wheel CHERY TIGGO 2009 Service User Guide

[x] Cancel search | Manufacturer: CHERY, Model Year: 2009, Model line: TIGGO, Model: CHERY TIGGO 2009Pages: 1903, PDF Size: 33.38 MB

Page 130 of 1903

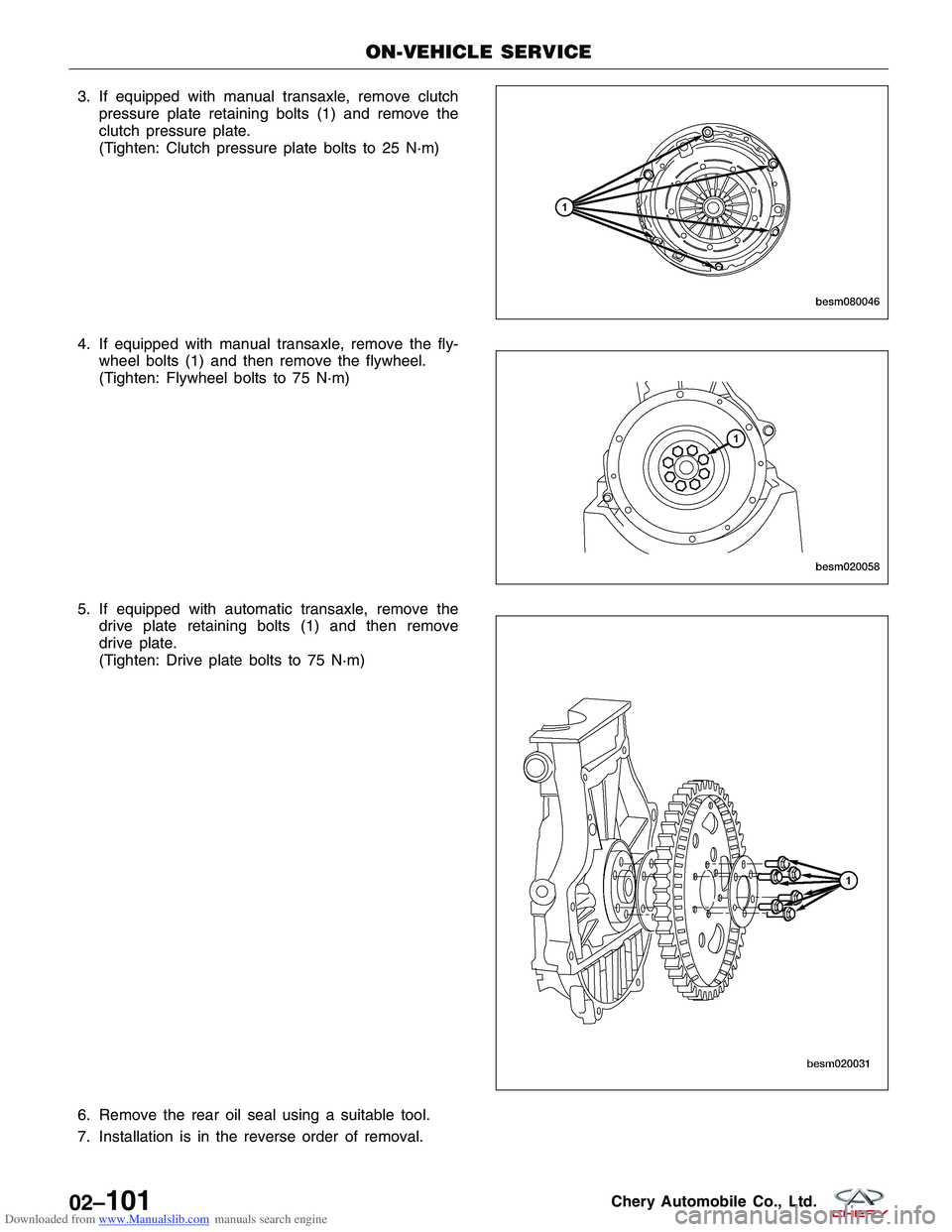

Downloaded from www.Manualslib.com manuals search engine 3. If equipped with manual transaxle, remove clutchpressure plate retaining bolts (1) and remove the

clutch pressure plate.

(Tighten: Clutch pressure plate bolts to 25 N·m)

4. If equipped with manual transaxle, remove the fly- wheel bolts (1) and then remove the flywheel.

(Tighten: Flywheel bolts to 75 N·m)

5. If equipped with automatic transaxle, remove the drive plate retaining bolts (1) and then remove

drive plate.

(Tighten: Drive plate bolts to 75 N·m)

6. Remove the rear oil seal using a suitable tool.

7. Installation is in the reverse order of removal.

ON-VEHICLE SERVICE

BESM080046

BESM020058

BESM020031

02–101Chery Automobile Co., Ltd.

