height CHERY TIGGO 2009 Service User Guide

[x] Cancel search | Manufacturer: CHERY, Model Year: 2009, Model line: TIGGO, Model: CHERY TIGGO 2009Pages: 1903, PDF Size: 33.38 MB

Page 108 of 1903

Downloaded from www.Manualslib.com manuals search engine DESCRIPTIONITEMSTANDARD LIMIT

Intake Camshaft Axial

Clearance -

0.15 - 0.20 mm -

Exhaust Camshaft Axial

Clearance -

0.15 - 0.20 mm -

Intake Valve Guide

Clearance -

0.012 - 0.043 mm -

Exhaust Valve Guide

Clearance -

0.032 - 0.063 mm -

Valve Outer Diameter Intake Valve

5.98 ± 0.008 mm -

Exhaust Valve 5.96 ± 0.008 mm -

Valve Guide Inner

Diameter Intake Valve

5.4 ± 0.1 mm -

Exhaust Valve 5.4 ± 0.1 mm -

Fringe Thickness On Top

Of Valve Intake Valve

0.3 ± 0.15 mm -

Exhaust Valve 0.3 ± 0.15 mm -

Valve Tilt Angle Intake Valve

65°-

Exhaust Valve 68°-

Valve Height Intake Valve

107.998 mm -

Exhaust Valve 106.318 mm -

Torque Specifications

CAUTION:

When torquing a fastener in two steps, DO NOT use a torque wrench for the second step.

DESCRIPTION TORQUE (N·m)

Accessory Drive Belt Tensioner Pulley Bolt 35

Camshaft Bearing Cap Bolts 11

Clutch Pressure Plate Bolts 25

Connecting Rod Cap Bolts 1st Step: Tighten the bolt to 25 N·m

2nd Step: Tighten the bolt an additional 90°

Crankshaft Holder 28

Crankshaft Main Bearing Cap Bolts 1st Step: Tighten the bolt to 45 N·m

2nd Step: Tighten the bolt an additional 180°

Crankshaft Timing Belt Pulley Bolt 1st Step: Tighten the bolt to 130 N·m

2nd Step: Tighten the bolt an additional 65°

Crankshaft Vibration Damper Bolts 25

Cylinder Head Cover Bolts 11

Cylinder Head Bolts 1st Step: Tighten the bolt to 40 ± 5 N·m

2nd Step: Tighten the bolt an additional 90 ± 5° 3rd Step: Tighten the bolt an additional 90 ± 5°

Dipstick Bracket Bolts 11

Drive Plate Bolts (automatic transaxle) 75

Engine Left Mount Bolt 70

Engine Right Mount Bolt 70

Engine Front Mount Bolt 60

Engine Rear Mount Bolt 60

GENERAL INFORMATION

02

02–79Chery Automobile Co., Ltd.

Page 165 of 1903

Downloaded from www.Manualslib.com manuals search engine CYLINDER HEAD UNIT REPAIR

Cylinder Head

Specifications

Torque Specifications

DESCRIPTIONTORQUE (N·m)

Cylinder Head Bolts 1st Step: Tighten the bolt to 40 ± 5 N·m

2nd Step: Tighten the bolt an additional 90 ± 5° 3rd Step: Tighten the bolt an additional 90 ± 5°

Cylinder Head Cover Bolts 11

Clearance Specifications

DESCRIPTIONSPECIFICATION (mm)

Cylinder Head Flatness 0.04

Intake Valve Deflection 0.02

Exhaust Valve Deflection 0.04

Spring Height 47.7

Disassembly

NOTE :

The following special tools are required to perform the repair procedure:

•CH-20010 - Camshaft Holder

• CH-20011 - Valve Seal Installer

• CH-20012 - Valve Stem Seal Installer Guide

• CH-20013 - Valve Seal Remover

• CH-20017 - Valve Keeper Installer

• CH-20018 - Valve Spring Compressor

NOTE :

Replacement cylinder head comes complete with valves, seals, springs, retainers, keepers, tappets, and camshafts. 1. Remove camshafts (See Camshaft Removal & Installation in Section 02 Engine).

2. Remove the hydraulic tappet assembly (1).

BESM020071

02

02–136Chery Automobile Co., Ltd.

