service CADILLAC STS 2008 1.G Manual Online

[x] Cancel search | Manufacturer: CADILLAC, Model Year: 2008, Model line: STS, Model: CADILLAC STS 2008 1.GPages: 500, PDF Size: 5.81 MB

Page 388 of 500

The Tire Pressure Monitor System (TPMS) operates on

a radio frequency and complies with RSS-210 of

Industry and Science Canada. Operation is subject to

the following two conditions:

1. This device may not cause interference.

2. This device must accept any interference received,

including interference that may cause undesired

operation of the device.

Changes or modi�cations to this system by other than

an authorized service facility could void authorization to

use this equipment.

Tire Pressure Monitor Operation

The Tire Pressure Monitor System (TPMS) is designed

to warn the driver when a low tire pressure condition

exists. TPMS sensors are mounted onto each tire

and wheel assembly, excluding the spare tire and wheel

assembly. The TPMS sensors monitor the air pressure

in the vehicle’s tires and transmits the tire pressure

readings to a receiver located in the vehicle.When a low tire pressure

condition is detected, the

TPMS illuminates the

low tire pressure warning

light located on the

instrument panel cluster.

At the same time a message to check the pressure in a

speci�c tire appears on the Driver Information Center

(DIC) display. The low tire pressure warning light

and the DIC warning message come on at each ignition

cycle until the tires are in�ated to the correct in�ation

pressure. Using the DIC, tire pressure levels can

be viewed by the driver. For additional information and

details about the DIC operation and displays see

DIC Operation and Displays on page 3-74andDIC

Warnings and Messages on page 3-80.

5-70

Page 390 of 500

One or more TPMS sensors are missing or

damaged. The DIC message and the TPMS

malfunction light should go off when the TPMS

sensors are installed and the sensor matching

process is performed successfully. See your

dealer/retailer for service.

Replacement tires or wheels do not match your

vehicle’s original equipment tires or wheels.

Tires and wheels other than those recommended

for your vehicle could prevent the TPMS from

functioning properly. SeeBuying New Tires on

page 5-76.

Operating electronic devices or being near facilities

using radio wave frequencies similar to the TPMS

could cause the TPMS sensors to malfunction.

If the TPMS is not functioning it cannot detect or signal

a low tire condition. See your dealer/retailer for

service if the TPMS malfunction light and DIC message

comes on and stays on.

TPMS Sensor Matching Process

Each TPMS sensor has a unique identi�cation code.

Any time you replace one or more of the TPMS sensors

or rotate your vehicle’s tires, the identi�cation codes

will need to be matched to the new tire/wheel position.The sensors are matched to the tire/wheel positions in

the following order: driver side front tire, passenger

side front tire, passenger side rear tire, and driver side

rear tire using a TPMS diagnostic tool. See your

dealer/retailer for service.

The TPMS sensors may also be matched to each

tire/wheel position by increasing or decreasing the tire’s

air pressure. When increasing the tire’s pressure, do

not exceed the maximum in�ation pressure indicated on

the tire’s sidewall. If using this method to match

TPMS sensors, the complete procedure outlined below

must be performed within 15 minutes of the vehicle

being stationary.

To decrease air-pressure out of a tire you can use the

pointed end of the valve cap, a pencil-style air pressure

gage, or a key.

You will have one minute to match the �rst tire/wheel

position, and �ve minutes overall, to match all four

tire/wheel positions. If it takes longer than one minute to

match the �rst tire and wheel, or more than �ve

minutes to match all four tire/wheel positions, the

matching process stops and you will need to start over.

5-72

Page 397 of 500

Uniform Tire Quality Grading

Quality grades can be found where applicable on

the tire sidewall between tread shoulder and

maximum section width. For example:

Treadwear 200 Traction AA Temperature A

The following information relates to the system

developed by the United States National Highway

Traffic Safety Administration (NHTSA), which

grades tires by treadwear, traction, and

temperature performance. This applies only to

vehicles sold in the United States. The grades are

molded on the sidewalls of most passenger car

tires. The Uniform Tire Quality Grading (UTQG)

system does not apply to deep tread, winter-type

snow tires, space-saver, or temporary use

spare tires, tires with nominal rim diameters of

10 to 12 inches (25 to 30 cm), or to some

limited-production tires.

While the tires available on General Motors

passenger cars and light trucks may vary with

respect to these grades, they must also conform

to federal safety requirements and additional

General Motors Tire Performance Criteria (TPC)

standards.