Page 182 of 1903

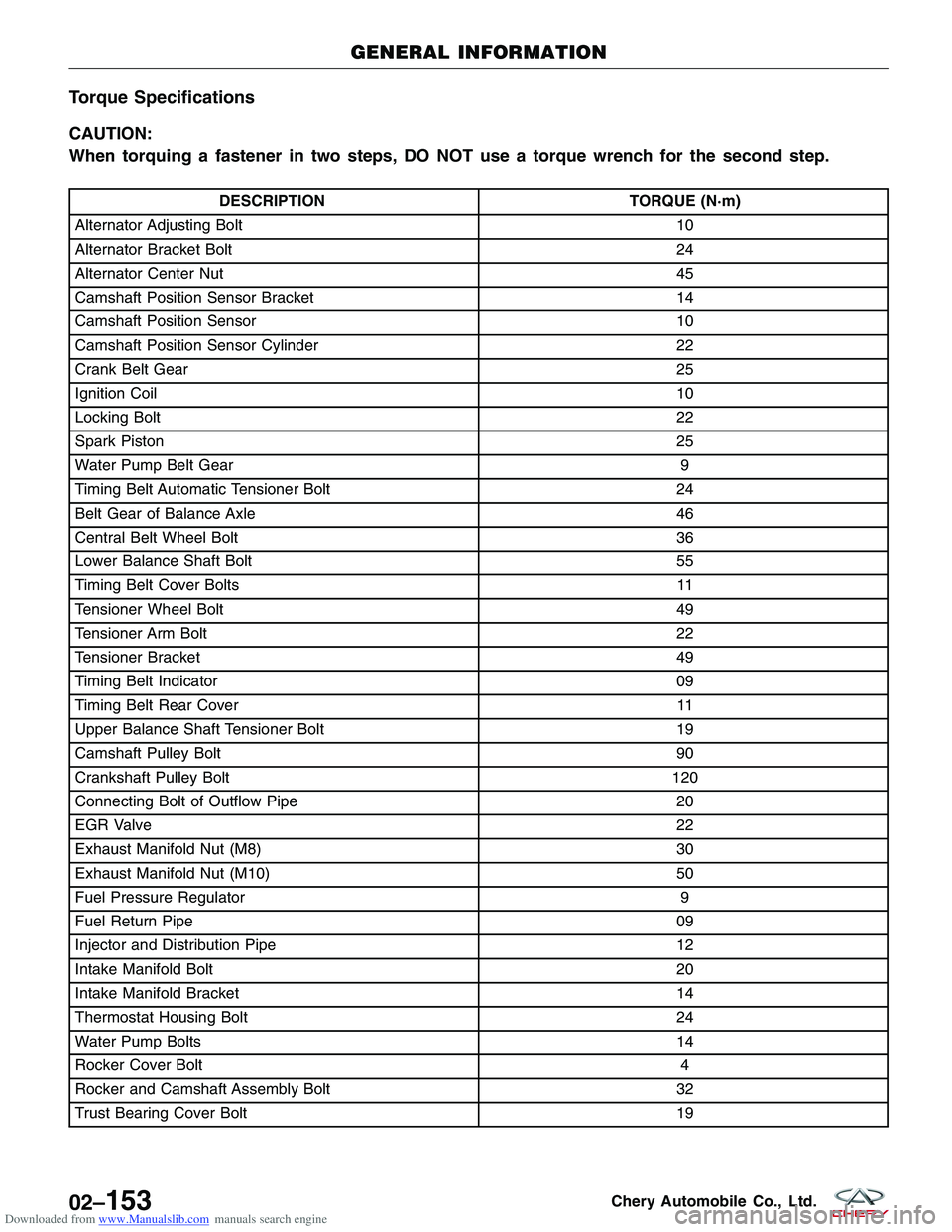

Downloaded from www.Manualslib.com manuals search engine Torque Specifications

CAUTION:

When torquing a fastener in two steps, DO NOT use a torque wrench for the second step.

DESCRIPTIONTORQUE (N·m)

Alternator Adjusting Bolt 10

Alternator Bracket Bolt 24

Alternator Center Nut 45

Camshaft Position Sensor Bracket 14

Camshaft Position Sensor 10

Camshaft Position Sensor Cylinder 22

Crank Belt Gear 25

Ignition Coil 10

Locking Bolt 22

Spark Piston 25

Water Pump Belt Gear 9

Timing Belt Automatic Tensioner Bolt 24

Belt Gear of Balance Axle 46

Central Belt Wheel Bolt 36

Lower Balance Shaft Bolt 55

Timing Belt Cover Bolts 11

Tensioner Wheel Bolt 49

Tensioner Arm Bolt 22

Tensioner Bracket 49

Timing Belt Indicator 09

Timing Belt Rear Cover 11

Upper Balance Shaft Tensioner Bolt 19

Camshaft Pulley Bolt 90

Crankshaft Pulley Bolt 120

Connecting Bolt of Outflow Pipe 20

EGR Valve 22

Exhaust Manifold Nut (M8) 30

Exhaust Manifold Nut (M10) 50

Fuel Pressure Regulator 9

Fuel Return Pipe 09

Injector and Distribution Pipe 12

Intake Manifold Bolt 20

Intake Manifold Bracket 14

Thermostat Housing Bolt 24

Water Pump Bolts 14

Rocker Cover Bolt 4

Rocker and Camshaft Assembly Bolt 32

Trust Bearing Cover Bolt 19

GENERAL INFORMATION

02–153Chery Automobile Co., Ltd.

Page 183 of 1903

Downloaded from www.Manualslib.com manuals search engine DESCRIPTIONTORQUE (N·m)