Page 167 of 1903

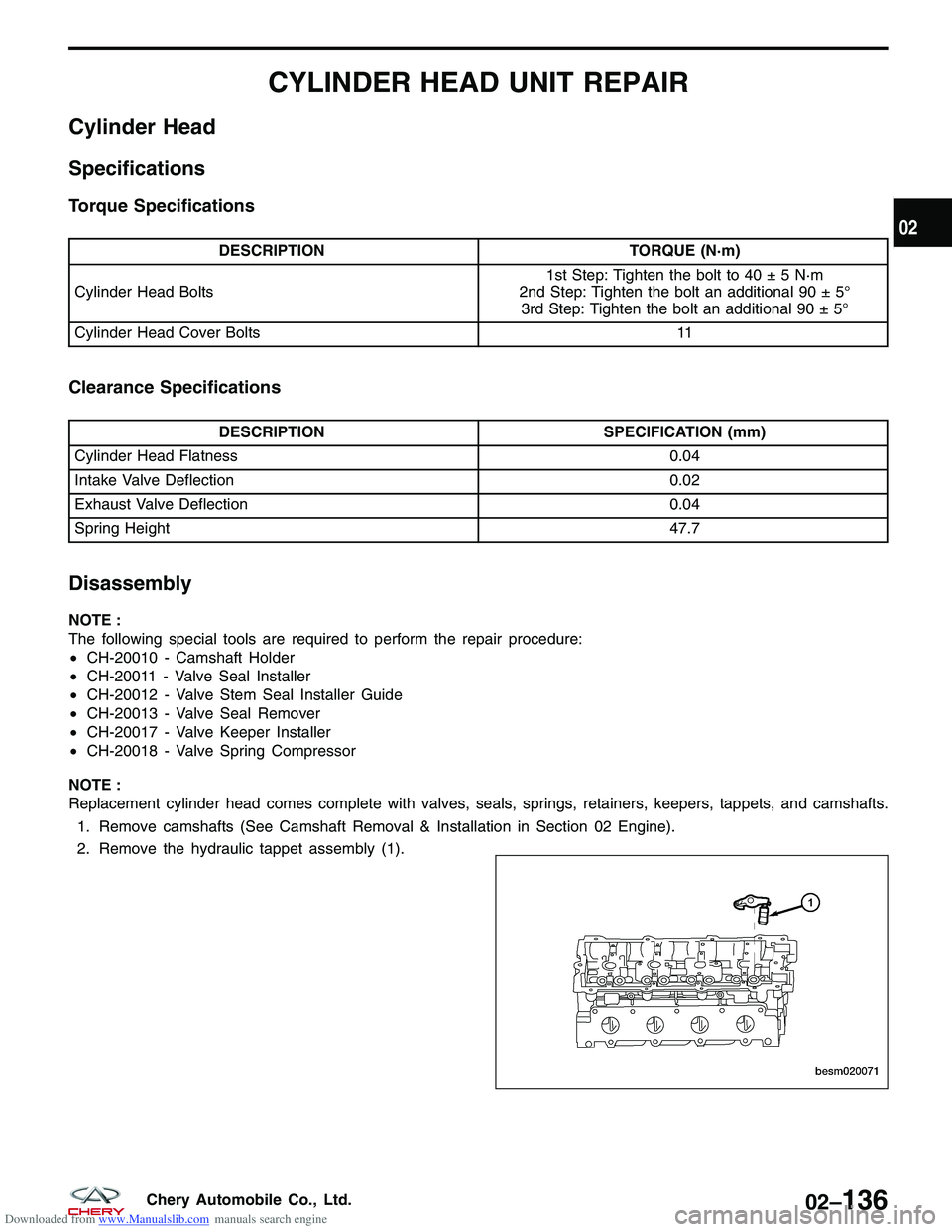

Downloaded from www.Manualslib.com manuals search engine Inspection

Inspect the cylinder head for the following:

•Cylinder head must be flat within 0.04 mm.

• Inspect camshaft bearing journals for scoring.

• Remove carbon and varnish deposits from inside of

valve guides with a valve guide cleaner.

• Verify the valve tappets move freely in their bores,

and that they have been rotating.

• Check the valve guide height.

Assembly

1. Install new valve guide if necessary.

2. Install new valve seat if necessary.

3. Using special tool CH-20011 (1) and CH-20012 (2),

install the new valve oil seal.

4. Install the valves into the cylinder head (larger diameter on intake side).

5. Install the valve springs.

6. Install the valve spring retainers.

CYLINDER HEAD UNIT REPAIR

BESM020068

LTSM020224

02

02–138Chery Automobile Co., Ltd.

Page 168 of 1903

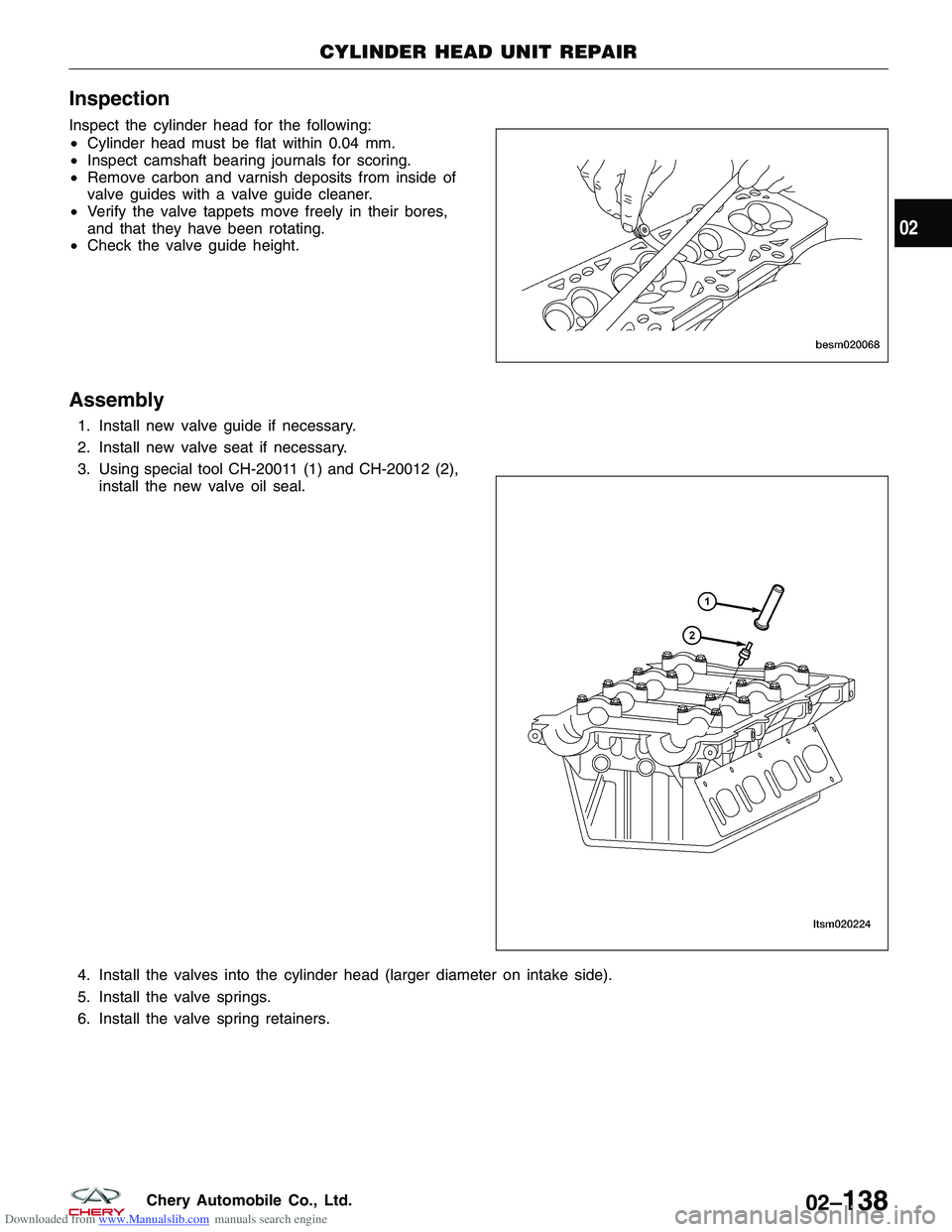

Downloaded from www.Manualslib.com manuals search engine 7. Using a valve spring compressor CH-20018 (1),compress the valve springs.