Treadwear

The treadwear grade is a comparative rating

based on the wear rate of the tire when tested

under controlled conditions on a speci�ed

government test course. For example, a tire

graded 150 would wear one and a half (1.5) times

as well on the government course as a tire

graded 100. The relative performance of tires

depends upon the actual conditions of their use,

however, and may depart signi�cantly from

the norm due to variations in driving habits, service

practices, and differences in road characteristics

and climate.

Traction – AA, A, B, C

The traction grades, from highest to lowest, are

AA, A, B, and C. Those grades represent the tire’s

ability to stop on wet pavement as measured

under controlled conditions on speci�ed

government test surfaces of asphalt and concrete.

A tire marked C may have poor traction

performance.

Warning

:The traction grade assigned to

this tire is based on straight-ahead braking

traction tests, and does not include

acceleration, cornering, hydroplaning,

or peak traction characteristics.

5-79

Page 403 of 500

Lifting From the Front

The front lifting points can be accessed from either side

of your vehicle, behind the front tires.

1. Locate the front lifting points using the diagram

above. The front lifting location is about 15 inches

(37 cm) from the rear edge of the front wheel well.

2. Be sure to place a block or pad between the jack

and the vehicle.

3. Lift the vehicle with the jack, making sure the jack

is centered on the front lifting point.

Lifting From the Rear

The rear lifting points can be accessed from either side

of your vehicle, in front of the rear tires.

1. Locate the rear lifting points using the diagram

above. The rear lifting location is about 7 inches

(17 cm) from the front edge of the rear wheel well.

2. Be sure to place a block or pad between the jack

and the vehicle.

3. Lift the vehicle with the jack, making sure the jack

is centered on the rear lifting point.

SeeDoing Your Own Service Work on page 5-4.

5-85

Page 405 of 500

Run-Flat Tires (STS-V)

If your vehicle has run-�at tires, there is no spare tire

and no tire changing equipment. Run-�at tires can

operate effectively with no air pressure for a limited

distance and speed. These tires perform so well without

any air pressure that a Tire Pressure Monitor (TPM)

is used to alert you when there is a low tire condition.

{CAUTION:

When the low tire warning light is displayed on

the instrument panel cluster, your vehicle’s

handling capabilities will be reduced during

severe maneuvers. If you drive too fast, you

could lose control of your vehicle. You or

others could be injured. Do not drive over

55 mph (90 km/h) when the low tire warning

light is displayed. Drive cautiously and check

your tire pressures as soon as you can.

SeeRun-Flat Tires (STS-V) on page 5-65andTire

Pressure Monitor System on page 5-68, for additional

information.

{CAUTION:

Special tools and procedures are required to

service a run-�at tire. If these special tools and

procedures are not used you or others could

be injured and your vehicle could be damaged.

Always be sure the proper tools and

procedures, as described in the service

manual, are used.

To order a service manual seeService Publications

Ordering Information on page 7-15.

Tire Sealant and Compressor Kit

Your vehicle has a tire sealant and compressor kit that

is capable of temporarily sealing small punctures in

the tread. There is no jack or spare tire. The kit in�ates

the tire with liquid sealant and air. After the tire is

in�ated to the recommended in�ation pressure, see

Inflation - Tire Pressure on page 5-66for more

information, the vehicle must be driven for �ve miles to

distribute the sealant in the tire and seal the puncture.

After driving �ve miles the tire pressure must be

rechecked and adjusted as needed. See Using the Tire

Sealant and Compressor Kit later in this section.

