brake CHERY TIGGO 2009 Service Repair Manual

[x] Cancel search | Manufacturer: CHERY, Model Year: 2009, Model line: TIGGO, Model: CHERY TIGGO 2009Pages: 1903, PDF Size: 33.38 MB

Page 1479 of 1903

Downloaded from www.Manualslib.com manuals search engine ON-VEHICLE SERVICE

Parking Brake Lever

Removal & Installation

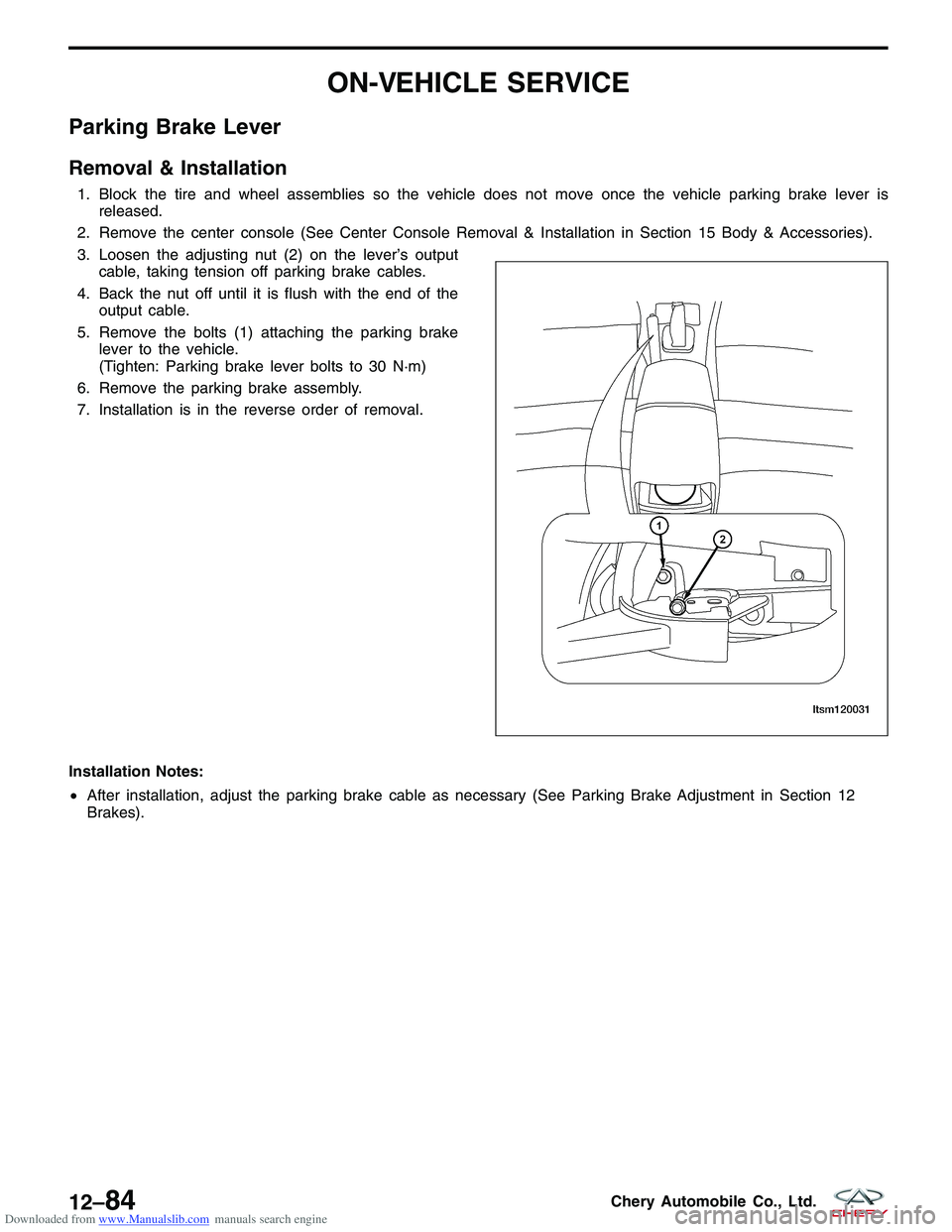

1. Block the tire and wheel assemblies so the vehicle does not move once the vehicle parking brake lever isreleased.

2. Remove the center console (See Center Console Removal & Installation in Section 15 Body & Accessories).

3. Loosen the adjusting nut (2) on the lever’s output cable, taking tension off parking brake cables.

4. Back the nut off until it is flush with the end of the output cable.

5. Remove the bolts (1) attaching the parking brake lever to the vehicle.

(Tighten: Parking brake lever bolts to 30 N·m)

6. Remove the parking brake assembly.

7. Installation is in the reverse order of removal.

Installation Notes:

• After installation, adjust the parking brake cable as necessary (See Parking Brake Adjustment in Section 12

Brakes).

LTSM120031

12–84Chery Automobile Co., Ltd.

