wheel CHERY TIGGO 2009 Service Owner's Manual

[x] Cancel search | Manufacturer: CHERY, Model Year: 2009, Model line: TIGGO, Model: CHERY TIGGO 2009Pages: 1903, PDF Size: 33.38 MB

Page 714 of 1903

Downloaded from www.Manualslib.com manuals search engine 4. Installation is in the reverse order of removal.

Installation Notes:

• Before installing the oxygen sensor, coat the threads with rust inhibiting lubricant.

Crankshaft Position (CKP) Sensor

Description

The Crankshaft Position (CKP) sensor is located on the flywheel shell facing the gear teeth of the signal plate. It

detects the fluctuation of the engine revolution. The sensor consists of a permanent magnet and Induction coil.

Operation

When the engine is running, the high and low parts of the teeth cause the gap with the sensor to change. The

changing gap causes the magnetic field near the sensor to change. Due to the changing magnetic field, the voltage

from the sensor changes. The Engine Control Module (ECM) receives the voltage signal and detects the fluctuation

of the engine revolution.

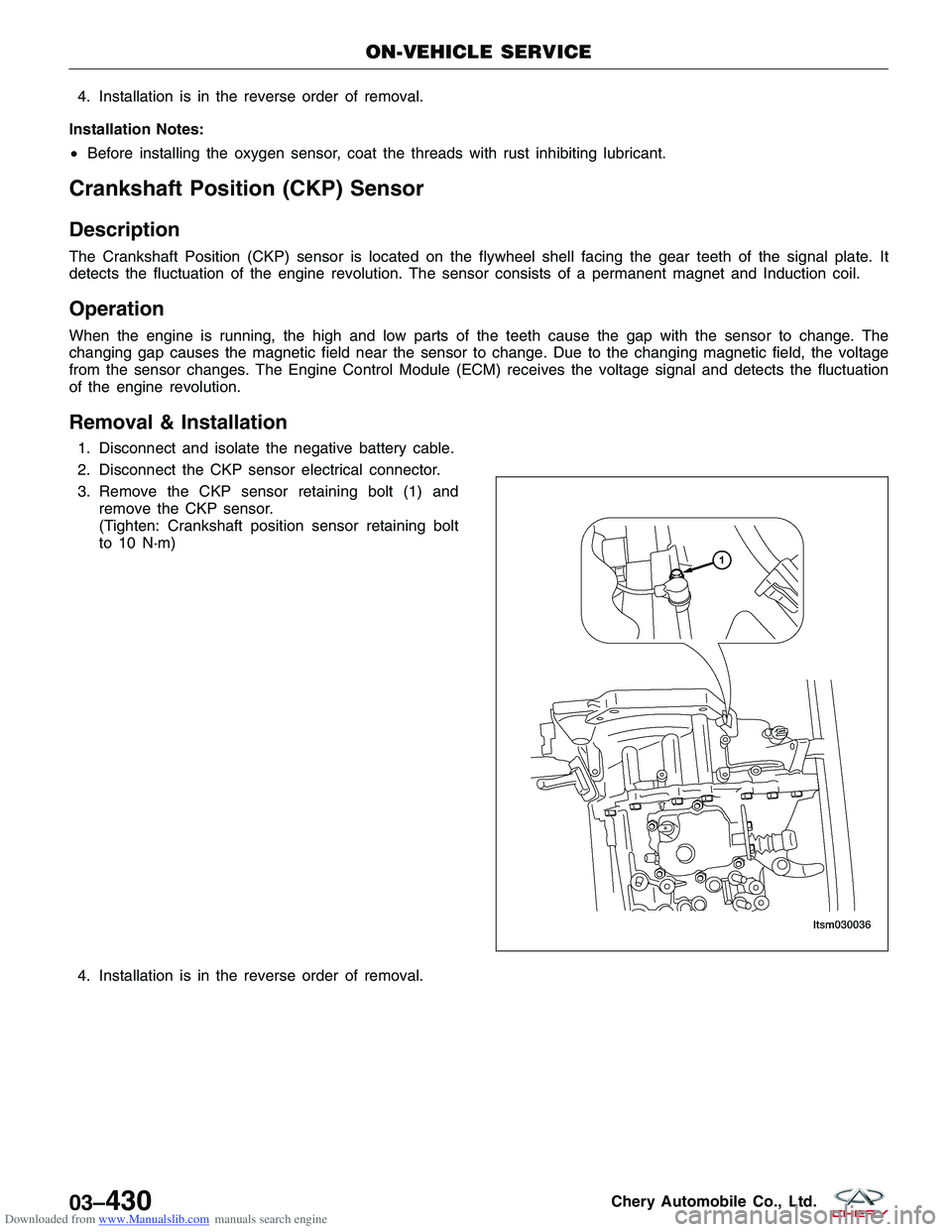

Removal & Installation

1. Disconnect and isolate the negative battery cable.

2. Disconnect the CKP sensor electrical connector.

3. Remove the CKP sensor retaining bolt (1) and

remove the CKP sensor.

(Tighten: Crankshaft position sensor retaining bolt

to 10 N·m)

4. Installation is in the reverse order of removal.

ON-VEHICLE SERVICE

LTSM030036

03–430Chery Automobile Co., Ltd.

Page 826 of 1903

Downloaded from www.Manualslib.com manuals search engine Crankshaft Position (CKP) Sensor

Description

The Crankshaft Position (CKP) sensor is located on the flywheel shell facing the gear teeth of the signal plate. It

detects the fluctuation of the engine revolution. The sensor consists of a permanent magnet and Induction coil.

