sensor CHERY TIGGO 2009 Service Repair Manual

[x] Cancel search | Manufacturer: CHERY, Model Year: 2009, Model line: TIGGO, Model: CHERY TIGGO 2009Pages: 1903, PDF Size: 33.38 MB

Page 18 of 1903

Downloaded from www.Manualslib.com manuals search engine Sensors & Relays

•Gently apply a slight vibration to sensors and relays in the system you are inspecting. This test may indicate a

loose or poorly mounted sensor or relay.

Engine Compartment

• There are several reasons a vehicle or engine vibration could cause an electrical complaint. Some of the things

to check for are:

� Connectors not fully seated.

� Wiring harness not long enough and is being stressed due to engine vibrations or rocking.

� Wires laying across brackets or moving components.

� Loose, dirty or corroded ground wires.

� Wires routed too close to hot components.

• To inspect components under the hood, start by verifying the integrity of the ground connections (See Ground

Inspection described later). First, verify that the system is properly grounded. Then check for any loose connec-

tions by gently shaking the wiring or components as previously explained. Using the wiring diagrams, inspect

the wiring for continuity.

Behind The Instrument Panel

• An improperly routed or improperly clamped harness can become pinched during accessory installation. Vehicle

vibration can aggravate a harness which is routed along a bracket or near a mounting screw.

• An unclamped or loose harness can cause wiring to be pinched by seat components (such as slide guides)

during vehicle vibration. If the wiring runs under seating areas, inspect wire routing for possible damage or

pinching.

Heat Sensitivity Test

The customer’s concern may occur during hot weather or after the vehicle has sat for a short time. In such cases you

will want to check for a heat sensitive condition.

To determine if an electrical component is heat sensitive, heat the component with a heat gun or equivalent.

CAUTION:

Do not heat components above 60°C (140°F).

If the incident occurs while heat testing the component, replace or properly insulate the component as needed.

Freezing Test

The customer may indicate the incident goes away after the vehicle warms up (winter time). The cause could be

related to water freezing somewhere in the wiring/electrical system. There are two methods to check for this:

•The first method is to arrange for the owner to leave the vehicle overnight. Make sure it will get cold enough to

duplicate the complaint. Leave the vehicle parked outside overnight. In the morning, do a quick and thorough

diagnosis of those electrical components which could be affected.

• The second method is to put the suspect component into a freezer long enough for any water to freeze. Rein-

stall the part into the vehicle and check for a reoccurrence of the incident. If it occurs, repair or replace the

component as needed.

Water Intrusion Test

The incident may occur only during high humidity or in rainy/snowy weather. In such cases the incident could be

caused by water intrusion on an electrical part. This can be simulated by soaking the car or running it through a car

wash.

Electrical Load Test

The incident may be electrical load sensitive. Perform diagnosis with all accessories (including A/C, rear window

defogger, radio, fog lamps) turned on.

Cold or Hot Starting Test

On some occasions an electrical incident may occur only when the vehicle is started cold, or it may occur when the

vehicle is restarted hot shortly after being turned off. In these cases you may have to keep the vehicle overnight to

make a proper diagnosis.

DIAGNOSING ELECTRICAL FAILURES

01

01–17Chery Automobile Co., Ltd.

