catalytic converter CHERY TIGGO 2009 Service User Guide

[x] Cancel search | Manufacturer: CHERY, Model Year: 2009, Model line: TIGGO, Model: CHERY TIGGO 2009Pages: 1903, PDF Size: 33.38 MB

Page 941 of 1903

Downloaded from www.Manualslib.com manuals search engine ON-VEHICLE SERVICE

Exhaust Pipe Assembly

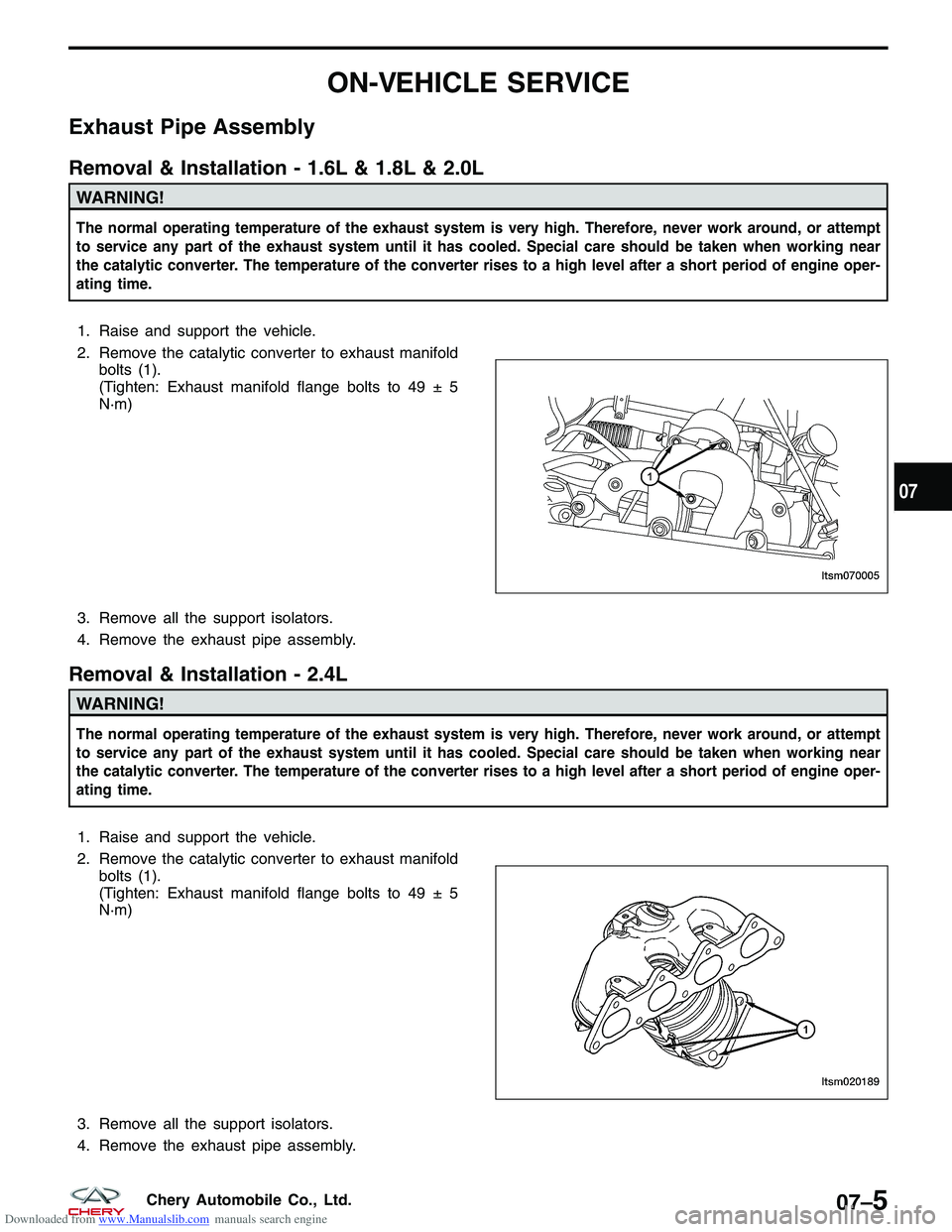

Removal & Installation - 1.6L & 1.8L & 2.0L

WARNING!