Cylinder Head Bolts 1st Step: Tighten the bolt to 78 N·m

2nd Step: Completely loosen the bolt

3rd Step: Retighten the bolt to 20 N·m

4th Step: Tighten the bolt an additional 90°

5th Step: Finish tightening the bolt an additional 90°

Engine Oil Pump Cover Bolt 16

Front Cover Bolts 24

Flange Bolt 37

Oil Pan Drain Plug 45

Oil Pan 18

Oil Pressure Switch 10

Oil Pressure Relief Plug 45

Oil Plug 24

Oil Strainer Screw Bolts 19

Oil Filter Adapter Bolts 19

Connecting Rod Nuts 1st Step: Tighten the nuts to 20 N·m

2nd Step: Tighten the nuts an additional 90°-100°

Flywheel Bolts 135

Oil Seal Cover Screw Bolts 11

Crankshaft Main Bearing Bolts 1st Step: Tighten the bolts to 25 N·m

2nd Step: Tighten the bolts an additional 90°-100°

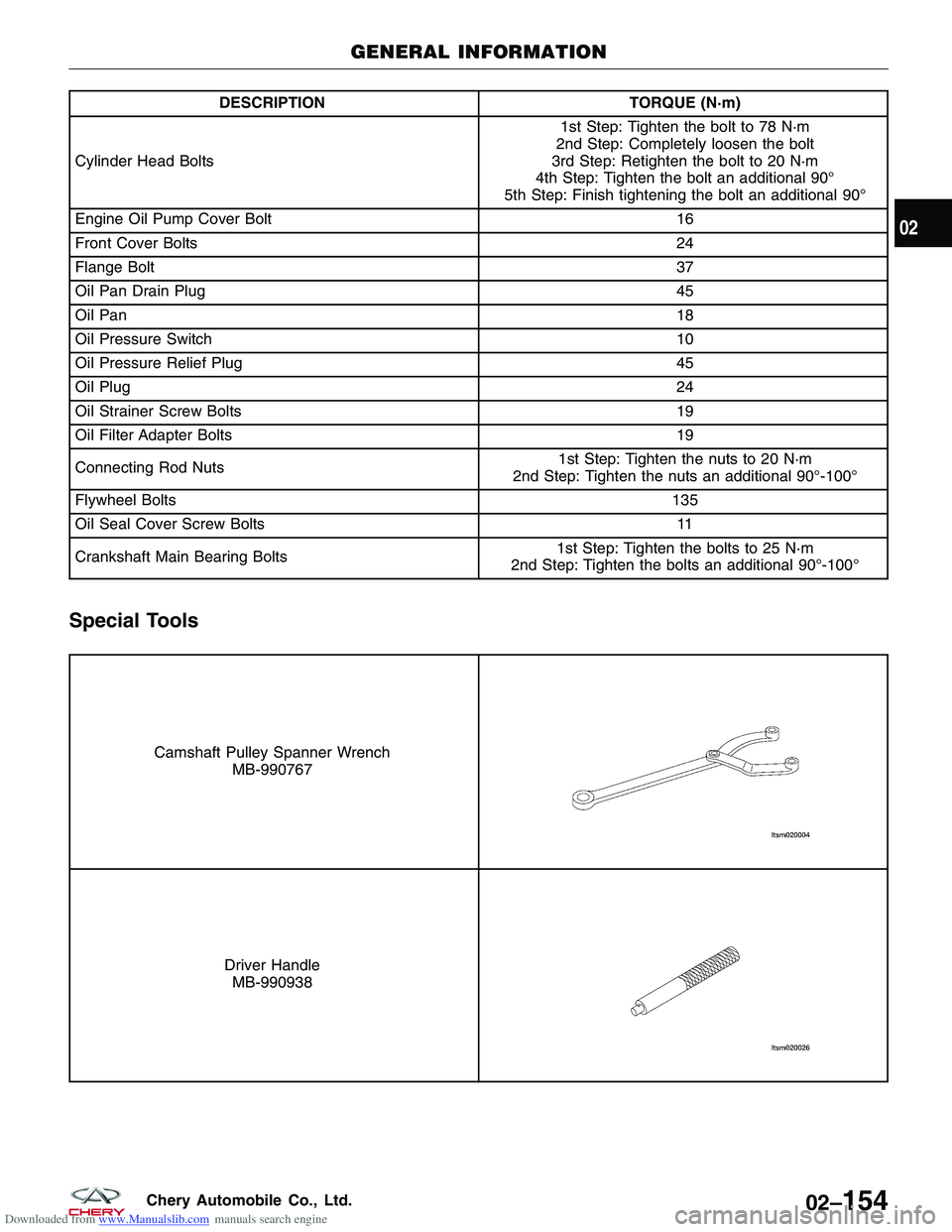

Special Tools

Camshaft Pulley Spanner Wrench MB-990767

Driver HandleMB-990938

GENERAL INFORMATION

02

02–154Chery Automobile Co., Ltd.