Page 26 of 1903

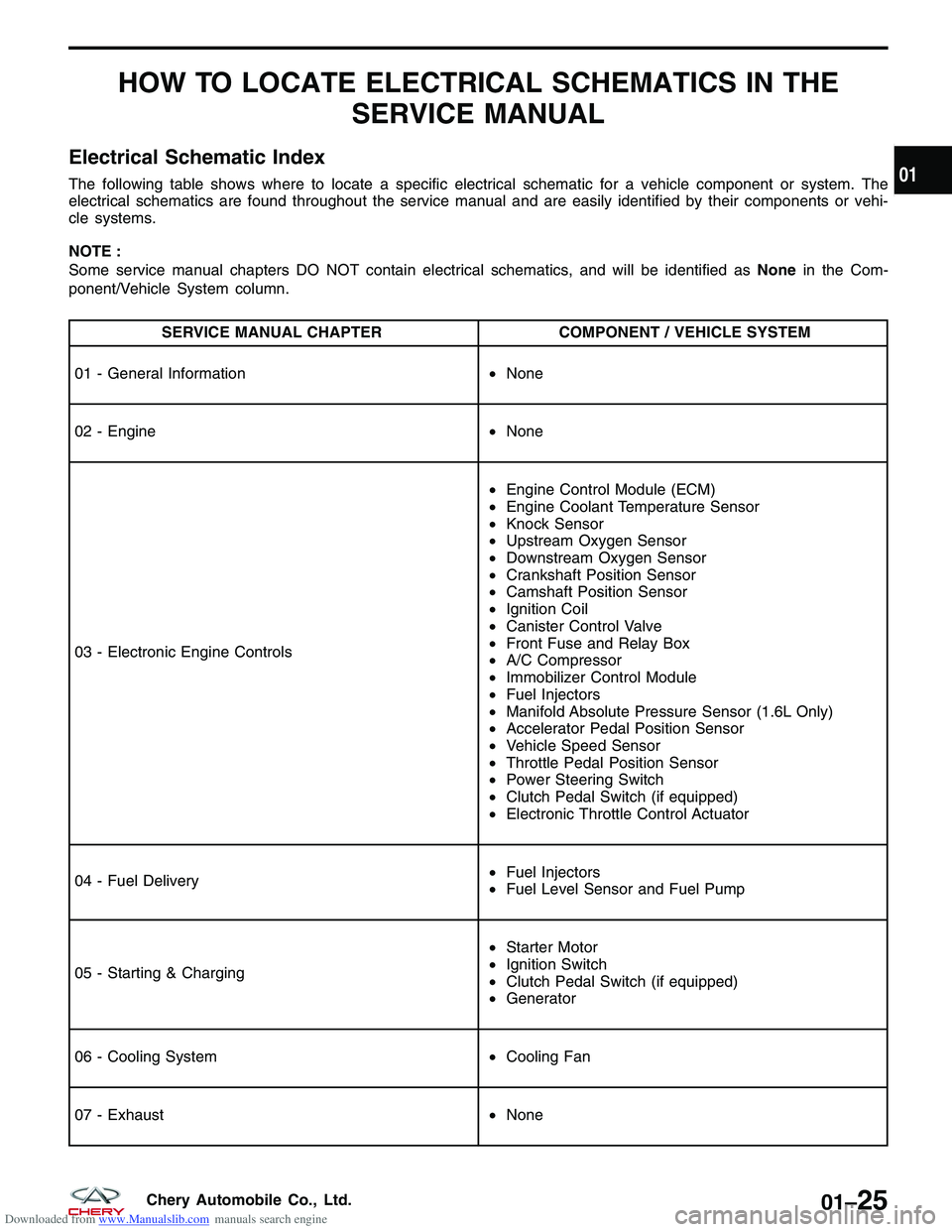

Downloaded from www.Manualslib.com manuals search engine HOW TO LOCATE ELECTRICAL SCHEMATICS IN THESERVICE MANUAL

Electrical Schematic Index

The following table shows where to locate a specific electrical schematic for a vehicle component or system. The

electrical schematics are found throughout the service manual and are easily identified by their components or vehi-

cle systems.

NOTE :

Some service manual chapters DO NOT contain electrical schematics, and will be identified as Nonein the Com-

ponent/Vehicle System column.

SERVICE MANUAL CHAPTER COMPONENT / VEHICLE SYSTEM

01 - General Information •None

02 - Engine •None

03 - Electronic Engine Controls •

Engine Control Module (ECM)

• Engine Coolant Temperature Sensor

• Knock Sensor

• Upstream Oxygen Sensor

• Downstream Oxygen Sensor

• Crankshaft Position Sensor

• Camshaft Position Sensor

• Ignition Coil

• Canister Control Valve

• Front Fuse and Relay Box

• A/C Compressor

• Immobilizer Control Module

• Fuel Injectors

• Manifold Absolute Pressure Sensor (1.6L Only)

• Accelerator Pedal Position Sensor

• Vehicle Speed Sensor

• Throttle Pedal Position Sensor

• Power Steering Switch

• Clutch Pedal Switch (if equipped)

• Electronic Throttle Control Actuator

04 - Fuel Delivery •

Fuel Injectors

• Fuel Level Sensor and Fuel Pump

05 - Starting & Charging •

Starter Motor

• Ignition Switch

• Clutch Pedal Switch (if equipped)

• Generator

06 - Cooling System •Cooling Fan

07 - Exhaust •None

01

01–25Chery Automobile Co., Ltd.

Page 27 of 1903

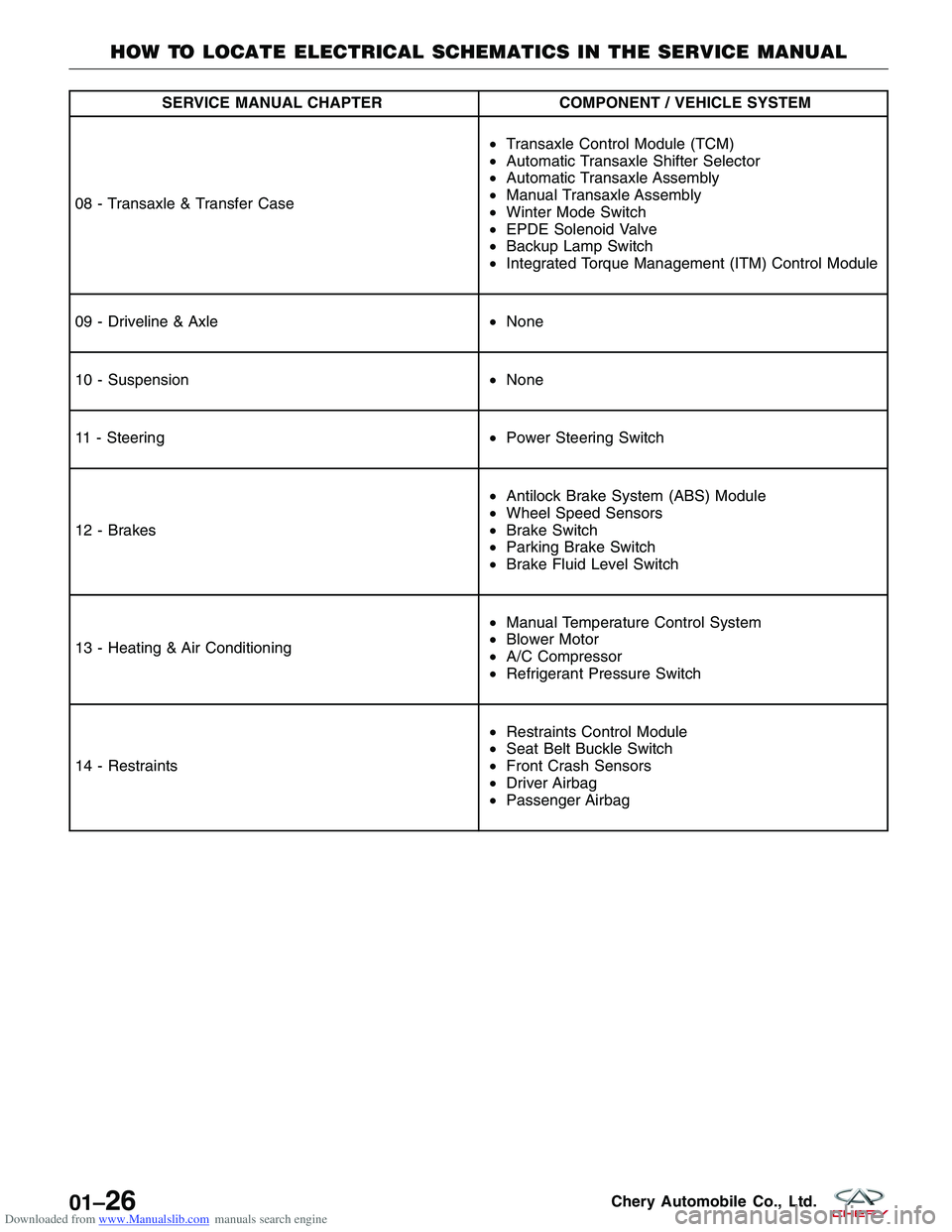

Downloaded from www.Manualslib.com manuals search engine SERVICE MANUAL CHAPTERCOMPONENT / VEHICLE SYSTEM

