headlamp CADILLAC XLR V 2007 1.G Owner's Manual

[x] Cancel search | Manufacturer: CADILLAC, Model Year: 2007, Model line: XLR V, Model: CADILLAC XLR V 2007 1.GPages: 512, PDF Size: 3.84 MB

Page 409 of 512

The vehicle should be properly prepared as

follows:

The vehicle should be placed so the

headlamps are 25 ft (7.6 m) from a light

colored wall.

The vehicle must have all four tires on a

perfectly level surface which is level all

the way to the wall.

The vehicle should be placed so it is

perpendicular to the wall.

The vehicle should not have any snow, ice or

mud attached to it.

The vehicle should be fully assembled and all

other work stopped while headlamp aiming is

being done.

The vehicle should be normally loaded with a

full tank of fuel and one person or 160 lbs

(75 kg) on the driver’s seat.

Tires should be properly in�ated.

Start the vehicle and rock it to level the

suspension.Headlamp aiming is done with the low-beam

headlamps. The high-beam headlamps are

correctly aimed if the low-beam headlamps are

aimed properly.

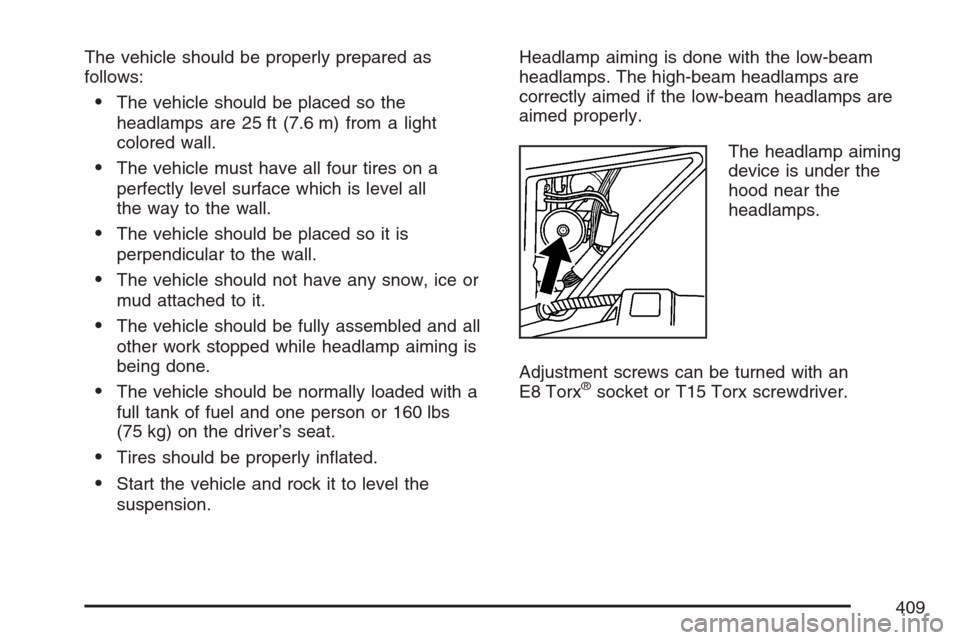

The headlamp aiming

device is under the

hood near the

headlamps.

Adjustment screws can be turned with an

E8 Torx

®socket or T15 Torx screwdriver.

409

Page 410 of 512

Headlamp Vertical Aiming

To properly prepare the vehicle for vertical

headlamp aiming seeHeadlamp Aiming on

page 408for more information.

To adjust the vertical aim, do the following:

Notice:Horizontal aiming must be performed

before making any adjustments to the

vertical aim. Adjusting the vertical aim �rst will

result in an incorrect headlamp aim.

1. Open the hood. SeeHood Release on

page 373for more information.

2. Locate the aim dot on the inner projector lens

of the low-beam headlamp.