5-87

Page 407 of 500

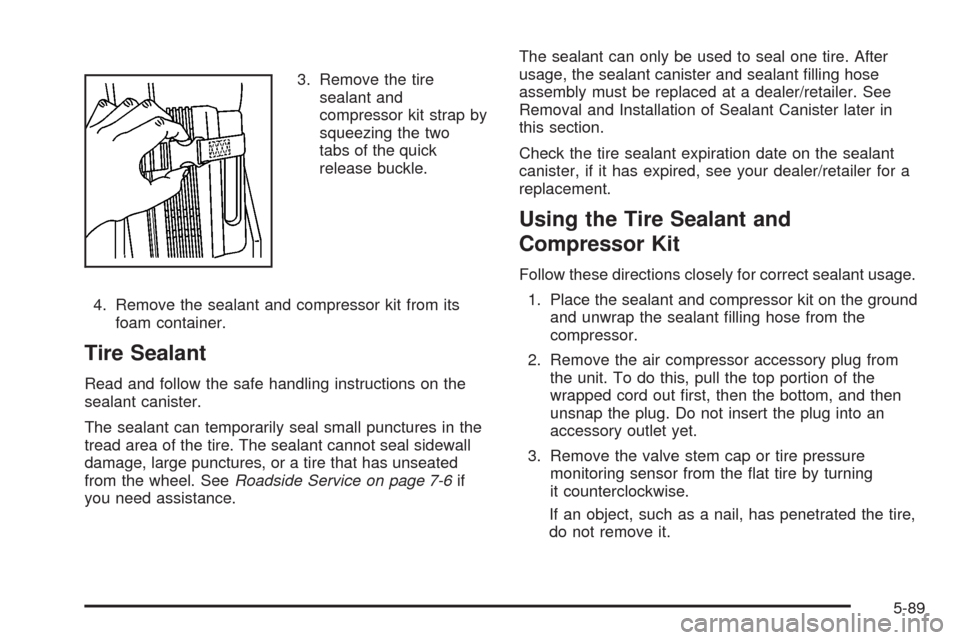

3. Remove the tire

sealant and

compressor kit strap by

squeezing the two

tabs of the quick

release buckle.

4. Remove the sealant and compressor kit from its

foam container.

Tire Sealant

Read and follow the safe handling instructions on the

sealant canister.

The sealant can temporarily seal small punctures in the

tread area of the tire. The sealant cannot seal sidewall

damage, large punctures, or a tire that has unseated

from the wheel. SeeRoadside Service on page 7-6if

you need assistance.The sealant can only be used to seal one tire. After

usage, the sealant canister and sealant �lling hose

assembly must be replaced at a dealer/retailer. See

Removal and Installation of Sealant Canister later in

this section.

Check the tire sealant expiration date on the sealant

canister, if it has expired, see your dealer/retailer for a

replacement.

Using the Tire Sealant and

Compressor Kit

Follow these directions closely for correct sealant usage.

1. Place the sealant and compressor kit on the ground

and unwrap the sealant �lling hose from the

compressor.

2. Remove the air compressor accessory plug from

the unit. To do this, pull the top portion of the

wrapped cord out �rst, then the bottom, and then

unsnap the plug. Do not insert the plug into an

accessory outlet yet.

3. Remove the valve stem cap or tire pressure

monitoring sensor from the �at tire by turning

it counterclockwise.

If an object, such as a nail, has penetrated the tire,

do not remove it.

5-89

Page 409 of 500

The pressure gage will initially show a high pressure

while the compressor pushes the sealant into the

tire. Once the sealant is completely dispersed

into the tire, the pressure will quickly drop and start

to rise again as the tire in�ates with air.

8. In�ate the tire to the recommended in�ation

pressure, found on the Tire and Loading Information

label located on the vehicle’s center pillar (B-pillar)

below the vehicle’s door latch, using the air

pressure gage on the top of the unit.

The pressure gage reads high while the compressor

is running. Turn the compressor off to get an

accurate pressure reading.

Notice:If the recommended pressure cannot be

reached after 15 minutes, the vehicle should not be

driven farther. Damage to the tire is severe and

the sealant will not be effective. Remove the

air compressor plug from the accessory power

outlet and unscrew the in�ating hose from the tire

valve. SeeRoadside Service on page 7-6.

9. Push the sealant and compressor kit switch to

the O (off) position.10. The tire is not sealed and will continue to leak air

until the vehicle is driven and the sealant is

distributed in the tire.

Steps 11 through 18 must be done right after

Step 10.

11. Unplug the air compressor accessory plug from the

accessory power outlet in the vehicle.

12. Disconnect the sealant �lling hose from the tire

valve stem, by turning it counterclockwise, and

replace the tire valve stem cap.

Be careful when handling the tire in�ator

components as they may be hot after usage.

13. Wrap the sealant �lling hose around the air

compressor channel to stow it in its original location.

14. Stow the air compressor accessory plug back in the

air compressor. To do this, wrap the air compressor

accessory plug, snap in the plug, and then push

in the bottom and then the top of the wrapped

air compressor accessory plug.

5-91

Page 411 of 500

18. If the tire pressure has fallen more then 10 psi

(68 kPa), below the recommended in�ation

pressure, stop driving the vehicle. The tire is too

severely damaged and the tire sealant and

compressor kit cannot seal the tire. SeeRoadside

Service on page 7-6for more information.

If the tire pressure has not dropped more than

10 psi (68 kPa) from the recommended in�ation

pressure, you can in�ate the tire back up to

the recommended in�ation pressure.

19. Wipe off any sealant from the wheel, tire, and

vehicle with a rag.

20. Dispose of the sealant canister at a local

dealer/retailer or in accordance with your local state

codes and practices.