Operation

When the engine is running, the high and low parts of the teeth cause the gap with the sensor to change. The

changing gap cause the magnetic field near the sensor to change. Due to the changing magnetic field, the voltage

from the sensor changes. The Engine Control Module (ECM) receives the voltage signal and detects the fluctuation

of the engine revolution.

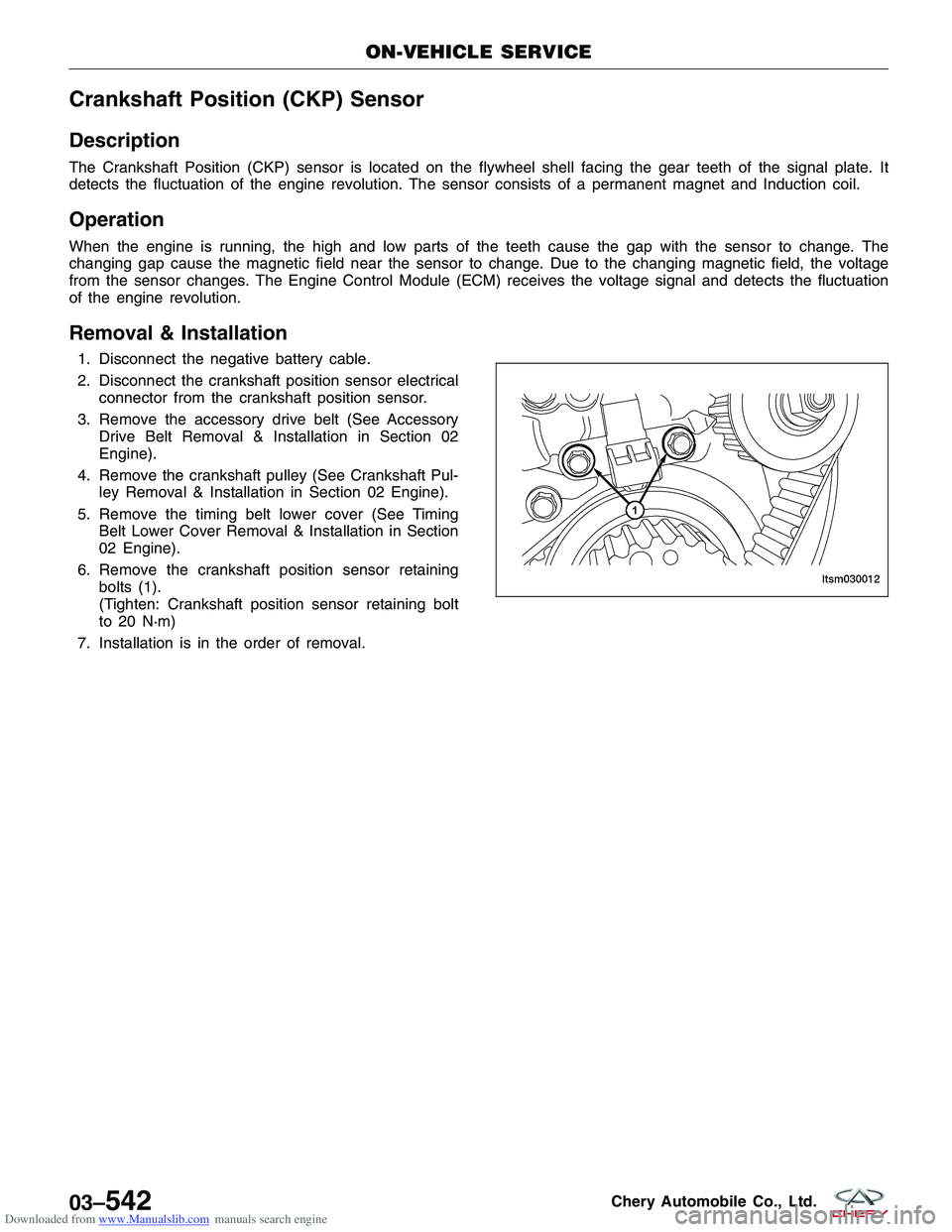

Removal & Installation

1. Disconnect the negative battery cable.

2. Disconnect the crankshaft position sensor electricalconnector from the crankshaft position sensor.

3. Remove the accessory drive belt (See Accessory Drive Belt Removal & Installation in Section 02

Engine).

4. Remove the crankshaft pulley (See Crankshaft Pul- ley Removal & Installation in Section 02 Engine).

5. Remove the timing belt lower cover (See Timing Belt Lower Cover Removal & Installation in Section

02 Engine).

6. Remove the crankshaft position sensor retaining bolts (1).

(Tighten: Crankshaft position sensor retaining bolt

to 20 N·m)

7. Installation is in the order of removal.

ON-VEHICLE SERVICE

LTSM030012

03–542Chery Automobile Co., Ltd.

Page 996 of 1903

Downloaded from www.Manualslib.com manuals search engine 2.HYDRAULIC TEST

• Preheat the transaxle fluid to 80° - 100°C.

• Lift the vehicle until the wheels can rotate freely.

• Connect the special fluid pressure gage onto the

fluid pressure measurement port as (3).

CONNECTOR AND TEST CAVITY

CONNECTOR AND CAVITY 12 3

Figure name Output speed sensor Fluid pressure sensor Fluid pressure test port

STANDARD FLUID PRESSURE TEST

MEASURE STATUS ENGINE SPEED (RPM)STANDARD FLUID PRESSURE

(BAR)

Gear lever position Not runningBelow 0.2

D/R 820 RPM 2.6

D/R 1400 RPM 8.7

• In accordance with the shown status of standard fluid pressure measurement table, measure the fluid pressure

of measurement port. The measurement of port should be within the standard range.