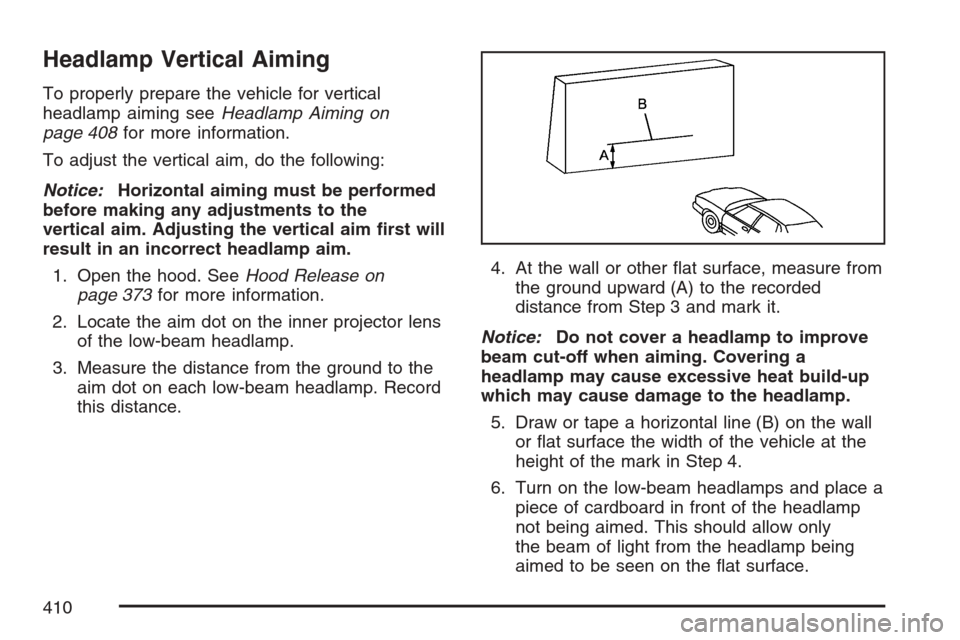

3. Measure the distance from the ground to the

aim dot on each low-beam headlamp. Record

this distance.4. At the wall or other �at surface, measure from

the ground upward (A) to the recorded

distance from Step 3 and mark it.

Notice:Do not cover a headlamp to improve

beam cut-off when aiming. Covering a

headlamp may cause excessive heat build-up

which may cause damage to the headlamp.

5. Draw or tape a horizontal line (B) on the wall

or �at surface the width of the vehicle at the

height of the mark in Step 4.

6. Turn on the low-beam headlamps and place a

piece of cardboard in front of the headlamp

not being aimed. This should allow only

the beam of light from the headlamp being

aimed to be seen on the �at surface.

410

Page 411 of 512

7. Locate the vertical headlamp aiming screws,

which are under the hood near each headlamp

assembly.

The adjustment screw can be turned with a

6 mm male hex.

8. Turn the vertical

aiming screw until

the headlamp

beam is aimed to

the horizontal

tape line.

9. The top edge of the cut-off should be

positioned at the bottom edge of the horizontal

tape line.10. Make sure that the light from the headlamp is

positioned at the bottom edge of the horizontal

tape line. The lamp on the left (A) shows

the correct headlamp aim. The lamp on the

right (B) shows the incorrect headlamp aim.

11. Repeat Steps 7 through 9 for the opposite

headlamp.

411

Page 433 of 512

If you need to replace any of your wheels, wheel

bolts or wheel nuts, replace them only with

new GM original equipment parts. This way, you

will be sure to have the right wheel, wheel

bolts, and wheel nuts for your vehicle.

{CAUTION:

Using the wrong replacement wheels,

wheel bolts, or wheel nuts on your vehicle

can be dangerous. It could affect the

braking and handling of your vehicle,

make your tires lose air and make you

lose control. You could have a collision in

which you or others could be injured.

Always use the correct wheel, wheel bolts,

and wheel nuts for replacement.

Notice:The wrong wheel can also cause

problems with bearing life, brake cooling,

speedometer or odometer calibration,

headlamp aim, bumper height, vehicle ground

clearance, and tire clearance to the body

and chassis.

{CAUTION:

Rust or dirt on a wheel, or on the parts to

which it is fastened, can make wheel nuts

become loose after a time. The wheel

could come off and cause a crash. When

you change a wheel, remove any rust or

dirt from places where the wheel attaches

to the vehicle. In an emergency, you can

use a cloth or a paper towel to do this;

but be sure to use a scraper or wire brush

later, if you need to, to get all the rust or

dirt off.

{CAUTION:

Never use oil or grease on studs or the

threads of the wheel nuts. If you do, the

wheel nuts might come loose and the

wheel could fall off, causing a crash.

