height CHERY TIGGO 2009 Service Owner's Guide

[x] Cancel search | Manufacturer: CHERY, Model Year: 2009, Model line: TIGGO, Model: CHERY TIGGO 2009Pages: 1903, PDF Size: 33.38 MB

Page 1264 of 1903

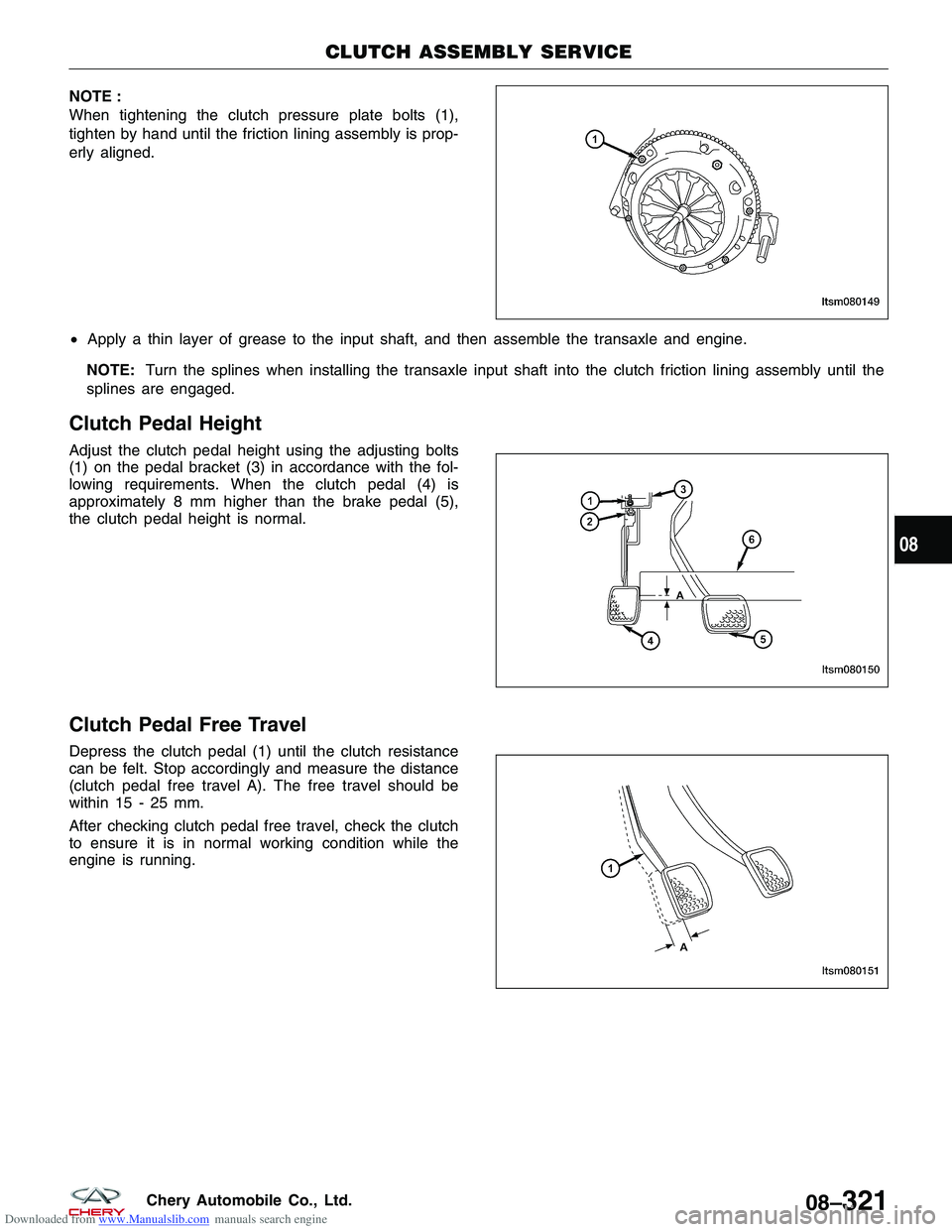

Downloaded from www.Manualslib.com manuals search engine NOTE :

When tightening the clutch pressure plate bolts (1),

tighten by hand until the friction lining assembly is prop-

erly aligned.