After using the sealant canister, replace it with a

new canister from your dealer/retailer.

21. After temporarily sealing a tire with the tire sealant

and compressor kit, take your vehicle to your

dealer/retailer to have the tire inspected and

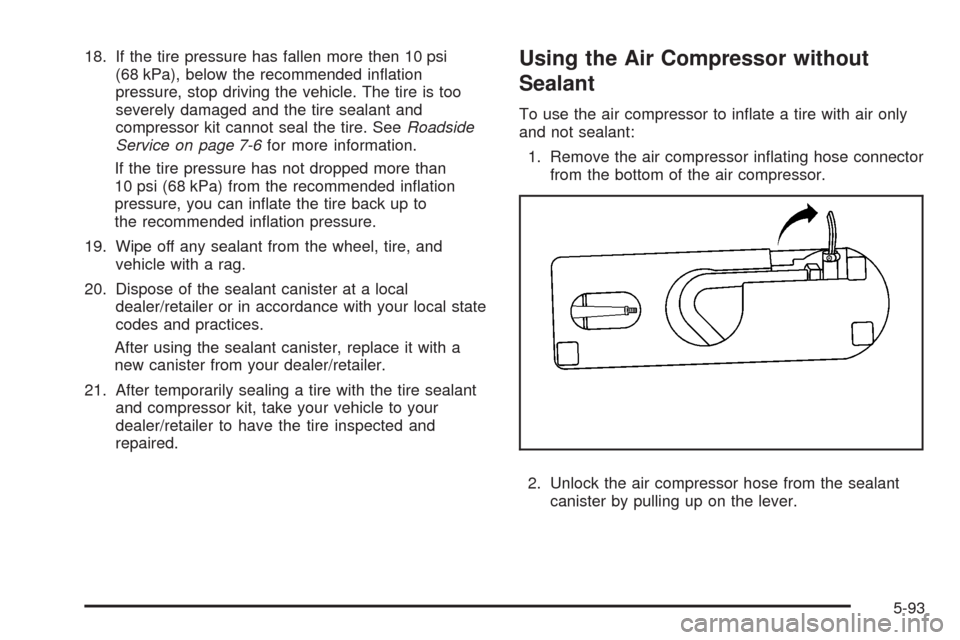

repaired.Using the Air Compressor without

Sealant

To use the air compressor to in�ate a tire with air only

and not sealant:

1. Remove the air compressor in�ating hose connector

from the bottom of the air compressor.

2. Unlock the air compressor hose from the sealant

canister by pulling up on the lever.

5-93

Page 434 of 500

Vehicle Identi�cation

Vehicle Identi�cation Number (VIN)

This is the legal identi�er for your vehicle. It appears

on a plate in the front corner of the instrument panel,

on the driver side. You can see it if you look through the

windshield from outside your vehicle. The VIN also

appears on the Vehicle Certi�cation and Service Parts

labels and the certi�cates of title and registration.

Engine Identi�cation

The eighth character in the VIN is the engine code.

This code helps you identify your vehicle’s engine,

speci�cations, and replacement parts.

Service Parts Identi�cation Label

This label is on the spare tire cover. It is very helpful if

you ever need to order parts. The label has the

following information:

Vehicle Identi�cation Number (VIN)

Model designation

Paint information

Production options and special equipment

Do not remove this label from the vehicle.

Electrical System

Add-On Electrical Equipment

Notice:Do not add anything electrical to your

vehicle unless you check with your dealer/retailer

�rst. Some electrical equipment can damage your

vehicle and the damage would not be covered by

your warranty. Some add-on electrical equipment can

keep other components from working as they should.

Add-on equipment can drain your vehicle’s battery, even

if your vehicle is not operating.

Your vehicle has an airbag system. Before attempting to

add anything electrical to your vehicle, seeServicing

Your Airbag-Equipped Vehicle on page 1-64.

5-116

Page 449 of 500

Maintenance Schedule......................................6-2

Introduction...................................................6-2

Maintenance Requirements..............................6-2

Your Vehicle and the Environment....................6-2

Using the Maintenance Schedule......................6-3

Scheduled Maintenance...................................6-4

Additional Required Services............................6-6

Maintenance Footnotes...................................6-8Owner Checks and Services............................6-9

At Each Fuel Fill............................................6-9

At Least Once a Month.................................6-10

At Least Once a Year...................................6-11

Recommended Fluids and Lubricants...............6-13

Normal Maintenance Replacement Parts..........6-15

Engine Drive Belt Routing..............................6-16

Maintenance Record.....................................6-18

Section 6 Maintenance Schedule

6-1