• If some measurement values is beyond the standard range, please refer to the fluid pressure measurement and

diagnosis table for causes.

Is the check result normal?

Ye s>>Go to step 5 for disc or plate abrasion.

No

>>Go to the next step.

3.CHECK VALVE BODY ASSEMBLY AND FLUID PUMP AND PIPELINE

• Turn the ignition switch off.

• Remove and disassemble the DP0 Automatic Transaxle Assembly (See Automatic Transaxle Removal & Instal-

lation in Section 08 Transaxle & Transfer Case).

• Check valve body and fluid pump and pipeline.

Is the check result normal?

Ye s>>Go to the next step.

No

>>Replace the damaged components as needed.

DIAGNOSIS & TESTING

LTSMD080021

08

08–53Chery Automobile Co., Ltd.

Page 1152 of 1903

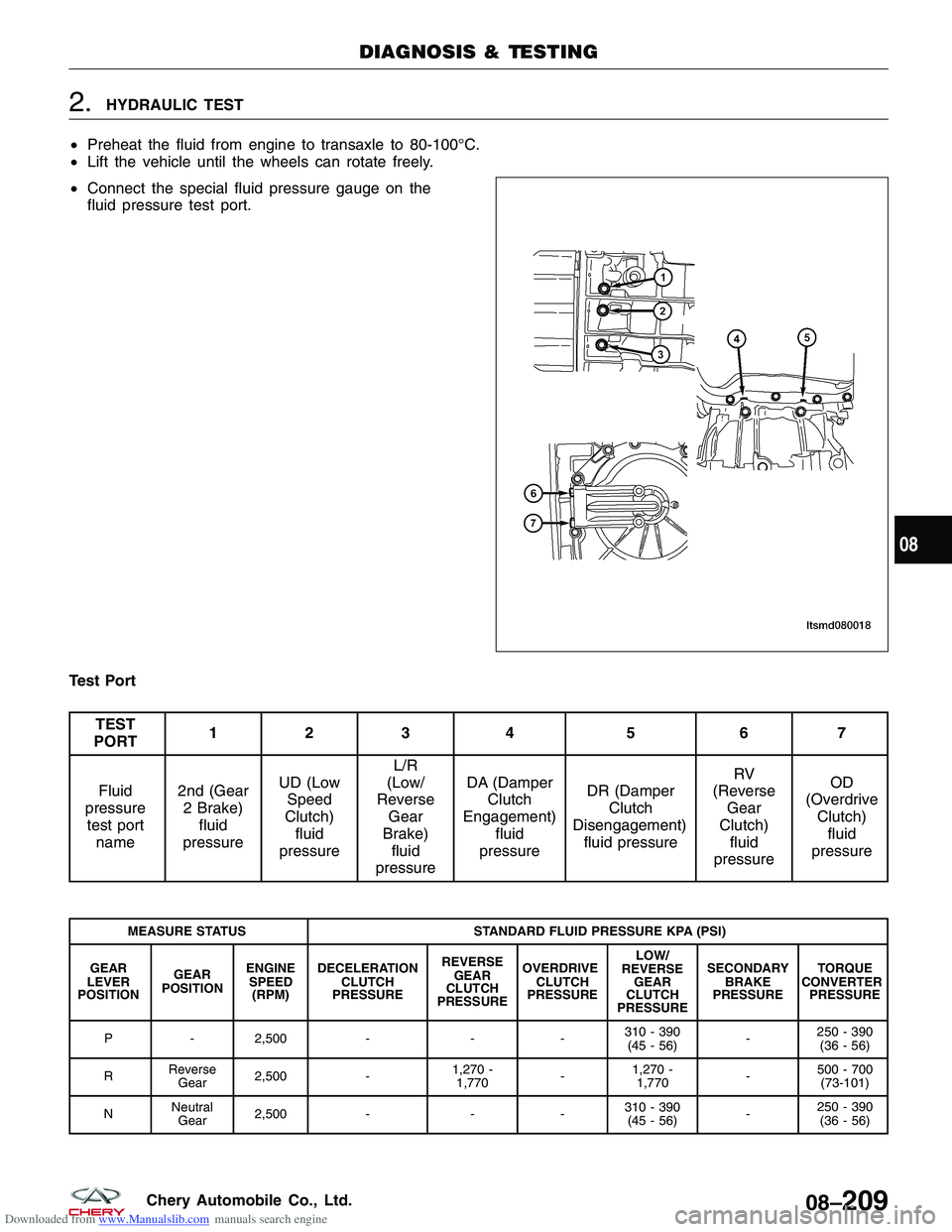

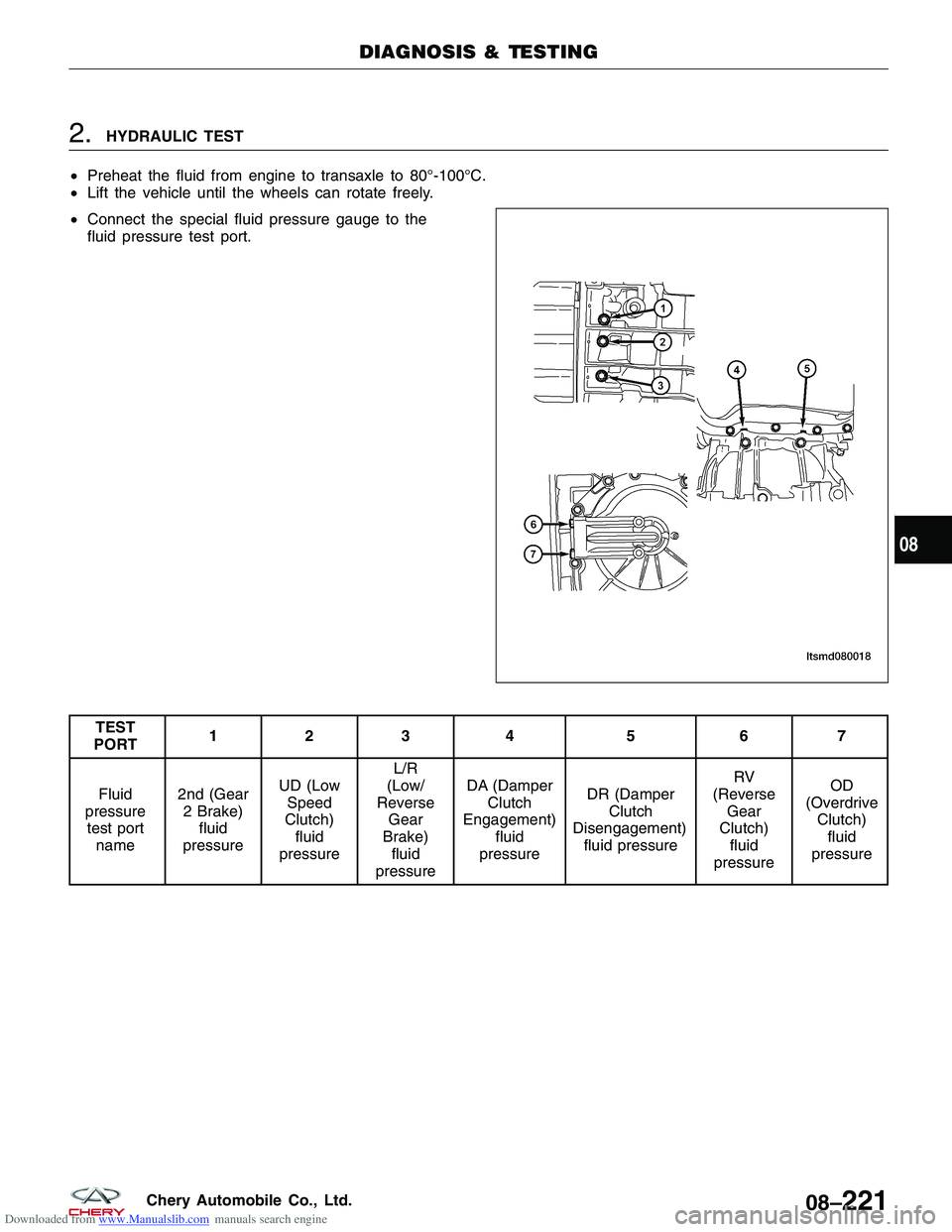

Downloaded from www.Manualslib.com manuals search engine 2.HYDRAULIC TEST

• Preheat the fluid from engine to transaxle to 80-100°C.

• Lift the vehicle until the wheels can rotate freely.