08 - Transaxle & Transfer Case •

Transaxle Control Module (TCM)

• Automatic Transaxle Shifter Selector

• Automatic Transaxle Assembly

• Manual Transaxle Assembly

• Winter Mode Switch

• EPDE Solenoid Valve

• Backup Lamp Switch

• Integrated Torque Management (ITM) Control Module

09 - Driveline & Axle •None

10 - Suspension •None

11 - Steering •Power Steering Switch

12 - Brakes •

Antilock Brake System (ABS) Module

• Wheel Speed Sensors

• Brake Switch

• Parking Brake Switch

• Brake Fluid Level Switch

13 - Heating & Air Conditioning •

Manual Temperature Control System

• Blower Motor

• A/C Compressor

• Refrigerant Pressure Switch

14 - Restraints •

Restraints Control Module

• Seat Belt Buckle Switch

• Front Crash Sensors

• Driver Airbag

• Passenger Airbag

HOW TO LOCATE ELECTRICAL SCHEMATICS IN THE SERVICE MANUAL

01–26Chery Automobile Co., Ltd.

Page 28 of 1903

Downloaded from www.Manualslib.com manuals search engine SERVICE MANUAL CHAPTERCOMPONENT / VEHICLE SYSTEM

15 - Body & Accessories •

Windshield Wiper Motor

• Windshield Washer Motor

• Rear Window Defroster

• Power Door Locks

• Power Windows

• Power Mirrors

• Sunroof Control Unit

• Radio

• Interior Lights

• Exterior Lights

• Oil Pressure Switch

• Warning Buzzer

• Body Control Module (BCM)