•Apply a thin layer of grease to the input shaft, and then assemble the transaxle and engine.

NOTE: Turn the splines when installing the transaxle input shaft into the clutch friction lining assembly until the

splines are engaged.

Clutch Pedal Height

Adjust the clutch pedal height using the adjusting bolts

(1) on the pedal bracket (3) in accordance with the fol-

lowing requirements. When the clutch pedal (4) is

approximately 8 mm higher than the brake pedal (5),

the clutch pedal height is normal.

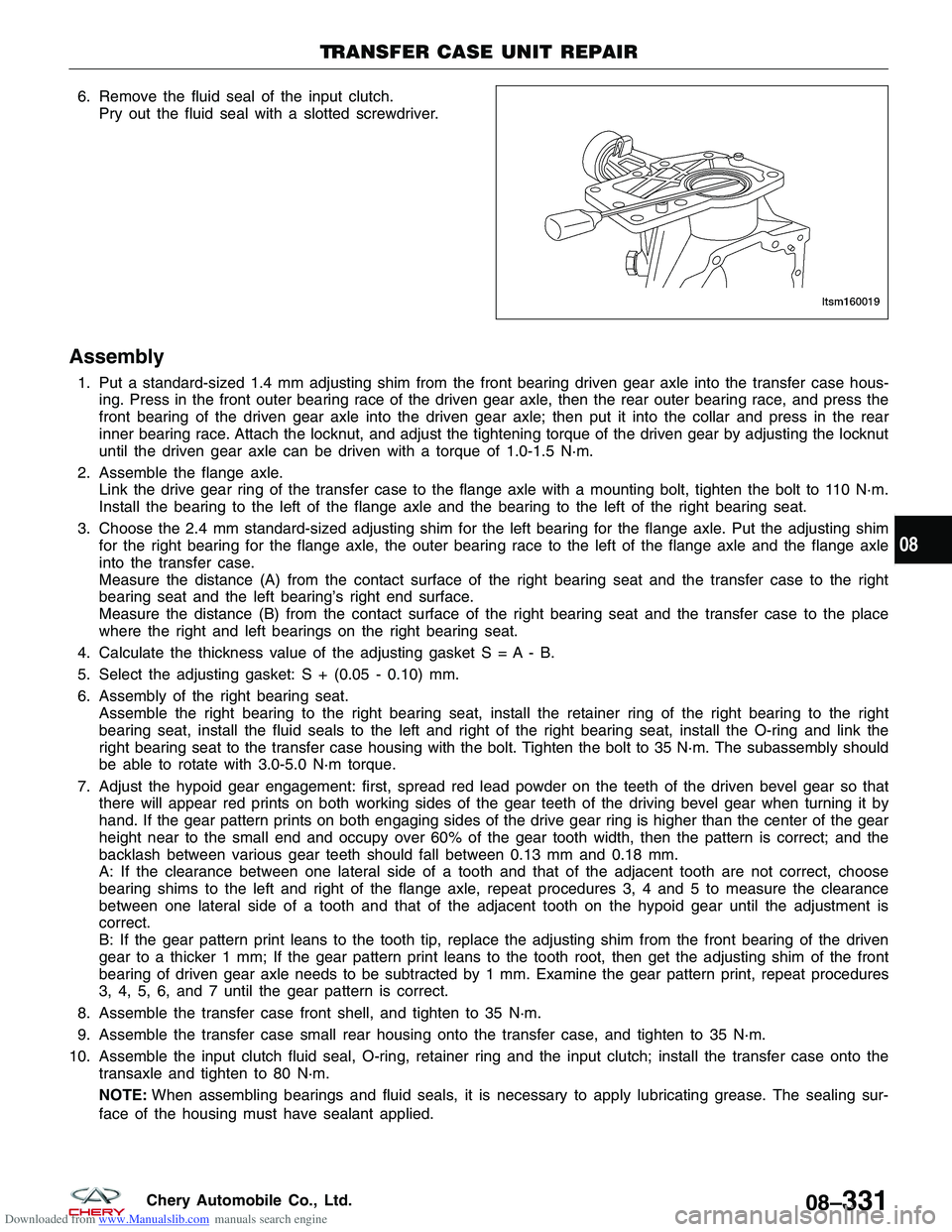

Clutch Pedal Free Travel

Depress the clutch pedal (1) until the clutch resistance

can be felt. Stop accordingly and measure the distance

(clutch pedal free travel A). The free travel should be

within 15 - 25 mm.