8. Install the valve keepers.

9. Strike the valve stem lightly with a plastic hammer after installation to verify proper assembly.

10. Install valve tappets in the head.

11. Install the camshafts.

Installation Notes:

• Coat the valve oil seal with engine oil.

Camshaft

Specifications

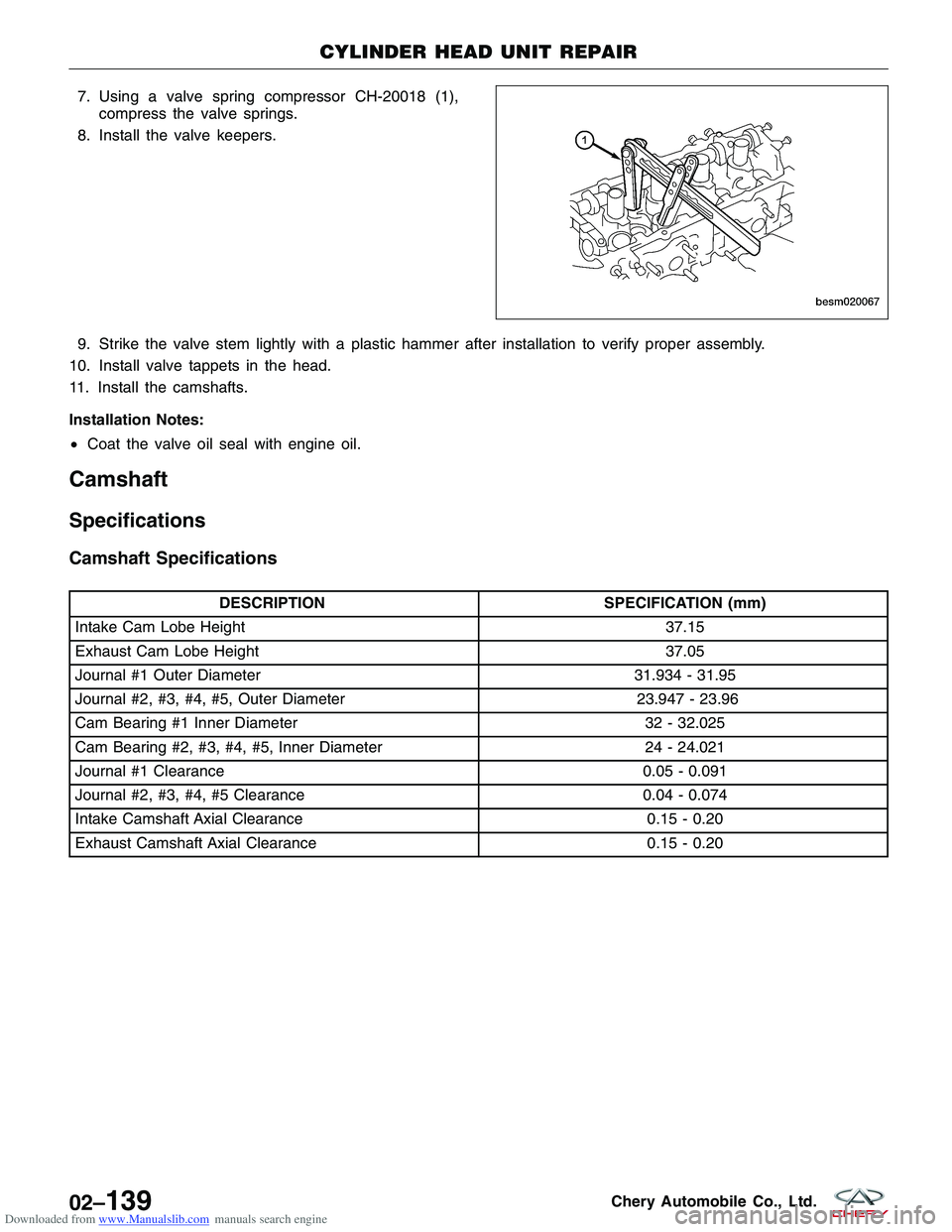

Camshaft Specifications

DESCRIPTION SPECIFICATION (mm)

Intake Cam Lobe Height 37.15

Exhaust Cam Lobe Height 37.05

Journal #1 Outer Diameter 31.934 - 31.95

Journal #2, #3, #4, #5, Outer Diameter 23.947 - 23.96

Cam Bearing #1 Inner Diameter 32 - 32.025

Cam Bearing #2, #3, #4, #5, Inner Diameter 24 - 24.021

Journal #1 Clearance 0.05 - 0.091

Journal #2, #3, #4, #5 Clearance 0.04 - 0.074

Intake Camshaft Axial Clearance 0.15 - 0.20

Exhaust Camshaft Axial Clearance 0.15 - 0.20

CYLINDER HEAD UNIT REPAIR

BESM020067

02–139Chery Automobile Co., Ltd.