• Instrument Cluster

• Key Switch

• Power Outlet

• Data Link Connector

• Immobilizer Control Module

• Horn

16 - Wiring •

Power Distribution

• Front Fuse and Relay Box

• Power Fuse Box

• Ignition Switch

• Ground Distribution

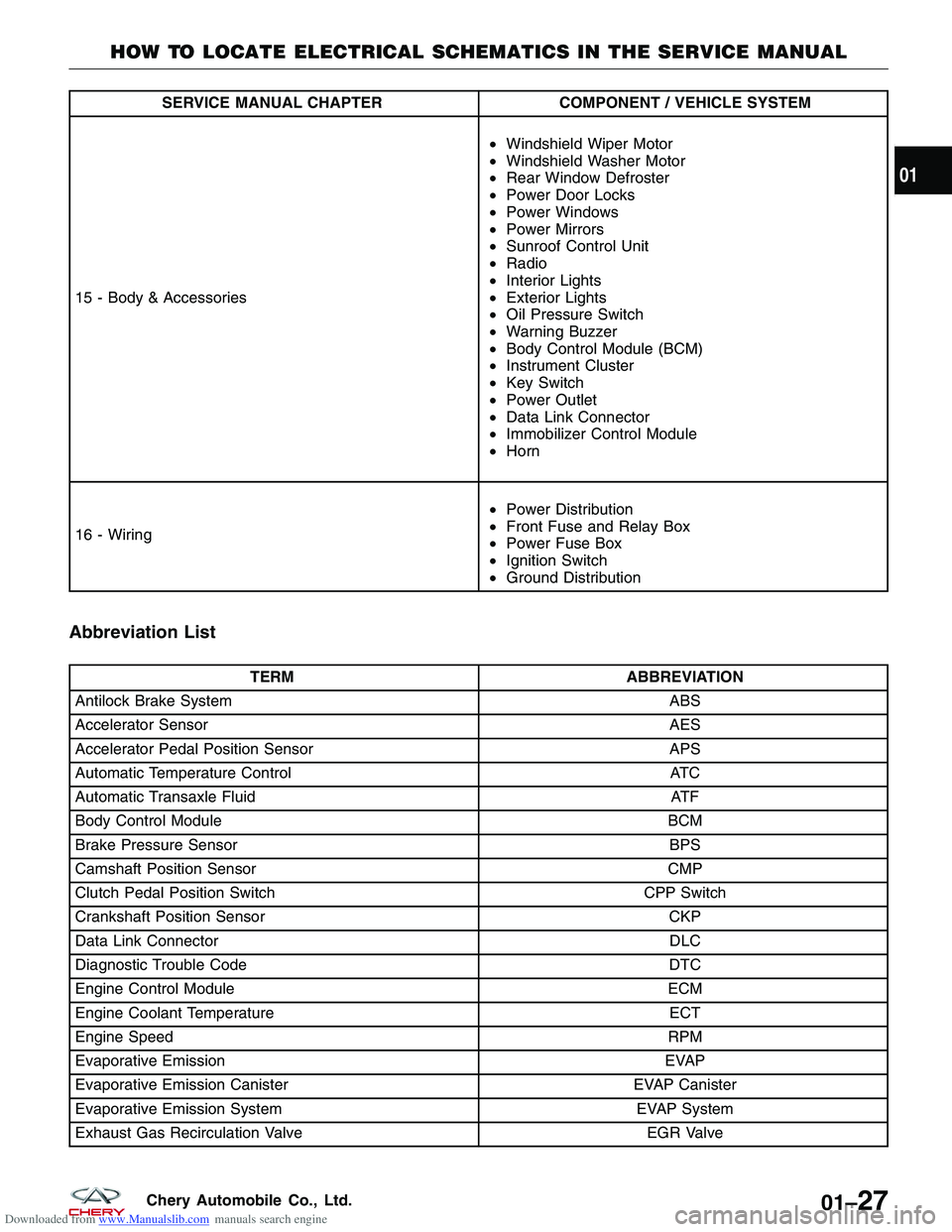

Abbreviation List

TERM ABBREVIATION

Antilock Brake System ABS

Accelerator Sensor AES

Accelerator Pedal Position Sensor APS

Automatic Temperature Control ATC

Automatic Transaxle Fluid ATF

Body Control Module BCM

Brake Pressure Sensor BPS

Camshaft Position Sensor CMP

Clutch Pedal Position Switch CPP Switch

Crankshaft Position Sensor CKP

Data Link Connector DLC

Diagnostic Trouble Code DTC

Engine Control Module ECM

Engine Coolant Temperature ECT

Engine Speed RPM

Evaporative Emission EVAP

Evaporative Emission Canister EVAP Canister

Evaporative Emission System EVAP System

Exhaust Gas Recirculation Valve EGR Valve

HOW TO LOCATE ELECTRICAL SCHEMATICS IN THE SERVICE MANUAL

01

01–27Chery Automobile Co., Ltd.

Page 29 of 1903

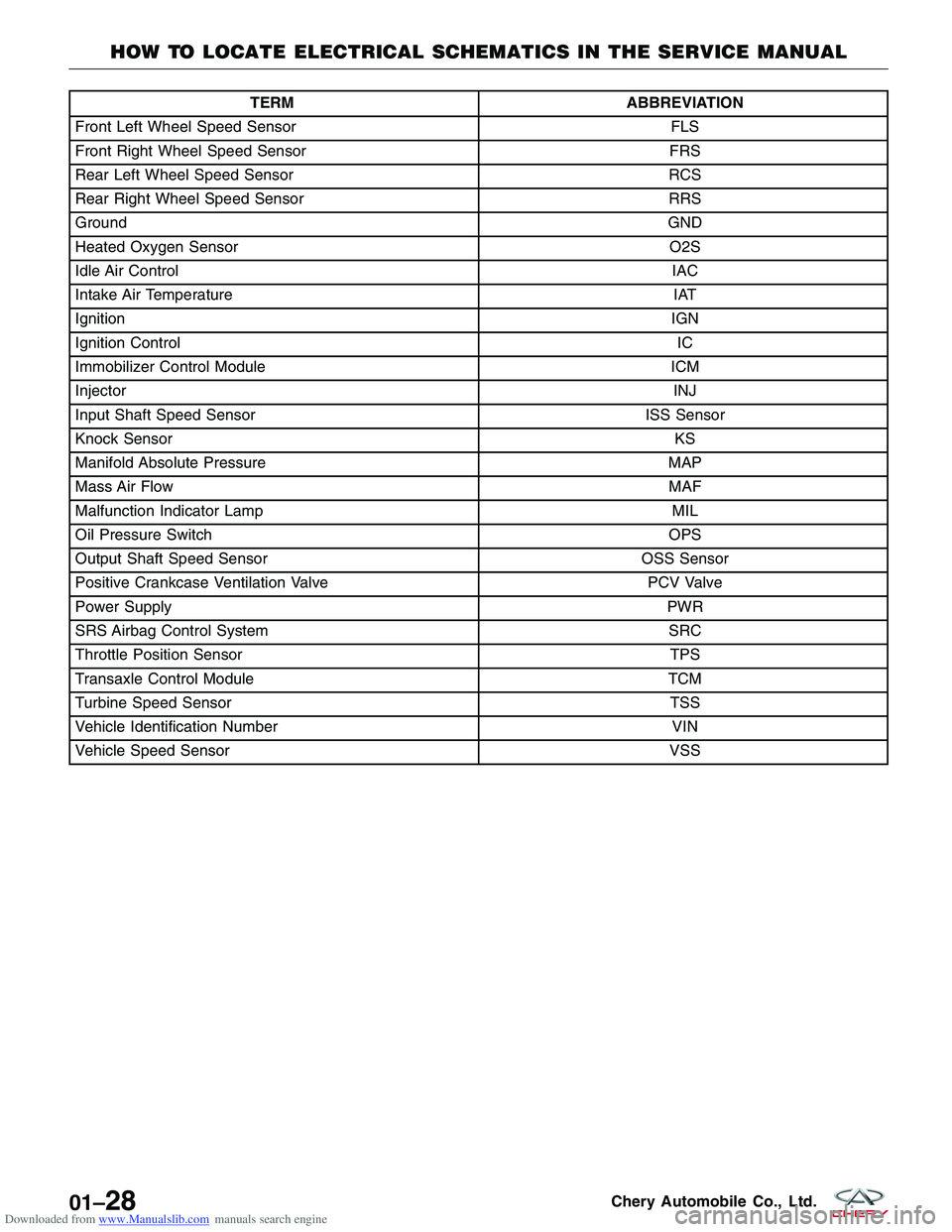

Downloaded from www.Manualslib.com manuals search engine TERMABBREVIATION

Front Left Wheel Speed Sensor FLS

Front Right Wheel Speed Sensor FRS

Rear Left Wheel Speed Sensor RCS

Rear Right Wheel Speed Sensor RRS

Ground GND

Heated Oxygen Sensor O2S

Idle Air Control IAC

Intake Air Temperature IAT

Ignition IGN

Ignition Control IC

Immobilizer Control Module ICM

Injector INJ

Input Shaft Speed Sensor ISS Sensor

Knock Sensor KS

Manifold Absolute Pressure MAP

Mass Air Flow MAF

Malfunction Indicator Lamp MIL

Oil Pressure Switch OPS

Output Shaft Speed Sensor OSS Sensor

Positive Crankcase Ventilation Valve PCV Valve

Power Supply PWR

SRS Airbag Control System SRC

Throttle Position Sensor TPS

Transaxle Control Module TCM

Turbine Speed Sensor TSS

Vehicle Identification Number VIN

Vehicle Speed Sensor VSS

HOW TO LOCATE ELECTRICAL SCHEMATICS IN THE SERVICE MANUAL

01–28Chery Automobile Co., Ltd.