After checking clutch pedal free travel, check the clutch

to ensure it is in normal working condition while the

engine is running.

CLUTCH ASSEMBLY SERVICE

LTSM080149

LTSM080150

LTSM080151

08

08–321Chery Automobile Co., Ltd.

Page 1274 of 1903

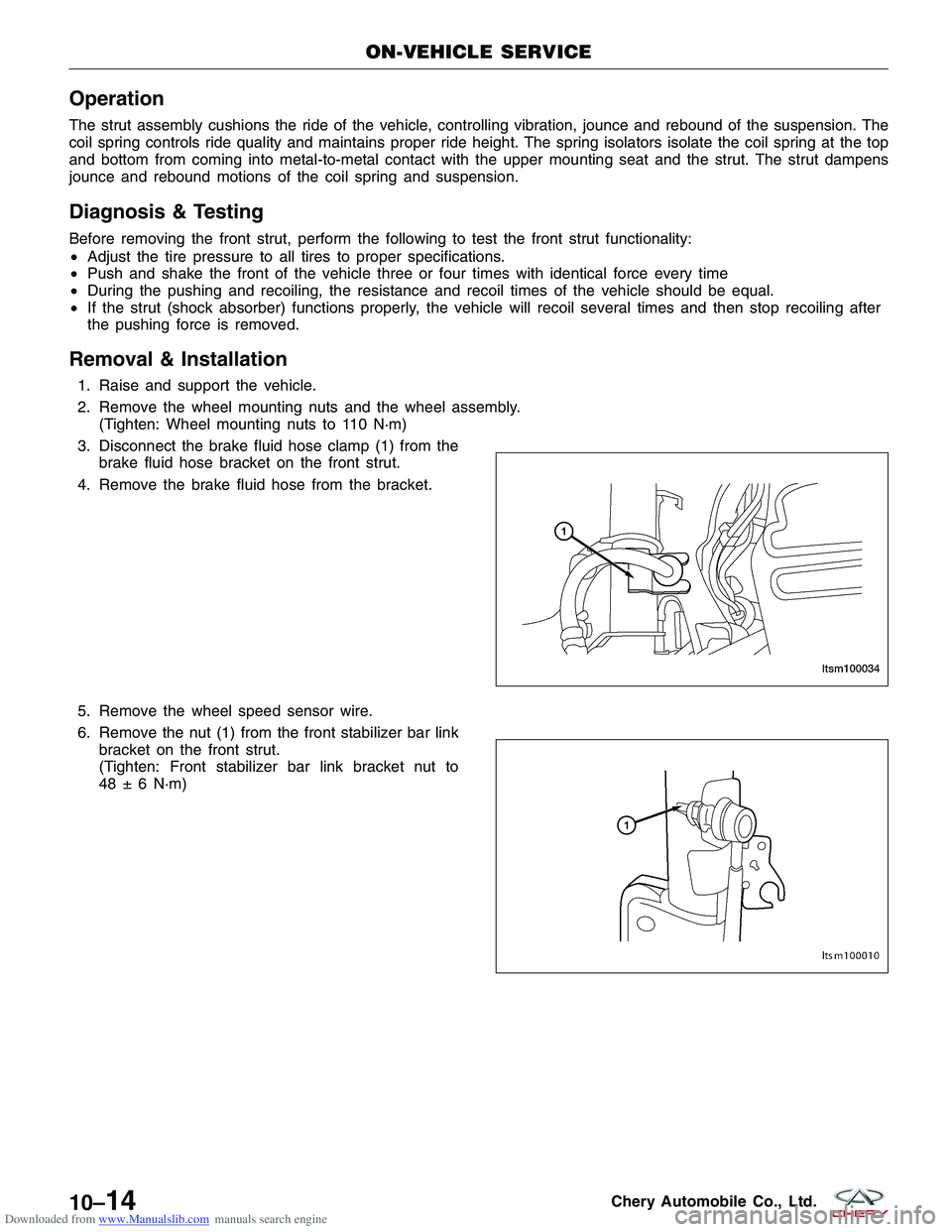

Downloaded from www.Manualslib.com manuals search engine 6. Remove the fluid seal of the input clutch.Pry out the fluid seal with a slotted screwdriver.