Page 169 of 1903

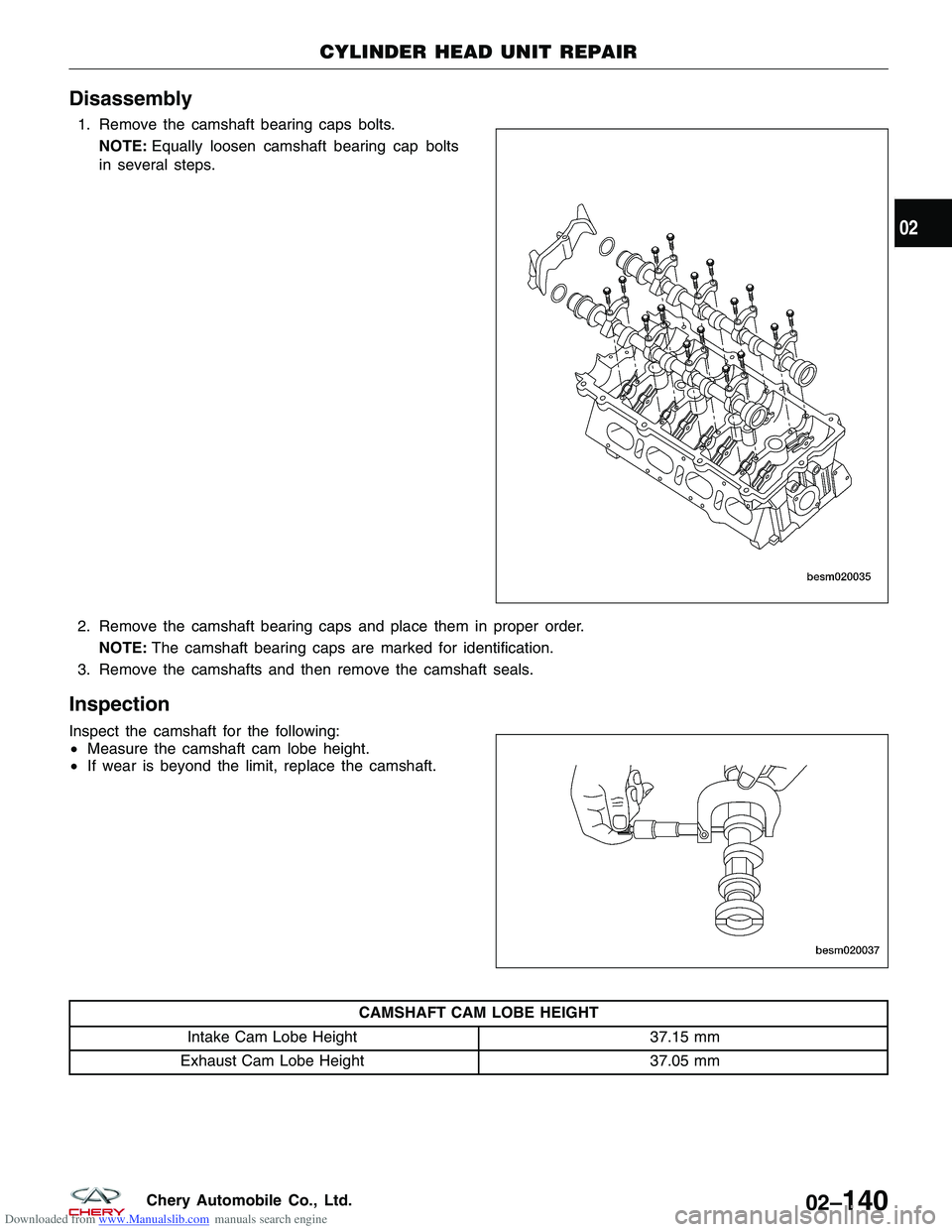

Downloaded from www.Manualslib.com manuals search engine Disassembly

1. Remove the camshaft bearing caps bolts.NOTE: Equally loosen camshaft bearing cap bolts

in several steps.

2. Remove the camshaft bearing caps and place them in proper order. NOTE: The camshaft bearing caps are marked for identification.