Page 47 of 1903

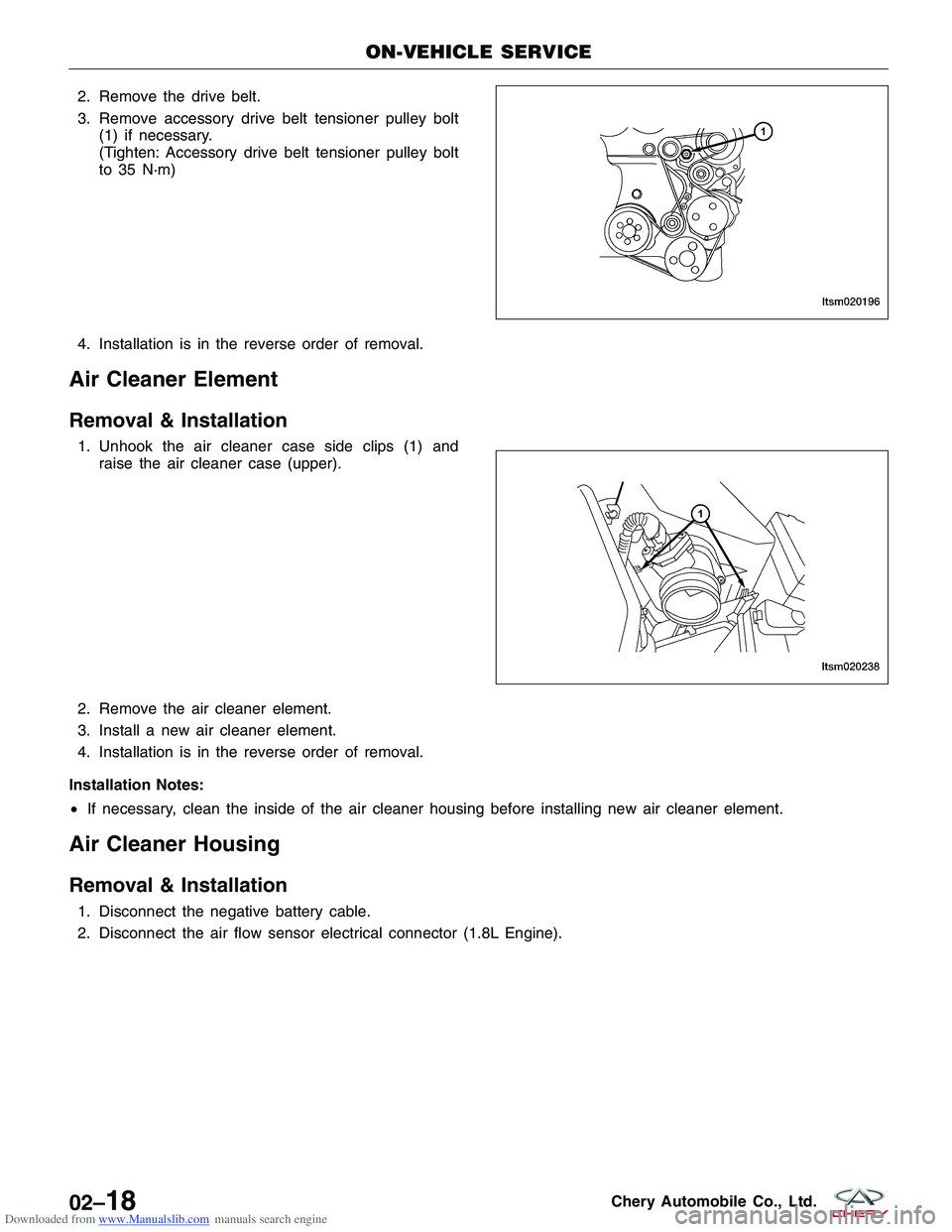

Downloaded from www.Manualslib.com manuals search engine 2. Remove the drive belt.

3. Remove accessory drive belt tensioner pulley bolt(1) if necessary.

(Tighten: Accessory drive belt tensioner pulley bolt

to 35 N·m)

4. Installation is in the reverse order of removal.

Air Cleaner Element

Removal & Installation

1. Unhook the air cleaner case side clips (1) and raise the air cleaner case (upper).

2. Remove the air cleaner element.

3. Install a new air cleaner element.

4. Installation is in the reverse order of removal.

Installation Notes:

• If necessary, clean the inside of the air cleaner housing before installing new air cleaner element.

Air Cleaner Housing

Removal & Installation

1. Disconnect the negative battery cable.

2. Disconnect the air flow sensor electrical connector (1.8L Engine).

ON-VEHICLE SERVICE

LTSM020196

LTSM020238

02–18Chery Automobile Co., Ltd.