• Connect the special fluid pressure gauge on the

fluid pressure test port.

Test Port

TEST

PORT 123 4 5 6 7

Fluid

pressure test port name 2nd (Gear

2 Brake) fluid

pressure UD (Low

Speed

Clutch) fluid

pressure L/R

(Low/

Reverse Gear

Brake) fluid

pressure DA (Damper

Clutch

Engagement) fluid

pressure DR (Damper

Clutch

Disengagement) fluid pressure RV

(Reverse Gear

Clutch) fluid

pressure OD

(Overdrive Clutch)fluid

pressure

MEASURE STATUS STANDARD FLUID PRESSURE KPA (PSI)

GEAR

LEVER

POSITION GEAR

POSITION ENGINE

SPEED (RPM) DECELERATION

CLUTCH

PRESSURE REVERSE

GEAR

CLUTCH

PRESSURE OVERDRIVE

CLUTCH

PRESSURE LOW/

REVERSE GEAR

CLUTCH

PRESSURE SECONDARY

BRAKE

PRESSURE TORQUE

CONVERTER PRESSURE

P - 2,500 ---310 - 390

(45 - 56) -250 - 390

(36 - 56)

R Reverse

Gear 2,500

-1,270 -

1,770 -1,270 -

1,770 -500 - 700

(73-101)

N Neutral

Gear 2,500

---310 - 390

(45 - 56) -250 - 390

(36 - 56)

DIAGNOSIS & TESTING

LTSMD080018

08

08–209Chery Automobile Co., Ltd.

