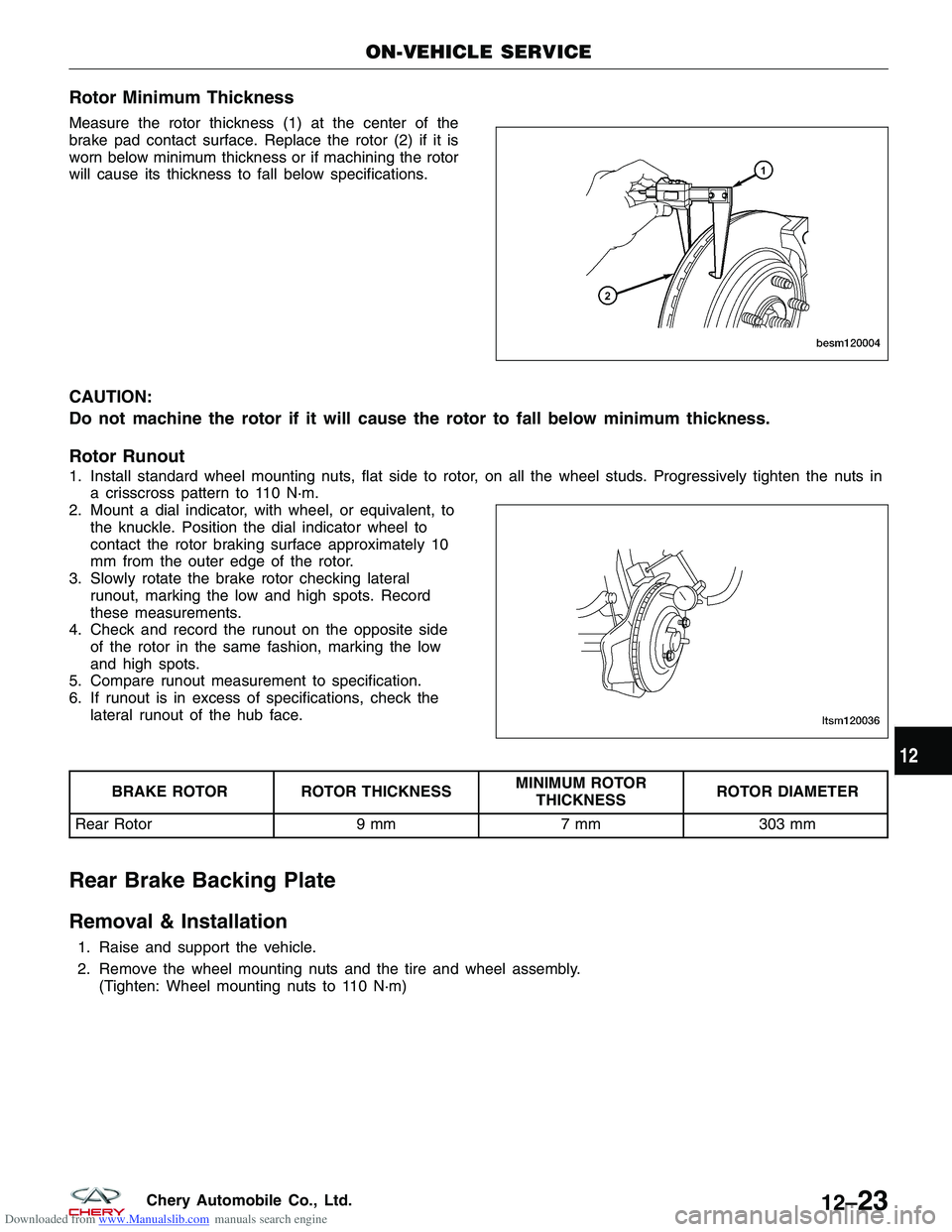

Downloaded from www.Manualslib.com manuals search engine Rotor Minimum Thickness

Measure the rotor thickness (1) at the center of the

brake pad contact surface. Replace the rotor (2) if it is

worn below minimum thickness or if machining the rotor

will cause its thickness to fall below specifications.

CAUTION:

Do not machine the rotor if it will cause the rotor to fall below minimum thickness.

Rotor Runout

1. Install standard wheel mounting nuts, flat side to rotor, on all the wheel studs. Progressively tighten the nuts ina crisscross pattern to 110 N·m.

2. Mount a dial indicator, with wheel, or equivalent, to the knuckle. Position the dial indicator wheel to

contact the rotor braking surface approximately 10

mm from the outer edge of the rotor.

3. Slowly rotate the brake rotor checking lateral runout, marking the low and high spots. Record

these measurements.

4. Check and record the runout on the opposite side of the rotor in the same fashion, marking the low

and high spots.

5. Compare runout measurement to specification.

6. If runout is in excess of specifications, check the lateral runout of the hub face.

BRAKE ROTOR ROTOR THICKNESS MINIMUM ROTOR

THICKNESS ROTOR DIAMETER

Rear Rotor 9 mm7 mm303 mm

Rear Brake Backing Plate

Removal & Installation

1. Raise and support the vehicle.

2. Remove the wheel mounting nuts and the tire and wheel assembly.

(Tighten: Wheel mounting nuts to 110 N·m)

ON-VEHICLE SERVICE

BESM120004

LTSM120036

12

12–23Chery Automobile Co., Ltd.