Page 48 of 1903

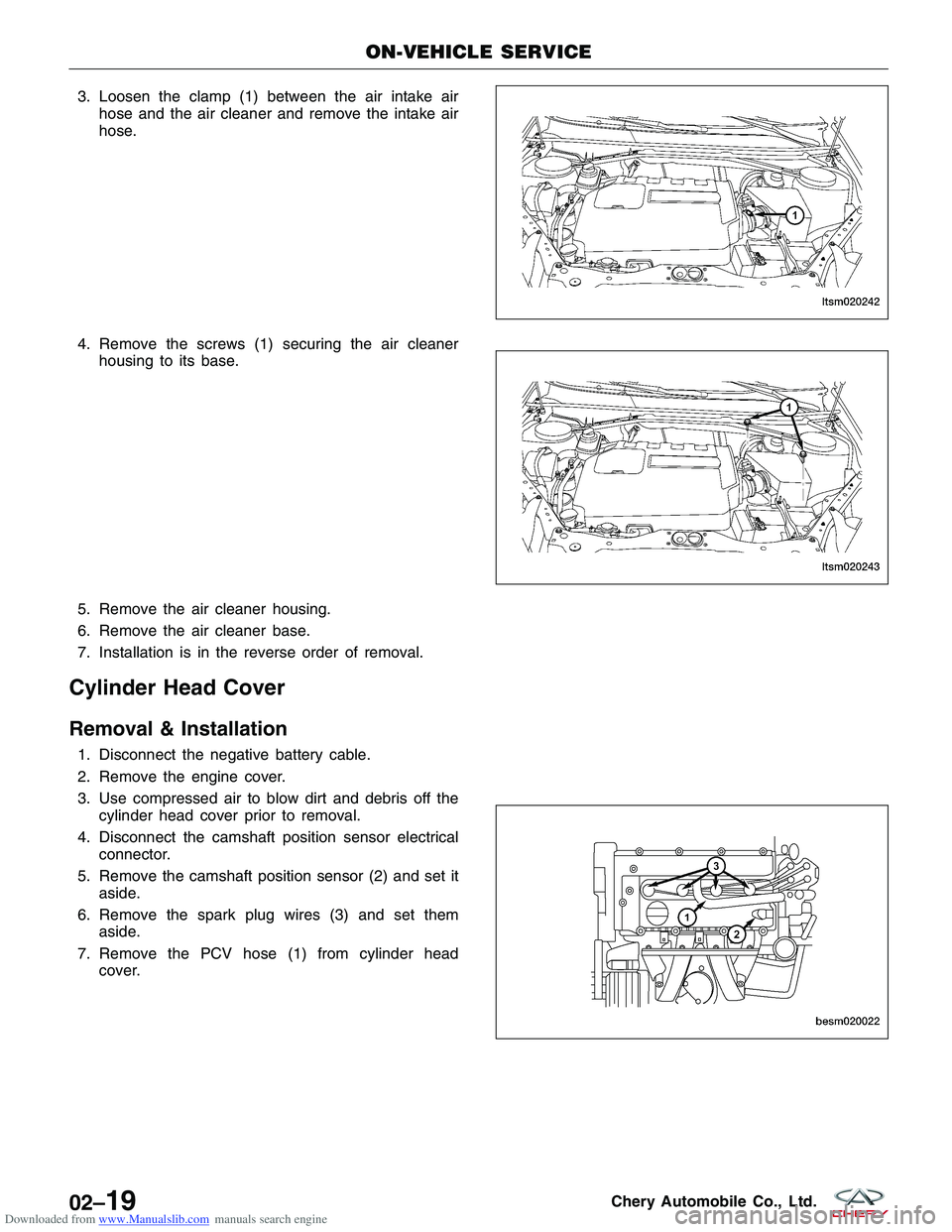

Downloaded from www.Manualslib.com manuals search engine 3. Loosen the clamp (1) between the air intake airhose and the air cleaner and remove the intake air

hose.

4. Remove the screws (1) securing the air cleaner housing to its base.

5. Remove the air cleaner housing.

6. Remove the air cleaner base.

7. Installation is in the reverse order of removal.

Cylinder Head Cover

Removal & Installation

1. Disconnect the negative battery cable.

2. Remove the engine cover.

3. Use compressed air to blow dirt and debris off the cylinder head cover prior to removal.

4. Disconnect the camshaft position sensor electrical connector.

5. Remove the camshaft position sensor (2) and set it aside.

6. Remove the spark plug wires (3) and set them aside.

7. Remove the PCV hose (1) from cylinder head cover.

ON-VEHICLE SERVICE

LTSM020242

LTSM020243

BESM020022

02–19Chery Automobile Co., Ltd.