Page 188 of 1903

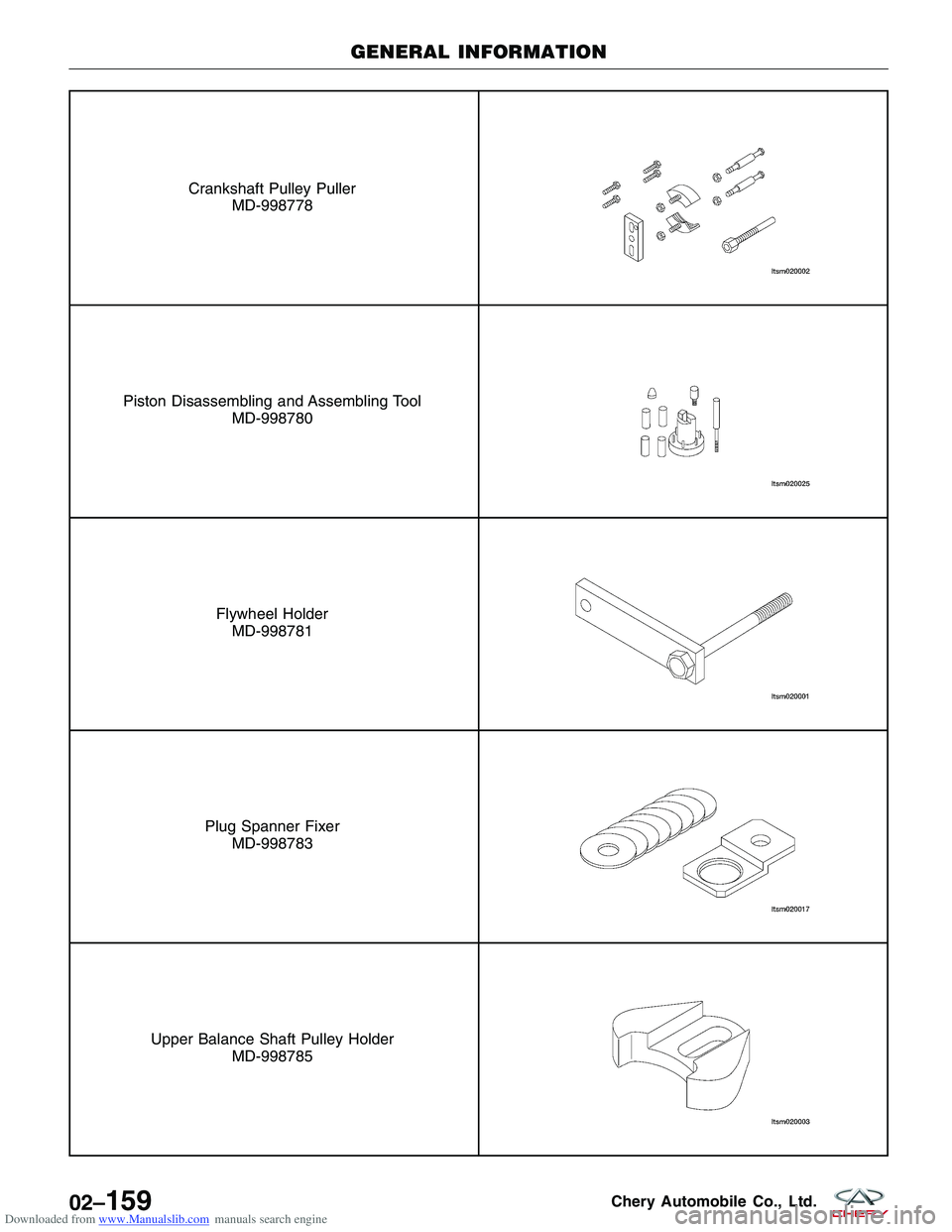

Downloaded from www.Manualslib.com manuals search engine Crankshaft Pulley PullerMD-998778

Piston Disassembling and Assembling Tool MD-998780

Flywheel HolderMD-998781

Plug Spanner Fixer MD-998783

Upper Balance Shaft Pulley Holder MD-998785

GENERAL INFORMATION

02–159Chery Automobile Co., Ltd.

Page 193 of 1903

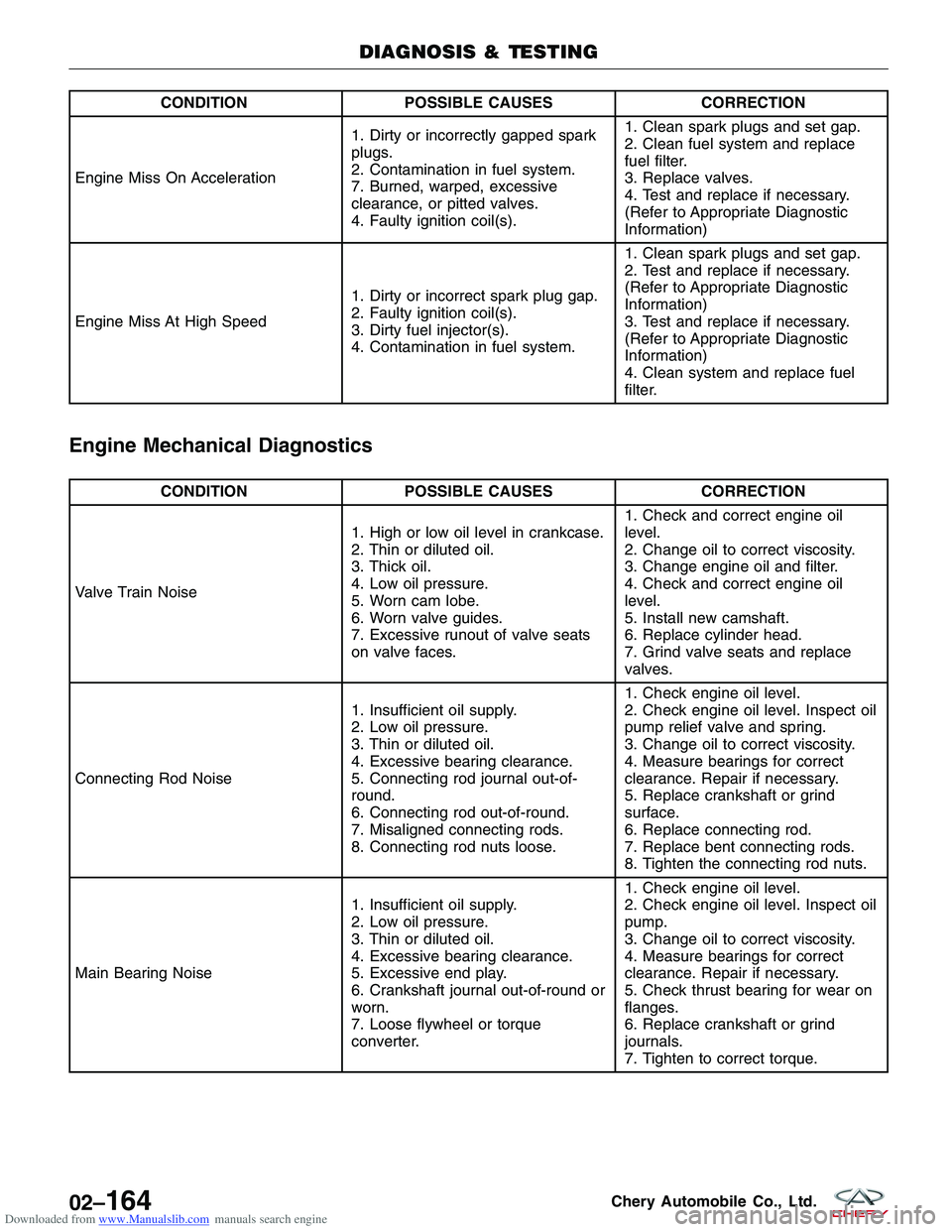

Downloaded from www.Manualslib.com manuals search engine CONDITIONPOSSIBLE CAUSES CORRECTION

Engine Miss On Acceleration 1. Dirty or incorrectly gapped spark

plugs.