Page 1480 of 1903

Downloaded from www.Manualslib.com manuals search engine Parking Brake Cable

Removal & Installation

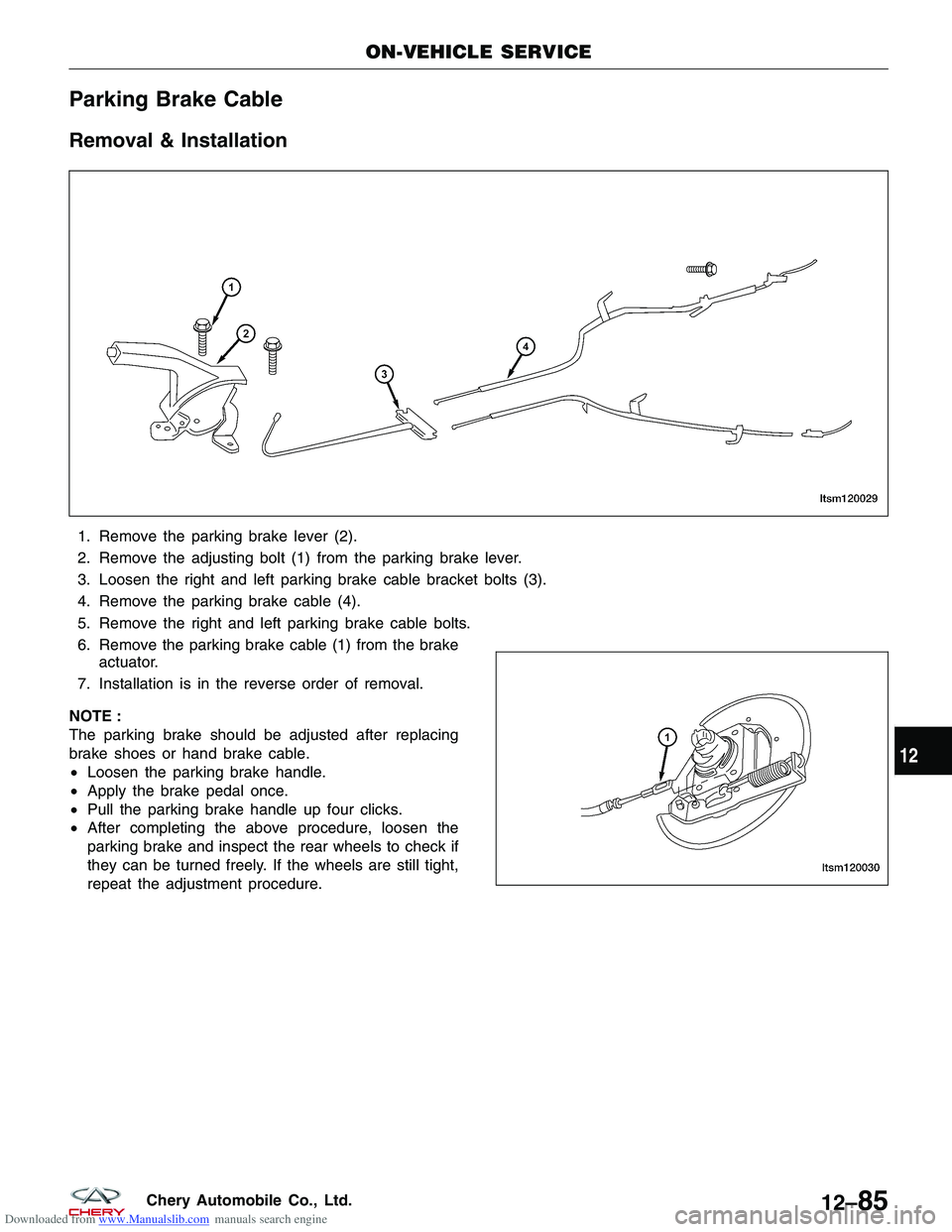

1. Remove the parking brake lever (2).

2. Remove the adjusting bolt (1) from the parking brake lever.

3. Loosen the right and left parking brake cable bracket bolts (3).

4. Remove the parking brake cable (4).

5. Remove the right and left parking brake cable bolts.

6. Remove the parking brake cable (1) from the brakeactuator.

7. Installation is in the reverse order of removal.

NOTE :

The parking brake should be adjusted after replacing

brake shoes or hand brake cable.

• Loosen the parking brake handle.

• Apply the brake pedal once.

• Pull the parking brake handle up four clicks.

• After completing the above procedure, loosen the

parking brake and inspect the rear wheels to check if

they can be turned freely. If the wheels are still tight,

repeat the adjustment procedure.

ON-VEHICLE SERVICE

LTSM120029

LTSM120030

12

12–85Chery Automobile Co., Ltd.