Page 1158 of 1903

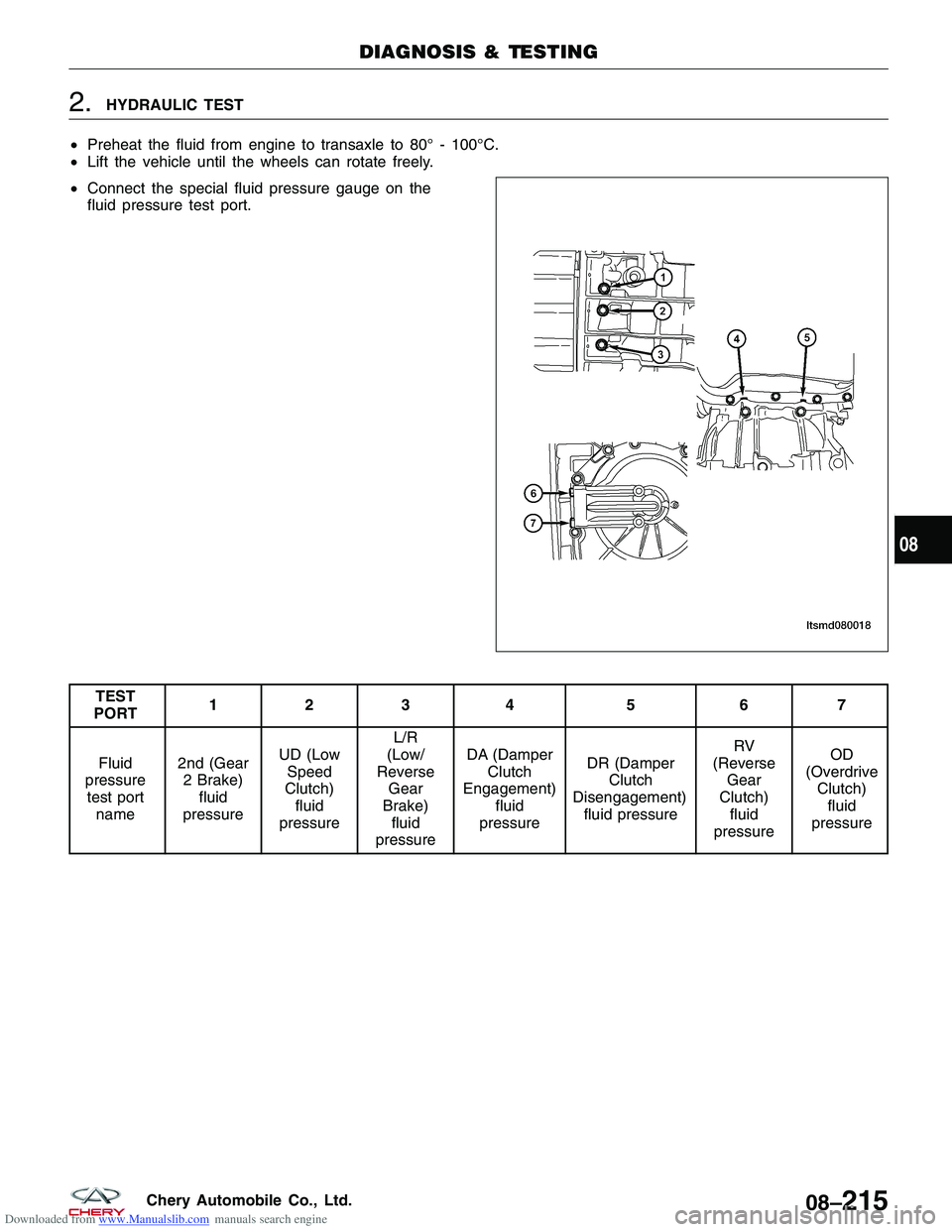

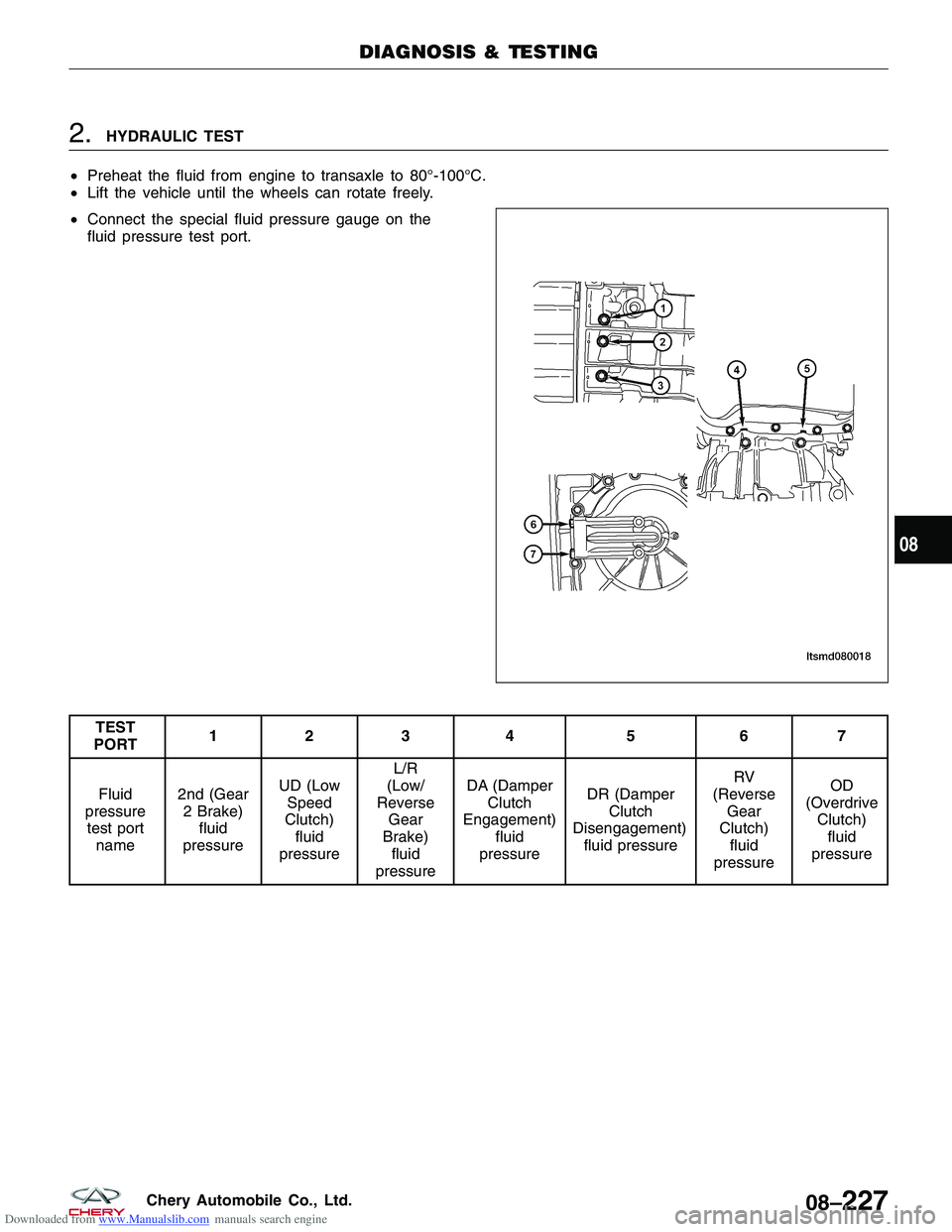

Downloaded from www.Manualslib.com manuals search engine 2.HYDRAULIC TEST

• Preheat the fluid from engine to transaxle to 80° - 100°C.

• Lift the vehicle until the wheels can rotate freely.

• Connect the special fluid pressure gauge on the

fluid pressure test port.

TEST

PORT 123 4 5 6 7

Fluid

pressure test port name 2nd (Gear

2 Brake) fluid

pressure UD (Low

Speed

Clutch) fluid

pressure L/R

(Low/

Reverse Gear

Brake) fluid

pressure DA (Damper

Clutch

Engagement) fluid

pressure DR (Damper

Clutch

Disengagement) fluid pressure RV

(Reverse Gear

Clutch) fluid

pressure OD

(Overdrive Clutch)fluid

pressure

DIAGNOSIS & TESTING

LTSMD080018

08

08–215Chery Automobile Co., Ltd.

Page 1164 of 1903

Downloaded from www.Manualslib.com manuals search engine 2.HYDRAULIC TEST

• Preheat the fluid from engine to transaxle to 80°-100°C.

• Lift the vehicle until the wheels can rotate freely.

• Connect the special fluid pressure gauge to the

fluid pressure test port.

TEST

PORT 123 4 5 6 7

Fluid

pressure test port name 2nd (Gear

2 Brake) fluid

pressure UD (Low

Speed

Clutch) fluid

pressure L/R

(Low/

Reverse Gear

Brake) fluid

pressure DA (Damper

Clutch

Engagement) fluid

pressure DR (Damper

Clutch

Disengagement) fluid pressure RV

(Reverse Gear

Clutch) fluid

pressure OD

(Overdrive Clutch)fluid

pressure

DIAGNOSIS & TESTING

LTSMD080018

08

08–221Chery Automobile Co., Ltd.