Assembly

1. Put a standard-sized 1.4 mm adjusting shim from the front bearing driven gear axle into the transfer case hous-ing. Press in the front outer bearing race of the driven gear axle, then the rear outer bearing race, and press the

front bearing of the driven gear axle into the driven gear axle; then put it into the collar and press in the rear

inner bearing race. Attach the locknut, and adjust the tightening torque of the driven gear by adjusting the locknut

until the driven gear axle can be driven with a torque of 1.0-1.5 N·m.

2. Assemble the flange axle. Link the drive gear ring of the transfer case to the flange axle with a mounting bolt, tighten the bolt to 110 N·m.

Install the bearing to the left of the flange axle and the bearing to the left of the right bearing seat.

3. Choose the 2.4 mm standard-sized adjusting shim for the left bearing for the flange axle. Put the adjusting shim for the right bearing for the flange axle, the outer bearing race to the left of the flange axle and the flange axle

into the transfer case.

Measure the distance (A) from the contact surface of the right bearing seat and the transfer case to the right

bearing seat and the left bearing’s right end surface.

Measure the distance (B) from the contact surface of the right bearing seat and the transfer case to the place

where the right and left bearings on the right bearing seat.

4. Calculate the thickness value of the adjusting gasket S = A - B.

5. Select the adjusting gasket: S + (0.05 - 0.10) mm.

6. Assembly of the right bearing seat. Assemble the right bearing to the right bearing seat, install the retainer ring of the right bearing to the right

bearing seat, install the fluid seals to the left and right of the right bearing seat, install the O-ring and link the

right bearing seat to the transfer case housing with the bolt. Tighten the bolt to 35 N·m. The subassembly should

be able to rotate with 3.0-5.0 N·m torque.

7. Adjust the hypoid gear engagement: first, spread red lead powder on the teeth of the driven bevel gear so that there will appear red prints on both working sides of the gear teeth of the driving bevel gear when turning it by

hand. If the gear pattern prints on both engaging sides of the drive gear ring is higher than the center of the gear

height near to the small end and occupy over 60% of the gear tooth width, then the pattern is correct; and the

backlash between various gear teeth should fall between 0.13 mm and 0.18 mm.

A: If the clearance between one lateral side of a tooth and that of the adjacent tooth are not correct, choose

bearing shims to the left and right of the flange axle, repeat procedures 3, 4 and 5 to measure the clearance

between one lateral side of a tooth and that of the adjacent tooth on the hypoid gear until the adjustment is

correct.

B: If the gear pattern print leans to the tooth tip, replace the adjusting shim from the front bearing of the driven

gear to a thicker 1 mm; If the gear pattern print leans to the tooth root, then get the adjusting shim of the front

bearing of driven gear axle needs to be subtracted by 1 mm. Examine the gear pattern print, repeat procedures

3, 4, 5, 6, and 7 until the gear pattern is correct.

8. Assemble the transfer case front shell, and tighten to 35 N·m.

9. Assemble the transfer case small rear housing onto the transfer case, and tighten to 35 N·m.

10. Assemble the input clutch fluid seal, O-ring, retainer ring and the input clutch; install the transfer case onto the transaxle and tighten to 80 N·m.

NOTE: When assembling bearings and fluid seals, it is necessary to apply lubricating grease. The sealing sur-

face of the housing must have sealant applied.

TRANSFER CASE UNIT REPAIR

LTSM160019

08

08–331Chery Automobile Co., Ltd.

Page 1315 of 1903

Downloaded from www.Manualslib.com manuals search engine Operation

The strut assembly cushions the ride of the vehicle, controlling vibration, jounce and rebound of the suspension. The

coil spring controls ride quality and maintains proper ride height. The spring isolators isolate the coil spring at the top

and bottom from coming into metal-to-metal contact with the upper mounting seat and the strut. The strut dampens

jounce and rebound motions of the coil spring and suspension.