Page 1481 of 1903

Downloaded from www.Manualslib.com manuals search engine Parking Brake Shoes

Removal & Installation

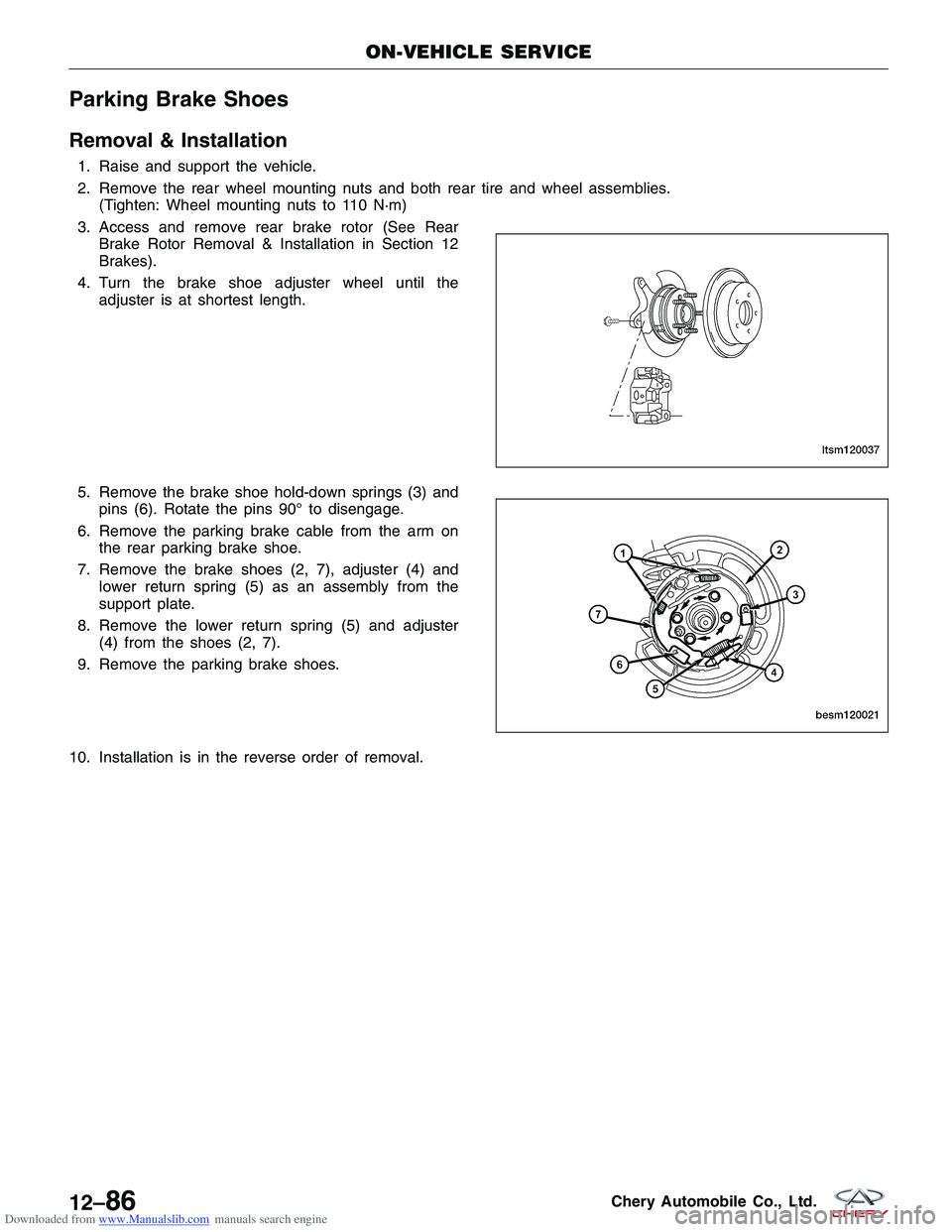

1. Raise and support the vehicle.

2. Remove the rear wheel mounting nuts and both rear tire and wheel assemblies.(Tighten: Wheel mounting nuts to 110 N·m)

3. Access and remove rear brake rotor (See Rear Brake Rotor Removal & Installation in Section 12

Brakes).

4. Turn the brake shoe adjuster wheel until the adjuster is at shortest length.

5. Remove the brake shoe hold-down springs (3) and pins (6). Rotate the pins 90° to disengage.

6. Remove the parking brake cable from the arm on the rear parking brake shoe.

7. Remove the brake shoes (2, 7), adjuster (4) and lower return spring (5) as an assembly from the

support plate.

8. Remove the lower return spring (5) and adjuster (4) from the shoes (2, 7).

9. Remove the parking brake shoes.

10. Installation is in the reverse order of removal.

ON-VEHICLE SERVICE

LTSM120037

BESM120021

12–86Chery Automobile Co., Ltd.

Page 1482 of 1903

Downloaded from www.Manualslib.com manuals search engine Installation Notes:

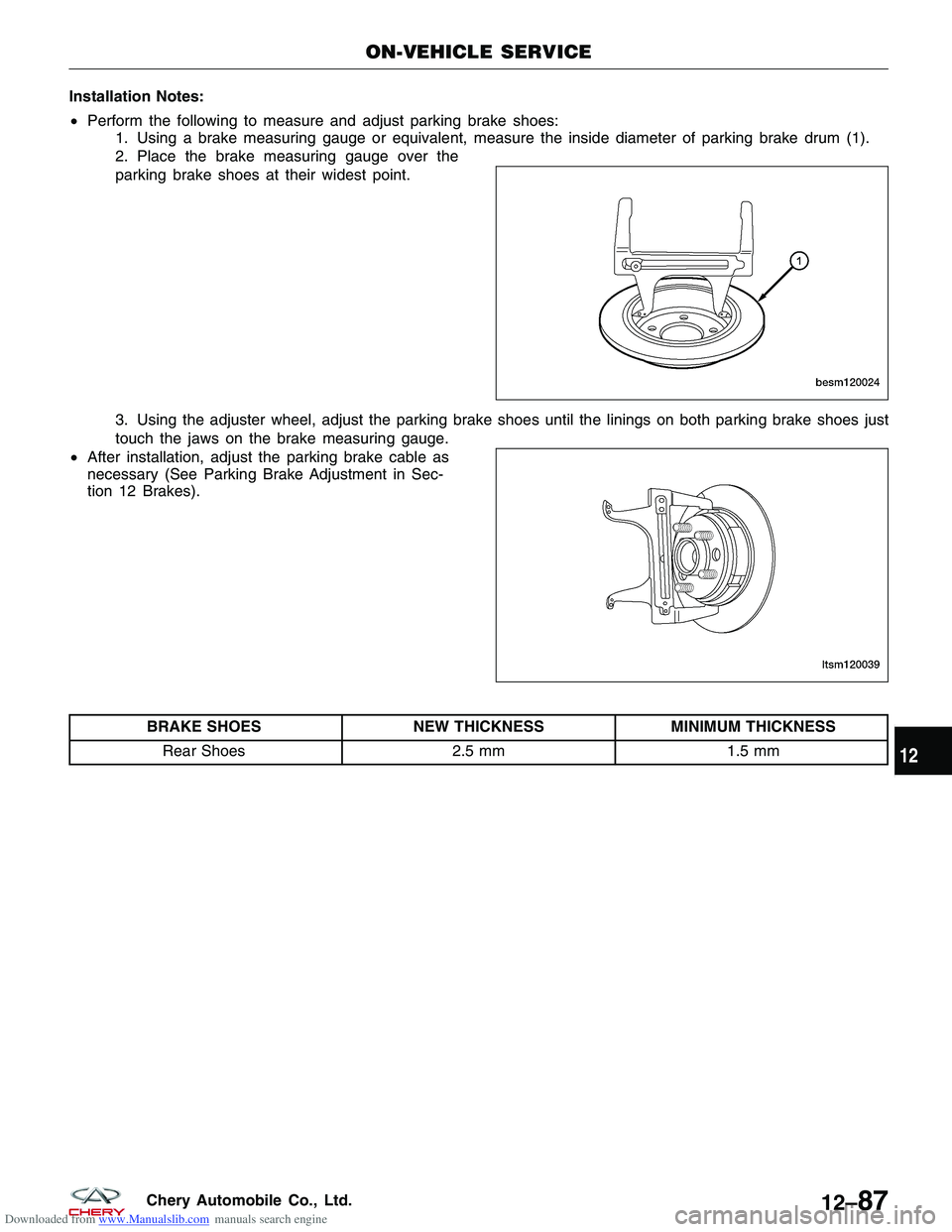

•Perform the following to measure and adjust parking brake shoes:

1. Using a brake measuring gauge or equivalent, measure the inside diameter of parking brake drum (1).

2. Place the brake measuring gauge over the

parking brake shoes at their widest point.

3. Using the adjuster wheel, adjust the parking brake shoes until the linings on both parking brake shoes just

touch the jaws on the brake measuring gauge.

• After installation, adjust the parking brake cable as

necessary (See Parking Brake Adjustment in Sec-

tion 12 Brakes).

BRAKE SHOES NEW THICKNESSMINIMUM THICKNESS

Rear Shoes 2.5 mm1.5 mm

ON-VEHICLE SERVICE

BESM120024

LTSM120039

12

12–87Chery Automobile Co., Ltd.

Page 1518 of 1903

Downloaded from www.Manualslib.com manuals search engine 12. If the noise is from liquid refrigerant slugging in the A/C suction line, replace the A/C accumulator and check therefrigerant oil level and the refrigerant system charge.

13. If a slugging condition still exists after replacing the A/C accumulator, replace the A/C compressor.

Refrigerant System Leaks

WARNING!

R-134a service equipment or vehicle A/C systems should not be pressure tested or leak tested with compressed

air. Mixture of air and R-134a can be combustible at elevated pressures. These mixtures are potentially danger-

ous and may result in fire or explosion causing property damage, personal injury or death. Avoid breathing A/C

refrigerant and lubricant vapor or mist. Exposure may irritate eyes, nose and throat. Use only approved service

equipment meeting SAE requirements to discharge an R-134a system. If accidental system discharge occurs,

ventilate work area before resuming service.

NOTE :

If the A/C refrigerant system charge is empty or low, a leak in the A/C system is likely. Inspect all A/C lines, fittings

and components for an oily residue. Oil residue can be an indicator of an A/C system leak location.

NOTE :

The only way to correctly determine if the refrigerant system is fully charged with R-134a is to completely evacuate

and recharge the A/C system.

Refrigerant System Empty

1. Evacuate the refrigerant system to the lowest degree of vacuum possible. Determine if the system holds a vac- uum for 15 minutes. If vacuum is held, a leak is probably not present. If system will not maintain vacuum level,

proceed to STEP 2.

2. Prepare and dispense 0.3 kilograms of R-134a refrigerant into the evacuated refrigerant system and proceed to STEP 1 of the System Low procedure.

Refrigerant System Low

1. Position the vehicle in a wind-free work area. This will aid in detecting small leaks.

2. Operate the heating-A/C system with the engine at idle under the following conditions for at least 5 minutes:Doors or windows open, transaxle in Park or Neutral with the parking brake set (depending on application), A/C-

Heater controls set to outside air, full cool, panel mode, high blower and with A/C compressor engaged.

3. Shut the vehicle Off and wait2-7minutes. Then use an electronic leak detector that is designed to detect R-134a refrigerant and search for leaks. Fittings, lines or components that appear to be oily usually indicate a

refrigerant leak. To inspect the A/C evaporator for leaks, insert the leak detector probe into the drain tube open-

ing or an air outlet. A dye for R-134a is available to aid in leak detection. Use only approved refrigerant dye.

CAUTION:

A leak detector only designed for R-12 refrigerant will not detect leaks in an R-134a refrigerant sys-

tem.

DIAGNOSIS & TESTING

13–36Chery Automobile Co., Ltd.

Page 1603 of 1903

Downloaded from www.Manualslib.com manuals search engine CHIME

Description

The chime is located in the Instrument Cluster (IC). The chime warning system is an audible notification to the driver.

The chime warning system is designed to alert the driver of a vehicle problem or condition.

Operation

The Instrument Cluster (IC) uses hard wired inputs from various sensors and switches to activate the chime. The

sensors and switches are located throughout the vehicle. The following conditions will cause the chime to operate:

•Turn signal on

• Hazard warning flashers on

• Seat belt unbuckled

• Low fuel level

• Low oil pressure

• Low brake fluid level

• Doors unlocked

CHIME

15

15–19Chery Automobile Co., Ltd.