Page 1170 of 1903

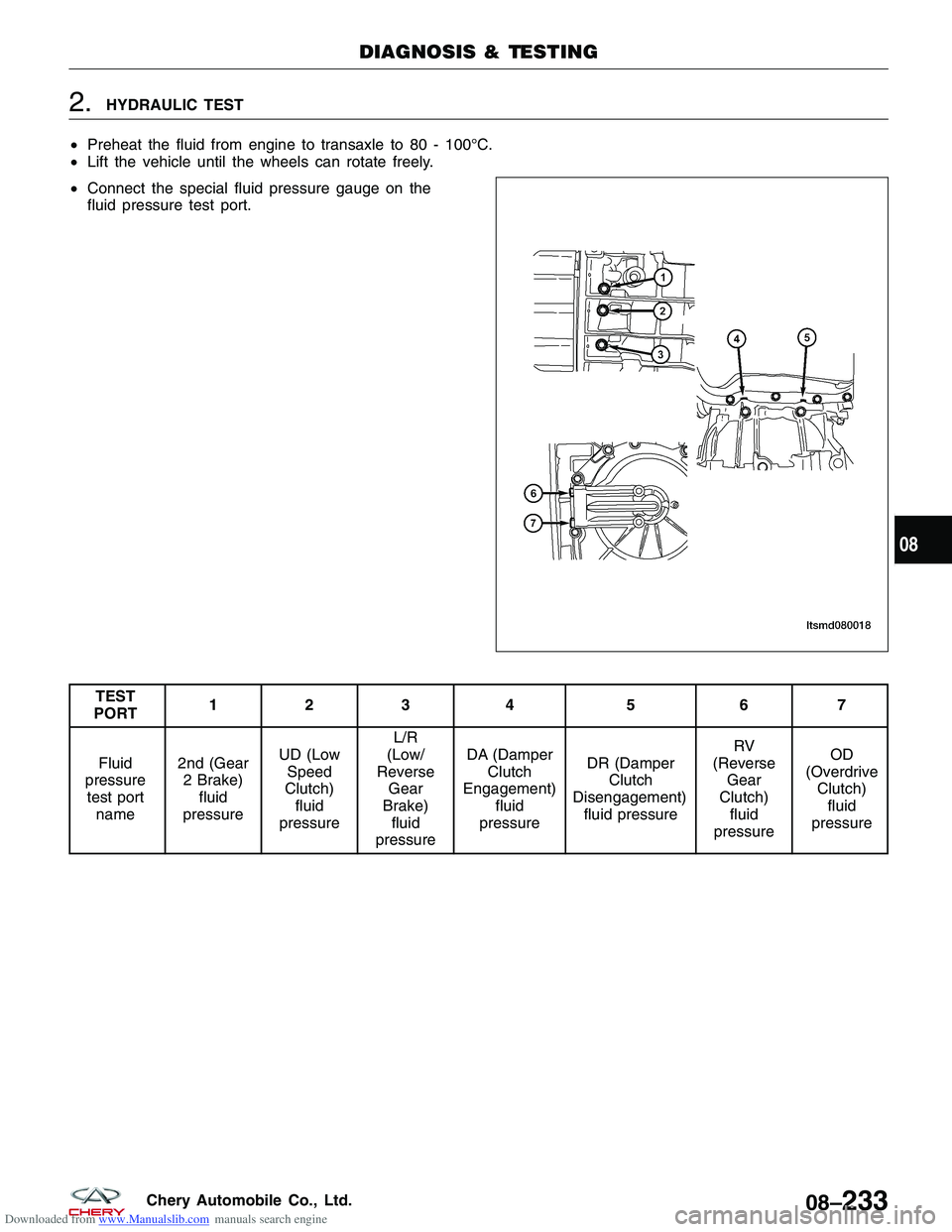

Downloaded from www.Manualslib.com manuals search engine 2.HYDRAULIC TEST

• Preheat the fluid from engine to transaxle to 80°-100°C.

• Lift the vehicle until the wheels can rotate freely.

• Connect the special fluid pressure gauge on the

fluid pressure test port.

TEST

PORT 123 4 5 6 7

Fluid

pressure test port name 2nd (Gear

2 Brake) fluid

pressure UD (Low

Speed

Clutch) fluid

pressure L/R

(Low/

Reverse Gear

Brake) fluid

pressure DA (Damper

Clutch

Engagement) fluid

pressure DR (Damper

Clutch

Disengagement) fluid pressure RV

(Reverse Gear

Clutch) fluid

pressure OD

(Overdrive Clutch)fluid

pressure

DIAGNOSIS & TESTING

LTSMD080018

08

08–227Chery Automobile Co., Ltd.

Page 1176 of 1903

Downloaded from www.Manualslib.com manuals search engine 2.HYDRAULIC TEST

• Preheat the fluid from engine to transaxle to 80 - 100°C.

• Lift the vehicle until the wheels can rotate freely.

• Connect the special fluid pressure gauge on the

fluid pressure test port.

TEST

PORT 123 4 5 6 7

Fluid

pressure test port name 2nd (Gear

2 Brake) fluid

pressure UD (Low

Speed

Clutch) fluid

pressure L/R

(Low/

Reverse Gear

Brake) fluid

pressure DA (Damper

Clutch

Engagement) fluid

pressure DR (Damper

Clutch

Disengagement) fluid pressure RV

(Reverse Gear

Clutch) fluid

pressure OD

(Overdrive Clutch)fluid

pressure

DIAGNOSIS & TESTING

LTSMD080018

08

08–233Chery Automobile Co., Ltd.

Page 1193 of 1903

Downloaded from www.Manualslib.com manuals search engine Operation

The following are the details of the manual transaxle:

Neutral

Engine power is transmitted to the input shaft via the clutch assembly and the input shaft turns. Since no synchro-

nizers are engaged on either the input or output shafts, power is not transmitted to the output shafts, power is not

transmitted to the output shaft and the differential does not turn.

1st Gear

Engine power is transmitted to the input shaft via the clutch assembly and the input shaft turns. The input shaft first

gear is integral to the input shaft, and is in constant mesh with the intermediate shaft first speed gear. Because of

this constant mesh, the output shaft first speed gear freewheels until first gear is selected. As the gearshift lever is

moved to the first gear position, the 1-2 fork moves the 1-2 synchronizer sleeve towards first gear on the output

shaft. The synchronizer sleeve engages the first gear clutch teeth, engaging the gear to the output shaft, and allow-

ing power to transmit through the output shaft to the differential.

2nd Gear

Engine power is transmitted to the input shaft via the clutch assembly and the input shaft turns. The input shaft

second gear is integral to the input shaft, and is in constant mesh with the output shaft second speed gear. Because

of this constant mesh, the output shaft second speed gear freewheels until second gear is selected. As the gearshift

lever is moved to the second gear position, the 1-2 fork moves the 1-2 synchronizer sleeve towards second gear on

the output shaft. The synchronizer sleeve engages the second gear clutch teeth, engaging the gear to the output

shaft, and allowing power to transmit through the output shaft to the differential.

3rd Gear

Engine power is transmitted to the input shaft via the clutch assembly and the input shaft turns. The input shaft third

speed gear is in constant mesh with the output shaft 3-4 cluster gear which is fixed to the output shaft. Because of

this constant mesh, the input shaft third speed gear freewheels until third gear is selected. As the gearshift lever is

moved to the third gear position, the 3-4 fork moves the 3-4 synchronizer sleeve towards third gear on the input

shaft. The synchronizer sleeve engages the third gear clutch teeth, engaging the gear to the input shaft, and allowing

power to transmit through the output shaft to the differential.

4th Gear

Engine power is transmitted to the input shaft via the clutch assembly and the input shaft turns. The input shaft fourth

speed gear is in constant mesh with the output shaft 3-4 cluster gear which is fixed to the output shaft. Because of

this constant mesh, the input shaft fourth speed gear freewheels until fourth gear is selected. As the gearshift lever

is moved to the fourth gear position, the 3-4 fork moves the 3-4 synchronizer sleeve towards fourth gear on the input

shaft. The synchronizer sleeve engages the fourth gear clutch teeth, engaging the gear to the input shaft, and allow-

ing power to transmit through the output shaft to the differential.