Diagnosis & Testing

Before removing the front strut, perform the following to test the front strut functionality:

•Adjust the tire pressure to all tires to proper specifications.

• Push and shake the front of the vehicle three or four times with identical force every time

• During the pushing and recoiling, the resistance and recoil times of the vehicle should be equal.

• If the strut (shock absorber) functions properly, the vehicle will recoil several times and then stop recoiling after

the pushing force is removed.

Removal & Installation

1. Raise and support the vehicle.

2. Remove the wheel mounting nuts and the wheel assembly.

(Tighten: Wheel mounting nuts to 110 N·m)

3. Disconnect the brake fluid hose clamp (1) from the brake fluid hose bracket on the front strut.

4. Remove the brake fluid hose from the bracket.

5. Remove the wheel speed sensor wire.

6. Remove the nut (1) from the front stabilizer bar link bracket on the front strut.

(Tighten: Front stabilizer bar link bracket nut to

48 ± 6 N·m)

ON-VEHICLE SERVICE

LTSM100034

LTSM100010

10–14Chery Automobile Co., Ltd.

Page 1340 of 1903

Downloaded from www.Manualslib.com manuals search engine GENERAL INFORMATION

Description

Vehicle wheel alignment is the positioning of all interrelated front and rear suspension angles. These angles affect the

handling and steering of the vehicle when it is in motion. Proper wheel alignment is essential for efficient steering,

good directional stability, and proper tire wear.

The method of checking a vehicle’s front and rear wheel alignment varies depending on the manufacturer and type

of equipment used. The manufacturer’s instructions should always be followed to ensure accuracy of the alignment.

On this vehicle, the suspension angles that can be adjusted are as follows:

Front Axle

•Camber

• Caster

• Toe-in

Rear Axle

• Camber

• Toe-in

Check the wheel alignment and make all wheel alignment adjustments with the vehicle standing at its proper curb

height specification. Curb height is the normal riding height of the vehicle. It is measured from a certain point on the

vehicle to the ground or a designated area while the vehicle is sitting on a flat, level surface.

Operation

Curb Height Measurement

The wheel alignment is to be checked and all alignment adjustments made with the vehicle at its required curb height

specification.

• Vehicle height is to be checked with the vehicle on a flat, level surface, preferably a vehicle alignment rack.

• The tires are to be inflated to the recommended pressure.

• All tires are to be the same size as standard equipment.

• Vehicle height is checked with the fuel tank full of fuel, and no passenger or luggage compartment load.

• Vehicle height is not adjustable.

• If the measurement is not within specifications, inspect the vehicle for bent or weak suspension components.

• Compare the parts tag on the suspect coil spring(s) to the parts book and the vehicle sales code, checking for

a match.

• Once removed from the vehicle, compare the coil spring height to a new or known good coil spring. The

heights should vary if the suspect spring is weak.

NOTE :

Prior to reading the curb height measurement, the front and rear of the vehicle must be jounced to settle the sus-

pension. Induce jounce by pushing down on the center of the bumper (fascia), using care not to damage the vehicle,

moving the vehicle up and down, gradually increasing the suspension travel with each stroke. Release the bumper at

the bottom of each stroke, repeating this action several times. Perform this to both front and rear suspensions an

equal number of times.

Pre-Wheel Alignment Inspection

Before any attempt is made to change or correct the wheel alignment, the following inspection and necessary cor-

rections must be made to the vehicle to ensure proper alignment. 1. Verify the fuel tank is full of fuel. If the fuel tank is not full, the reduction in weight will affect the curb height of the vehicle and the alignment specifications.

2. The passenger and luggage compartments of the vehicle should be free of any load that is not factory equip- ment.

10

10–39Chery Automobile Co., Ltd.

Page 1341 of 1903

Downloaded from www.Manualslib.com manuals search engine 3. Check the tires on the vehicle. The tires are to beinflated to the recommended air pressure. All tires

must be the same size and in good condition with

approximately the same tread wear.