Page 1636 of 1903

Downloaded from www.Manualslib.com manuals search engine INSTRUMENT CLUSTER

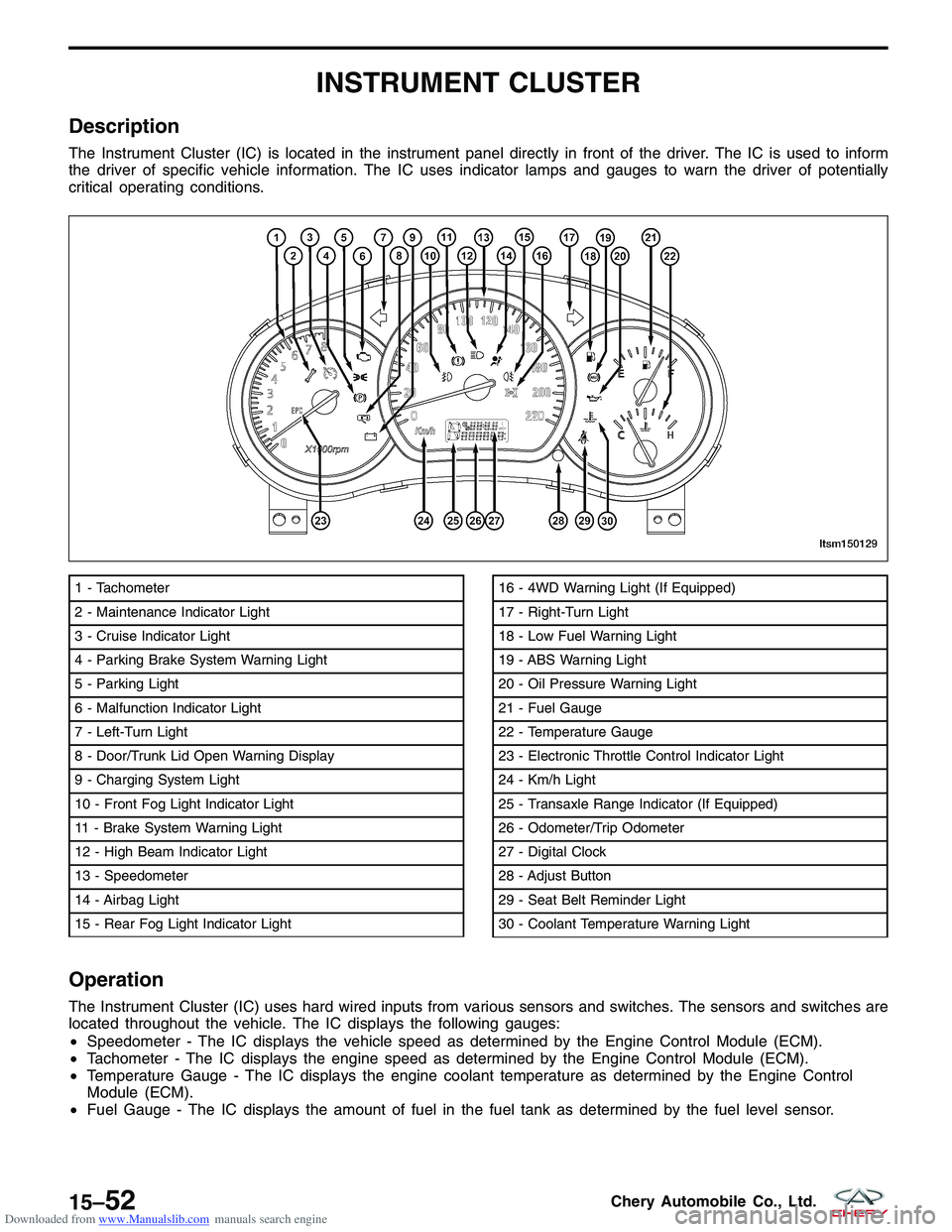

Description

The Instrument Cluster (IC) is located in the instrument panel directly in front of the driver. The IC is used to inform

the driver of specific vehicle information. The IC uses indicator lamps and gauges to warn the driver of potentially

critical operating conditions.

Operation

The Instrument Cluster (IC) uses hard wired inputs from various sensors and switches. The sensors and switches are

located throughout the vehicle. The IC displays the following gauges:

•Speedometer - The IC displays the vehicle speed as determined by the Engine Control Module (ECM).

• Tachometer - The IC displays the engine speed as determined by the Engine Control Module (ECM).

• Temperature Gauge - The IC displays the engine coolant temperature as determined by the Engine Control

Module (ECM).

• Fuel Gauge - The IC displays the amount of fuel in the fuel tank as determined by the fuel level sensor.

1 - Tachometer

2 - Maintenance Indicator Light

3 - Cruise Indicator Light

4 - Parking Brake System Warning Light

5 - Parking Light

6 - Malfunction Indicator Light

7 - Left-Turn Light

8 - Door/Trunk Lid Open Warning Display

9 - Charging System Light

10 - Front Fog Light Indicator Light

11 - Brake System Warning Light

12 - High Beam Indicator Light

13 - Speedometer

14 - Airbag Light

15 - Rear Fog Light Indicator Light16 - 4WD Warning Light (If Equipped)

17 - Right-Turn Light

18 - Low Fuel Warning Light

19 - ABS Warning Light

20 - Oil Pressure Warning Light

21 - Fuel Gauge

22 - Temperature Gauge

23 - Electronic Throttle Control Indicator Light

24 - Km/h Light

25 - Transaxle Range Indicator (If Equipped)

26 - Odometer/Trip Odometer

27 - Digital Clock

28 - Adjust Button

29 - Seat Belt Reminder Light

30 - Coolant Temperature Warning Light

LTSM150129

15–52Chery Automobile Co., Ltd.