3. Remove the camshafts and then remove the camshaft seals.

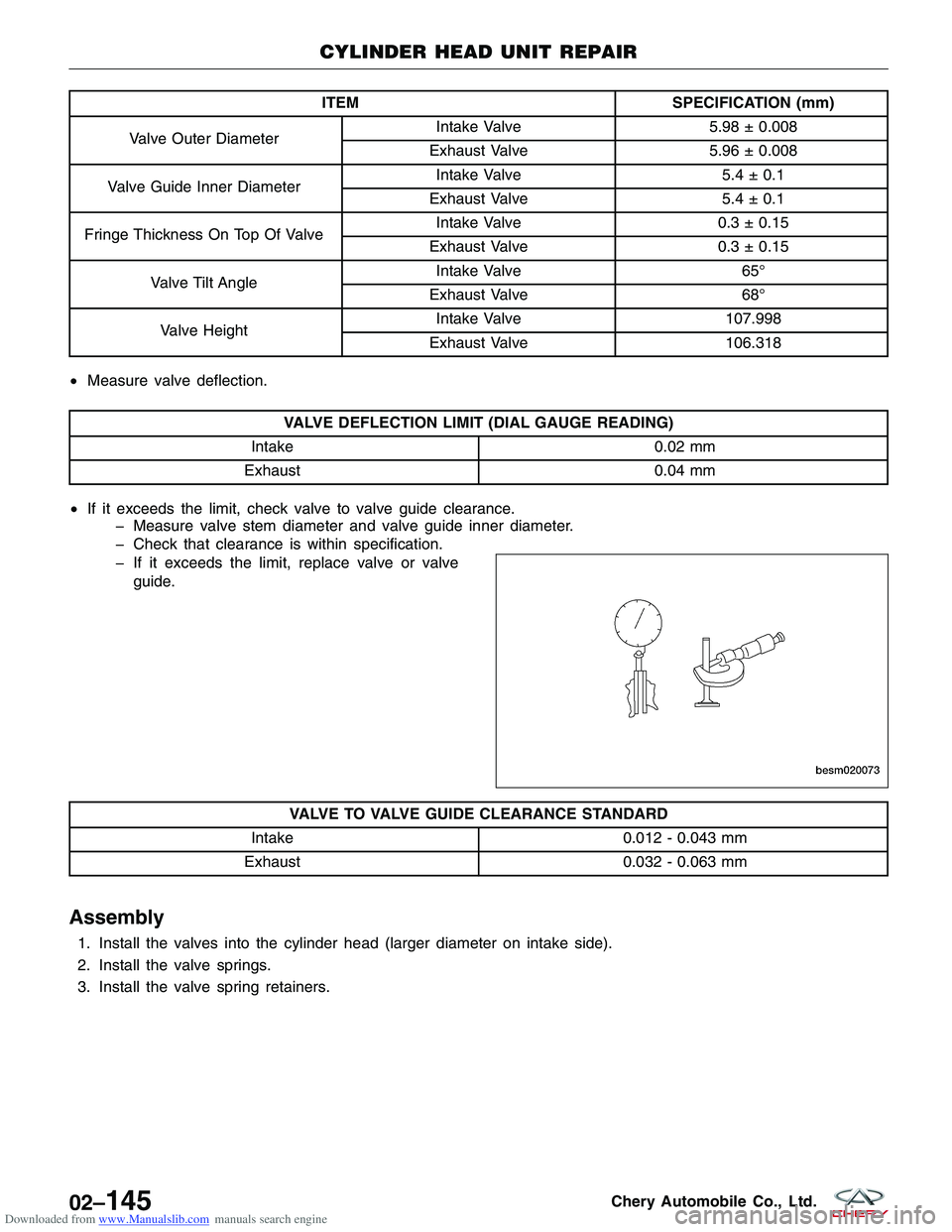

Inspection

Inspect the camshaft for the following:

• Measure the camshaft cam lobe height.

• If wear is beyond the limit, replace the camshaft.

CAMSHAFT CAM LOBE HEIGHT

Intake Cam Lobe Height 37.15 mm

Exhaust Cam Lobe Height 37.05 mm

CYLINDER HEAD UNIT REPAIR

BESM020035

BESM020037

02

02–140Chery Automobile Co., Ltd.

Page 174 of 1903

Downloaded from www.Manualslib.com manuals search engine ITEMSPECIFICATION (mm)

Valve Outer Diameter Intake Valve

5.98 ± 0.008

Exhaust Valve 5.96 ± 0.008

Valve Guide Inner Diameter Intake Valve

5.4 ± 0.1

Exhaust Valve 5.4 ± 0.1

Fringe Thickness On Top Of Valve Intake Valve

0.3 ± 0.15

Exhaust Valve 0.3 ± 0.15

Valve Tilt Angle Intake Valve

65°

Exhaust Valve 68°

Valve Height Intake Valve

107.998

Exhaust Valve 106.318

• Measure valve deflection.

VALVE DEFLECTION LIMIT (DIAL GAUGE READING)

Intake 0.02 mm

Exhaust 0.04 mm

• If it exceeds the limit, check valve to valve guide clearance.

� Measure valve stem diameter and valve guide inner diameter.

� Check that clearance is within specification.

� If it exceeds the limit, replace valve or valve

guide.

VALVE TO VALVE GUIDE CLEARANCE STANDARD

Intake 0.012 - 0.043 mm

Exhaust 0.032 - 0.063 mm

Assembly

1. Install the valves into the cylinder head (larger diameter on intake side).

2. Install the valve springs.

3. Install the valve spring retainers.

CYLINDER HEAD UNIT REPAIR

BESM020073

02–145Chery Automobile Co., Ltd.

Page 175 of 1903

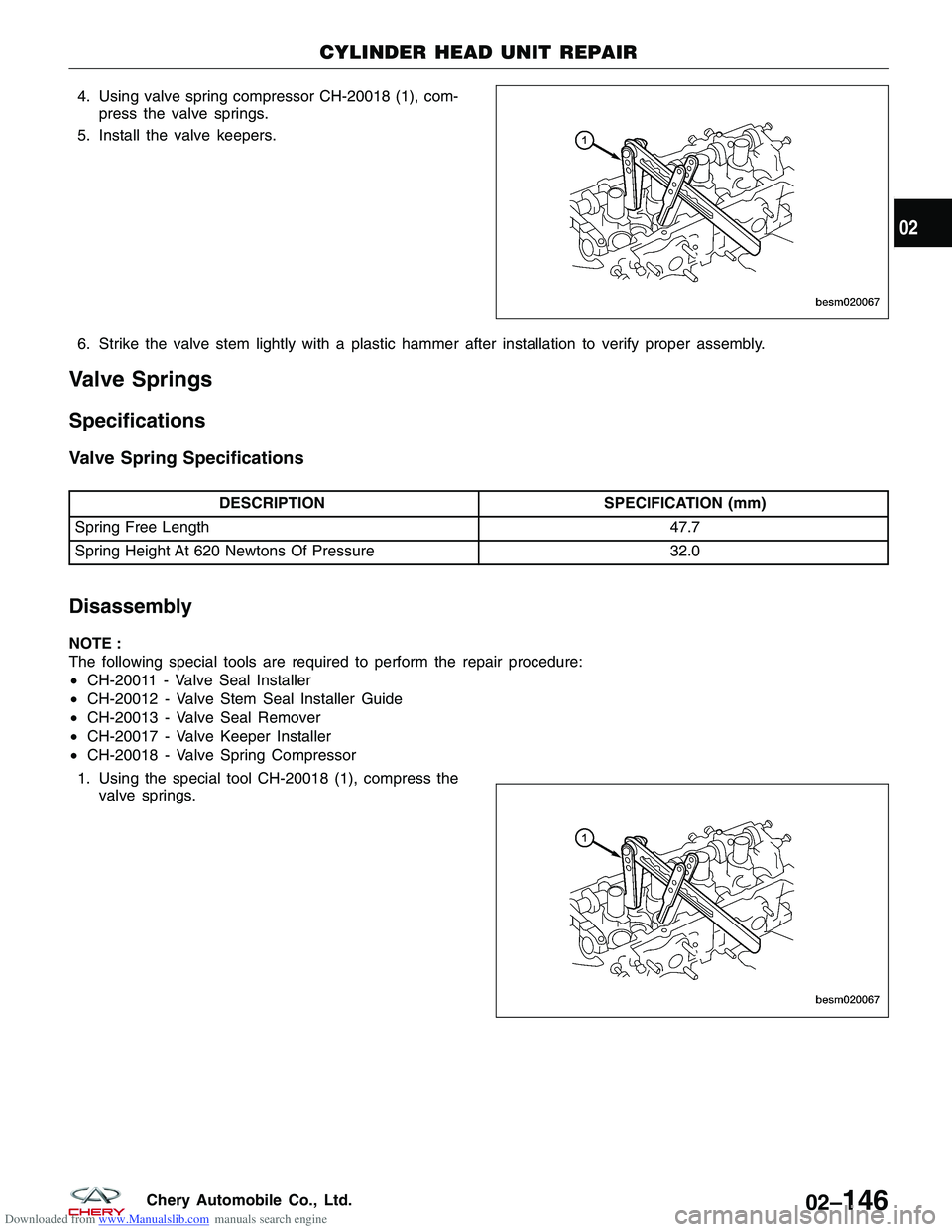

Downloaded from www.Manualslib.com manuals search engine 4. Using valve spring compressor CH-20018 (1), com-press the valve springs.