2. Contamination in fuel system.

7. Burned, warped, excessive

clearance, or pitted valves.

4. Faulty ignition coil(s).1. Clean spark plugs and set gap.

2. Clean fuel system and replace

fuel filter.

3. Replace valves.

4. Test and replace if necessary.

(Refer to Appropriate Diagnostic

Information)

Engine Miss At High Speed 1. Dirty or incorrect spark plug gap.

2. Faulty ignition coil(s).

3. Dirty fuel injector(s).

4. Contamination in fuel system.1. Clean spark plugs and set gap.

2. Test and replace if necessary.

(Refer to Appropriate Diagnostic

Information)

3. Test and replace if necessary.

(Refer to Appropriate Diagnostic

Information)

4. Clean system and replace fuel

filter.

Engine Mechanical Diagnostics

CONDITION

POSSIBLE CAUSES CORRECTION

Valve Train Noise 1. High or low oil level in crankcase.

2. Thin or diluted oil.

3. Thick oil.

4. Low oil pressure.

5. Worn cam lobe.

6. Worn valve guides.

7. Excessive runout of valve seats

on valve faces.1. Check and correct engine oil

level.

2. Change oil to correct viscosity.

3. Change engine oil and filter.

4. Check and correct engine oil

level.

5. Install new camshaft.

6. Replace cylinder head.

7. Grind valve seats and replace

valves.

Connecting Rod Noise 1. Insufficient oil supply.

2. Low oil pressure.

3. Thin or diluted oil.

4. Excessive bearing clearance.

5. Connecting rod journal out-of-

round.

6. Connecting rod out-of-round.

7. Misaligned connecting rods.

8. Connecting rod nuts loose.1. Check engine oil level.

2. Check engine oil level. Inspect oil

pump relief valve and spring.

3. Change oil to correct viscosity.

4. Measure bearings for correct

clearance. Repair if necessary.

5. Replace crankshaft or grind

surface.

6. Replace connecting rod.

7. Replace bent connecting rods.

8. Tighten the connecting rod nuts.

Main Bearing Noise 1. Insufficient oil supply.

2. Low oil pressure.

3. Thin or diluted oil.

4. Excessive bearing clearance.

5. Excessive end play.

6. Crankshaft journal out-of-round or

worn.

7. Loose flywheel or torque

converter.1. Check engine oil level.

2. Check engine oil level. Inspect oil

pump.

3. Change oil to correct viscosity.

4. Measure bearings for correct

clearance. Repair if necessary.

5. Check thrust bearing for wear on

flanges.

6. Replace crankshaft or grind

journals.

7. Tighten to correct torque.

DIAGNOSIS & TESTING

02–164Chery Automobile Co., Ltd.