Page 61 of 1903

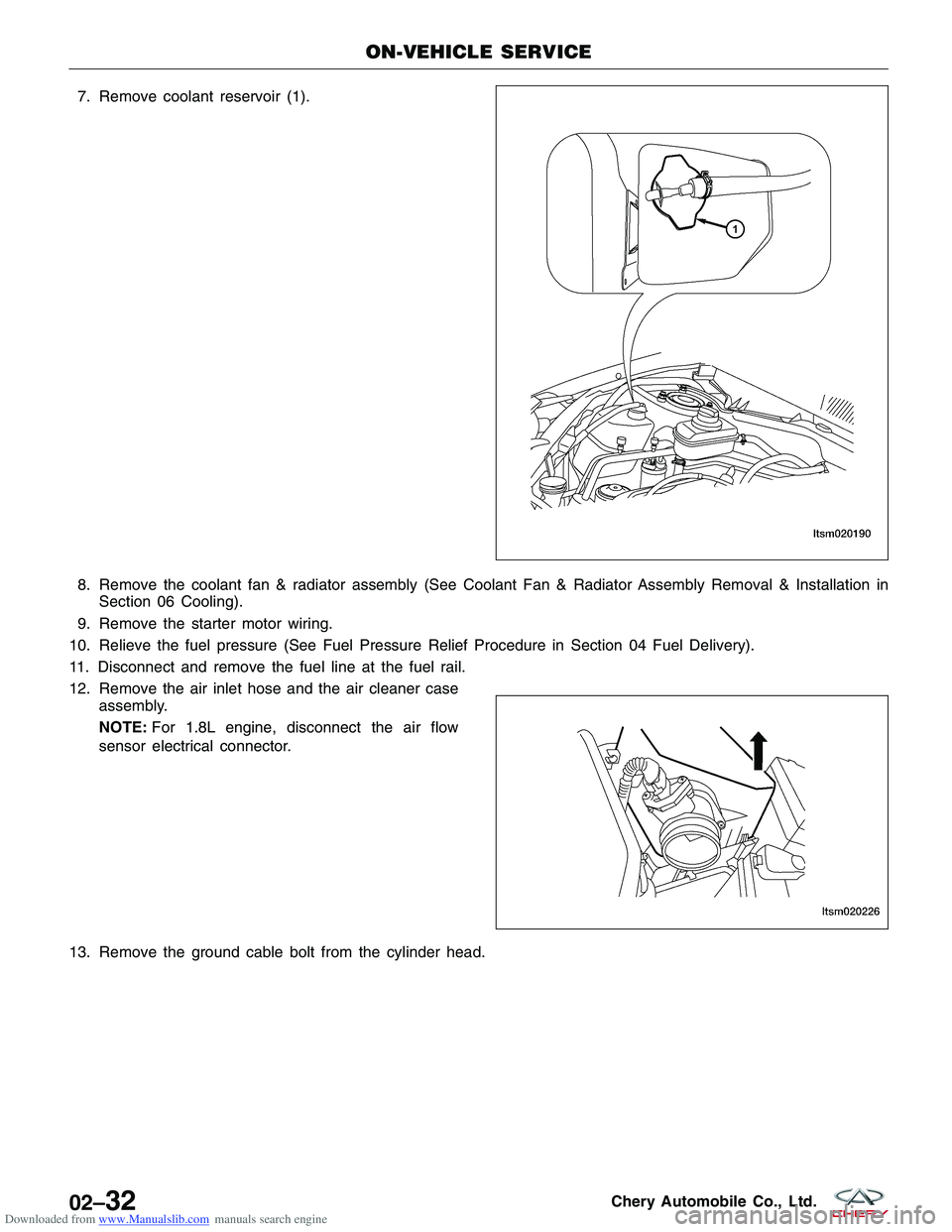

Downloaded from www.Manualslib.com manuals search engine 7. Remove coolant reservoir (1).

8. Remove the coolant fan & radiator assembly (See Coolant Fan & Radiator Assembly Removal & Installation inSection 06 Cooling).

9. Remove the starter motor wiring.

10. Relieve the fuel pressure (See Fuel Pressure Relief Procedure in Section 04 Fuel Delivery).

11. Disconnect and remove the fuel line at the fuel rail.

12. Remove the air inlet hose and the air cleaner case assembly.

NOTE: For 1.8L engine, disconnect the air flow

sensor electrical connector.

13. Remove the ground cable bolt from the cylinder head.

ON-VEHICLE SERVICE

LTSM020190

LTSM020226

02–32Chery Automobile Co., Ltd.

Page 62 of 1903

Downloaded from www.Manualslib.com manuals search engine 14.Disconnectandremovethefollowingelectricalconnectors:

€Coolanttemperaturesensor

€Camshaftpositionsensor

€Ignitioncoil

€Fourfuelinjectors

€Intakemanifoldairpressuresensor(1.6L)

€Airflowsensor(1.8L)

€Carboncanistersolenoidvalve

€Throttlebodycontrol

€A/Ccompressor

€Oilpressuresensor

€Powersteeringpumppressureswitch

€Generator

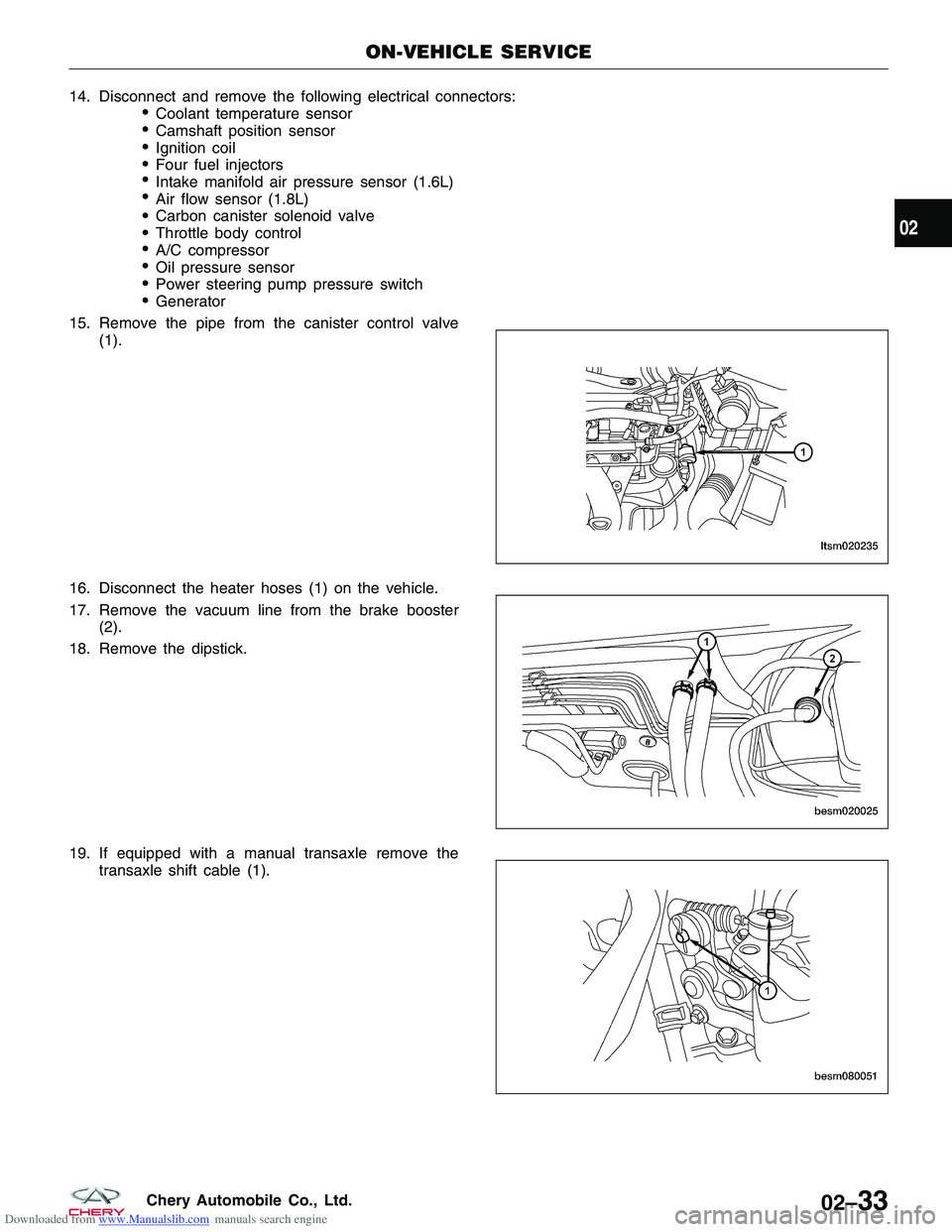

15.Removethepipefromthecanistercontrolvalve

(1).