The normal operating temperature of the exhaust system is very high. Therefore, never work around, or attempt

to service any part of the exhaust system until it has cooled. Special care should be taken when working near

the catalytic converter. The temperature of the converter rises to a high level after a short period of engine oper-

ating time.

1. Raise and support the vehicle.

2. Remove the catalytic converter to exhaust manifoldbolts (1).

(Tighten: Exhaust manifold flange bolts to 49 ± 5

N·m)

3. Remove all the support isolators.

4. Remove the exhaust pipe assembly.

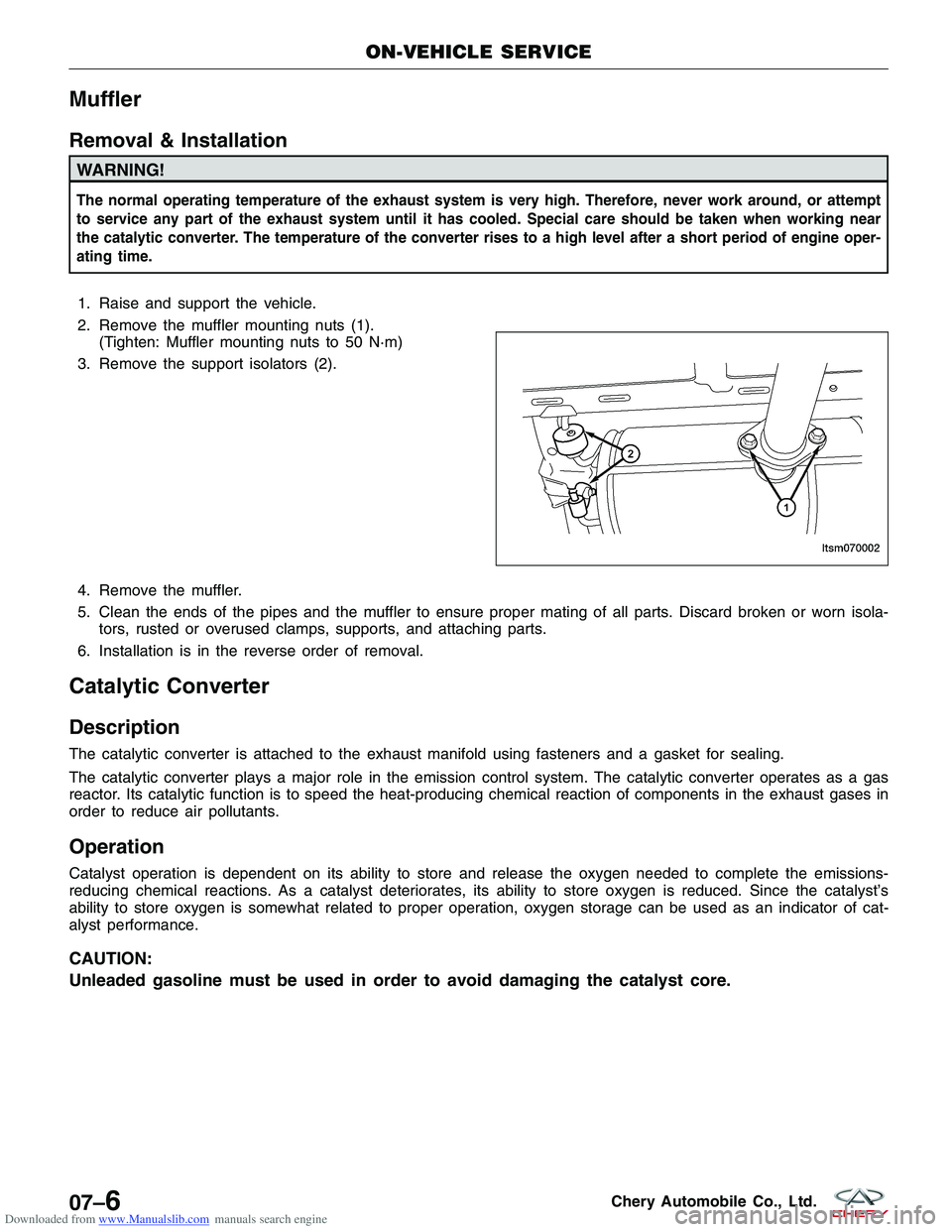

Removal & Installation - 2.4L

WARNING!

