, read all the instructions before beginning.

Failure to follow these instructions could cause

damage to headlamp parts.

The vehicle should be properly prepared as follows:

·The vehicle should be placed so the headlamps are

25 ft. (7.6 m) from a light colored wall or other ¯at

surface.

·The vehicle must have all four tires on a perfectly

level surface which is level all the way to the wall

or other ¯at surface.

·The vehicle should be placed so it is perpendicular

to the wall or other ¯at surface.

·The vehicle should not have any snow, ice or mud

attached to it.

·The vehicle should be fully assembled and all other

work stopped while headlamp aiming is being done.

·The vehicle should be normally loaded with a

full tank of fuel and one person or 160 lbs. (75 kg)

on the driver's seat.

·Tires should be properly in¯ated.

·Start the vehicle and rock it to level the suspension.

Headlamp aiming is done with the vehicle low beam

lamps. The high beam lamps will be correctly aimed if

the low beam lamps are aimed properly.

5-51

Page 383 of 478

TPM Sensor Identi®cation Codes

Each TPM sensor has a unique identi®cation code. Any

time you rotate your vehicle's tires or replace one or

more of the TPM sensors, the identi®cation codes

will need to be matched to the new tire/wheel position.

Each tire/wheel position is matched to a sensor, by

increasing or decreasing the tire's air pressure.

The sensors are matched to the tire/wheel positions in

the following order: left front (LF); right front (RF);

right rear (RR) and left rear (LR).

You will have one minute to match the ®rst tire/wheel

position, and ®ve minutes overall to match all four

tire/wheel positions. If it takes longer than one minute,

to match the ®rst tire and wheel, or more than ®ve

minutes to match all four tire and wheel positions the

matching process stops and you will need to start over.

The TPM sensor matching process is outlined below:

1. Set the Parking brake.

2. Turn the ignition switch to RUN with the engine off.3. Turn the exterior lamp switch from ªOffº to ªOnº

four times within 3 seconds. A double horn chirp

will sound and the TPM low tire warning light

will begin to ¯ash. The double horn chirp and

¯ashing TPM warning light indicate that the TPM

matching process has started. The TPM warning

light should continue ¯ashing throughout the

matching procedure. The SERVICE TIRE

MONITOR message will be displayed on the Driver

Information Center (DIC).

4. Start with the left (driver's side) front tire.

5. Remove the valve cap from the valve cap stem.

Activate the TPM sensor by increasing or

decreasing the tire's air pressure for 10 seconds,

then stop and listen for a single horn chirp.

The single horn chirp should sound within

15 seconds, con®rming that the sensor identi®cation

code has been matched to this tire and wheel

position. If you do not hear the con®rming single

horn chirp, you will need to start over with step

number one. To let air-pressure out of a tire you can

use the pointy end of the valve cap, a pencil-style

air pressure gage or a key.

5-73

Page 427 of 478

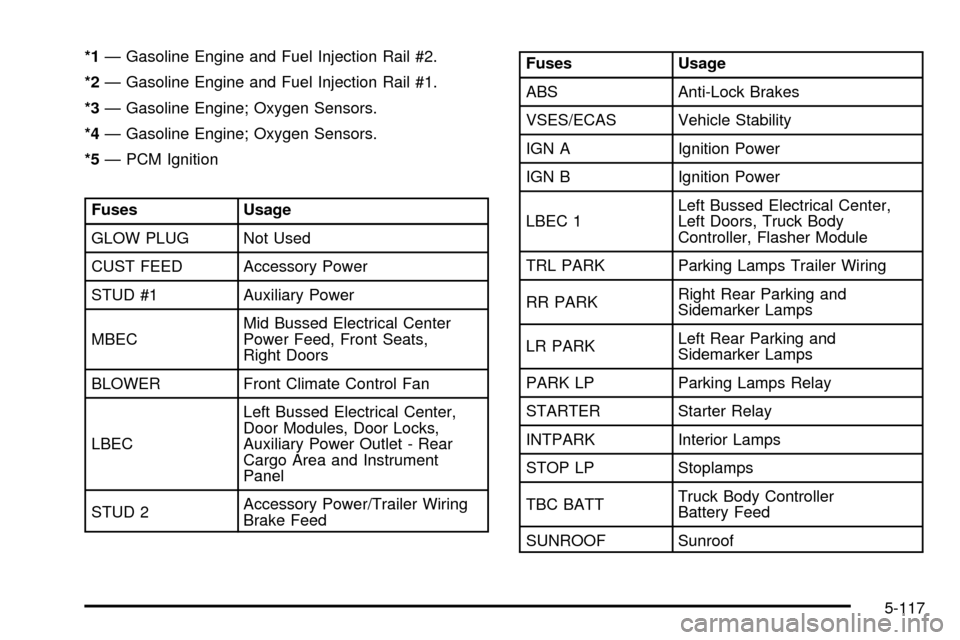

*1Ð Gasoline Engine and Fuel Injection Rail #2.

*2Ð Gasoline Engine and Fuel Injection Rail #1.

*3Ð Gasoline Engine; Oxygen Sensors.

*4Ð Gasoline Engine; Oxygen Sensors.

*5Ð PCM Ignition

Fuses Usage

GLOW PLUG Not Used

CUST FEED Accessory Power

STUD #1 Auxiliary Power

MBECMid Bussed Electrical Center

Power Feed, Front Seats,

Right Doors

BLOWER Front Climate Control Fan

LBECLeft Bussed Electrical Center,

Door Modules, Door Locks,

Auxiliary Power Outlet - Rear

Cargo Area and Instrument

Panel

STUD 2Accessory Power/Trailer Wiring

Brake Feed

Fuses Usage

ABS Anti-Lock Brakes

VSES/ECAS Vehicle Stability

IGN A Ignition Power

IGN B Ignition Power

LBEC 1Left Bussed Electrical Center,

Left Doors, Truck Body

Controller, Flasher Module

TRL PARK Parking Lamps Trailer Wiring

RR PARKRight Rear Parking and

Sidemarker Lamps

LR PARKLeft Rear Parking and

Sidemarker Lamps

PARK LP Parking Lamps Relay

STARTER Starter Relay

INTPARK Interior Lamps

STOP LP Stoplamps

TBC BATTTruck Body Controller

Battery Feed

SUNROOF Sunroof

5-117