5. Install the valve keepers.

6. Strike the valve stem lightly with a plastic hammer after installation to verify proper assembly.

Valve Springs

Specifications

Valve Spring Specifications

DESCRIPTION SPECIFICATION (mm)

Spring Free Length 47.7

Spring Height At 620 Newtons Of Pressure 32.0

Disassembly

NOTE :

The following special tools are required to perform the repair procedure:

•CH-20011 - Valve Seal Installer

• CH-20012 - Valve Stem Seal Installer Guide

• CH-20013 - Valve Seal Remover

• CH-20017 - Valve Keeper Installer

• CH-20018 - Valve Spring Compressor

1. Using the special tool CH-20018 (1), compress the valve springs.

CYLINDER HEAD UNIT REPAIR

BESM020067

BESM020067

02

02–146Chery Automobile Co., Ltd.

Page 176 of 1903

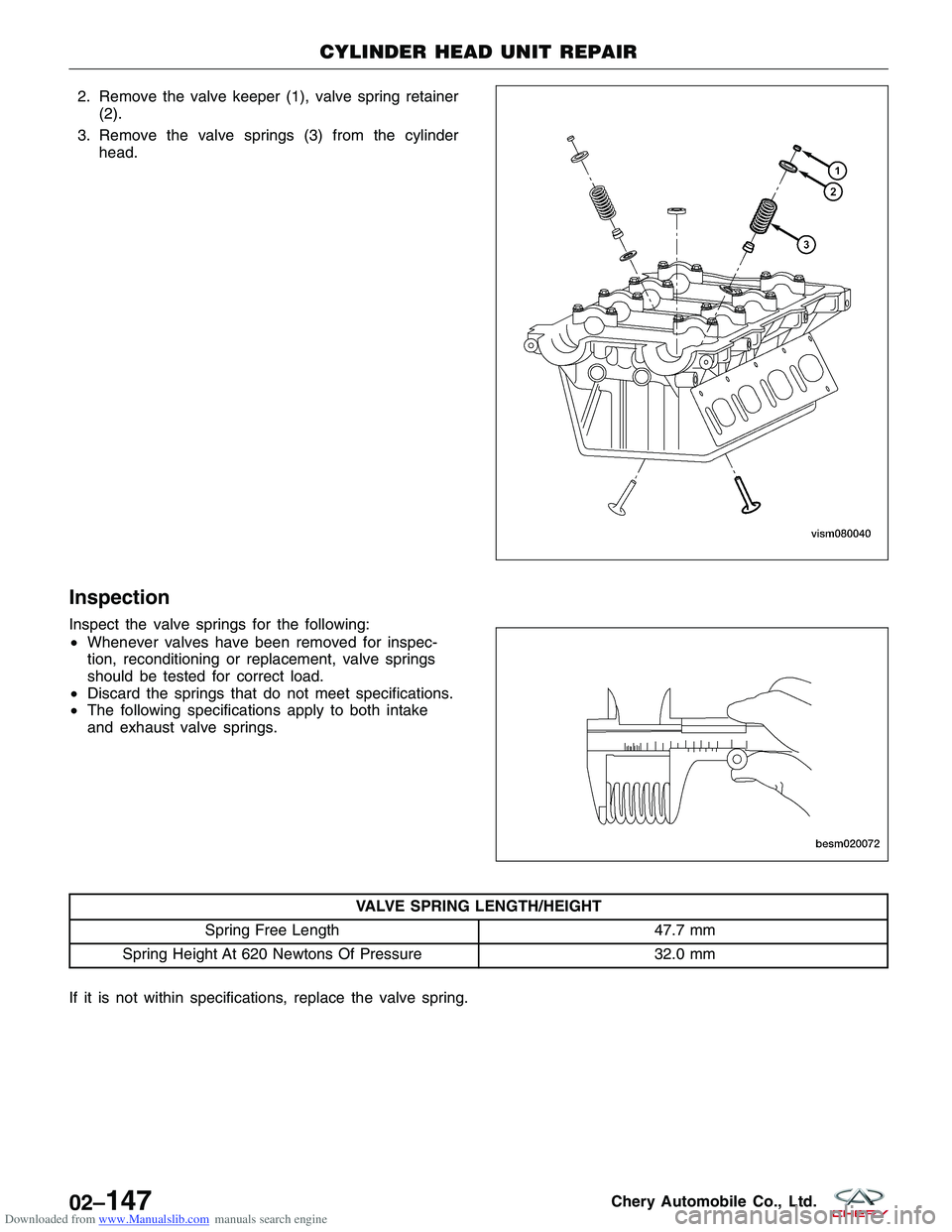

Downloaded from www.Manualslib.com manuals search engine 2. Remove the valve keeper (1), valve spring retainer(2).

3. Remove the valve springs (3) from the cylinder head.

Inspection

Inspect the valve springs for the following:

•Whenever valves have been removed for inspec-

tion, reconditioning or replacement, valve springs

should be tested for correct load.

• Discard the springs that do not meet specifications.

• The following specifications apply to both intake

and exhaust valve springs.

VALVE SPRING LENGTH/HEIGHT

Spring Free Length 47.7 mm

Spring Height At 620 Newtons Of Pressure 32.0 mm

If it is not within specifications, replace the valve spring.