16.Disconnecttheheaterhoses(1)onthevehicle.

17.Removethevacuumlinefromthebrakebooster

(2).

18.Removethedipstick.

19.Ifequippedwithamanualtransaxleremovethe

transaxleshiftcable(1).

ON-VEHICLESERVICE

LTSM020235

BESM020025

BESM080051

02

02–33CheryAutomobileCo.,Ltd.

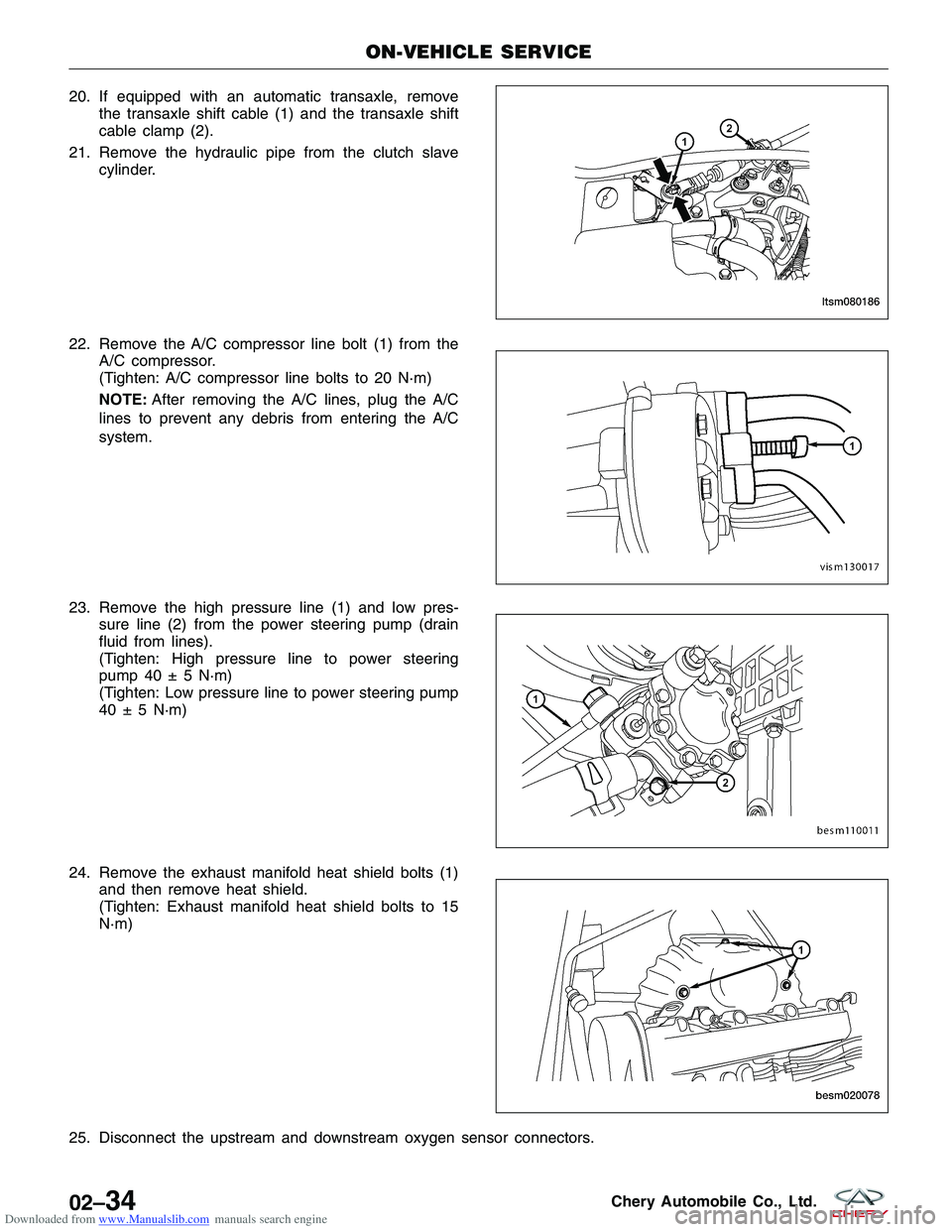

Page 63 of 1903

Downloaded from www.Manualslib.com manuals search engine 20. If equipped with an automatic transaxle, removethe transaxle shift cable (1) and the transaxle shift

cable clamp (2).

21. Remove the hydraulic pipe from the clutch slave cylinder.

22. Remove the A/C compressor line bolt (1) from the A/C compressor.

(Tighten: A/C compressor line bolts to 20 N·m)

NOTE: After removing the A/C lines, plug the A/C

lines to prevent any debris from entering the A/C

system.

23. Remove the high pressure line (1) and low pres- sure line (2) from the power steering pump (drain

fluid from lines).

(Tighten: High pressure line to power steering

pump 40 ± 5 N·m)

(Tighten: Low pressure line to power steering pump

40 ± 5 N·m)

24. Remove the exhaust manifold heat shield bolts (1) and then remove heat shield.

(Tighten: Exhaust manifold heat shield bolts to 15

N·m)

25. Disconnect the upstream and downstream oxygen sensor connectors.

ON-VEHICLE SERVICE

LTSM080186

VISM130017

BESM110011

BESM020078

02–34Chery Automobile Co., Ltd.