Page 1646 of 1903

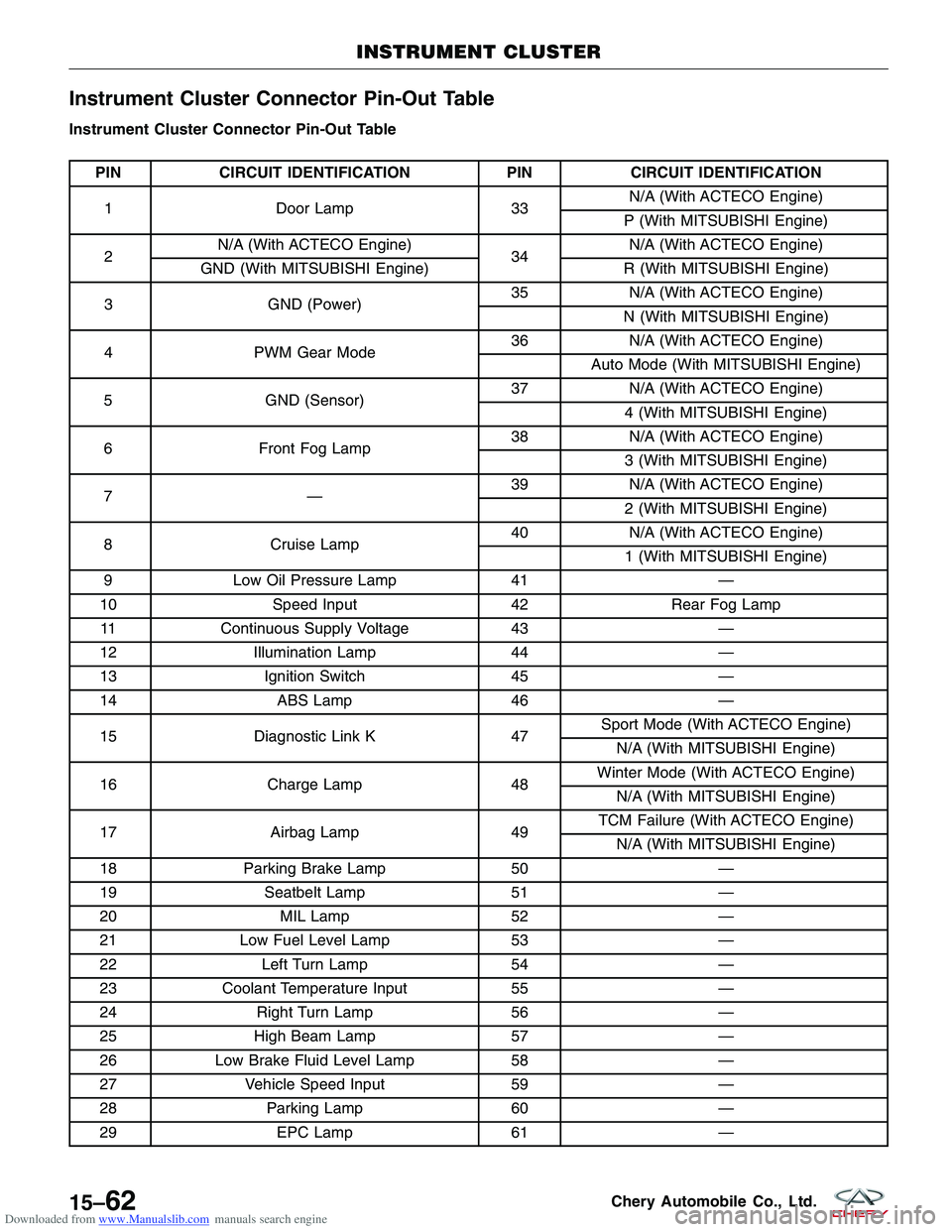

Downloaded from www.Manualslib.com manuals search engine Instrument Cluster Connector Pin-Out Table

Instrument Cluster Connector Pin-Out Table

PINCIRCUIT IDENTIFICATION PINCIRCUIT IDENTIFICATION

1 Door Lamp 33N/A (With ACTECO Engine)

P (With MITSUBISHI Engine)

2 N/A (With ACTECO Engine)

34N/A (With ACTECO Engine)

GND (With MITSUBISHI Engine) R (With MITSUBISHI Engine)

3 GND (Power) 35

N/A (With ACTECO Engine)

N (With MITSUBISHI Engine)

4 PWM Gear Mode 36

N/A (With ACTECO Engine)

Auto Mode (With MITSUBISHI Engine)

5 GND (Sensor) 37

N/A (With ACTECO Engine)

4 (With MITSUBISHI Engine)

6 Front Fog Lamp 38

N/A (With ACTECO Engine)

3 (With MITSUBISHI Engine)

7— 39

N/A (With ACTECO Engine)

2 (With MITSUBISHI Engine)

8 Cruise Lamp 40

N/A (With ACTECO Engine)

1 (With MITSUBISHI Engine)

9 Low Oil Pressure Lamp 41—

10 Speed Input 42Rear Fog Lamp

11 Continuous Supply Voltage 43—

12 Illumination Lamp 44—

13 Ignition Switch 45—

14 ABS Lamp 46—

15 Diagnostic Link K 47Sport Mode (With ACTECO Engine)

N/A (With MITSUBISHI Engine)

16 Charge Lamp 48Winter Mode (With ACTECO Engine)

N/A (With MITSUBISHI Engine)

17 Airbag Lamp 49TCM Failure (With ACTECO Engine)

N/A (With MITSUBISHI Engine)

18 Parking Brake Lamp 50—

19 Seatbelt Lamp 51—

20 MIL Lamp 52—

21 Low Fuel Level Lamp 53—

22 Left Turn Lamp 54—

23 Coolant Temperature Input 55—

24 Right Turn Lamp 56—

25 High Beam Lamp 57—

26 Low Brake Fluid Level Lamp 58—

27 Vehicle Speed Input 59—

28 Parking Lamp 60—

29 EPC Lamp 61—

INSTRUMENT CLUSTER

15–62Chery Automobile Co., Ltd.