4. Check the front tire and wheel assemblies for excessive radial runout.

5. Inspect all suspension component fasteners for looseness and proper torque.

6. Inspect all ball joints and all steering linkage for looseness and any sign of wear or damage.

7. Inspect the rubber bushings on all the suspension components for signs of wear or deterioration. If any bushings show signs of wear or deterioration, they should be replaced prior to aligning the vehicle.

8. Check vehicle curb height.

Wheel Alignment Setup

1. Position the vehicle on an alignment rack.

2. Install all required alignment equipment on the vehicle, per the alignment equipment manufacturer’s instructions. On this vehicle, a four-wheel alignment is recommended.

3. Read the vehicle’s current front and rear alignment settings. Compare the vehicle’s current alignment settings to the vehicle specifications for camber, caster and toe-in.

NOTE :

Prior to reading the vehicle’s alignment readouts, the front and rear of vehicle should be jounced. Induce jounce (rear

first, then front) by grasping the center of the bumper and jouncing each end of the vehicle an equal number of

times. The bumper should always be released when vehicle is at the bottom of the jounce cycle.

Specifications

Torque Specifications

DESCRIPTION TORQUE (N·m)

Camber Adjustment Bolts 100

Inner Tie Rod Adjuster Jam Nut 30

Rear Lower Control Arm Eccentric Cam Bolt 80 - 100

Rear Upper Control Arm Eccentric Cam Bolt 80 - 100

Wheel Mounting Nuts 110

GENERAL INFORMATION

LTSM100027

LTSM110026

10–40Chery Automobile Co., Ltd.

Page 1756 of 1903

Downloaded from www.Manualslib.com manuals search engine 30. Detach the lock from the linkage rod, remove thelock and the cover of left front door.

31. Remove the outside handle.

Assembly

Assemble is in the reverse order of disassembly

Front Door Adjustment

1. Adjust the door gap with a spacer gauge. •The gap of the upper section between the front door and the back door should be 5.5 ± 0.7 mm

• The gap of the outboard side should be 5.5 ± 0.7 mm

• The gap between the front door and pole A should be 6.5±1mm

• The gap of upper section between front door and back door should be 5.5 ± 0.7 mm

• The gap between the front/back door and the doorsill should be6±1mm

• The overall levelness when measured with a magnet should be 0-0.5 mm

2. Install the bolts (Part Number: T11-6101103, 2 pcs both upper and lower) into the body for 2-3 turns, tighten with pneumatic wrench. Torque: 35 ± 3 N·m.

Check for the following after repair:

• Any scratches from reassembly

• Whether the bolts and nuts are assembled properly

• Whether the bolts and nuts are properly tightened

• Whether the gap and levelness between front door and back door is within the specifications

• Whether the edge height is 0-0.5 mm.

Replacing Front Door Hinge

1. Remove the front fender to gain access to the door hinge (See Fender Removal & Installation in Section 15

Body & Accessories).

2. Support the door.

3. Remove the four retaining bolts from the upper and lower hinges, and then remove the hinges.

DOORS

LTSM150120

15–172Chery Automobile Co., Ltd.