The normal operating temperature of the exhaust system is very high. Therefore, never work around, or attempt

to service any part of the exhaust system until it has cooled. Special care should be taken when working near

the catalytic converter. The temperature of the converter rises to a high level after a short period of engine oper-

ating time.

1. Raise and support the vehicle.

2. Remove the catalytic converter to exhaust manifold bolts (1).

(Tighten: Exhaust manifold flange bolts to 49 ± 5

N·m)

3. Remove all the support isolators.

4. Remove the exhaust pipe assembly.

LTSM070005

LTSM020189

07

07–5Chery Automobile Co., Ltd.

Page 942 of 1903

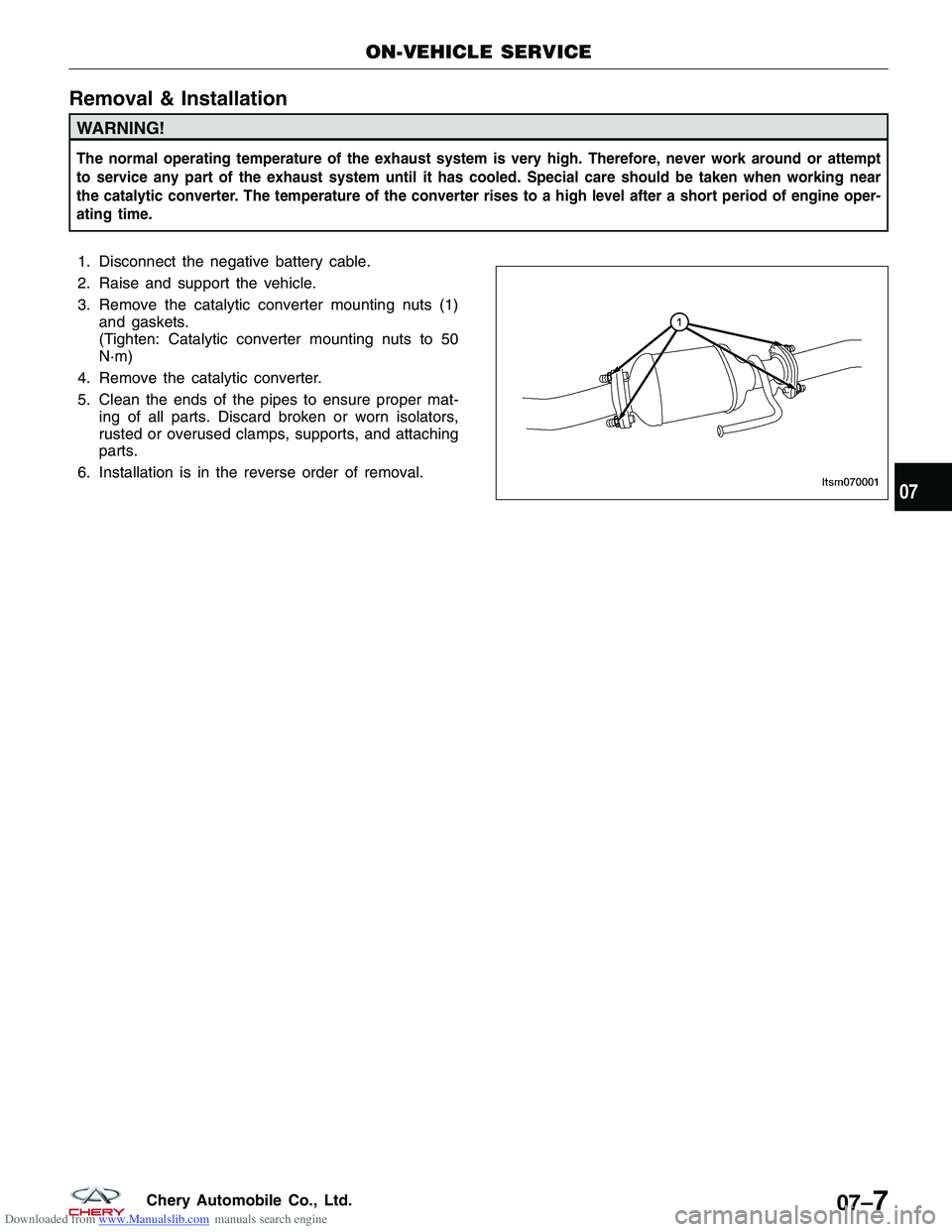

Downloaded from www.Manualslib.com manuals search engine Muffler

Removal & Installation

WARNING!