Page 1762 of 1903

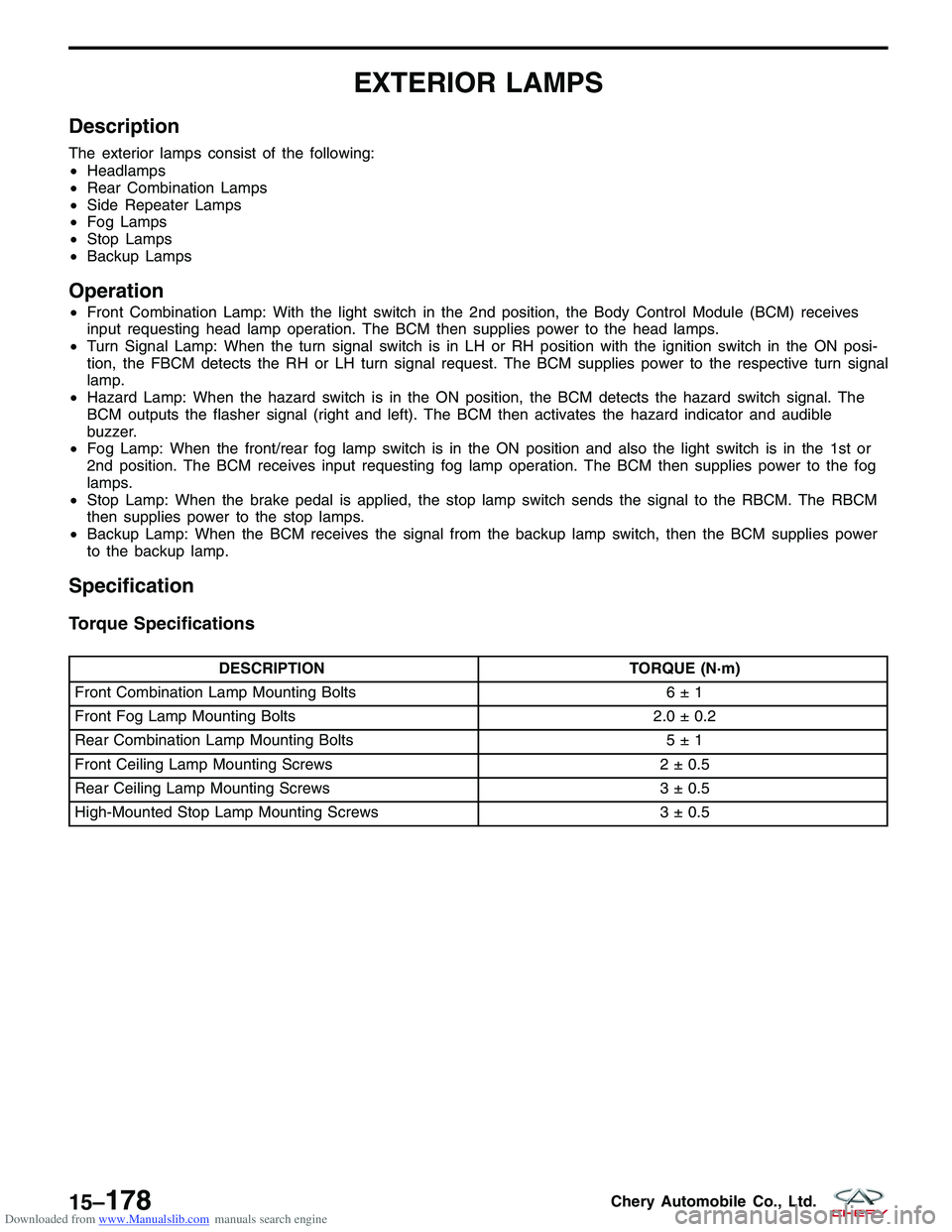

Downloaded from www.Manualslib.com manuals search engine EXTERIOR LAMPS

Description

The exterior lamps consist of the following:

•Headlamps

• Rear Combination Lamps

• Side Repeater Lamps

• Fog Lamps

• Stop Lamps

• Backup Lamps

Operation

•Front Combination Lamp: With the light switch in the 2nd position, the Body Control Module (BCM) receives

input requesting head lamp operation. The BCM then supplies power to the head lamps.

• Turn Signal Lamp: When the turn signal switch is in LH or RH position with the ignition switch in the ON posi-

tion, the FBCM detects the RH or LH turn signal request. The BCM supplies power to the respective turn signal

lamp.

• Hazard Lamp: When the hazard switch is in the ON position, the BCM detects the hazard switch signal. The

BCM outputs the flasher signal (right and left). The BCM then activates the hazard indicator and audible

buzzer.

• Fog Lamp: When the front/rear fog lamp switch is in the ON position and also the light switch is in the 1st or

2nd position. The BCM receives input requesting fog lamp operation. The BCM then supplies power to the fog

lamps.

• Stop Lamp: When the brake pedal is applied, the stop lamp switch sends the signal to the RBCM. The RBCM

then supplies power to the stop lamps.

• Backup Lamp: When the BCM receives the signal from the backup lamp switch, then the BCM supplies power

to the backup lamp.

Specification

Torque Specifications

DESCRIPTION TORQUE (N·m)

Front Combination Lamp Mounting Bolts 6 ± 1

Front Fog Lamp Mounting Bolts 2.0 ± 0.2

Rear Combination Lamp Mounting Bolts 5 ± 1

Front Ceiling Lamp Mounting Screws 2 ± 0.5

Rear Ceiling Lamp Mounting Screws 3 ± 0.5

High-Mounted Stop Lamp Mounting Screws 3 ± 0.5

15–178Chery Automobile Co., Ltd.