Page 206 of 1903

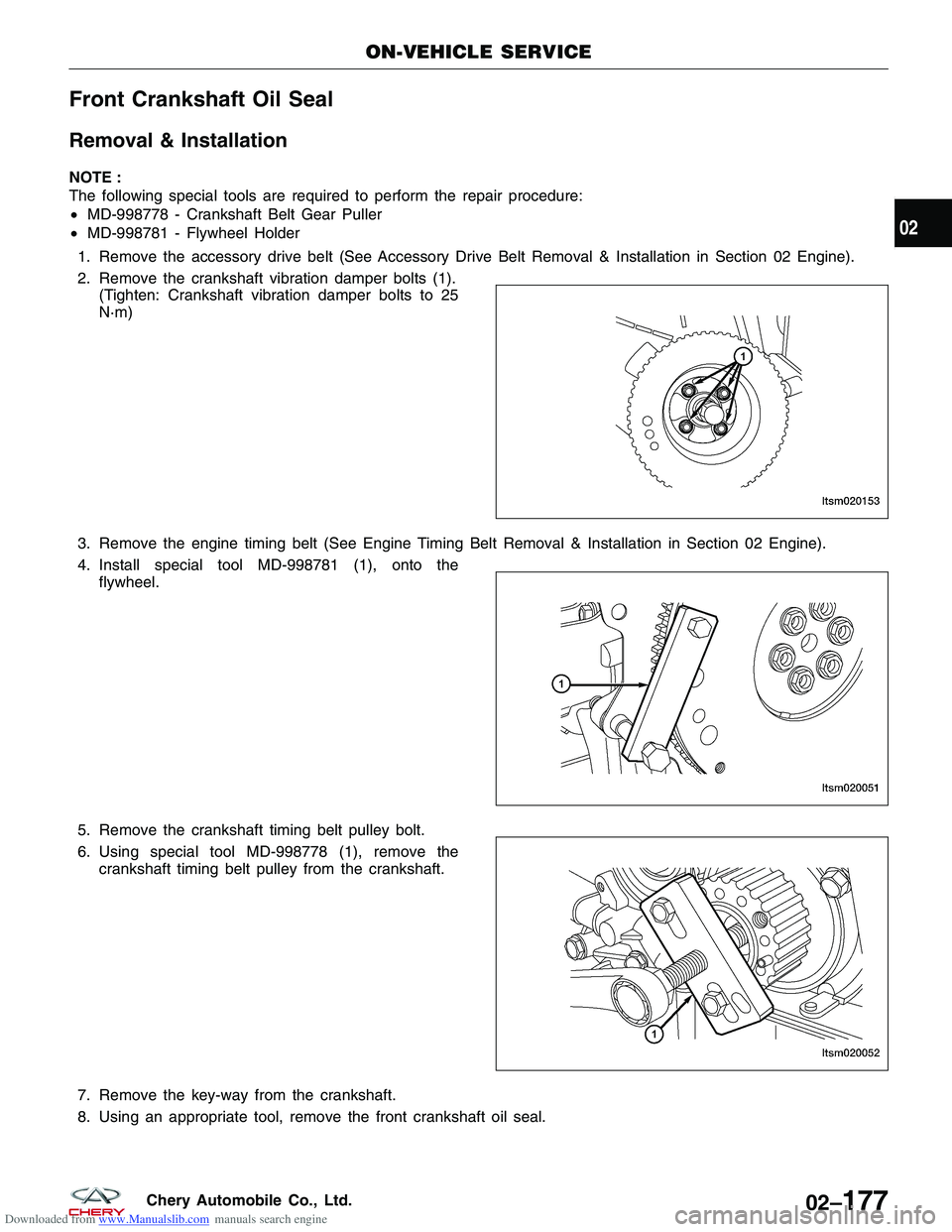

Downloaded from www.Manualslib.com manuals search engine Front Crankshaft Oil Seal

Removal & Installation

NOTE :

The following special tools are required to perform the repair procedure:

•MD-998778 - Crankshaft Belt Gear Puller

• MD-998781 - Flywheel Holder

1. Remove the accessory drive belt (See Accessory Drive Belt Removal & Installation in Section 02 Engine).

2. Remove the crankshaft vibration damper bolts (1). (Tighten: Crankshaft vibration damper bolts to 25

N·m)

3. Remove the engine timing belt (See Engine Timing Belt Removal & Installation in Section 02 Engine).

4. Install special tool MD-998781 (1), onto the flywheel.

5. Remove the crankshaft timing belt pulley bolt.

6. Using special tool MD-998778 (1), remove the crankshaft timing belt pulley from the crankshaft.

7. Remove the key-way from the crankshaft.

8. Using an appropriate tool, remove the front crankshaft oil seal.

ON-VEHICLE SERVICE

LTSM020153

LTSM020051 LTSM020052

02

02–177Chery Automobile Co., Ltd.

Page 208 of 1903

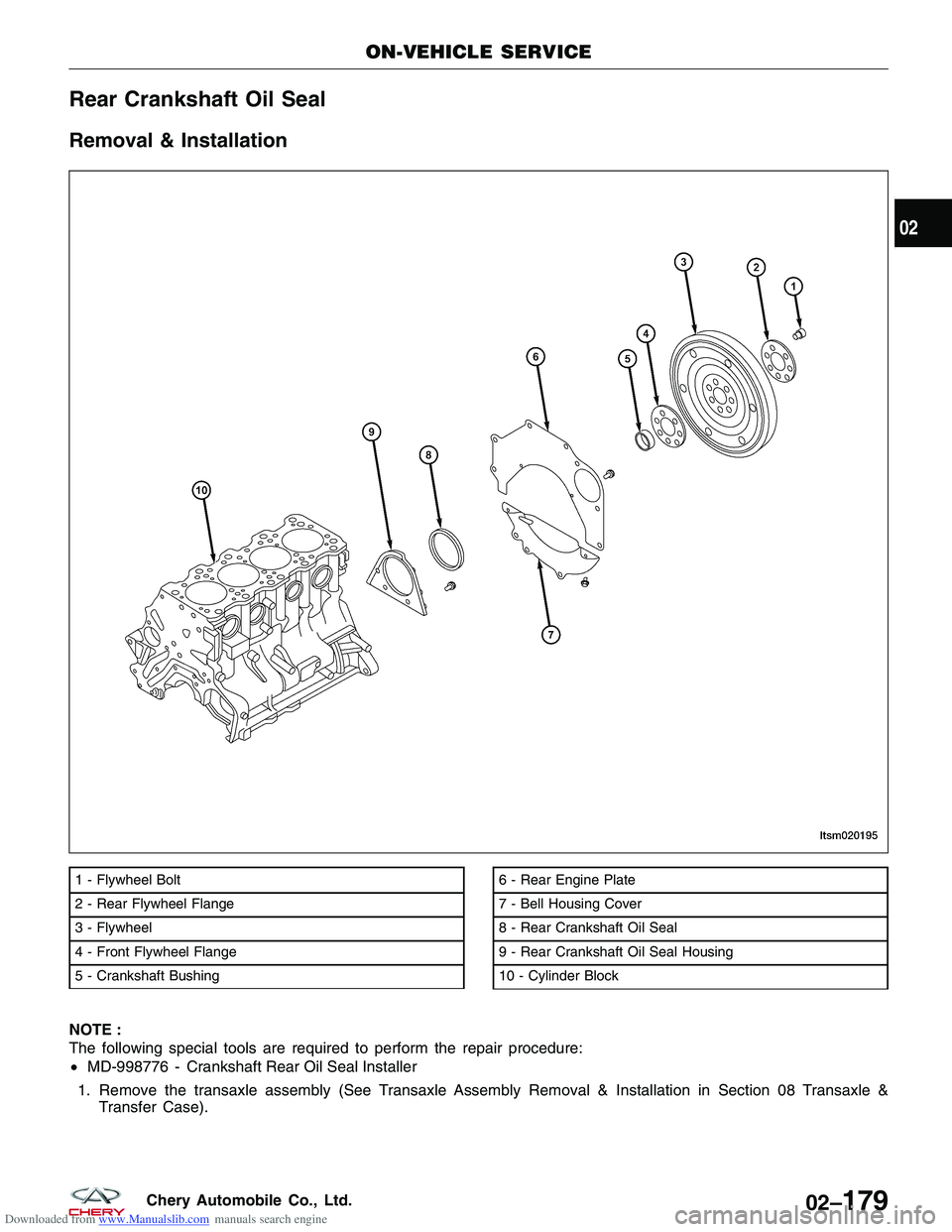

Downloaded from www.Manualslib.com manuals search engine Rear Crankshaft Oil Seal

Removal & Installation

NOTE :

The following special tools are required to perform the repair procedure:

•MD-998776 - Crankshaft Rear Oil Seal Installer

1. Remove the transaxle assembly (See Transaxle Assembly Removal & Installation in Section 08 Transaxle & Transfer Case).