The normal operating temperature of the exhaust system is very high. Therefore, never work around, or attempt

to service any part of the exhaust system until it has cooled. Special care should be taken when working near

the catalytic converter. The temperature of the converter rises to a high level after a short period of engine oper-

ating time.

1. Raise and support the vehicle.

2. Remove the muffler mounting nuts (1).(Tighten: Muffler mounting nuts to 50 N·m)

3. Remove the support isolators (2).

4. Remove the muffler.

5. Clean the ends of the pipes and the muffler to ensure proper mating of all parts. Discard broken or worn isola- tors, rusted or overused clamps, supports, and attaching parts.

6. Installation is in the reverse order of removal.

Catalytic Converter

Description

The catalytic converter is attached to the exhaust manifold using fasteners and a gasket for sealing.

The catalytic converter plays a major role in the emission control system. The catalytic converter operates as a gas

reactor. Its catalytic function is to speed the heat-producing chemical reaction of components in the exhaust gases in

order to reduce air pollutants.

Operation

Catalyst operation is dependent on its ability to store and release the oxygen needed to complete the emissions-

reducing chemical reactions. As a catalyst deteriorates, its ability to store oxygen is reduced. Since the catalyst’s

ability to store oxygen is somewhat related to proper operation, oxygen storage can be used as an indicator of cat-

alyst performance.

CAUTION:

Unleaded gasoline must be used in order to avoid damaging the catalyst core.

ON-VEHICLE SERVICE

LTSM070002

07–6Chery Automobile Co., Ltd.

Page 943 of 1903

Downloaded from www.Manualslib.com manuals search engine Removal & Installation

WARNING!

The normal operating temperature of the exhaust system is very high. Therefore, never work around or attempt

to service any part of the exhaust system until it has cooled. Special care should be taken when working near

the catalytic converter. The temperature of the converter rises to a high level after a short period of engine oper-

ating time.

1. Disconnect the negative battery cable.

2. Raise and support the vehicle.

3. Remove the catalytic converter mounting nuts (1)and gaskets.

(Tighten: Catalytic converter mounting nuts to 50

N·m)

4. Remove the catalytic converter.

5. Clean the ends of the pipes to ensure proper mat- ing of all parts. Discard broken or worn isolators,

rusted or overused clamps, supports, and attaching

parts.

6. Installation is in the reverse order of removal.

ON-VEHICLE SERVICE

LTSM07000107

07–7Chery Automobile Co., Ltd.

Page 1896 of 1903

Downloaded from www.Manualslib.com manuals search engine A

A-Pillar Trim Panel, Body Interior................15-11

A/C System Evacuation and Recharge, System Plumbing ......................... 13-37

Accelerator Pedal Position (APP) Sensor, 2.0L Engine Controls .......................... 3-438

Accelerator Pedal Position Sensor, 1.6L & 1.8L Engine Controls .......................... 3-224