433

Page 456 of 512

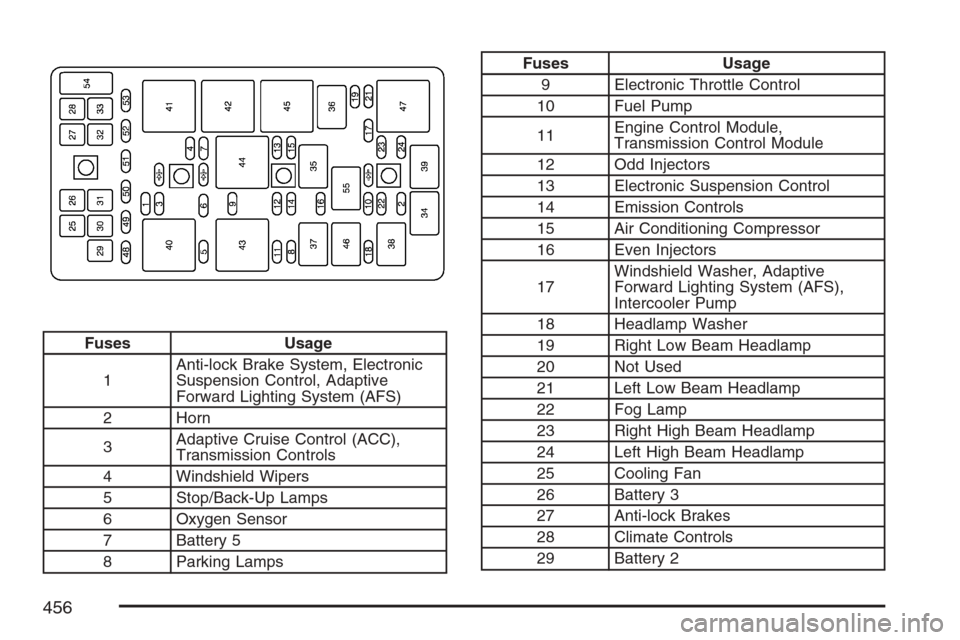

Fuses Usage

1Anti-lock Brake System, Electronic

Suspension Control, Adaptive

Forward Lighting System (AFS)

2 Horn

3Adaptive Cruise Control (ACC),

Transmission Controls

4 Windshield Wipers

5 Stop/Back-Up Lamps

6 Oxygen Sensor

7 Battery 5

8 Parking Lamps

Fuses Usage

9 Electronic Throttle Control

10 Fuel Pump

11Engine Control Module,

Transmission Control Module

12 Odd Injectors

13 Electronic Suspension Control

14 Emission Controls

15 Air Conditioning Compressor

16 Even Injectors

17Windshield Washer, Adaptive

Forward Lighting System (AFS),

Intercooler Pump

18 Headlamp Washer

19 Right Low Beam Headlamp

20 Not Used

21 Left Low Beam Headlamp

22 Fog Lamp

23 Right High Beam Headlamp

24 Left High Beam Headlamp

25 Cooling Fan

26 Battery 3

27 Anti-lock Brakes

28 Climate Controls

29 Battery 2

456

Page 457 of 512

Fuses Usage

30 Starter

31 Audio Ampli�er

32 Not Used

33 Battery 1

48 Spare

49 Spare

50 Spare

51 Spare

52 Spare

53 Not Used

54 Fuse Puller

Relays Usage

34 Horn

35 Air Conditioning Compressor

36 Windshield Washer

37 Parking Lamps

38 Fog Lamps

39 High Beam Headlamps

Relays Usage

40 Rear Window Defogger

41 Windshield Wiper High/Low

42 Wiper RUN/ACCESSORY Power

43 Starter/Crank

44 Ignition 1

45 Windshield Wiper On/Off

46 Headlamp Washer

47 Low Beam Headlamps

55 Fuel Pump

Diodes Usage

§Diode 1

§Wiper Diode

§Diode 2

457

Page 500 of 512

Appearance Care (cont.)