CYLINDER HEAD UNIT REPAIR

VISM080040

BESM020072

02–147Chery Automobile Co., Ltd.

Page 180 of 1903

Downloaded from www.Manualslib.com manuals search engine GENERAL INFORMATION

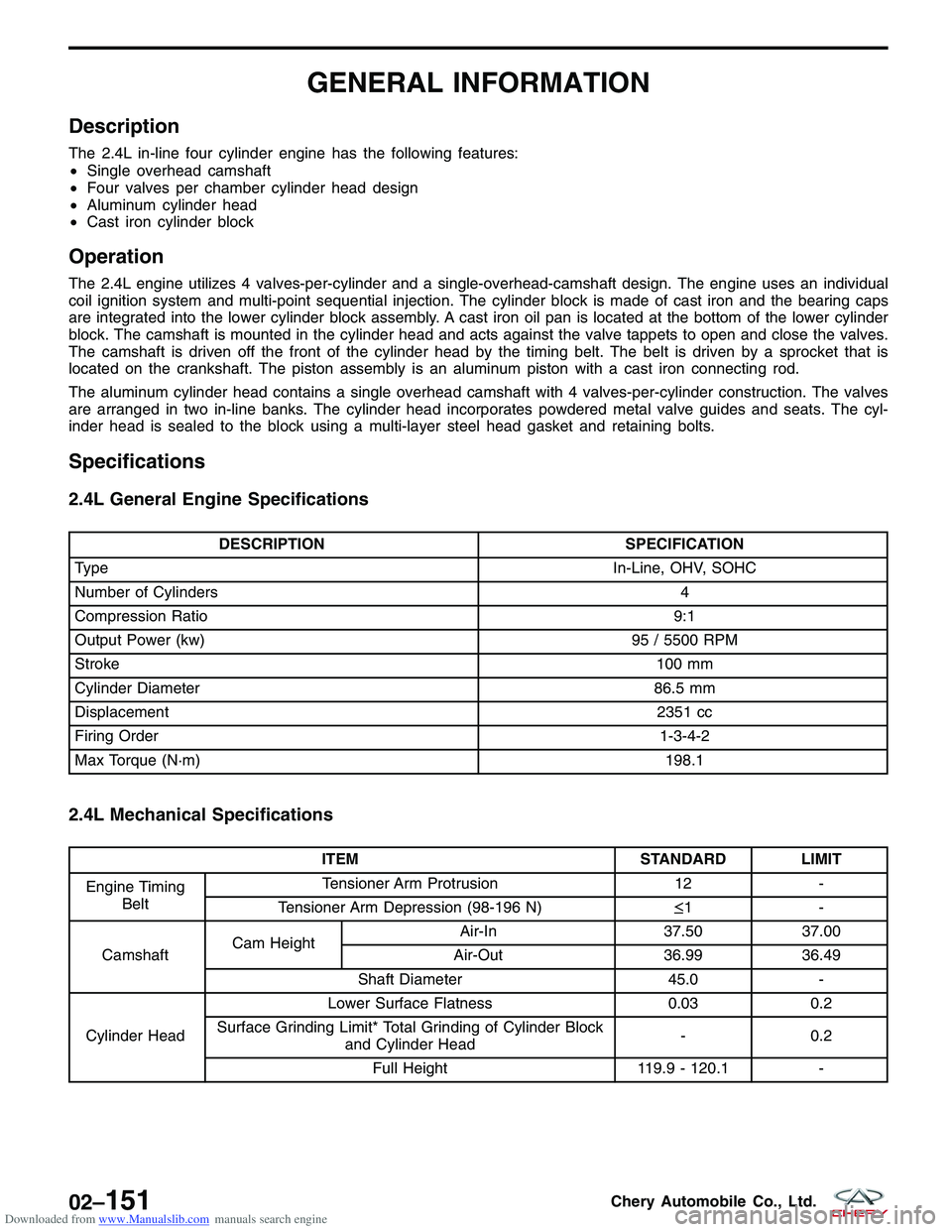

Description

The 2.4L in-line four cylinder engine has the following features:

•Single overhead camshaft

• Four valves per chamber cylinder head design

• Aluminum cylinder head

• Cast iron cylinder block

Operation

The 2.4L engine utilizes 4 valves-per-cylinder and a single-overhead-camshaft design. The engine uses an individual

coil ignition system and multi-point sequential injection. The cylinder block is made of cast iron and the bearing caps

are integrated into the lower cylinder block assembly. A cast iron oil pan is located at the bottom of the lower cylinder

block. The camshaft is mounted in the cylinder head and acts against the valve tappets to open and close the valves.

The camshaft is driven off the front of the cylinder head by the timing belt. The belt is driven by a sprocket that is

located on the crankshaft. The piston assembly is an aluminum piston with a cast iron connecting rod.

The aluminum cylinder head contains a single overhead camshaft with 4 valves-per-cylinder construction. The valves

are arranged in two in-line banks. The cylinder head incorporates powdered metal valve guides and seats. The cyl-

inder head is sealed to the block using a multi-layer steel head gasket and retaining bolts.

Specifications

2.4L General Engine Specifications

DESCRIPTION SPECIFICATION

Type In-Line, OHV, SOHC

Number of Cylinders 4

Compression Ratio 9:1

Output Power (kw) 95 / 5500 RPM

Stroke 100 mm

Cylinder Diameter 86.5 mm

Displacement 2351 cc

Firing Order 1-3-4-2

Max Torque (N·m) 198.1

2.4L Mechanical Specifications

ITEMSTANDARD LIMIT

Engine Timing Belt Tensioner Arm Protrusion

12-

Tensioner Arm Depression (98-196 N) ≤1-

Camshaft Cam Height Air-In

37.5037.00

Air-Out 36.9936.49

Shaft Diameter 45.0-

Cylinder Head Lower Surface Flatness

0.030.2

Surface Grinding Limit* Total Grinding of Cylinder Block and Cylinder Head -

0.2

Full Height 119.9 - 120.1-

02–151Chery Automobile Co., Ltd.