Accelerator Sensor, 1.6L & 1.8L Engine Controls .....3-221

Accelerator Sensor, 2.0L Engine Controls ..........3-432

Accessory Drive Belt, 1.6L & 1.8L Engine Mechanical . . 2-17

Accessory Drive Belt, 2.0L Engine Mechanical ........2-91

Accessory Drive Belt, 2.4L Engine Mechanical .......2-167

Accumulator, System Plumbing .................13-43

Air Cleaner Element, 1.6L & 1.8L Engine Mechanical . . . 2-18

Air Cleaner Element, 2.0L Engine Mechanical .........2-92

Air Cleaner Element, 2.4L Engine Mechanical ........2-168

Air Cleaner Housing, 1.6L & 1.8L Engine Mechanical . . . 2-18

Air Cleaner Housing, 2.0L Engine Mechanical ........2-93

Air Cleaner Housing, 2.4L Engine Mechanical .......2-169

Air Distribution ............................ 13-25

Air Flow Sensor - 1.8L, 1.6L & 1.8L Engine Controls . . 3-223

Air Flow Sensor, 2.0L Engine Controls ............3-431

Air Flow Sensor, 2.4L Engine Controls ............3-537

Airbag System ............................. 14-1

Airbag System Disarming Procedure, Airbag System . . . 14-46

Alignment ................................ 10-38

Antenna, Body Interior ....................... 15-10

Antilock Brake System (ABS) Bleeding Procedure, Antilock Brakes .......................... 12-76

Antilock Brake System (ABS) Hydraulic Control Module, Antilock Brakes .......................... 12-77

Antilock Brakes ............................ 12-34

Assist Handle, Body Interior ...................15-13

Audio System, Body Interior ....................15-4

Automatic Shifter Selector, DP0 Automatic Transaxle . . . 8-140

Automatic Shifter Selector, F4A4 Automatic Transaxle . . 8-243

B

B-Pillar Lower Trim Panel, Body Interior ...........15-11

B-Pillar Upper Trim Panel, Body Interior ...........15-12

Back Cargo Door, Body Exterior ................15-175

Base Brakes ............................... 12-1

Battery Hold Down, Starting System ...............5-8

Battery Tray, Starting System ....................5-9

Battery, Starting System ........................5-7

Bleeding Hydraulic Clutch, Clutch System ..........8-325Blower Motor Resistor, Manual Temperature Control . . . 13-16

Blower Motor, Air Distribution

..................13-30

Body Control Module (BCM), Body Interior .........15-44

Body Control Module - BCM, Body Interior .........15-38

Body Dimensions, Body Exterior ................15-147

Body Exterior ............................ 15-145

Body Fuse and Relay Box, Vehicle Fuse Box Information .......................... 16-42

Body Interior .............................. 15-1

Body Interior Trim, Body Interior ................15-11

Body, Body Exterior ........................ 15-157

Brake Bleeding, Base Brakes ....................12-9

Bumpers, Body Exterior ..................... 15-166

C

C-Pillar Lower Trim Panel, Body Interior ...........15-12

C-Pillar Upper Trim Panel, Body Interior ...........15-13

Camshaft Position (CMP) Sensor, 1.6L & 1.8L Engine Controls .......................... 3-220

Camshaft Position (CMP) Sensor, 2.0L Engine Controls ............................... 3-431

Camshaft Position (CMP) Sensor, 2.4L Engine Controls ............................... 3-536

Camshaft, 1.6L & 1.8L Engine Mechanical ......2-20, 2-66

Camshaft, 2.0L Engine Mechanical ...........2-139, 2-94

Camshaft, 2.4L Engine Mechanical ..........2-171, 2-243

CAN Vehicle Communications, Body Interior ........15-16

Canister Control Solenoid Valve 2.4L, Evaporative Emissions ...................... 3-584

Canister Control Valve 1.6L & 1.8L & 2.0L, Evaporative Emissions ...................... 3-584

Catalytic Converter, Exhaust System ................7-6

Charging System ............................ 5-11

Chime, Body Interior ........................ 15-19

Clutch and Pressure Plate, Clutch System ..........8-319

Clutch Assembly Service, Clutch System ...........8-319

Clutch Master Cylinder, Clutch System ............8-322

Clutch Slave Cylinder, Clutch System .............8-324

Clutch System ............................. 8-316

Compressor, System Plumbing .................13-39

Condenser, System Plumbing ..................13-42

Connecting Rods, 1.6L & 1.8L Engine Mechanical .....2-58

Connecting Rods, 2.0L Engine Mechanical ..........2-131

Connecting Rods, 2.4L Engine Mechanical ..........2-229

Coolant Pump, Cooling System ..................6-16

Coolant Temperature Sensor (For Instrument Cluster), 2.4L Engine Controls ....................... 3-532

Cooling Fan, Cooling System ...................6-18

INDEX

AI

AI-1