Page 1813 of 1903

Downloaded from www.Manualslib.com manuals search engine ON-VEHICLE SERVICE

Sunroof Glass

Removal & Installation

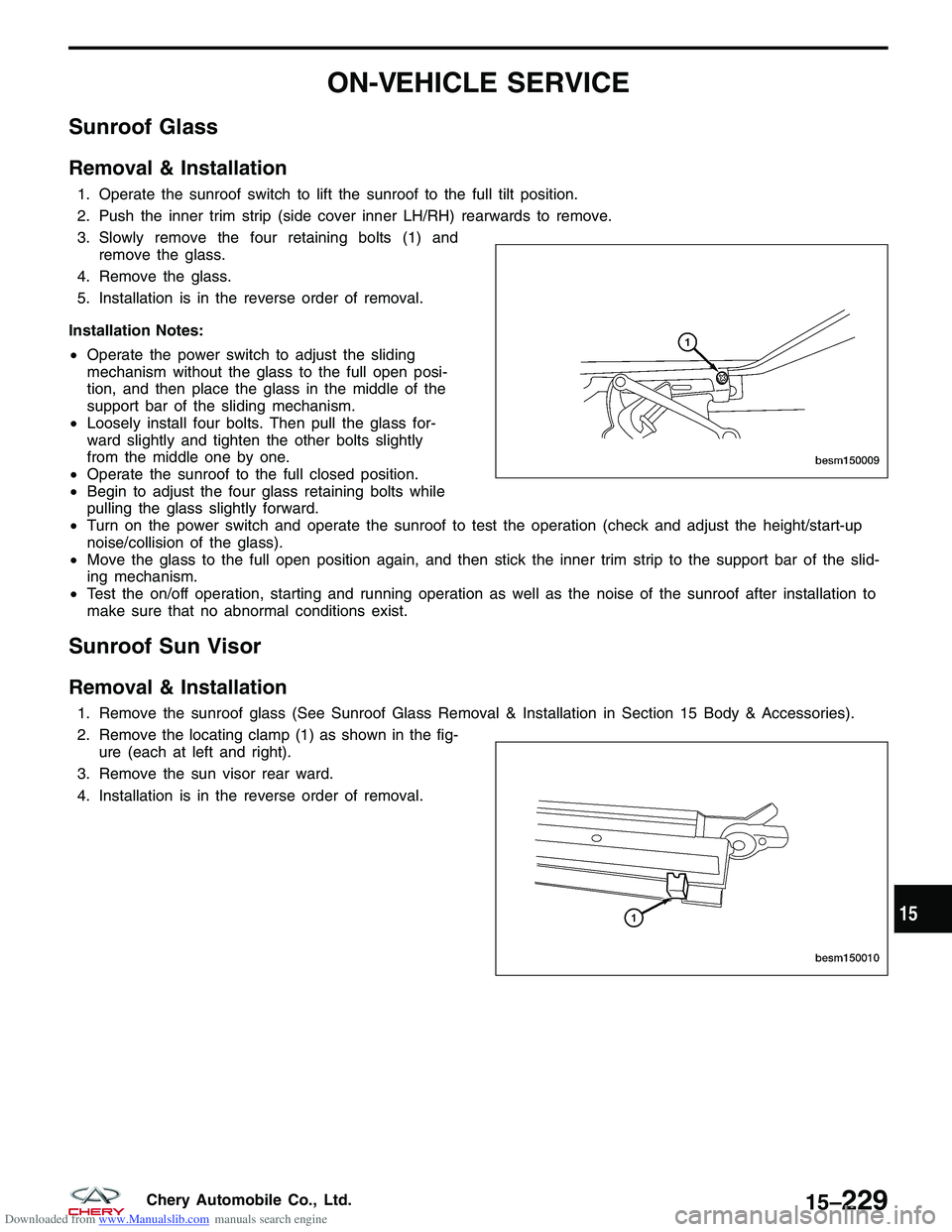

1. Operate the sunroof switch to lift the sunroof to the full tilt position.

2. Push the inner trim strip (side cover inner LH/RH) rearwards to remove.

3. Slowly remove the four retaining bolts (1) andremove the glass.

4. Remove the glass.

5. Installation is in the reverse order of removal.

Installation Notes:

• Operate the power switch to adjust the sliding

mechanism without the glass to the full open posi-

tion, and then place the glass in the middle of the

support bar of the sliding mechanism.

• Loosely install four bolts. Then pull the glass for-

ward slightly and tighten the other bolts slightly

from the middle one by one.

• Operate the sunroof to the full closed position.

• Begin to adjust the four glass retaining bolts while

pulling the glass slightly forward.

• Turn on the power switch and operate the sunroof to test the operation (check and adjust the height/start-up

noise/collision of the glass).

• Move the glass to the full open position again, and then stick the inner trim strip to the support bar of the slid-

ing mechanism.

• Test the on/off operation, starting and running operation as well as the noise of the sunroof after installation to

make sure that no abnormal conditions exist.

Sunroof Sun Visor

Removal & Installation

1. Remove the sunroof glass (See Sunroof Glass Removal & Installation in Section 15 Body & Accessories).

2. Remove the locating clamp (1) as shown in the fig-

ure (each at left and right).

3. Remove the sun visor rear ward.

4. Installation is in the reverse order of removal.

BESM150009

BESM150010

15

15–229Chery Automobile Co., Ltd.