Weatherstrips........................................... 445

Windshield and Wiper Blades................... 447

Wood Panels........................................... 445

Ashtray(s).................................................... 178

Audio System.............................................. 285

Audio System(s).......................................... 225

Audio Steering Wheel Controls................. 227

Care of Your CD Player........................... 230

Care of Your CDs.................................... 229

Diversity Antenna System......................... 230

Theft-Deterrent Feature............................ 226

Understanding Radio Reception............... 228

XM™ Satellite Radio Antenna System...... 230

Automatic Door Lock..................................... 76

Automatic Transmission

Fluid........................................................ 384

Operation................................................... 92

Avoid Point/Area, Edit.................................. 257

B

Battery........................................................ 402

Exterior Lighting Battery Saver................. 169

Run-Down Protection............................... 171

Before Leaving on a Long Trip.................... 345Brake

Anti-Lock Brake System (ABS)................. 327

Emergencies............................................ 329

Parking...................................................... 97

System Warning Light.............................. 192

Brakes........................................................ 399

Braking....................................................... 326

Braking in Emergencies............................... 329

Break-In, New Vehicle................................... 87

Bulb Replacement....................................... 412

Headlamp Aiming..................................... 408

Buying New Tires........................................ 428

C

California Fuel............................................. 367

California Proposition 65 Warning................ 364

Canadian Owners........................................... 3

Capacities and Speci�cations...................... 458

Carbon Monoxide............... 77,102, 349, 359

Care of

Safety Belts............................................. 445

Your CD Player........................................ 230

Your CDs ................................................. 229

CD

Six-Disc Changer..................................... 302

CD/DVD Player........................................... 305

500

Page 504 of 512

Fuel............................................................ 365

Additives.................................................. 367

California Fuel.......................................... 367

Filling a Portable Fuel Container.............. 371

Filling Your Tank...................................... 369

Fuels in Foreign Countries....................... 368

Gage....................................................... 202

Gasoline Octane...................................... 366

Gasoline Speci�cations............................ 366

Fuses

Fuses and Circuit Breakers...................... 453

Instrument Panel Fuse Block................... 453

Underhood Fuse Block............................. 455

Windshield Wiper..................................... 452

G

Gage

Engine Coolant Temperature.................... 195

Engine Oil Pressure................................. 200

Fuel......................................................... 202

Speedometer........................................... 187

Tachometer.............................................. 187

Voltmeter Gage........................................ 192

Garage Door Opener..........................110, 111Gasoline

Octane..................................................... 366

Speci�cations........................................... 366

Getting Started

Getting Started, Navigation....................... 234

Global Positioning System (GPS)................ 281

Glove Box................................................... 121

GM Mobility Reimbursement Program.......... 486

H

Hazard Warning Flashers............................ 140

Headlamp

Aiming..................................................... 408

Vertical Aiming......................................... 410

Headlamps

Adaptive Forward Lighting System........... 167

Bulb Replacement.................................... 412

Daytime Running Lamps.......................... 166

Flash-to-Pass........................................... 143

High/Low Beam Changer ......................... 143

On Reminder........................................... 166

Washer.................................................... 146

Wiper Activated........................................ 166

Head-Up Display (HUD).............................. 171

504

Page 512 of 512

Vehicle Data Collection and Event Data

Recorders................................................ 491

Vehicle Identi�cation

Number (VIN).......................................... 451

Service Parts Identi�cation Label.............. 451

Vehicle Personalization

DIC .......................................................... 220

Vehicle Positioning...................................... 282

Ventilation Adjustment.................................. 184

Visors........................................................... 84

Voice Recognition........................................ 312

Voltmeter Gage........................................... 192

W

Warning Lights, Gages and Indicators......... 185

Warnings

DIC Warnings and Messages................... 206

Hazard Warning Flashers......................... 140

Other Warning Devices............................ 140

Safety and Symbols..................................... 4

Vehicle Damage.......................................... 5

Waypoint, Edit............................................. 254

Wheels

Alignment and Tire Balance..................... 432

Different Size........................................... 430

Replacement............................................ 432Windows....................................................... 81

Power........................................................ 82

Windshield

Rainsense™ Wipers................................. 145

Replacement............................................ 412

Washer.................................................... 146

Washer Fluid........................................... 397

Wiper Blade Replacement........................ 412

Wiper Blades, Cleaning............................ 447

Wiper Fuses............................................ 452

Wipers..................................................... 144

Winter Driving............................................. 349

Winter Tires................................................. 414

Wiper Activated Headlamps ......................... 166X

XM™ Satellite Radio Antenna System......... 230

Y

Your Vehicle and the Environment............... 462

512