Page 181 of 1903

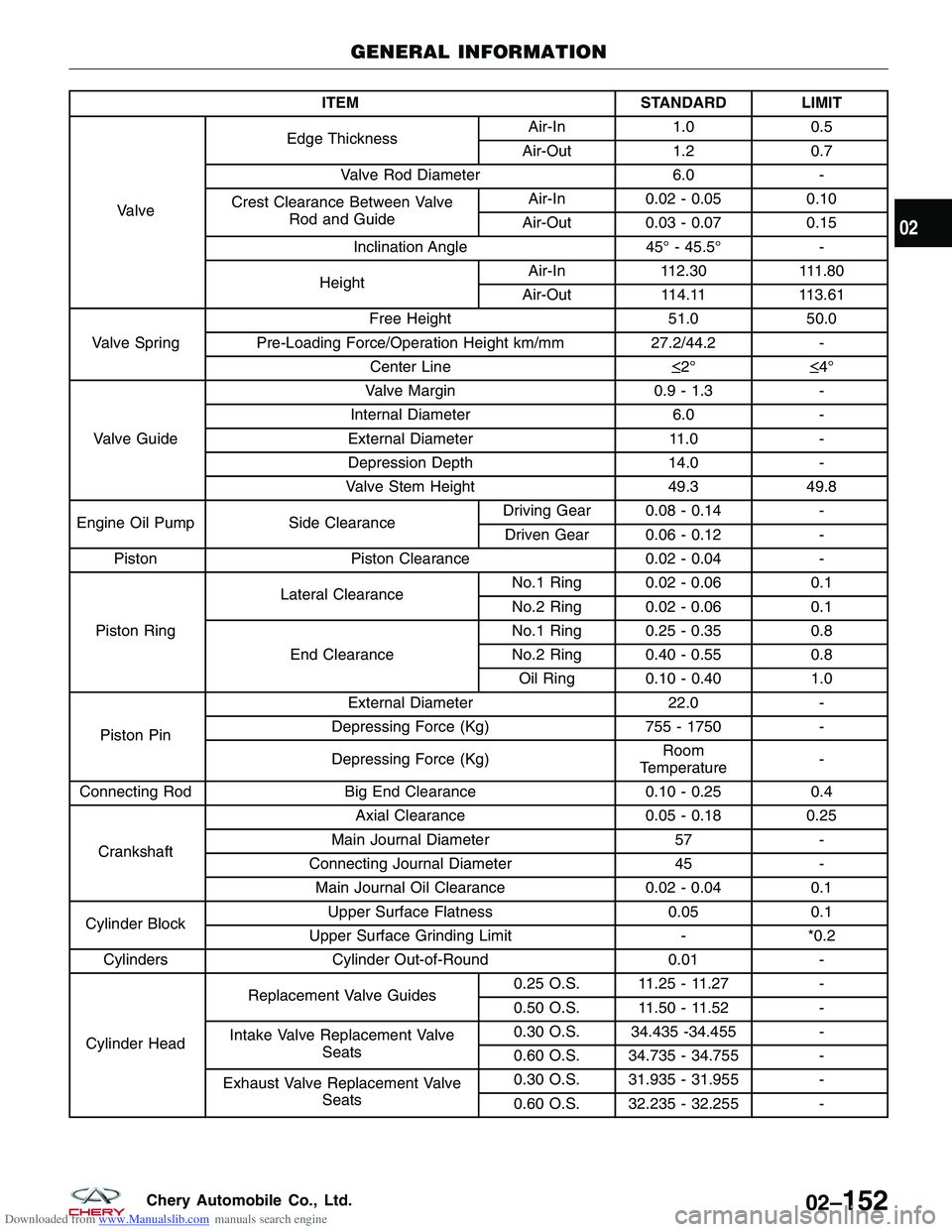

Downloaded from www.Manualslib.com manuals search engine ITEMSTANDARD LIMIT

Valve Edge Thickness

Air-In

1.00.5

Air-Out 1.20.7

Valve Rod Diameter 6.0-

Crest Clearance Between Valve Rod and Guide Air-In

0.02 - 0.05 0.10

Air-Out 0.03 - 0.07 0.15

Inclination Angle 45° - 45.5°-

Height Air-In

112.30 111.80

Air-Out 114.11113.61

Valve Spring Free Height

51.050.0

Pre-Loading Force/Operation Height km/mm 27.2/44.2-

Center Line ≤2°≤4°

Valve Guide Valve Margin

0.9 - 1.3-

Internal Diameter 6.0-

External Diameter 11.0-

Depression Depth 14.0-

Valve Stem Height 49.349.8

Engine Oil Pump Side Clearance Driving Gear 0.08 - 0.14

-

Driven Gear 0.06 - 0.12 -

Piston Piston Clearance 0.02 - 0.04-

Piston Ring Lateral Clearance

No.1 Ring 0.02 - 0.06

0.1

No.2 Ring 0.02 - 0.06 0.1

End Clearance No.1 Ring 0.25 - 0.35

0.8

No.2 Ring 0.40 - 0.55 0.8

Oil Ring 0.10 - 0.40 1.0

Piston Pin External Diameter

22.0-

Depressing Force (Kg) 755 - 1750-

Depressing Force (Kg) Room

Temperature -

Connecting Rod Big End Clearance 0.10 - 0.250.4

Crankshaft Axial Clearance

0.05 - 0.180.25

Main Journal Diameter 57-

Connecting Journal Diameter 45-

Main Journal Oil Clearance 0.02 - 0.040.1

Cylinder Block Upper Surface Flatness

0.050.1

Upper Surface Grinding Limit -*0.2

Cylinders Cylinder Out-of-Round 0.01-

Cylinder Head Replacement Valve Guides

0.25 O.S. 11.25 - 11.27

-

0.50 O.S. 11.50 - 11.52 -

Intake Valve Replacement Valve Seats 0.30 O.S. 34.435 -34.455

-

0.60 O.S. 34.735 - 34.755 -

Exhaust Valve Replacement Valve Seats 0.30 O.S. 31.935 - 31.955

-

0.60 O.S. 32.235 - 32.255 -

GENERAL INFORMATION

02

02–152Chery Automobile Co., Ltd.