1 - Flywheel Bolt

2 - Rear Flywheel Flange

3 - Flywheel

4 - Front Flywheel Flange

5 - Crankshaft Bushing6 - Rear Engine Plate

7 - Bell Housing Cover

8 - Rear Crankshaft Oil Seal

9 - Rear Crankshaft Oil Seal Housing

10 - Cylinder Block

ON-VEHICLE SERVICE

LTSM020195

02

02–179Chery Automobile Co., Ltd.

Page 209 of 1903

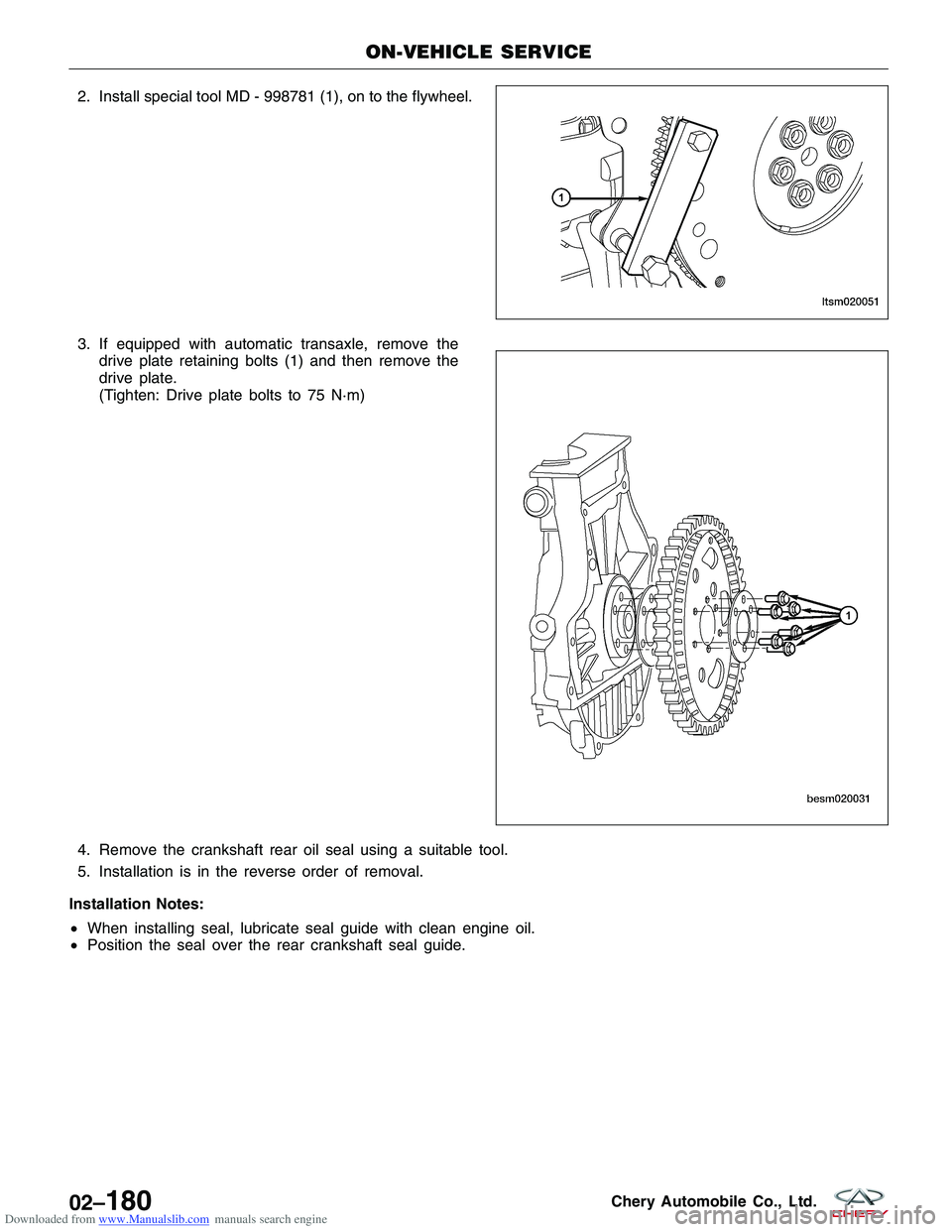

Downloaded from www.Manualslib.com manuals search engine 2. Install special tool MD - 998781 (1), on to the flywheel.flywheel.

3. If equipped with automatic transaxle, remove the drive plate retaining bolts (1) and then remove the

drive plate.

(Tighten: Drive plate bolts to 75 N·m)

4. Remove the crankshaft rear oil seal using a suitable tool.

5. Installation is in the reverse order of removal.

Installation Notes:

• When installing seal, lubricate seal guide with clean engine oil.

• Position the seal over the rear crankshaft seal guide.

ON-VEHICLE SERVICE

LTSM020051

BESM020031

02–180Chery Automobile Co., Ltd.