Page 1875 of 1903

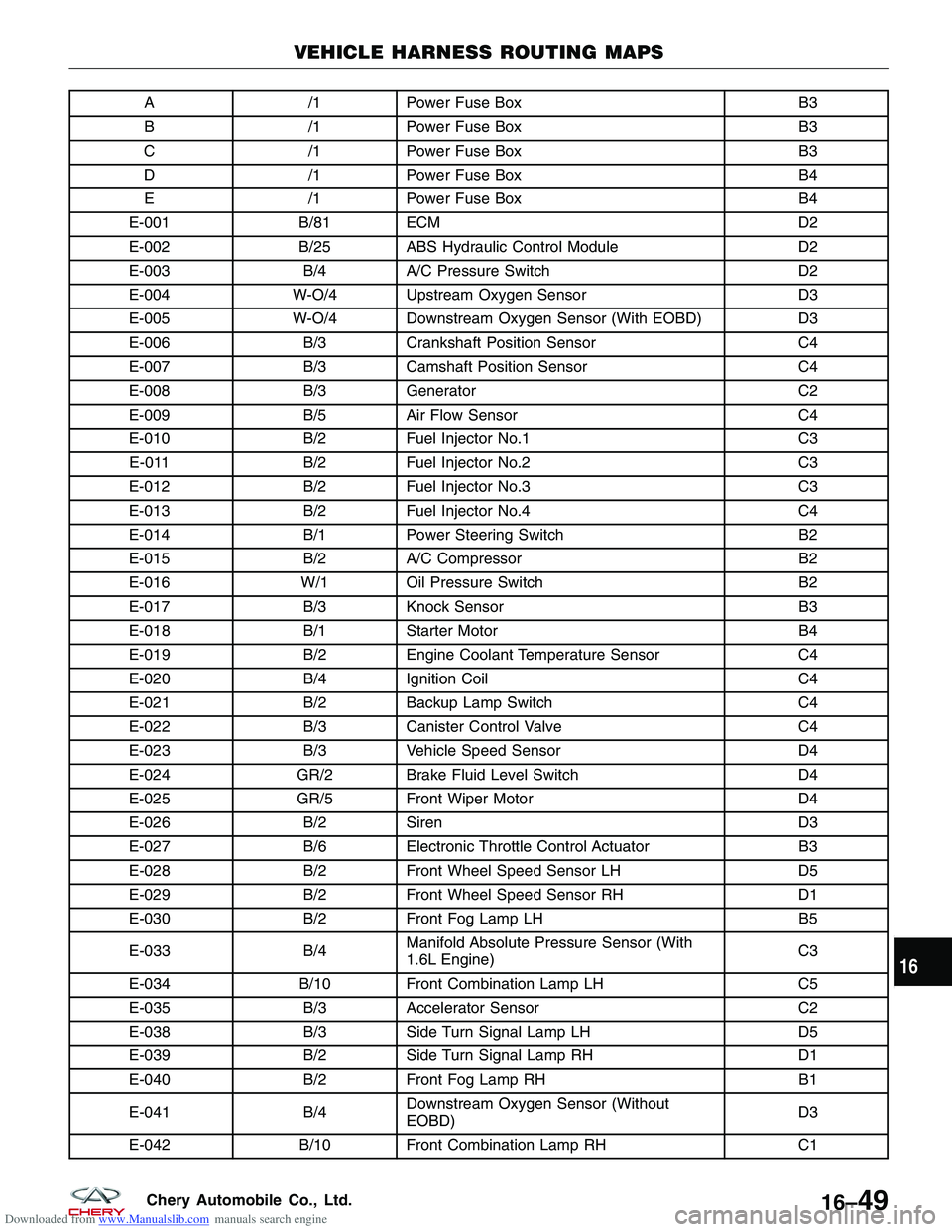

Downloaded from www.Manualslib.com manuals search engine A/1Power Fuse Box B3

B /1Power Fuse Box B3

C /1Power Fuse Box B3

D /1Power Fuse Box B4

E /1Power Fuse Box B4

E-001 B/81 ECM D2

E-002 B/25 ABS Hydraulic Control Module D2

E-003 B/4A/C Pressure Switch D2

E-004 W-O/4 Upstream Oxygen Sensor D3

E-005 W-O/4 Downstream Oxygen Sensor (With EOBD) D3

E-006 B/3Crankshaft Position Sensor C4

E-007 B/3Camshaft Position Sensor C4

E-008 B/3Generator C2

E-009 B/5Air Flow Sensor C4

E-010 B/2Fuel Injector No.1 C3

E-011 B/2Fuel Injector No.2 C3

E-012 B/2Fuel Injector No.3 C3

E-013 B/2Fuel Injector No.4 C4

E-014 B/1Power Steering Switch B2

E-015 B/2A/C Compressor B2

E-016 W/1 Oil Pressure Switch B2

E-017 B/3Knock Sensor B3

E-018 B/1Starter Motor B4

E-019 B/2Engine Coolant Temperature Sensor C4

E-020 B/4Ignition Coil C4

E-021 B/2Backup Lamp Switch C4

E-022 B/3Canister Control Valve C4

E-023 B/3Vehicle Speed Sensor D4

E-024 GR/2 Brake Fluid Level Switch D4

E-025 GR/5 Front Wiper Motor D4

E-026 B/2Siren D3

E-027 B/6Electronic Throttle Control Actuator B3

E-028 B/2Front Wheel Speed Sensor LH D5

E-029 B/2Front Wheel Speed Sensor RH D1

E-030 B/2Front Fog Lamp LH B5

E-033 B/4Manifold Absolute Pressure Sensor (With

1.6L Engine) C3

E-034 B/10 Front Combination Lamp LH C5

E-035 B/3Accelerator Sensor C2

E-038 B/3Side Turn Signal Lamp LH D5

E-039 B/2Side Turn Signal Lamp RH D1

E-040 B/2Front Fog Lamp RH B1

E-041 B/4Downstream Oxygen Sensor (Without

EOBD) D3

E-042 B/10 Front Combination Lamp RH C1

VEHICLE HARNESS ROUTING MAPS

16

16–49Chery Automobile Co., Ltd.