5th Gear

Engine power is transmitted to the input shaft via the clutch assembly and the input shaft turns. The input shaft fifth

speed gear is pressed on to the input shaft, and is in constant mesh with the output shaft fifth speed gear. Because

of this constant mesh, the output shaft fifth speed gear freewheels until fifth gear is selected. As the gearshift lever

is moved to the fifth gear position, the 5-R fork moves the 5-R synchronizer sleeve towards the output shaft fifth

speed gear. The synchronizer sleeve engages the fifth gear clutch teeth, engaging the gear to the input shaft, and

allowing power to transmit through the output shaft to the differential.

Reverse Gear

Engine power is transmitted to the input shaft via the clutch assembly and the input shaft turns. The input shaft

reverse gear is integral to the input shaft, and is in constant mesh with the reverse idler gear. The reverse idler gear,

which reverses the rotation of the output shaft, is in constant mesh with the output shaft reverse gear. Because of

this constant mesh, the output shaft reverse gear freewheels until reverse gear is selected. As the gearshift lever is

moved to the reverse gear position, the 5-R fork moves the 5-R synchronizer sleeve towards the output shaft reverse

gear. The synchronizer sleeve engages the reverse gear clutch teeth, engaging the gear to the output shaft, and

allowing power to transmit through the output shaft to the differential.

GENERAL INFORMATION

08–250Chery Automobile Co., Ltd.

Page 1201 of 1903

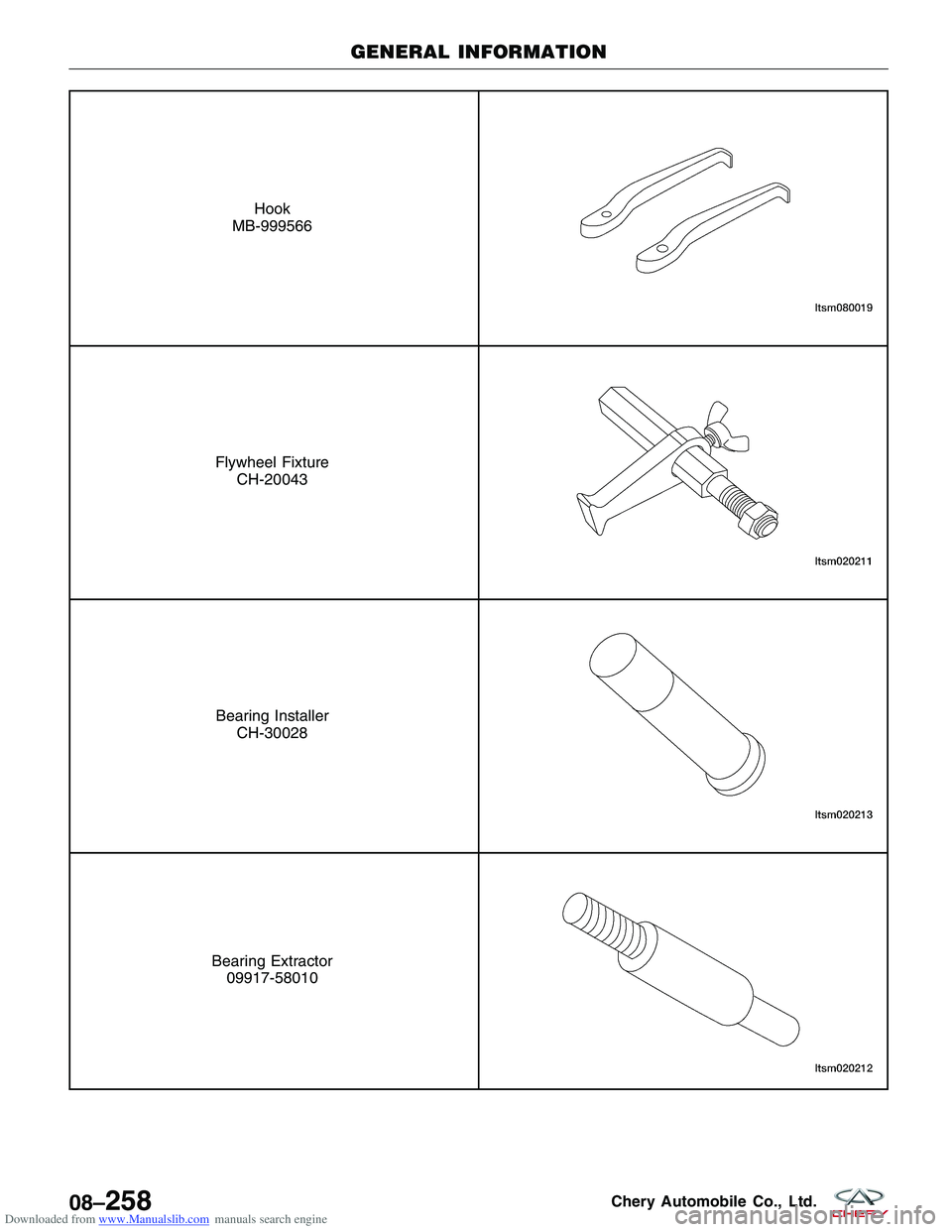

Downloaded from www.Manualslib.com manuals search engine Hook

MB-999566

Flywheel Fixture CH-20043

Bearing InstallerCH-30028

Bearing Extractor09917-58010

GENERAL INFORMATION

08–258Chery Automobile Co., Ltd.