Page 227 of 1903

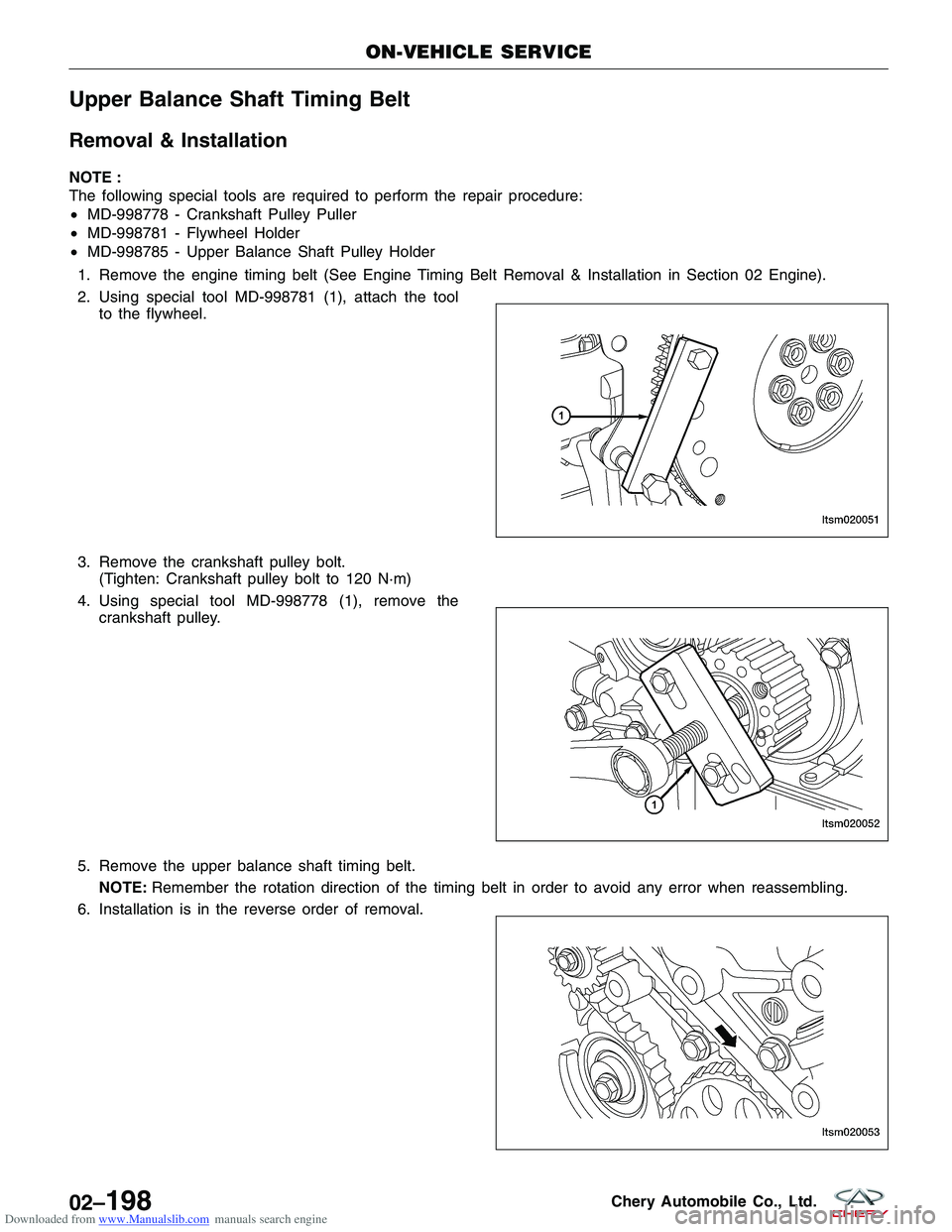

Downloaded from www.Manualslib.com manuals search engine Upper Balance Shaft Timing Belt

Removal & Installation

NOTE :

The following special tools are required to perform the repair procedure:

•MD-998778 - Crankshaft Pulley Puller

• MD-998781 - Flywheel Holder

• MD-998785 - Upper Balance Shaft Pulley Holder

1. Remove the engine timing belt (See Engine Timing Belt Removal & Installation in Section 02 Engine).

2. Using special tool MD-998781 (1), attach the tool to the flywheel.

3. Remove the crankshaft pulley bolt. (Tighten: Crankshaft pulley bolt to 120 N·m)

4. Using special tool MD-998778 (1), remove the crankshaft pulley.

5. Remove the upper balance shaft timing belt. NOTE: Remember the rotation direction of the timing belt in order to avoid any error when reassembling.

6. Installation is in the reverse order of removal.

ON-VEHICLE SERVICE

LTSM020051

LTSM020052

LTSM020053

02–198Chery Automobile Co., Ltd.

Page 504 of 1903

Downloaded from www.Manualslib.com manuals search engine 4. Installation is in the reverse order of removal.

Installation Notes:

• Before installing the oxygen sensor, coat the threads with rust inhibiting lubricant.

Crankshaft Position (CKP) Sensor

Description

The Crankshaft Position (CKP) sensor is located on the flywheel shell facing the gear teeth of the signal plate. It

detects the fluctuation of the engine revolution. The sensor consists of a permanent magnet and induction coil.

Operation

The crankshaft sensor is made of a toothed metal disk mounted on the crankshaft and a stationary detector that

covers a magnetic coil that the current passes through. As the metal teeth move past the coil, its magnetic field is

disturbed. This causes a stream of pulses in the current. The Engine Control Module (ECM) can calculate the speed

of the engine from the crankshaft’s frequency of pulses

Removal & Installation

1. Disconnect the negative battery cable.

2. Disconnect the CKP sensor electrical connector.

3. Remove the CKP sensor retaining bolt (1) and

remove the CKP sensor.

(Tighten: Crankshaft position sensor retaining bolt

to 10 N·m)

4. Installation is in the reverse order of removal.

Camshaft Position (CMP) Sensor

Description

The Camshaft Position (CMP) sensor senses the protrusion of inlet valve cam sprocket to identify a particular cyl-

inder. The CMP sensor senses the piston position. When the Crankshaft Position (CKP) sensor becomes inoperative,

the CMP sensor provides various controls of engine parts instead, utilizing timing of cylinder identification signals.

The sensor consists of a permanent magnet and Hall IC.

ON-VEHICLE SERVICE

LTSM030036

03–220Chery Automobile Co., Ltd.